End of years DT

1/209

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

210 Terms

what is an ore? what is the extraction process like?

rocks that contain metals that can be economically extracted - not evenly distributed around the world, localised in certain areas. sometimes mined in one area and then transported to another where the metals are extracted. extracting metal from ore is complex and energy intensive.

what are metals made up of?

metals are crystalline structures made up of grains

how is grain size determined, and what does it influence?

grain size is influenced by the type of heat treatment a metal receives while it is cooling. rapid cooling forms small grains, slow cooling forms large grains.

large grains = slow cooling = high tensile strength, toughness, ductility and malleability

small grains = fast cooling = low tensile strength, toughness and ductility - high brittleness

what is alloying?

mixing one metal with another material (metal or non-metal) - this combination creates a material that has unique properties than if the metal was just used alone. generally, alloying increases hardness and strength and reduces malleability and ductility.

what are the three most common alloys?

steel: iron and carbon

bronze: copper and tin

brass: copper and zinc

what is work hardening?

the process of increasing the hardness of a metal through applying a process when the metal is cold. the most common work hardening method is the application of force to compress the grains through cold rolling.

what is tempering?

the application of heat after work hardening. this reduces some of the hardness and stiffness and increase the toughness and ductility of the metal.

what is a super alloy?

metal alloys that exhibit high degrees of mechanical strength, resistance to corrosion and surface stability.

specifically, a high resistance to creep and high oxidation and corrosion resistance.

what is creep?

the slow expansion or deformation of a material over time. can be exaggerated by high temperatures and prolonged forces.

what is oxidation?

the reaction of a metal with oxygen (e.g. rust). metals may also corrode in the presence of high temperatures and acids or alkalis.

how are metals recovered and disposed of? is this eco-friendly?

metals and metal alloys are easily recyclable. compared to the extraction of raw materials, recycling metals uses less energy, produces less waste and uses materials that have already been extracted.

metals can be infinitely recycled, unlike plastics which can degrade in quality and properties through recycling.

what is design for disassembly? how does it relate to metals and alloys?

allows for products to be easily and efficiently disassembled without the need for specialised tools, machines or processes.

since many consumer products such as phones, computers and even cars use large quantities of valuable metals, effective dfd can ensure the environmental impact of the design is reduced.

what are the design contexts of different ferrous metals?

mild steel: car body parts, general engineering, nuts, bolts, nails, screws

stainless steel: cutlery, cooking and cleaning surfaces

cast iron: heavy duty machinery, vices and clamps

what are the design contexts of different non-ferrous metals?

aluminium: soft drink cans, kitchen foil, engine components

copper: printed circuits

silver: jewellery

tin: solder, tin cans

zinc: galvanising (protective coatings that protect against corrosion)

what are the different design contexts of alloys?

brass: castings, marine and plumbing fittings

high speed steel: used for cutting tools such as drills and saw blades

what are modern plastics usually derived from?

a non-renewable petroleum resource - such as crude oil, coal or natural gas

8-10% of annual oil production is used for the production of plastics

what are thermoplastics? what processes are they ideal for?

linear chain molecules with weak secondary bonds between the chains- they can be heated and reformed

ideal for processes that use heat to form the plastic over or around a mould: low production costs, easily injectable into moulds, low stiffness (flexible), reshapable

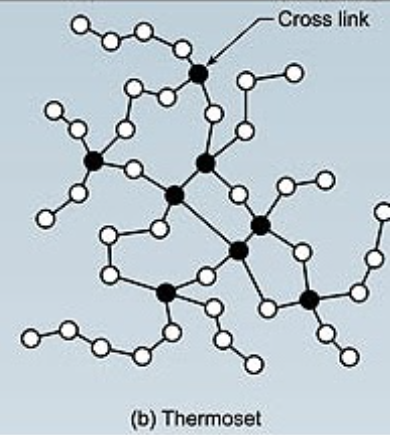

what are thermosets? what processes are they used for?

linear chain molecules with strong primary bonds between adjacent polymer chains

once formed, they cannot be reheated or re-moulded

higher level of stiffness and strength

more heat resistant and rigid

what type of plastic is polypropylene (pp) ? what are some facts about it?

thermoplastic

used for shopping bags, packaging, bottle caps, straws, food and medicine containers

easily formed, can be formed into solids or flexible fabrics, transparent or opaque

low cost, can have a variety of forming methods

what type of plastic is polyethylene (hdpe and lpde)? what are some facts about it?

