ETech HVAC Exam 02

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

45 Terms

Air Source Heat Pump components

compressor, condenser, evaporator, expansion valve, and refrigerant (freon)

Air Source Heat Pump purpose

efficiently move heat, rather than generate it, using electricity to transfer heat from the outside air to the inside for heating and, in reverse, to cool the inside by extracting heat

Compressor

compresses the refrigerant gas, increasing its pressure and temperature

Condenser

gas from the compressor moves to the condenser and lets off its heat in the interior (if heating) or to the exterior (if cooling the interior)

Evaporator

The component in a refrigeration system that absorbs heat into the system so the heat pump can distribute it somewhere else

Expansion Valve

The expansion valve acts like a nozzle that releases the amount of refrigerant into the evaporator, dropping its pressure so it can get cold and start absorbing heat again

refrigerant (freon)

Refrigerant is a chemical compound that can easily change between a liquid and a gas at low temperatures

reversing valve

changes the direction of refrigerant flow to switch between heating and cooling modes

Heat exchange process in the heat pump:

1. Outside air has heat, even when it's cold.

2. The refrigerant in the outdoor coil absorbs that heat (this part is called the evaporator).

3. The compressor squeezes the refrigerant, making it hotter.

4. The hot refrigerant flows to the indoor coil (called the condenser), where it releases heat into your home.

5. The refrigerant cools down, turns back into a liquid, and goes through the expansion valve to get cold again.

6. The cycle repeats.

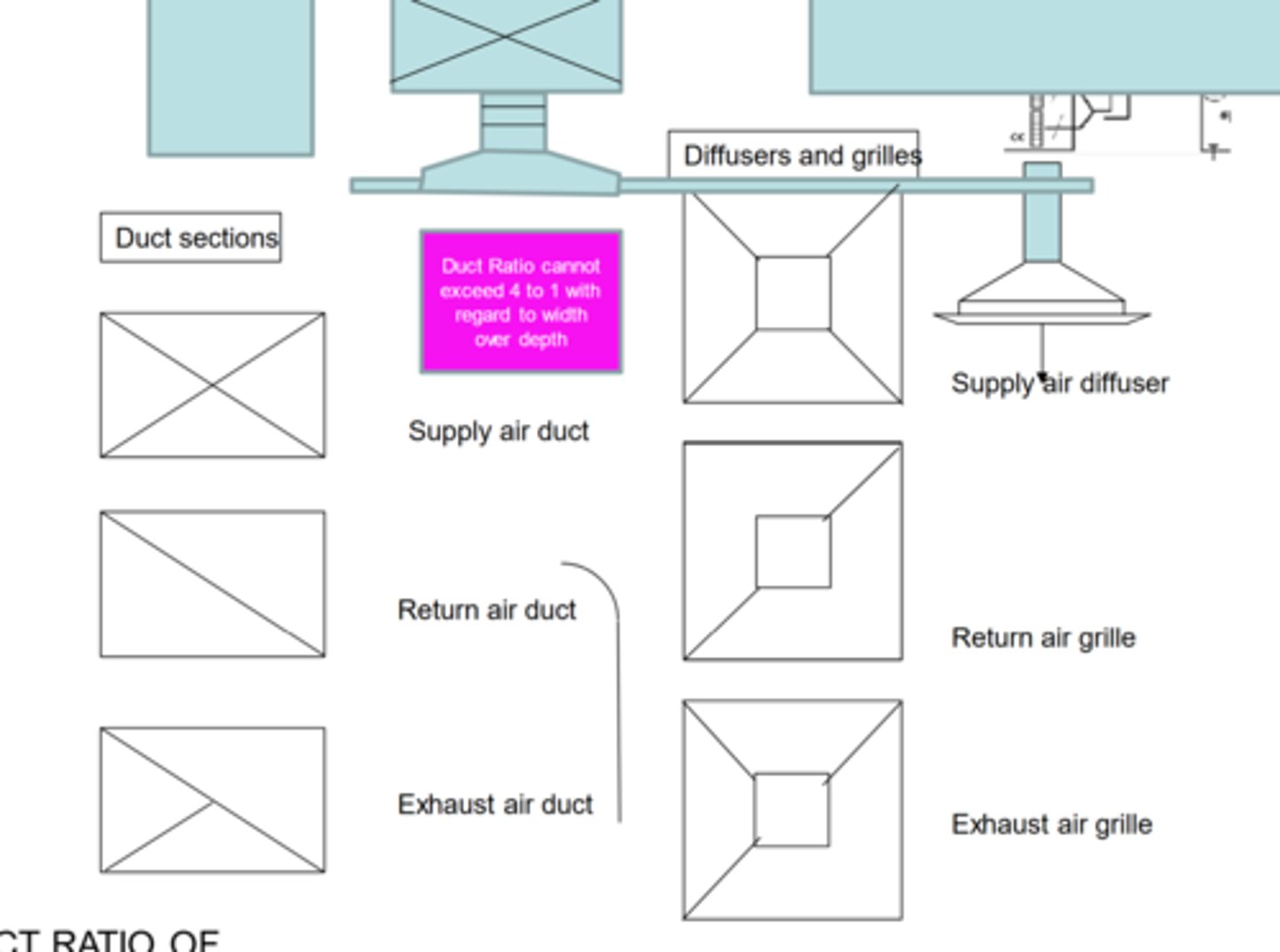

Shape of the duct sections

Round: best airflow, most efficient

Rectangular: fits in tight spots, but more drag, most economic

Oval: best of both, but harder installation

Why are elbows in ducts not desirable?

slow down airflow, make systems noisier, and reduce efficiency

Ideal width : depth ratio in ducts and why you shouldn't exceed?

anything greater than a 1:4 ratio results in more friction and noise than desirable

Difference between water and freon in heat exchange?

Freon does not freeze

Purpose of a flexible connection

