Manufacturing Operations

1/39

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

40 Terms

What is the technical definition of Manufacturing

Application of physical and chemical processes to alter the geometry, properties and/or appearance of a given starting material to make parts/products

Also means to join together multiple parts to make assembled products

What is the economic definition?

Transformation of materials into items of greater value through processing and assembly operations

Manufacturing adds value to the material e.g. iron ore to steel

3 types of industry: (same as geog)

Primary industries - obtain and provide natural resources (e.g. agriculture, oil)

Secondary industries - convert output of primary industries into products (e.g. automotive, construction etc)

Tertiary industries - Service sector (e.g. banking, teaching etc)

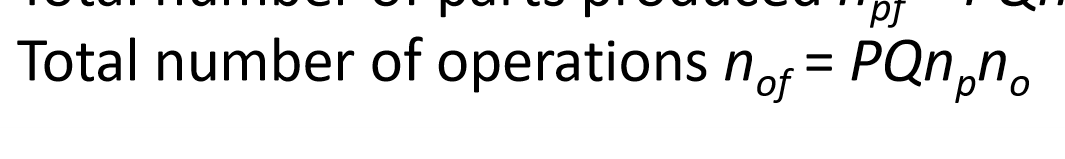

What are process industries?

Industries that manufacture products by processing raw materials, and dont necassarily have individual countable products e.g. food and drink, energy , basic metals etc

What are discrete product industries

Produce indidual counatble units, e.g. cars, aircraft, machinery

What do continuous and batch production look like in process and discrete industries?

What are manufacturing operations?

Basic activities in a factory to convert raw materials into finished products

What does this consist of for discrete products:

1) Manufacturing processing

2) Material handling

3) Inspection and testing

4) Coordination and Control

What are the 2 main overall manufacturing processes

Processing operations

Assembly operations

What are the 3 types of process operation?

Shaping operations (e.g. additive and subtractive manufacturing, solidifcation processes (casting))

Property-enhancement operations (e.g. heat treatment)

Surface processing operations

What are the 2 types of Assembly operation?

Joining process (welding, adhesive etc)

Mechanical assembly process (threaded nuts and bolts, interlocking assemblies etc)

What occcurs in material handling? (3)

Material transport (e.g. veichles, conveyors, trucks)

Storage systems

Automated identification and data capture (AIDC) (e.g. bar codes)