thermoplastic

hdpe used for: detergent and shampoo bottles - resistant to chemicals and bacteria

ldpe: used for cling film, squeeze bottles, dry cleaner bags - very cheap

hdpe: rigid and opaque

ldpe: transparent and very flexible

both relatively low cost

what type of plastic is high impact polystyrene (hips)? what are some facts about it?

thermoplastic

easy to machine and shape, impact resistant, formed using vacuum forming

used for packaging and disposable cutlery - relatively low cost

what type of plastic is acrylonitrile butadiene styrene (abs)? what are some facts about it?

low cost, heat resistant, dimensionally stable

used in car bumpers, 3d printer filament, children’s toys, phone cases'

useful for vacuum forming, injection moulding and 3d printing

high stiffness and strength, high impact, chemical and abrasion resistance

low cost, safe for food processing, easy to paint and glue, good dimensional stability

what type of plastic is polyethylene terephthalate (pet)? what are some facts about it?

thermoplastic

used for drink bottles, consumer product containers and makeup containers

lightweight, shatter-resistant, chemical resistant, very low cost

what type of plastic is urea-formadelhyde? what are some facts about it?

thermoset

electrical case, plastic tableware and cups, plug and switch covers, primary adhesive in plywood

high tensile strength, resistant to distortion from heat

releases well from moulds, does not shrink, provides a hard, durable surface that is resistant to wear

cannot be recycled, can be downcycled into lower grade plastics or ground into pellets

what type of plastic is polyurethane (pu)? what are some facts about it?

thermoset

used for wheels and castors, and plastic parts in devices and machines

high abrasion resistance, high cut and tear resistance, superior load bearing, non-conductive

can be cast in moulds, or cut using subtractive methods

cannot be recycled efficiently, can be down-cycled into lower grade plastics or pellets and used as filler in other materials

what type of plastic is melamine resin? what are some facts about it?

thermoset

kitchen worktops, kitchenware, flooring, cabinets, flame retardants

highly durable, lightweight, high electrical resistivity, high heat resistant

can be produced in a wide range of colours, fda certified

cannot be recycled, can be down cycled into pellets and used as filling

when used in engineered wood, it then cannot be composted

what type of plastic is epoxy resin? what are some facts about it?

thermoset

general adhesive, automotive, plane and boat parts with fiberglass or carbon fibre

tough, high compressive and tension strength

chemical resistant, can create a variety of forms, can be toxic to work with

cannot be recycled - can be ground into pellets and used as filler

how is plastic disposed of?

needs to be separated by type to be recycled

thermoplastics can be recycled but thermosets go to landfill or are incinerated

what strategies can be used to limit plastic waste that may be unnecessary?

design for disassembly: labelling plastic parts with their type of plastic to ensure proper recycling

lightweighting: reducing the amount of material required in a product and its packaging

promoting and using recycled plastic: encourages user acceptance of the unique aesthetic properties

selecting other materials when appropriate

what is a softwood tree?

coniferous trees that have cones and needle-like leaves

what are the physical properties of softwoods?

low density compared to hardwoods

open grain makes the wood more likely to absorb water

what are the mechanical properties of softwoods?

more flexible than most hardwoods, less strong in tension and compression

what are the aesthetic properties of softwoods?

generally lighter coloured, can have very strong aroma, can be marked easily (since soft)

what are the environmental considerations of softwoods?

relatively fast growing (25 years to reach maturity) and thus considered a renewable resource

what are the design contexts of softwoods?

low cost furniture, framing for houses, indoor furniture (very workable)

what are hardwood trees?

have broad leaves, and bear fruit, seeds or nuts. typically have higher density and hardness.

what are the physical properties of hardwoods?

higher density, more resistant to water, high hardness

what are the mechanical properties of hardwood?

less flexible, stronger in tension and compression

what are the aesthetic properties of hardwoods?

smoother, more consistent colour and grain, wider range of colours

what are the environmental considerations for hardwoods?

relatively slow growing (100 years), thus considered a non-renewable resource

what are the design contexts of hardwoods?

high quality furniture, handles, outdoor furniture, surfaces that need resistant to wear

