Laser Welding

1/71

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

72 Terms

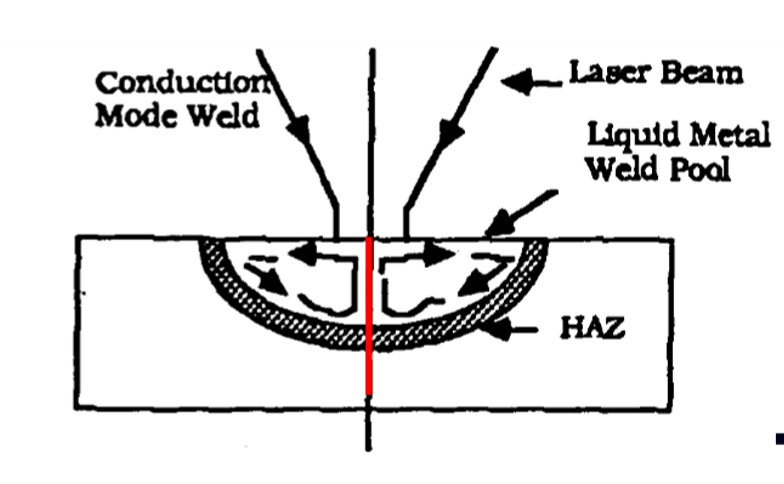

What is the principle of Conduction Limited Welding

The laser is absorbed at the surface (skin depth) only, and heat is transferred to the rest of the body by conduction

Melting only, no vapourisation

The melt pool is re-solidified behind the laser spot, joining 2 pieces together

Power Density

< 10^5 W

Advantage and Disadvantage

Adv: Low thermal damage

Disadv: Slow, Low efficiency

Applications?

Hardly used for metal welding, usually used for thin plastic film welding

Next type of welding?

Deep penetration (keyhole) welding

When the laser power density is >10^6……

fast vapourisation of metals occurs

Vapour pressure causes

the depression of molten metals and the formation of a keyhole

The keyhole acts as a ______ allowing for _______

black body, trapping the laser beam and allowing for very efficient laser-material energy transfer

The process is similar to _____ except ______

Similar to capourisation cutting, except the melt pool is not blow away but resolidified to join the 2 sheets

Temp and preressure is highest at:

The bottom of the keyhole

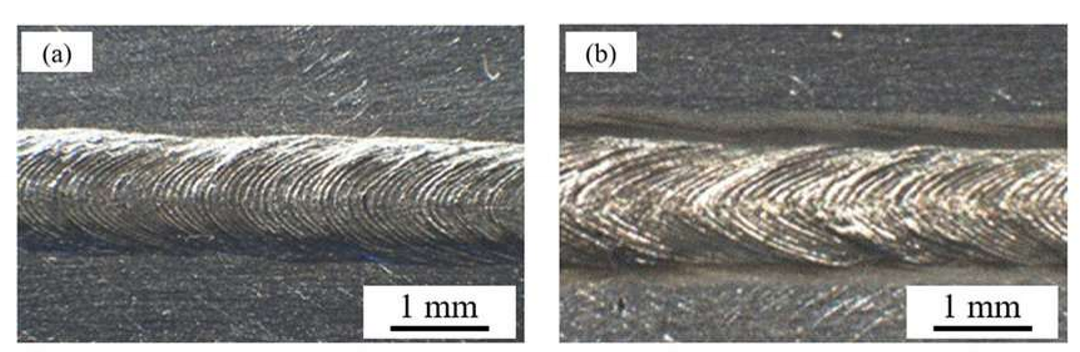

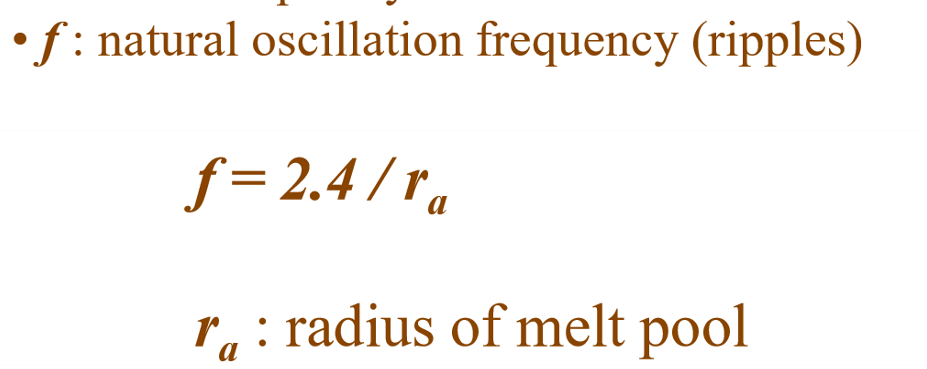

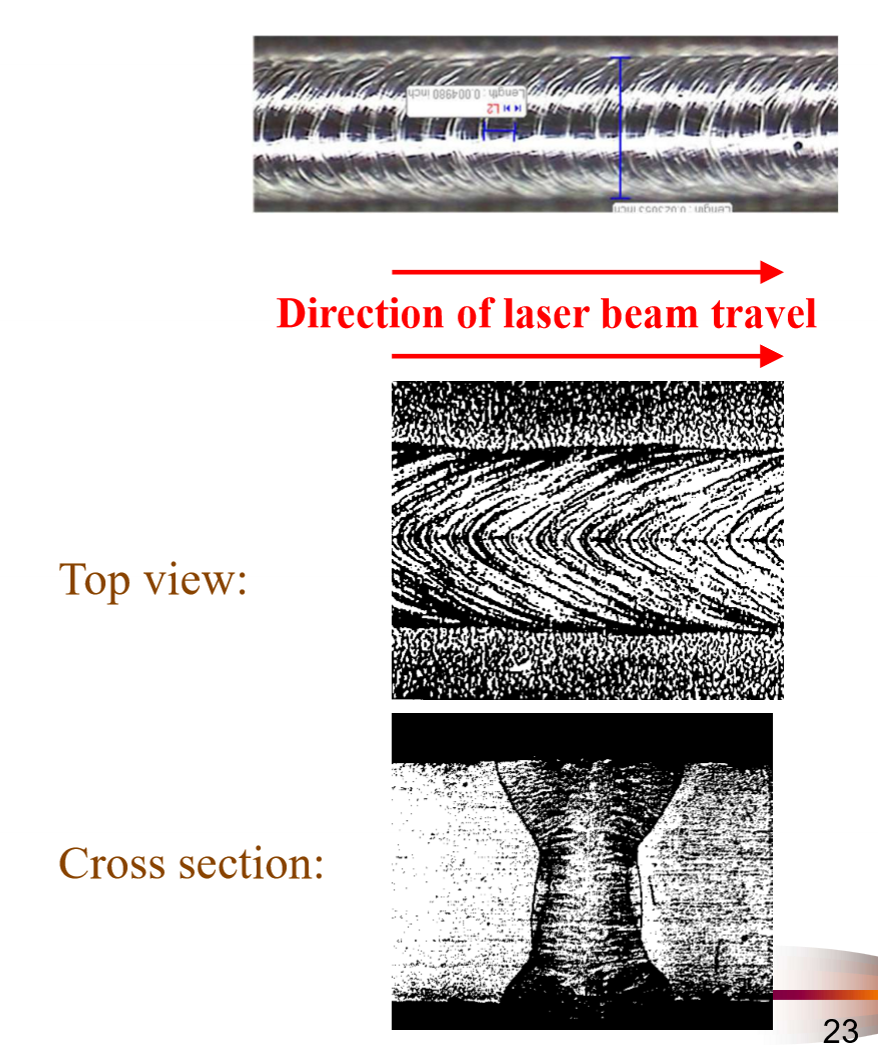

What are ripples?