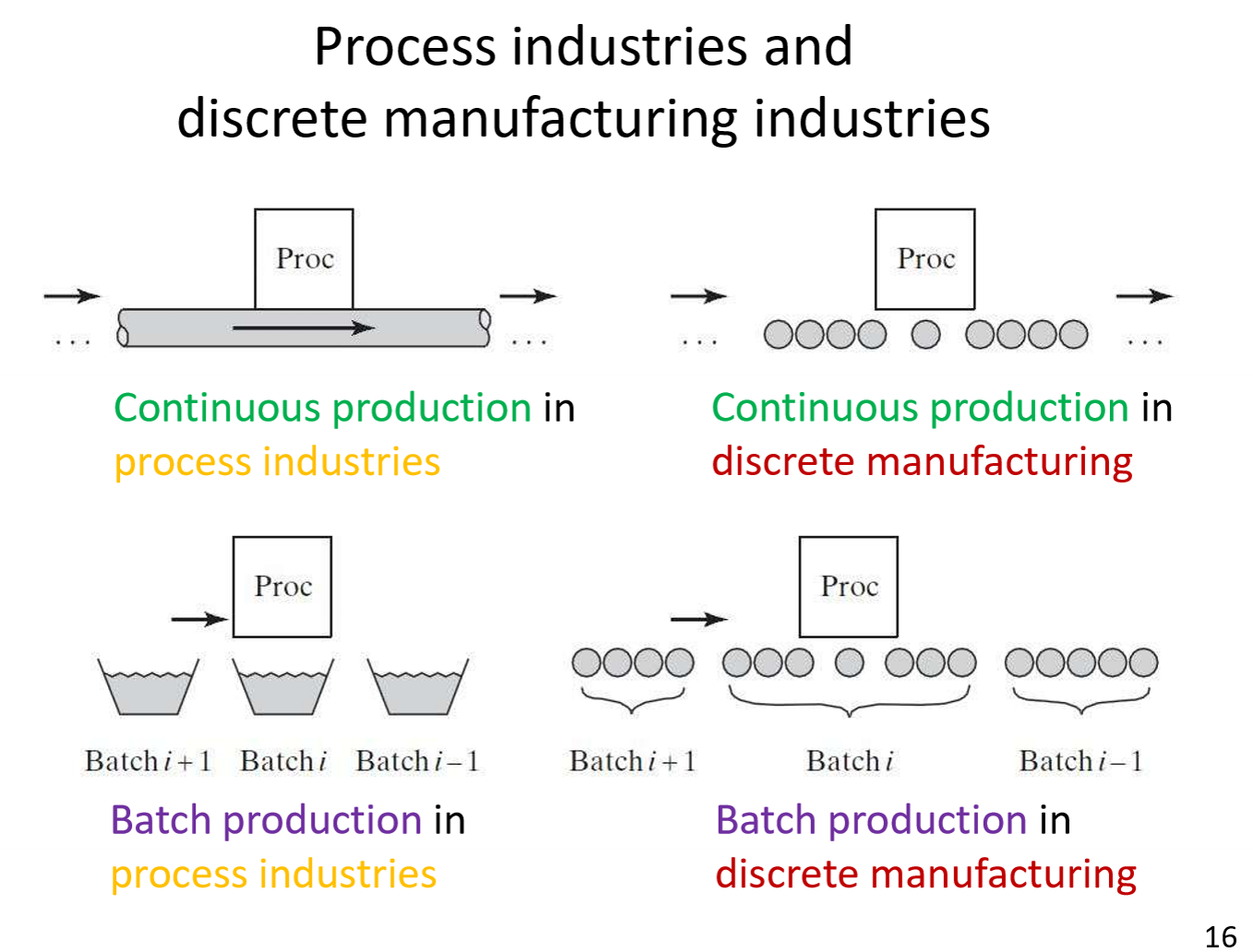

Why is material handling significant?

What is inspection?

What is measuring

What is gauging

Examination of the product to see if it conforms to design specifications

(inspection for variables is measuring, inspection for attributes is gauging)

What is testing?

Observing the product under actual operation (or under conditions that migh occur under operation)

What does coordination and control consist of?

Regulation of individual processing and assembly operations

Includes quality control, process control and optimisation

Management of plant-level activities

ie production, planning and control (PPC)

What does low production mean:

1-100 units anually

Medium production:

100 - 10,000 units

High production:

10,000 to millions of units

Product variety refers to

The number of different product or part variations in a design

There is an inverse relationship between

Production quantity and variety

Diff between hard and soft product variety

Hard - Products differ greatly

Soft - Products differ slightly

What are the three types of manufacturing system?

Job shop (low production)

Cellular Manufacturing System (Medium Production)

Flow Line (High production)

Can a factory consist of multiple in 1?