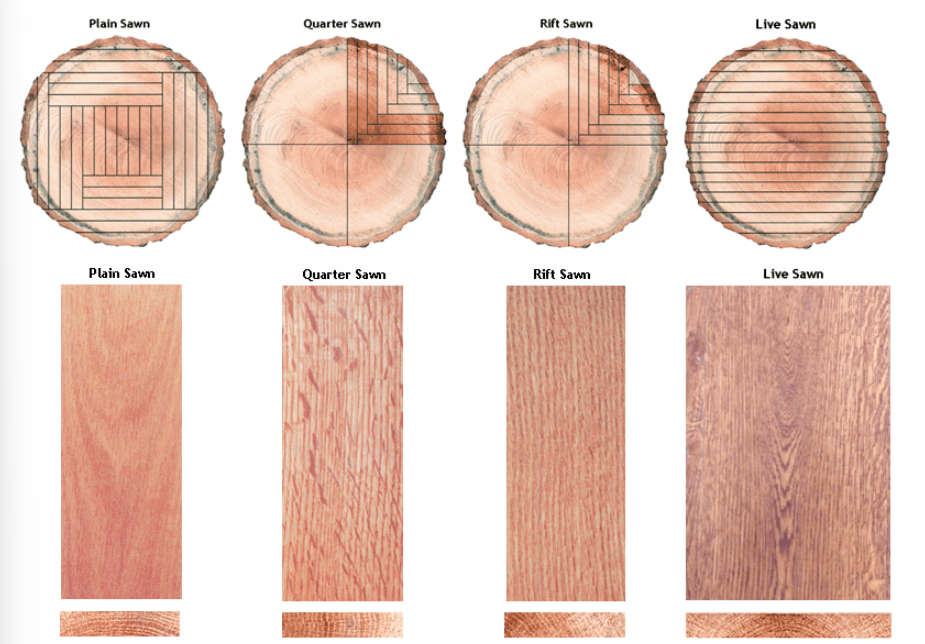

how do different cuts of wood influence their surface texture?

what is an engineered timber?

made by adhering waste materials together to create a new material. ensures that particular performance characteristics can be designed into the final product.

what is plywood? what are its uses, properties, (dis)advantages, sustainability considerations and cost?

layers of veneer laid down at 90 degrees to each other. each layer glued to the next.

furniture, great with cnc manufacture because of its consistency and standard size

strong in compression, thin: can be bent to create curved forms, thicker: quite strong in tension, dimensional stability (does not expand or contract in heat or humidity), medium high density

available in standard forms globally

often sustainably produced, but transportation adds costs and co2 emissions. all plywood uses glues, and these can vary in their toxicity (but could have negative impacts on humans and the environment)

what is mdf? what are its uses, properties, (dis)advantages, sustainability considerations and cost?

small fibres pressed into a form using binding agents (glue)

used for furniture, doors, cabinets and frames, ideal for cnc due to its consistency, standard size and smooth finish.

heavy and strong, high density, consistent throughout (no knots or splinters)

standard sizes available globally, smooth surface (easy to machine and paint), can absorb moisture very easily and swell or rot

the fine dust generated when cutting this material is a health hazard. binders contain formaldehyde (a known carcinogen), also not easily recyclable.

cost-effective

what is chipboard? what are its uses, properties, (dis)advantages, sustainability considerations and cost?

cheap furniture, table tops and work surfaces

not strong in tension or compression, lightweight

standard sizes and thicknesses available globally, can have a higher quality wood or plastic veneer, unable to hold heavy loads, flat as long as it doesn’t get wet

made from waste wood scraps (eco-friendly) - uses glue though, doesn’t last very long

cheapest

what is oriented strand board? what are its uses, properties, (dis)advantages, sustainability considerations and cost?

large chips of wood are pressed and glued together to make panels

cheap furniture, table tops and work surfaces, available in large panels

strong, heavy, somewhat flexible

standard size available globally, can have higher quality veneers

made from waste wood scraps, but most brands use a toxic glue

one of the cheapest

why is wood seasoned?

when harvested, timber has a high moisture content which makes it unsuitable for most applications as it is subject to warping. thus, seasoning it (drying it out) allows it to have useful mechanical and physical properties.

why are treatments applied to timber?

improves/enhances aspects of its physical or mechanical performance- usually its degradation due to moisture or attack by fungus and insects.

what is the main strategy to protect wood from insects and fungus (dry rot)?

apply chemicals that make the wood poisonous to these insects and fungi

what is the main strategy to protect wood from the weather?