Ripple like defects on the resolidified metal due to the natural oscillation frequency of the membrane

Equation?

Typical Lasers used for welding:

CO2 Laser, Fibre Laser, Nd:YAG Laser

Low order beam (ie TEM00) preferrer

Suitable materials:

All the same as arc welding can be used for laser welding

What is a plasma cloud?

When metal vapour and shroud gas is broken down into positive ions and electrons

When electron density reaches a critical value:

Avalanching breakdown occurs (large quantity of plasma formed)

_______ has to overcome ______ to start _____

Laser beam energy has to overcome ionisation potential to start ionisation

Minimum of ____ is required to generate breakdown

10^6 W/cm²

The degree of ionisation is

An exponential function describing material energy levels

Ionisation at comparable temps differs by order of ____ between metal and gas

_____ ionises first

e²

Metal ionises first

Plasma is high ________ that _____

Thus?

High temp, pressure and velocty that disturbs beam absorption

Thus, should be avoided (but practically not possible)

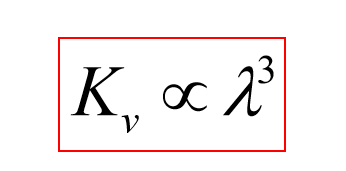

Plasma absorption coefficient to laserbeam relationship:

Therefore?

Shorter wavelength results in less beam absorption by plasma, meaning shorter wavelengths are desirable for laser welding

What happens in Laser Supported Combustion? (LSC)

Laser intensity between 10^6 & 10^7 W/cm²

Expansion of plasma is below sonic speed (slow, meaning it hovers over the weld pool)

Results in Beam Absorption of up to 30% (Plasma is transparent to beam)

The plasma lenses the original beam (meaning it is poorly reflected and further diminishes beam)

Plasma re-radiates the energy in the form of light

Plasma is confined to surface, meaning energy is transferred via thermal conduction and radiation

All of these effects result in the Weld Width Increasing, and the Penetration Decreasing

Cheeky Diagram:

What happens in Laser Supported Detonation? (LSD)

For Laser Intensity >10^7 W/cm²

Plasma detatches from the surface, travelling perpendicular to the surface at supersonic speeds

Plasma absorbs up to 50% of the beam (plasma is considered opaque to beam) - blocking the beam

Transfers energy to workpiece in form of re-emitted light, in a larger spot size

Weld is disrupted and stopped

When the plasma expands, the plasma density decreases, allowing the beam to reach the workpiece, resulting in more plasma formation - Results in periodic plasma formation

What happens when the Laser Intensity is >10^8 W/cm²

Plasma/Vapour pressure is too high, meaning expulsion of molten metals occurs (splattering)

