Lecture VII. cGMP and HACCP

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

59 Terms

RA10611-FOOD SAFETY ACT OF 2013

An act to strengthen the Food Safety regulatory system in the country to protect consumer health and facilitate market access of local food and food products, and for other purposes.

Government's effort of taking the country's level of food safety assurance on higher scale.

FOOD SAFETY REGULATORY AGENCIES

DOA

DOH

LGU

5S + 2S OF GOOD HOUSEKEEPING

DOA

Primary production

Post harvest stages

National Food Authority (NFA)

Bureau of Animal Industry (BAI)

Bureau of Fisheries and Aquatic Resources (BFAR)

National Meat Inspection Services (NMIS)

Philippine Coconut Authority (PCA)

Bureau of Plant Industry (BPI)

Sugar Regulatory Administration (SRA)

Fertilizer and Pesticide Authority (FPA)

National Dairy Authority (NDA)

DOH

Processed and pre-packed foods

Food and Drug Administration (FDA)

FDA Center for Food Regulation (CFRR)

Bureau of Quarantine (BoQ)

National Epidemiology Center (NEC)

National Center for Health Promotion (NCHP)

Research Institute of Tropical Medicine (RITM)

National Center for Diseases Prevention and Control (NCDPC)

LGU

Wet markets

Slaughter houses dressing plants

Fish ports

Street food sale

Ambulant vending

Food service catering

Supermarkets

School canteens

Restaurants

Water refilling

5S+2S OF GOOD HOUSEKEEPING

➤ Words beginning with S

➤ Systematic procedure to achieve a pleasant workplace

➤ "CLAY GO (Clean As You GO)" practice

➤ Affects personnel performance and production

Seiri (Sort) - remove unnecessary items

Seiton (Systematize) -arrange items in order

Seiso (Sweep) - clean your workplace completely

Seiketsu (Standardize)-maintain high standards of housekeeping

Shitsuke (Self-discipline) do things spontaneously without being told or ordered.

Sustain

Safety

current Good Manufacturing Practices (cGMP)

Are sets of standards, criteria or guidelines to establish sanitary conditions and/or to eliminate/reduce the risk of contamination of food in the manufacture of food/ingredients, production/processing of food which includes handling, storage, packaging, warehousing, transporting display and other food contact materials to assure clean food.

GMP

refers to a quality assurance system aimed at ensuring that products are consistently manufactured, packed, repacked or held to quality standards appropriate for the intended use. It is thus compared with both manufacturing and quality control procedure.

The c= current, to emphasize that the guidelines or criteria set by statutory and regulatory requirements and expectations are dynamic.

Why Do We Need GMP?

Statutory and regulatory requirements

Buyer requirements

Most important reason: SAFE FOOD

SAFE FOOD

Is...

our responsibility

a service for a good BUSINESS

Shared Responsibility for FOOD SAFETY

Industry/Trade

Government

Academe

Consumer

FOOD SAFETY

Providing assurance that food, which has been produces, processed, stored, distributed, and prepared would ensure safe, sound, wholesome and fit for human consumption.

Absence of any contaminants

FOOD SAFETY PROGRAMS AND RESULTS

Why Address Food Safety?

Outbrakes of food borne illnesses can damage trade and tourism leading to loss of earnings, unemployment and litigation.

Changes in eating habits, such as relying more on "ready-to-eat" and "take-away" food and changes in the ways foods are prepared and distributed, may contribute to risks to food safety

Vulnerable groups suffer (elderly, sick, pregnant, infant, etc.)

Food Hygiene

all conditions and measures necessary to ensure the safety and suitability of food at all stages of the food chain

HOW?

Correct handling

Proper storage, Preparation, Processing and Display of food

YOUR TOOLS

GMP/CODEX Guidelines,

SSOPS, HACCP,

Accurate labeling

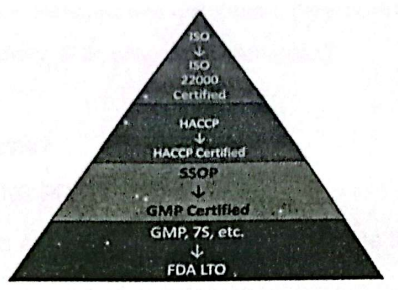

Food Safety Management System

What are the food safety tools?

CGMP

SSOP

HACCP

Accurate Labeling

Current Good Manufacturing Practices/Good Warehousing Practices

Pre-requisite program for HACCP

Sanitation Standard Operating Procedures

Pre-requisite program for HACCP

Hazard Analysis and Critical Control Points

CGMP Element: Premises - Grounds

No animals on the ground

Rats and pest control

Roaches spread filth and germs

Arch enemy of cleanliness & health

CGMP Element: Premises

Protect and maintain grounds against weather, flood, ground seepage, and the access and harboring of vermin, rodents, birds, insects or other animals.