the wood is treated with a waterproofing chemical/another chemical that resists the absorption of water and prevents rotting

what is the main strategy to improve woods chemical resistance?

apply treatments that protect woods from corrosive chemicals such as acids

why are finishes applied to timber?

to alter its aesthetic qualities and provide protection from environmental factors

stains colour the wood to a desired tone and provide uv protection

oils and waxes can alter the surface from smooth to shiny and also provides some protection from abrasion

what often happens to waste timber?

it is chipped to make new products, such as engineered timber and wood chips for play areas

what is a sustainably managed forest?

the stewardship and use of forests in a way, and at a rate that maintains their biodiversity, productivity, regeneration capacity, vitality and their ability and potential to fulfil relevant economic and social functions at global levels, without damaging other ecosystems

why do designers need to understand the properties of materials?

to select the most appropriate material to meet their design

what is a physical property of a material?

those that can be measured using non-destructive testing

what is mass?

the amount of matter contained in a space. constant (irrespective of gravity), measured in kg.

what is weight?

technically a force, measured in newtons (dependent on gravitational field)

what is volume?

the amount of 3 dimensional space a solid, liquid or gas occupies

what is density?

the relationship between mass and unit of volume. measured in mass/volume.

what is electrical resistivity?

a materials ability to conduct or resist electricity

what is thermal conductivity?

measures how fast heat moves through a material

what is thermal expansion?

the degree to which a material increases its dimensions when heated. different materials may expand at different rates.

what is hardness?

the resistance of a material to scratching or penetration

what is a mechanical property of a material?

those that are usually measured through some form of destructive testing

what is tensile strength?

the ability of a material to resist pulling forces

what is compressive strength?

the ability of a material to resist pushing forces

what is stiffness?

the ability to resist deflection (bending) by a force. the object can maintain its shape when a force is applied to it

what is toughness?

the ability to deform but resist cracking and not fracture under impact. if a material breaks into numerous small pieces when impacted, it has a low degree of toughness.

what is ductility?

the ability to be drawn or extruded into a wire-like form

what is elasticity?

the ability of a material to bend and then return to its original shape

what is plasticity?

the ability of a material to be formed into a new shape. when the material is bent or deformed beyond its yield it does not return to its original shape.

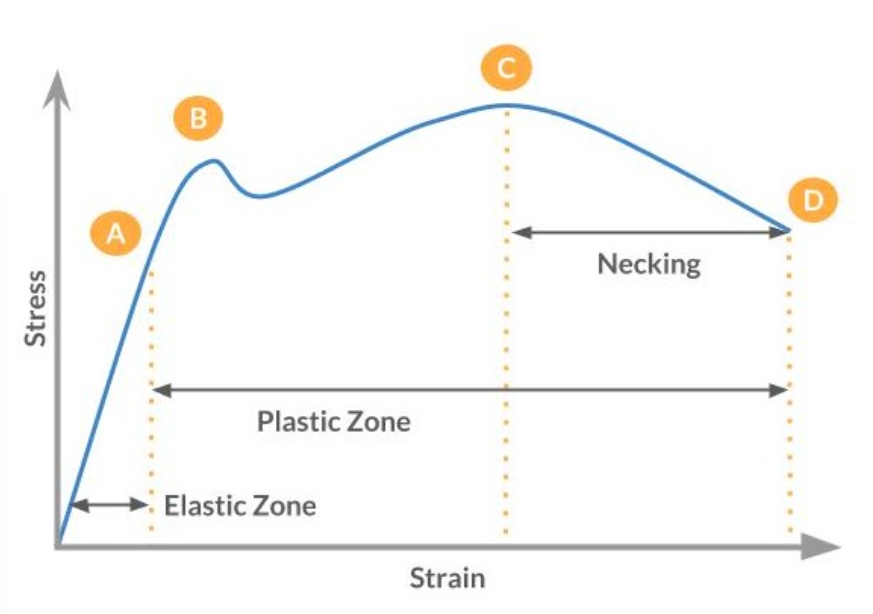

what is young’s modulus?

a measure of the stiffness of an elastic material. the ratio of stress to strain of a material as force is applied along its length. stress and strain are usually plotted on a graph, and show the relationship between the amount of force applied (stress) to how much the materials change in length.

stress is the tensile force applied to a given area

strain is the percentage of change in length when a force is applied to the initial length