Beam may be totally reflected

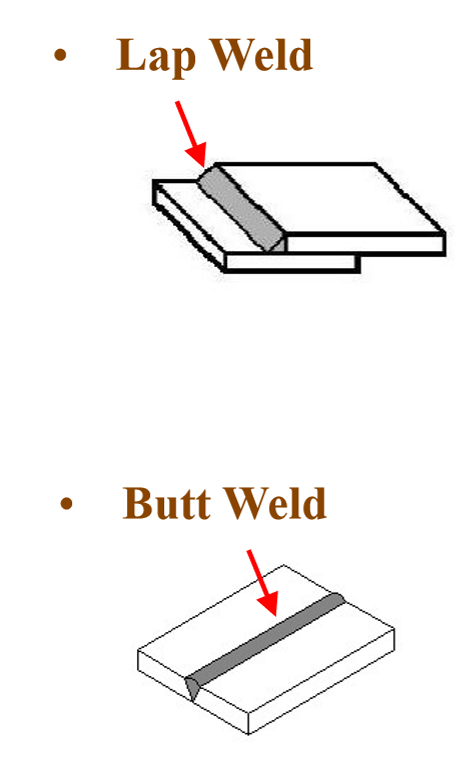

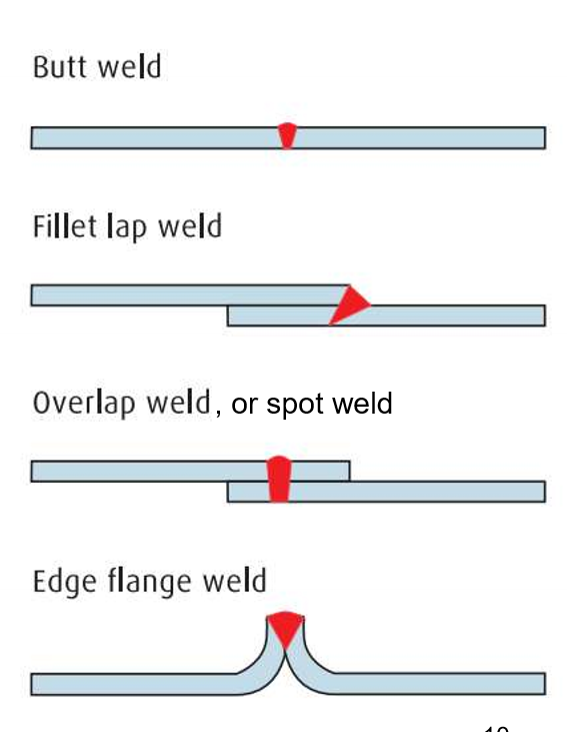