Yes, can be either one of a combination of them

A job shop is a manufacturing system that _____

produces unique products in low variety

Features and applications of a job shop

Complex products

General purpose equipment

Prototypes

Special machinery

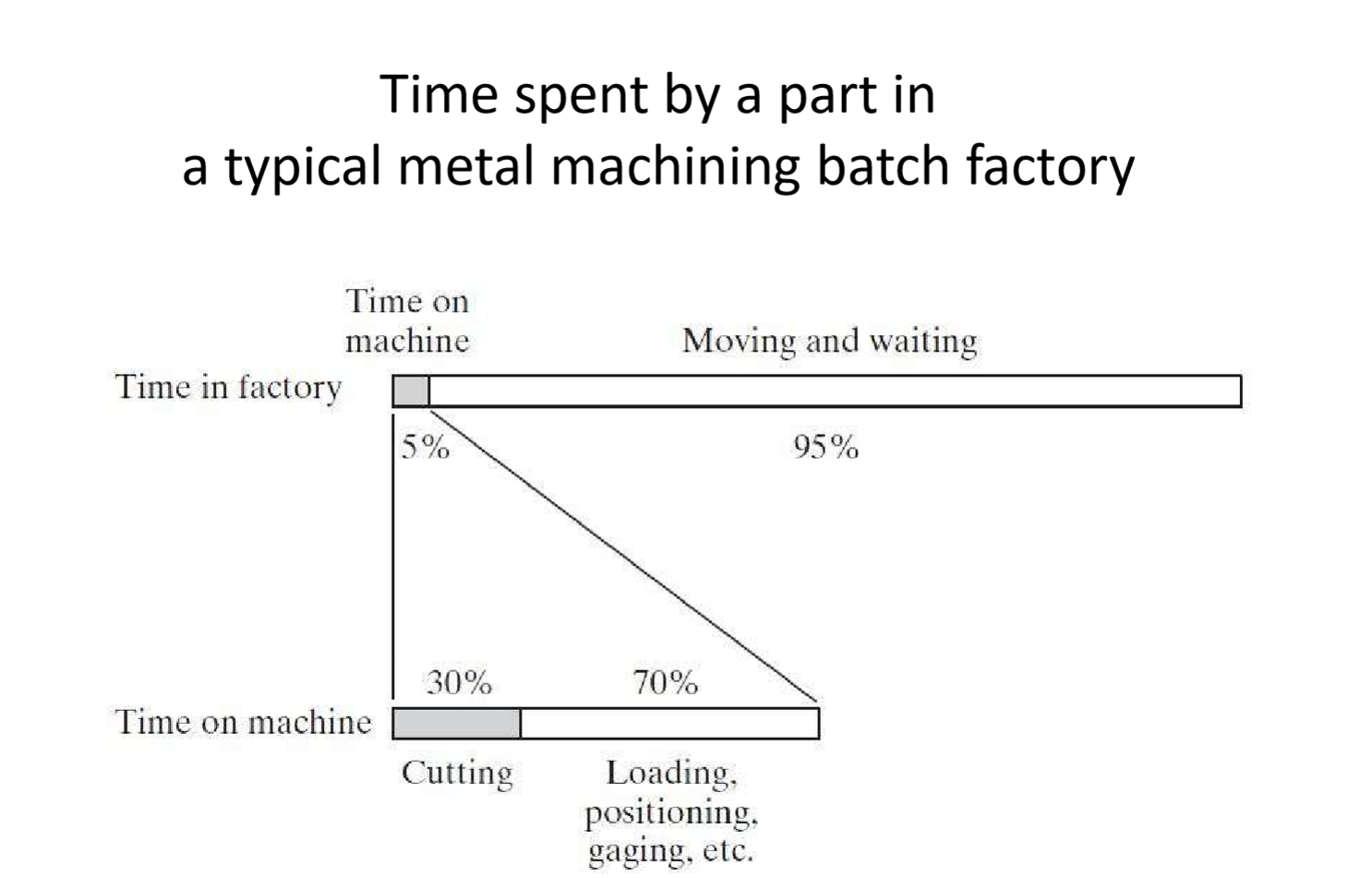

What are the two types of layout in a job shop

Process layout - Equipment arranged and fixed, while materials go through the workstations (normal factory)

Fixed position layout - worker and equi[ment go to the product as its too heavy (like a fair ground ride)

What are the two types of medium production:

Batch

Batch of product is produced, then facility is changed over to produce another product

Hard product variety

Cellular

Mixture of products is made without changeover

Soft product variety

A cellular manufacturing system is a system that

Produces several families of products in low volume

Features of a CMS:

Applications of a CMS:

Large product variety

Variable process routings

Small to Medium Volumes

Dissimilar Machines

Products customised for applications (e.g. office cabinets and aeroplane seats)

2 types of high production:

Quantity production - Mass production of single parts

Flow line production - Multiple workstations arranged in sequence, for products with assembly and processing steps

Features of a flow line:

Applications of a flow line:

Sequential config

Fixed process routings

No/little variety

Automotive final assembly, computer assembly etc

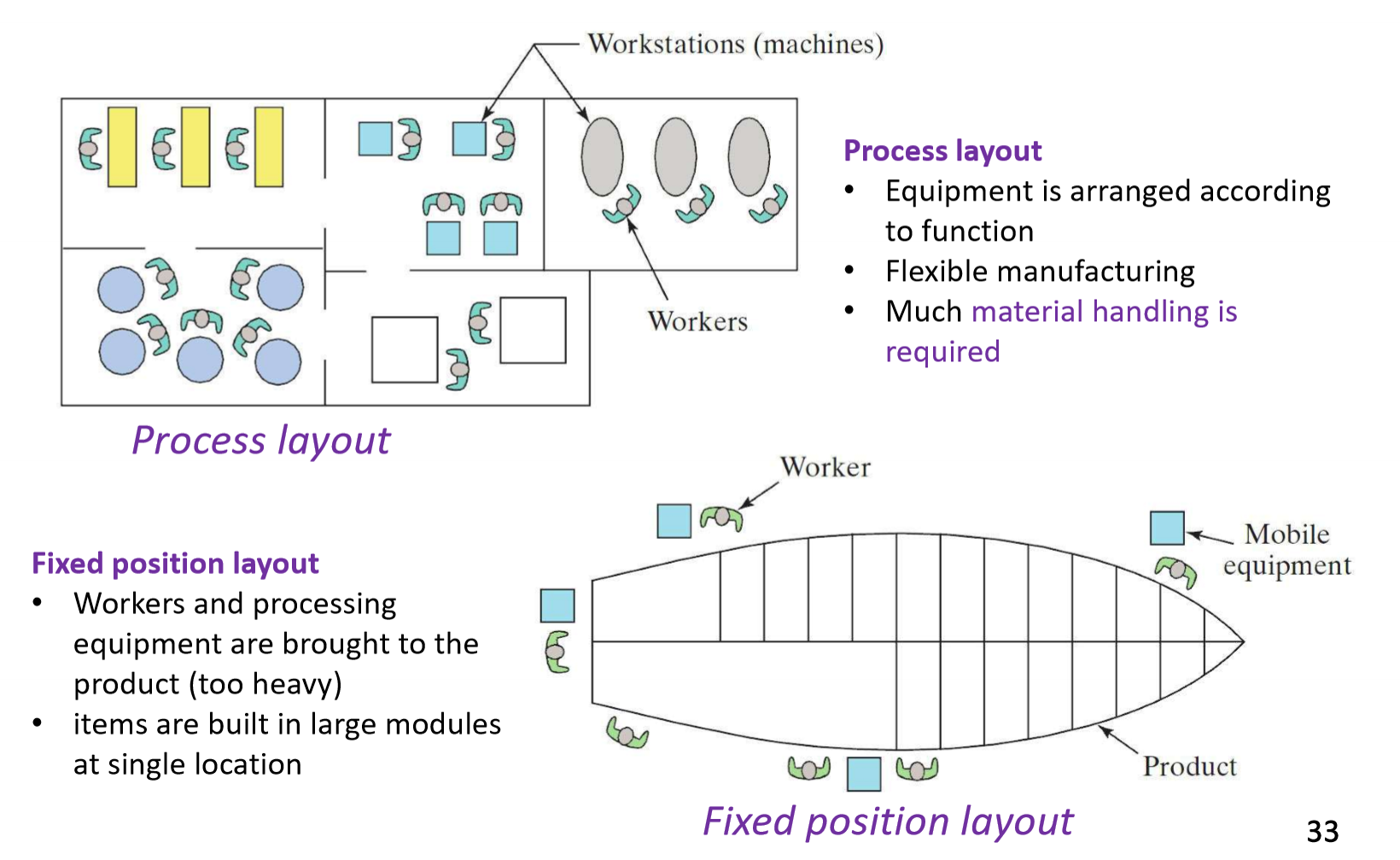

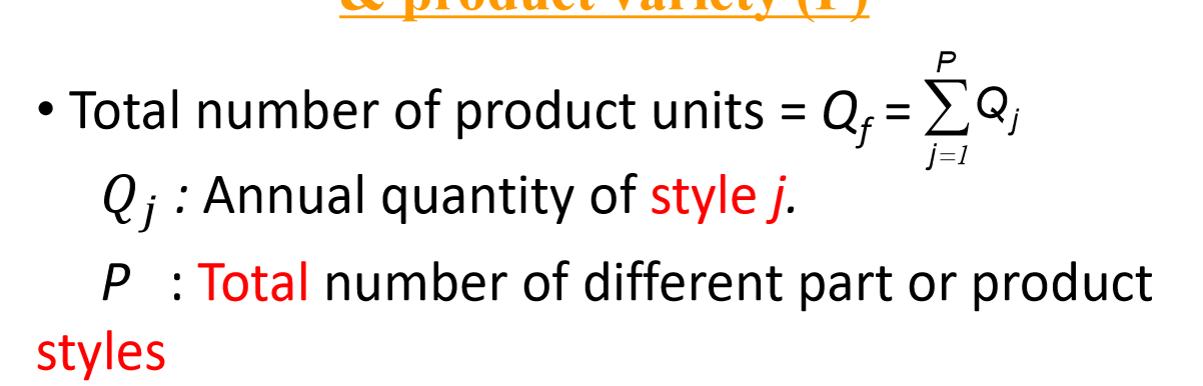

What is the total number of product units Qf equation

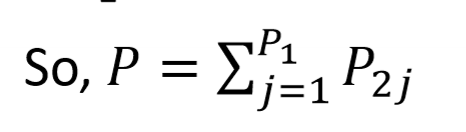

How can product variety P be divided

P1 → The number of distinct product lines produced by the factory