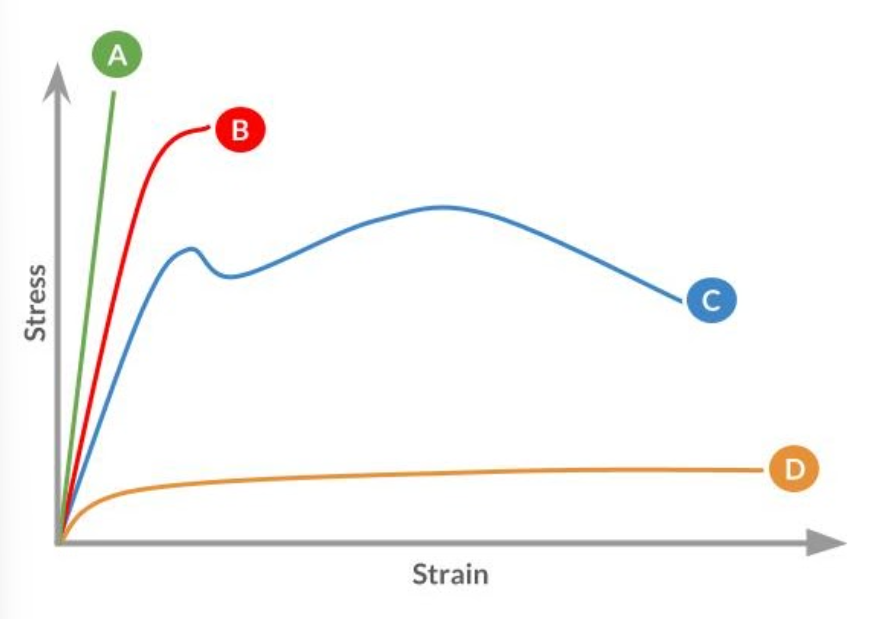

what do the different regions of the stress-strain graph represent?

A to B: region of elasticity - if the material was stretched and then the force was released, it would return to its original shape

B: yield point: the point at which the material will no longer return to its original shape (it has now entered the plastic region)

C: ultimate tensile strength (uts) - the point at which the material can maintain a maximum load, after this point the material is moving towards its breaking (failure) point - necking occurs between points c and d

D- Failure point: this is the point at which the material actually breaks

what do these different stress-strain profiles show?

material a: represents a material that can withstand a great amount of force, but then fails suddenly. it is brittle, and would likely break into many pieces. glass or ceramics.

material b: represents a material that is strong, but not ductile. steel wires are very strong, but break suddenly. there is a small elastic zone.

material c: represents a material that is ductile, and could be extruded to create wires or cables

material d: represents a very plastic material, with almost no elastic zone, and a very large plastic zone.

what is an aesthetic property of a material?

those related to beauty and pleasure derived from a material. designers need to consider the aesthetic properties of the materials they choose, and how these are perceived by different users.

what are smart materials?

reactive materials - they change their properties when exposed to stimuli such as electrical charges, moisture, or temperature.

what is a piezoelectric material?

a material with the ability to release an electric charge when deformed. when an electric current is passed through a piezoelectric material its volume will increase or it will vibrate.

what is a shape memory alloy (sma)?

smas have a pseudo-elastic property that allows the body to return to its original shape after deforming. their shape changing property can be stimulated by either a change in temperature or the application of an electrical current. when the load is released, the body returns to its original shape.

what is photochromacity?

the ability to change colour when exposed to light

what does it mean if a material is magneto-rheostatic?

fluids that undergo a change in their viscosity when a magnetic force is applied. they can change from a thick fluid to a solid almost instantly.

what does it mean when a material is electro-rheostatic?

fluids that undergo a change in their viscosity when an electrical force is applied. the change can be almost instantaneous.

what is thermoelectricity?

two different conductors, that when joined together generate electricity when heat is applied. the materials of the conductors determine the amount of electricity generated.

how is glass made?

melting a mixture of silica, soda and lime, before rapidly cooling it

to what extent is glass a sustainable material?

it can be recycled easily, and can be used in applications that reduce energy usage (such as thermal insulation)

it has valuable applications in health and safety (it can preserve food, and doesn’t react with medicines)

it requires a very large amount of energy in its manufacture, and uses non-renewable resources (silica and soda)