2 Types of Weld:

Formation of a good weld

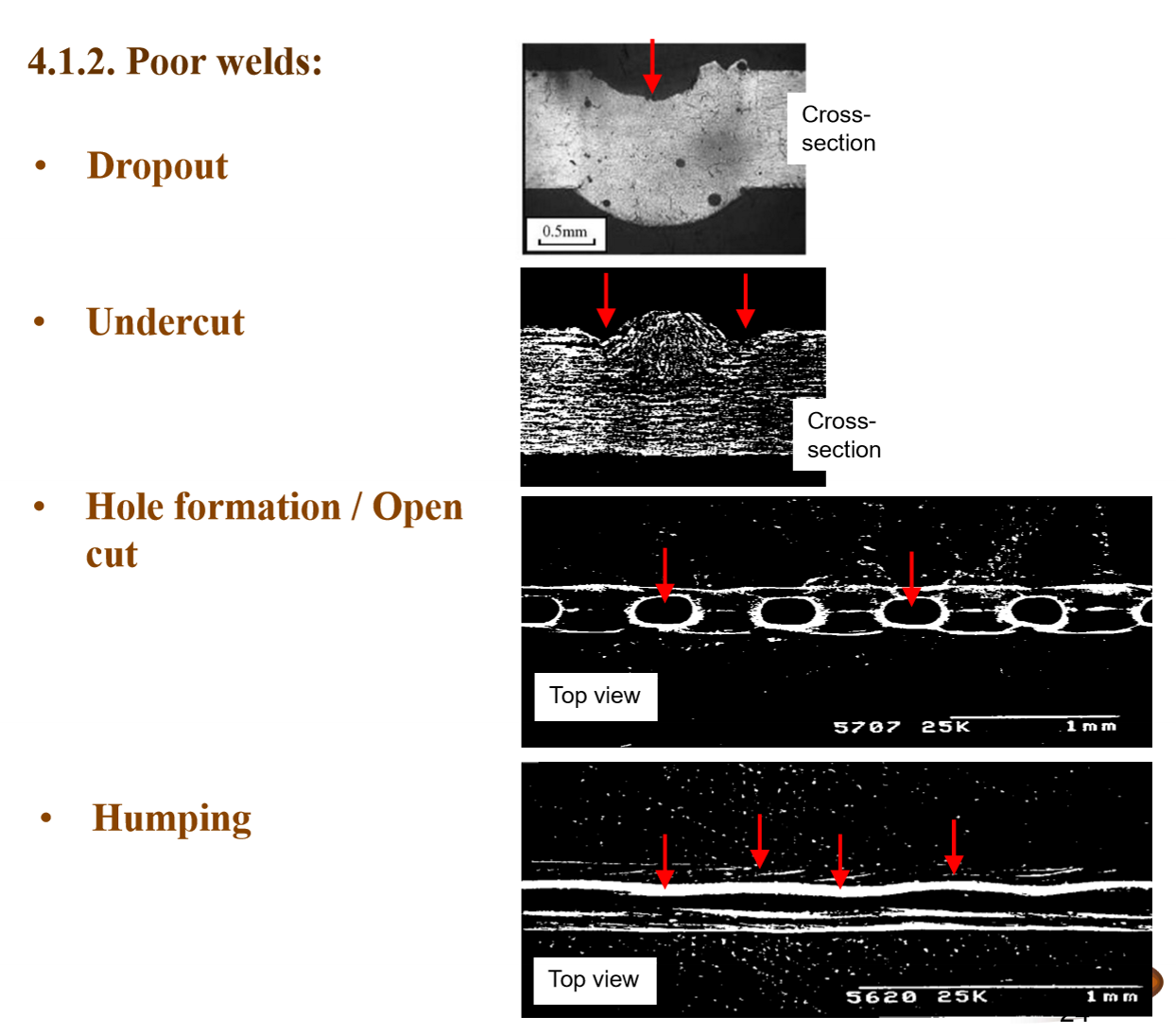

4 indicators of bad welds:

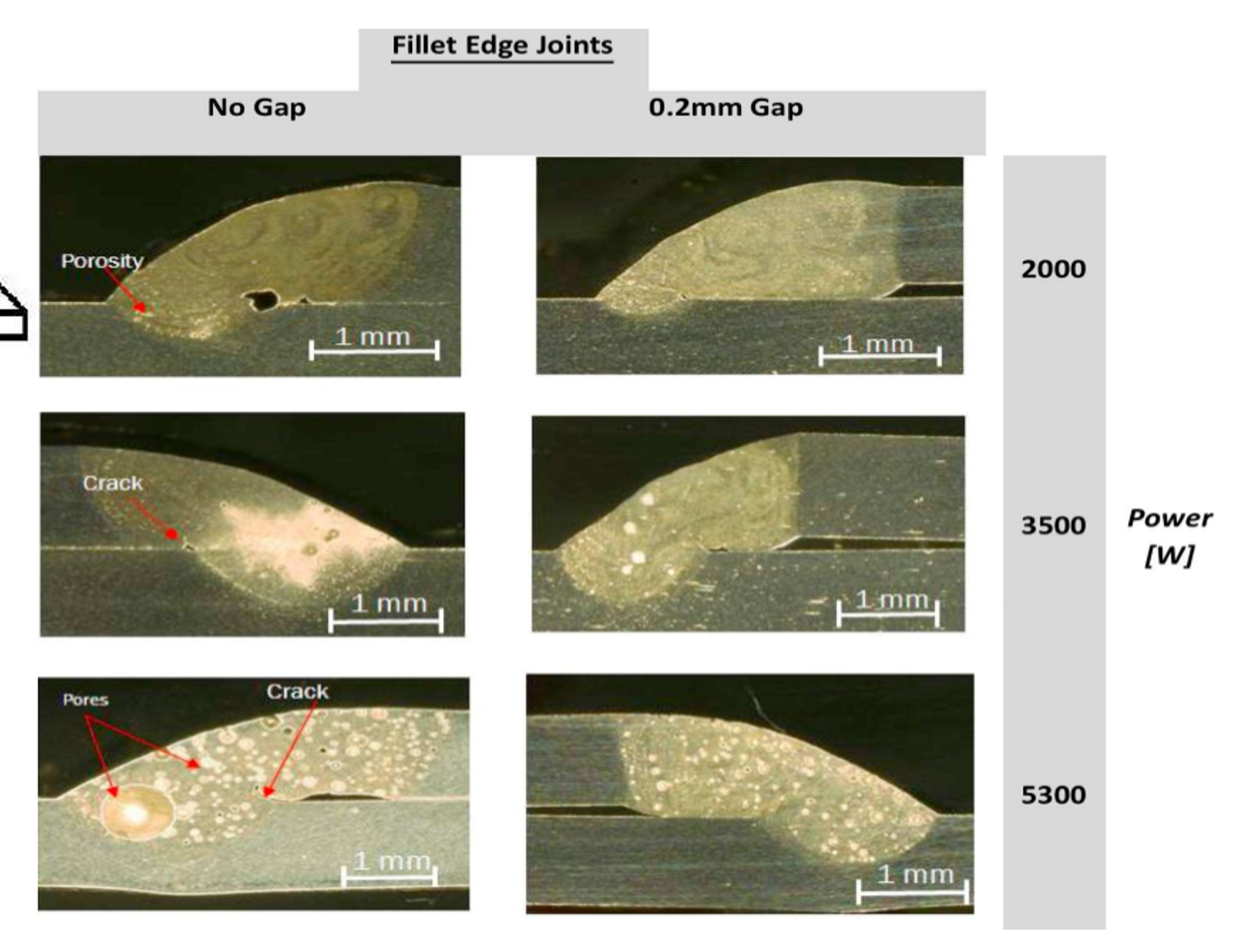

What two effects reduce porosity in welds?

Leaving a gap

Changing the material

Why does gap help reduce porosity?

Helps evaporation of vapours

What materials reduce porosity

Al-Mg-Mn filler materials

Why does the filler material reduce porosity? (5)

Increases molten pool size

Slows cooling

Improves flow and degassing

Stabilises the keyhole

Adds alloy elements that reduce gas entrapment

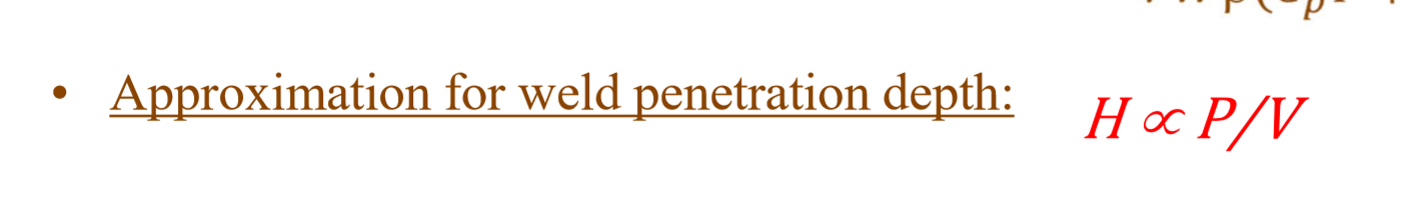

Weld penetration depth relationship

H = Weld Pen Depth

P = Power

V = Cutting speed

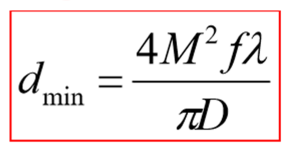

How else can H be increased without changing P or V?

Increasing power density, by decreasing focal spot area, by reducing focal length

Too high welding speed also causes

Himpung (knowt wouldnt let me type it)

Undercut

Low speed causes

High HAZ

More Porosity

(Plasma inc)

What is the role of process gas? (3)

To cool and blow away plasma

To protect melt pool and hot work piece from atmospheric contamination + oxidation

To protect laser optics from metal vapour

It affects: (4)

Porosity of the weld

Absorption Coefficient

Weld pool melt flow patterns

Plasma Density

Adv of CO2 gas: (1)

Increases absorption by generating oxides at high temp

Limitations of CO2: (2)

Oxides may cause corrosion issues, (thus is not good for steel and titanium alloy welding)

Has a low ionisation threshold, producing more plasma :(

Adv of N2 (1):

Low Cost

Disadvantages of N2:

Low ionisation threshold (easy to ionise)