P2 → Number of models in a product line

So whats the P equation?

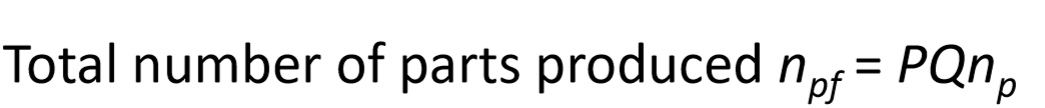

What do np and no stand for

np stands for number of parts per product (so product complexity)

no stands for number of operations per part (so part complexity)

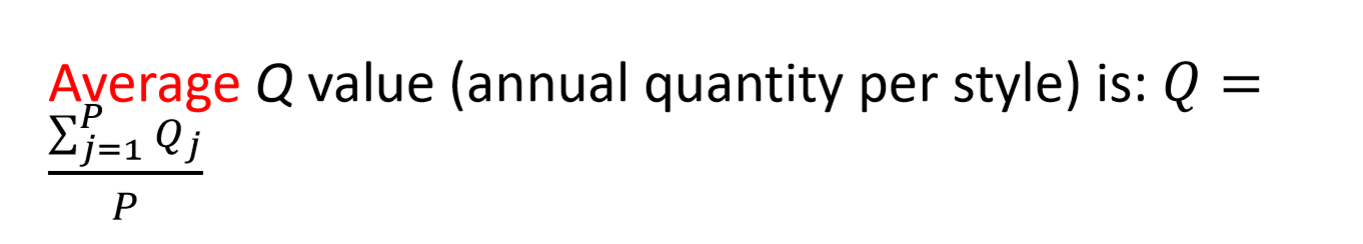

What are the simplified equations?

Qf = PQ

(Qf = total number of parts

P = number of diff product styles

Q = average quantity per style)

What is the average Q eq?

What is the number of parts produced eq?

(Number of products x number of parts per product)

What is the number of operations eq?

(number of parts x number of operations per part)