vibration dampening which decrease chance of noise and structural damage, allow thermal expansion that may happen in HVAC systems, easier installation

Heat Recovery Wheel process and purpose:

A heat recovery wheel acts like a big heat sponge that catches heat from the outgoing air and transfers it to the incoming fresh air — saving energy and keeping your system more efficient.

Steps:

1. Warm Air (Exhaust): As air leaves the building, it carries heat with it.

2. Heat Transfer: The heat recovery wheel rotates and absorbs this heat from the outgoing air.

3. Cool Air (Fresh Air): Fresh air coming into the building passes through the wheel, and the wheel transfers heat to the incoming cool air.

4. Energy Saving: This helps pre-heat the incoming air, reducing the amount of energy needed to warm it up, which saves energy and reduces heating costs.

4 ducts connected to the AHU:

1. Supply Duct (Hot or Cool Air)

Purpose: This duct carries conditioned air (heated or cooled) from the AHU to the rooms in the building. Brings fresh air to every room.

2. Return Duct (Used Air)

Purpose: This duct brings air from the rooms back to the AHU to be either cooled or heated again, depending on the system's needs.

3. Exhaust Duct (Air Out)

Purpose: This duct takes stale air or air that needs to be vented outside (e.g., bathroom or kitchen air) and moves it out of the building.

4. Fresh Air (Intake) Duct

Purpose: This duct brings in fresh, outdoor air into the AHU for circulation in the building.

Simple Example: like a door that brings in fresh air from outside to keep the indoor air healthy.

Inside or Outside: Air cooled condenser/chiller

OUTSIDE

Inside or Outside: Boiler

INSIDE

Inside or Outside: Cooling Tower

OUTSIDE

Inside or Outside: Water-cooled Chiller

INSIDE

Geothermal Heat Pump

How it works:

1. Underground Loop: The system uses pipes buried in the ground (either horizontally or vertically) to absorb heat from the earth in winter or release heat into the earth in summer.

2. Heat Transfer: The heat from the earth is carried by a fluid (water or antifreeze) through the pipes to the heat pump inside your home.

3. Heating & Cooling: The heat pump either extracts heat from the fluid to warm your home in the winter or removes heat from the air in your home and sends it into the earth in the summer.