Ti-alloys are sensitive to N2 (ie not good at Ti Alloy Welding)

Ar Gas adv (2) and disadv (1)

Heavy(good for shroud)

Cheap

Low Ionisation threshold

He gas adv and disadv:

High ionisation threshold, meaning good for high welding penetration depth

Light (bad for shroud)

Expensive

Optimum gas:

High ionisation threshold (He) for plasma prevention

Heavy gas (Ar) for good shroud

Low cost (N2)

Why is O2 not used by itself

To avoid oxidation

At high power, _______ assist gas _____

He assist gas almost doubles penetration length

At lower power or higher welding speed, ______ so _____ is preferred

type of assist gas does not affect penetration depth, so Ar or N2 is preffered (low cost)

At longer wavelength (ie CO2 Laser) _______ thus _______ is preffered

Assist gas strongly affects welding penetration depth, thus He is preferred

At shorter wavelength (Nd:YAG, Fibre) ______ thus ______

Assist gas has less influence on welding depth, thus N2 or Argon is preferred

If the gas flowrate is too low:

Plasma shielding causes low penetration and porosity formation

If the gas flowrate is too high:

Gas flow widens keyhole, reducing multiple reflection effect, reducing beam absorptivity

Produces himpung

Weld penetration is increased by adjusting focal position to:

0.5-1.0 mm below the surface

Focusing above the surface leads to

Poor weld quality

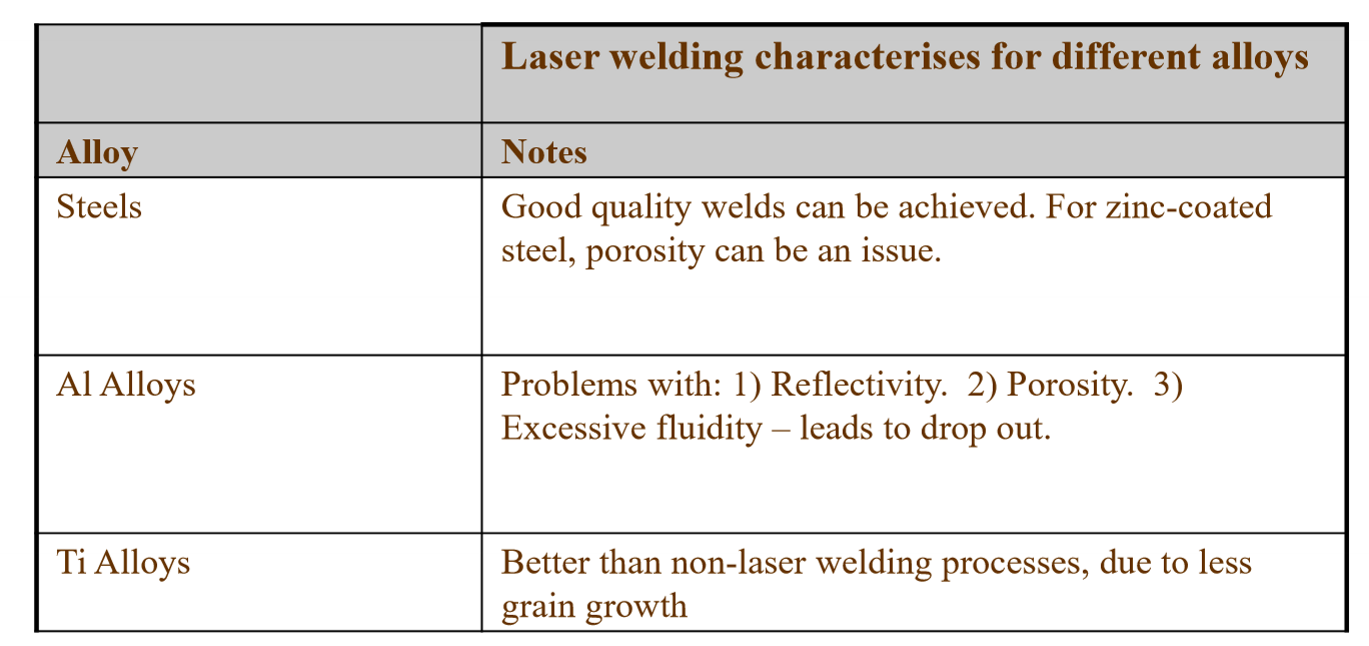

Overview of Steels for Welding: (4)