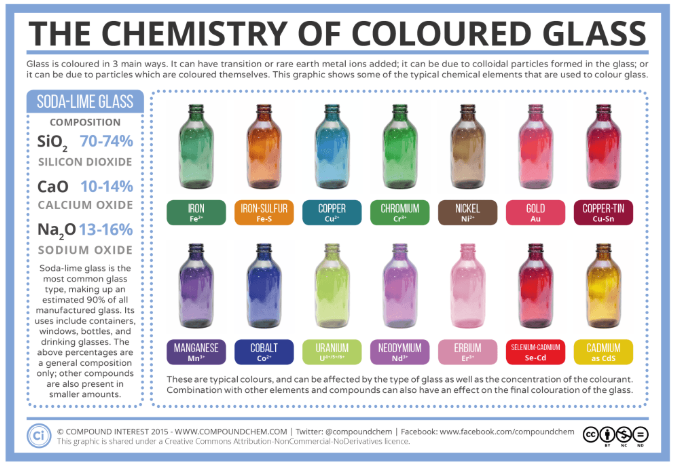

how can the colour of glass be modified?

by adding metallic oxides

is glass strong?

very high compressive strength, very low tensile strength

is glass brittle?

yes - low shock absorbance, shatters easily when hit

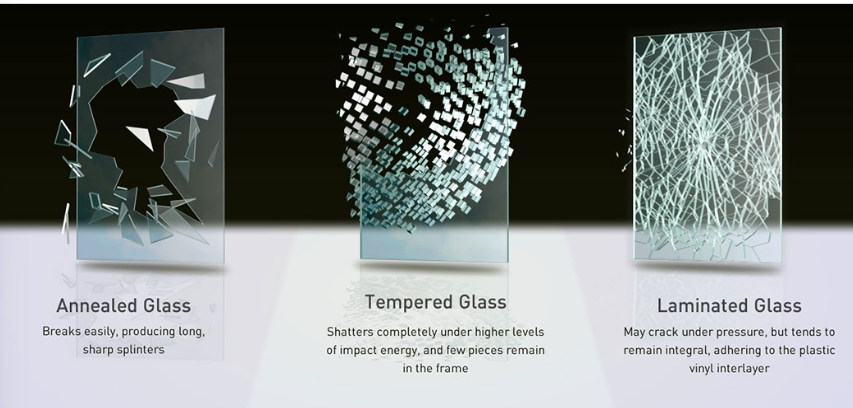

processes such as laminating or tempering glass can decrease some of the brittleness, and increase safety by reducing the amount of glass fragments producing

is glass hard?

yes, resists scratching to a great degree

glass is nonporous, non-toxic and unreactive: why is this good?

ideal container: doesn’t absorb liquids, smells or chemicals. chemically inert, ideal for containing acidic contents.

what are the properties of borosilicate glass?

very resistant to thermal shock, used when exposed to high temperatures

expands less when heated, resists shattering

easily recycled, but very energy intensive to make

used in kitchenware and laboratory glass

soda glass with added oxides to increase thermal conductivity

how is glass disposed of/recovered?

easily recycled. cullet (crushed recycled glass) is added to molten mixtures of other glass to reduce the melting temperature and amount of raw materials used. adding 25% cullet reduces energy by 5%.

what is the glass container recycling loop?

what is a composite material?

a combination of two or more materials that are bonded together to improve their mechanical or physical properties. composites can be investigated as a whole but breaking them down into three key areas is most useful to achieve a detailed understanding - form, process and composition

how can textiles form part of a composite material?

fibres can be spun into filaments, string or rope, used as a component of a composite material or matted into sheets to make such products as fabrics, paper or felt. synthetic fibres can be produced very inexpensively and in large quantities, compared with natural fibres.

what can fabric fibres be combined with to form composite materials?

woven fabric fibres and other reinforcements are used in conjunction with resins (the matrix) to produce composite materials which combine the strengths and overcome the weaknesses of materials to produce very strong materials.

how can glass form part of a composite material? what can glass be combined with?

glass is generally made into sheets. when glass is laminated it becomes a composite because there is an interlayer between the glass sheets made from PVB (polyvinyl butyral). when the glass is shattered the interlayer keeps the glass layers bonded, preventing the glass breaking up/fragmenting.

how can metals form part of a composite material?

generally in particles. particle reinforced composites are less effective than fibre reinforcement. generally achieves gains in stiffness, strength and toughness.

what are the two categories of constituent materials?

matrix and reinforcement. the matrix for carbon fibre is an epoxy resin which surrounds and supports the reinforcement materials