Exclude pest, dirt, and filth that may be a source of food contamination

Maintain grounds as follows:

Properly store equipment, remove litter and waste, and cut weeds or grass that may serve a breeding place or harborage of pest.

Provision of waste treatment and disposal in conformance with DENR that do not constitute a source of contamination of areas where food is exposed

CGMP Element: Equipment

Equipment made of materials easily and adequately cleanable

Installed and located to eliminate cross contamination, distance at least 1 meter apart

Equipment shall be fitted with proper measuring devices for regulating the control parameters

Equipment shall be protected from dust from splash, dust and others

No glass parts, corrosion resistant, made of non-toxic materials, seems smoothly bonded

Must allow the sampling and measuring of product quality

WHAT IS HACCP?

It is a process control system that identifies where hazards might occur in the food production process and puts into place stringent actions to take to prevent the hazards from occurring.

A management tool used to protect the food supply against biological, chemical and physical hazards.

It is a system that identifies, assesses, and controls the biological, chemical, and physical hazards that are associated with food production or practice to prevent potential problems before they happen.

HACCP

Hazard

Analysis

Critical

Control

Points

1950s

It was first used in the _______by the Pillsbury Company to produce the safest and highest quality food possible for astronauts in the space program.

1959-1960

: NASA wanted to produce food for astronauts to guarantee food safety.

1963

: World health organization issued HACCP principles in Codex Alimentarius (Book of Food)

1974

: FDA incorporated HACCP in the regulations due to clostridium botulinum in canned food.

1985

: USA national science academy suggested that HACCP should be applied in food operations for food safety.

1997

: HACCP becomes mandatory for Seafood.

1998

: HACCP becomes mandatory for large meat and poultry manufacturers.

1999

: HACCP becomes mandatory for small meat and poultry manufacturers.

: HACCP becomes mandatory for frozen dessert manufacturers.

2000

: ISO was developed with major contributions to food safety management systems.

2002

: The juice HACCP regulation begins to be mandatory for processors, small businesses, and very small businesses.

Who are Applicable to get HACCP Certification?

The HACCP certification is applicable to all organizations in the food supply chain from producers to retailers. Also, it applies to the hotels, restaurants, and enterprises that provide:

Fruits and vegetables

Dairy Products

Fish and fishery products

Bakery and confectionary products

Meat and meat products

Why HACCP Certification?

HACCP Certification helps the food business industries to improve food safety management in compliance with HACCP principles. This helps you meet the applicable legal food safety requirements. By achieving the HACCP Certification, the organization can gain the following benefits.

Reduce food safety hazards and risks

Implement the food safety system performance

Ensure food safety

Enhance consumer confidence

Reduce customer complaints

New business opportunities

International recognition

Principle 1: Conduct an Hazard Analysis.

The very first principle of HACCP is conducting an Hazard Analysis. It includes 2 stages. The first stage involves brainstorming session where the ingredients used, activities conducted at each step, equipment used to check whether any glass or harmful products being used and are reviewed by an HACCP team and potential hazards due to glass are listed. HACCP consultant services can help you with the process. The second stage involves evaluation of identified and listed hazards.

Principle 2: Determine the critical control points (CCPs)

Determining the Critical Control Point means the step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. It is recommendable to choose an HACCP consultant in Philippines to find and assess critical control points.

Principle 3: Establish critical limits.

Everything should be considered and eliminated within the threshold limit which could be maximum or minimum value of which physical chemical and Biological Hazard relating to food safety can be controlled. It is always better to apply preventive measures rather within taking a corrective action after the occurrence of any errors. This saves money time and effort of the organization.

Principle 4: Establish monitoring procedures

Any process or anything in this world regardless of the nature of business in world it needs a thorough handling of guidance to get the things streamlined. It is necessary to monitor established plan in accordance with the HACCP. Monitoring the procedure will help to complete the project well before the stipulated time frame.

Principle 5: Establish corrective actions

Corrective action is like a solution tool in order to correct any errors which is happened knowingly or unknowingly. Errors or mistakes are common which is inevitable in the working area. HACCP certification cost in Philippines is the right choice of investing. But then it has to be mitigated with the proper solution by establishing a corrective action appropriate to the issue to resolve it.

Principle 6: Establish verification procedures.

This could be the final task which is very important to streamline the process happening internal to the organization. Cost of HACCP in Philippines us economical. Validation of the procedure according to the standard operating procedure is required to get the process a line with the plan that has been drafted by an expert on HACCP team.

Principle 7: Establish record-keeping and documentation procedures.