Excellent Weld

Higher Tensile Strength

Higher Aspect Ratio

Corrosion resistance not affected/improved

Very good quality welds can be achieved provided ________

Sulphur and phosphorous levels are low (they promote grain boundary weakening/cracking)

High carbon steels require care to avoid _____

______ can be used to avoid ____

Weld cracking

Preheat can be used to avoid cracking

Low alloy steels can be used but _____- is an issue and _____ can be used to help

hardness can be an issue (may lead to cracking), preheat can be used to help

What can occur when zinc coated sheets are welded?

Zinc vapour is produced, which could cause porosity issues

(May lea

______ and _______ steels weld well but _____

Austenitic and Ferritic Stainless Steels weld well, but Martensitic steels develop brittle and hard behavior

Aluminum welds can be poor quality due to: (5)

High reflectivity (leading to low absorption and back reflectivity causing damage to optics)

High thermal conductivity resulting in crack

Porosity Generation (due to gas from surface oxidation layer)

Lower joints tensile strength

Low melting temp and high fluidity, which can cause dropout of weld seam

How to increase Beam Absorption and reduce back reflection? (5)

Using shorter wavelength laser source

High intensity

Tilting surface to Brewsters angle and using p-polarised beam

Tilting surface to prevent back reflection

Use surface coating or sand-blasting

How to reduce dropout and porosity? (2)

Filler wire to modify composition and microstructure

Use a mixed beam (e.g. an excimer laser) to remove oxidation layer

How to prevent Cracking? (1)

Preheating workpiece!!

Adv of Ti-alloy welding?

Good quality weld with fine grais

What is essential?

Prior material cleaning

Weld pool shielding

Summary of welding properties: (remember if you cba with rest)

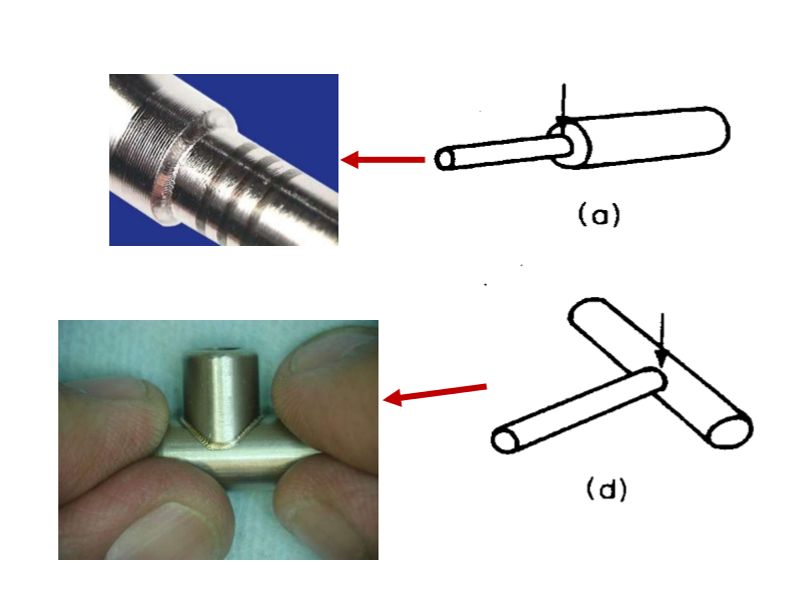

4 main types of weld:

Welding of _____ may require specific geometries

Cylinders

Designing a laser welding process also involves designing of a ___ to provide a ____

jig to provide a suitable clamp force