Why are Geothermal Heat Pumps better than ASHP?

A geothermal heat pump uses the earth's natural heat (from underground) to warm or cool your home. It's more efficient and consistent than an air-source heat pump, making it a better long-term choice, especially for energy savings and environmental benefits.

Air Handling Unit (AHU)

The AHU is like a giant air processor that makes sure the air inside a building is clean, the right temperature, and comfortable to breathe. It then sends that air to every room through ducts.

Air Handling Unit (AHU): How it works + components

1. The AHU takes in fresh air from outside and can mix it with indoor air.

2. The filters clean the air.

3. Then, the air passes through either a heating or cooling coil to adjust its temperature.

4. Finally, the fan pushes the air into the ducts that deliver it to different rooms or spaces.

Components:

Filters: Clean the air by removing dust, dirt, and other particles.

Heating Coil: Heats the air if it's cold.

Cooling Coil: Cools the air if it's too hot.

Blower/Fan: Pushes the air through ducts and into rooms.

Humidifier or Dehumidifier: Adds or removes moisture to maintain comfortable humidity levels.

Rooftop Unit (RTU)

An RTU is a type of air handling unit that is installed on the roof of a building. It works just like an AHU, but it's placed on the roof for space-saving and convenience.

Variable Air Volume boxes

A VAV box is like a smart air regulator that controls how much air goes into a room to keep it at the right temperature. It adjusts the airflow automatically to make sure every space is comfortable.

Variable Air Volume boxes: How it works

1. The HVAC system sends air into the VAV box.

2. The thermostat inside the VAV box checks the room temperature.

3. If the room is too warm or too cold, the damper adjusts to allow more or less air into the room.

4. The air is then delivered to the room at the right volume to maintain the desired temperature.

Variable Air Volume boxes: Components

Damper: A movable panel inside the VAV box that controls the airflow. It opens or closes based on the temperature needs in a room.

Thermostat: A sensor that measures the temperature in the room and tells the VAV box how much air to deliver.

Fan (Optional): Some VAV boxes have small fans to help push the air into the room.

Controls: The system can be set to adjust the air volume automatically based on room temperature, or it can be manually controlled.

Conventions for pipes and ducts in drawings:

Ducts: Rectangular, round, or oval symbols with airflow arrows.

Pipes: Solid lines (water), dashed lines (drainage), or specific labels for different fluids (chilled water, hot water).

Airflow/Fluid Flow: Indicated with arrows showing direction.

Why is fresh air delivered to spaces?

due to the need for indoor air quality control

Main Duct Area=

Q (air flow rate in CFM)/V (velocity in ft/min)

Mechanical Air-conditioning Systems

systems categorized by how they control heating or cooling in a conditioned area

All-air systems

systems that provide complete cooling and heating through air. provide complete sensible and latent cooling capacity through air, with various subtypes like single zone and dual duct.

All-water systems

systems that use chilled or hot water to control temperature. use chilled water for cooling and hot water for heating, with types like two-pipe and four-pipe systems.

Air-water systems

systems that utilize both air and water for temp control. allowing for individual room control and reduced duct space.

Direct Expansion Systems

systems that contain a complete refrigeration system to provide cooled or heated air. includes integrated refrigeration systems for individual room control, such as window air conditioners and heat pumps.

Types of all-air systems

single-zone, reheat, variable volume, induction, dual duct

types of all-water systems

two-pipe changeover, three-pipe, four-pipe, under-glass convectors, fin coils.

types of air-water systems

induction, fan-coil with primary air, induction-recovery

types of direct expansion systems

window air conditioners, packaged terminal air conditioners, air source heat pumps, water source pumps, two pipe water-loop heat pumps.

all-air system advantages

centralized equipment, flexibility, and adaptability to heat recovery

all-water systems advantages

reduced building space needs and individual room control

air-water systems advantages

low distribution system space and long-lasting components

direct expansion systems advantages

include individual room control and simple operation

what are the three mediums in which transmission of heating and cooling to a location

water, air, freon