If at all and HACCP Certification plan or approach is implemented in a successful way it is not going to be a one day wonder and it has to be maintained all the way for Continual Improvement. HACCP audit in Philippines can verify. The record for document maintained today is going to be a reference for tomorrow.

Principles of HACCP Certification in Philippines

Principle 1: Conduct an Hazard Analysis.

Principle 2: Determine the critical control points (CCPs)

Principle 3: Establish critical limits.

Principle 4: Establish monitoring procedures

Principle 5: Establish corrective actions

Principle 6: Establish verification procedures.

Principle 7: Establish record-keeping and documentation procedures.

Understand the requirements of HACCP

The first step in becoming HACCP certified is to understand the requirements of HACCP.

Become familiar with the system. By knowing about HACCP, you gain a better understanding of the HACCP certification process. Get ready for performance evaluations and documentation reviews. Conduct a thorough review of your organization's system so as to measure the performance benchmarks required by the HACCP Certification standard.

Develop a HACCP Plan

The HACCP plan is the core system of your organization. It includes all the critical control points (CCP). Get training that helps you to develop a HACCP plan.

Complete a gap analysis

The gap analysis identifies the gaps between the current food safety system and the requirements of HACCP. This file will help you to make improvements to your existing food safety system.

Application

Compile the application for HACCP and apply for it. Upon review, auditors will return with the decisive HACCP audit date.

Undergo the HACCP audit

The auditor will carry out an audit based on the updated HACCP application.

Audit Report

The audit report is prepared, which reflects the findings during the certification process. This will act as a reference tool in case of any future audits.

HACCP Certification

After the inspection and upon successful completion of the process, auditors issue the HACCP certification to your organization if it is found compliant with all the requirements of HACCP. The certificate will reflect all aspects of the food safety system and list out all the CCPs.

Process For HACCP Certification in Philippines

Understand the requirements of HACCP

Develop a HACCP Plan

Complete a gap analysis

Application

Undergo the HACCP audit

Audit Report

HACCP Certification

How Long Does it take to get HACCP Certification?

HACCP implementation for any organization depends on the focus, knowledge, expertise, and resources available. It also depends on various factors like the complexity of the business, the number of employees, working shifts, and so on.

HACCP assessments generally range from one to five days, depending on the size of your organization and the extent of the audit. It's important not only that you do all of the required tasks in a timely manner but also that you complete them correctly. Because audits take less time when completed entirely, meticulously following your HACCP strategy is critical.

How long is my HACCP Certification good for?

Technically a HACCP certification does not have an expiration date. It may be required to renew based on employer, insurance, auditor, client, local or state requirements. For high-risk foods like meat, there are "requirements" that they are renewed every 3-5 years. It's best to check with the auditor,

Benefits and Impacts of HACCP

Whether you're required to do so by law, or just want to ensure your product is safe, the work you put into your HACCP plan will pay off in the long run. The HACCP system allows you to Identify and control any hazards that pose a danger, and can be applied throughout the food chain from production to consumption.

But it's no easy task, implementing a successful HACCP plan involves the full commitment from management and your HACCP team, which must include one person who is HACCP-trained.

Reduction In Product Loss

Prerequisite programs, such as Standard Operating Procedures (SOPs), are the foundation of HACCP, SOPs are written procedures that accurately describe and detail essential job tasks. The use of SOP pre-operations and cleanup checklists help ensure the steps throughout the production process are done correctly, resulting in fewer mistakes.

Increase in Product Quality

By identifying and controlling potential hazards, such as microbiological, chemical and physical contaminants, the company can better assure consumers that its products are safe. By reducing hazards, you maintain a clean record, which in turn will strengthen the company's public image.

Better Inventory Control

The required prerequisite program checklists layout in establish monitoring procedures, detailing the correct way to complete the job, taking the guessing work out of it.

Prerequisite programs must be continuously documented by the designated employee and reviewed by the company to ensure HACCP compliance. During review, personnel can monitor and correct purchase specifications.

Consistency in Product Preparation

As part of the HACCP system critical control points, at which a control can be applied to prevent a hazard, are identified. From there critical, measurable limits of acceptability are outlined for each critical control point, as well as monitoring procedures. These steps guarantee product consistency. However, if the criteria is not met and deviation occurs, the product will either be corrected or disposed of.

Increase in Profit

The costs of implementing and operating a HACCP system vary depending on the requirements the facility needs for compliance. But the investment will contribute to profitability, here's why: by applying all seven of the HACCP principles, safe and quality products will be produced, earning the trust of customers who will continue to keep purchasing the product.

In summary, taking action to ensure the safety of the food being produced has a ripple effect of positive outcomes. It all starts with the implementation of prerequisite programs, which set the stage for applying HACCP principles.