Food Service Exam 2

1/277

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

278 Terms

types of delivery systems

conventional

comissary

ready prepared

assemble serve

factors to consider for layout and design

layout based on menu

what equipment is needed/where it will be place

good flow of materials and labor

flower of food service

receiving → storage → preparation → cooking → serving → clean-up

dominant food service in the US

conventional

traditionally used in most operations

conventional foodservice

foods are purchased in various stages of preparation for an individual operation, and production, distribution, and service are completed on the same premises

cook serve

foods may be distributed for service directly to an adjacent or nearby serving area

centralized or decentralized

as labor costs increase, managers often explore procuring more extensively processed foods

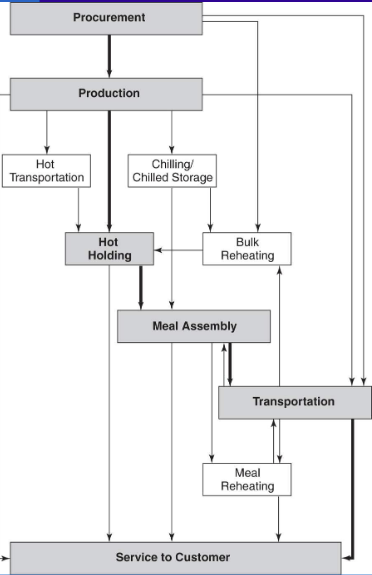

conventional operation flow in a hospital operation

food goes is purchased, prepared in production, then help hot until patient trays are assembled

assembled trays are transported to the patient areas and served

hot holding, meal assembly, and transportation increase time between production and service

ready prepared

menu items are produced and help chilled or frozen until heated for service later

food items are stored and recorded in storage and withdrawn when needed for production

after production items are stored in refrigerators or freezers, and entered in the distribution inventory

time to use cook-chill foods

< 7 days

time to use cook-freeze foods

2 weeks to 3 months

when to reheat cook-chill and plate chilled food

just prior to service

HACCP

Hard Analysis Critical Control Points

program and follow specific production, storage, and documentation practices

commissary food service

centralized procurement and production facilities

distribution of prepared items to several remote areas for final preparation and service

central commissaries, commissariats, or food factories

satellite service centers

equipment preprocessing and production often is different from the used in conventional foodservice

large-scale production quantities require major modification of recipes and food production techniques

specialized distribution equipment may be needed, depending untype and location of service centers

assembly/serve

assembly/serve foodservice occurred primary. because of the market availability of foods that are ready to serve or require minimum cooking

convenience-foods foodservice or minimal cooking concept

another factor has been chronic shortage of skilled personnel in food production and increasing labor cost.

limited proceeding needs to occur

flow

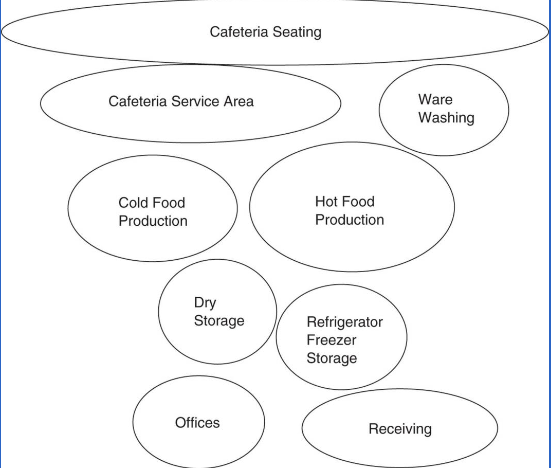

movement of materials and people in an operation

goal is to have a straight-line flow from receiving through warewashing to minimize backtracking and cross over movement of food and people

product flow

food from receiving through trash removal

traffic flow

movement of employees as they complete their work

points to remember for flow

store at point of first use

keep products close to where they will be used

allow for economy of motion

store based on usage, heavy use within normal reach, heavier products lower

use space economically by providing for specific sizes

minimize handling

storage close to receiving, have carts available

systemize

organize, like products together

good handling practice

use lifts and trucks for lifting and moving, aisles clean, good traffic flow

communicate

conceptual planning committee

brad estimates for cost, space, equipment

actual physical plan

specific list of equipment, specification and actual physical plan

charrette planning process

collaborative planning session for a design project

bubble diagram

defining spaces so can see the flow

what to consider when planning

Quantity of food and supplies

Amount and kind of production (to determine equipment)

Type of delivery system

How food served to the customers

to renovate or build

Operating cost of the facility

Any food safety issues of concern

# of employees

Any future plans

Going about getting started

network

visit facilities

seminars

tradeshows

equipment manufacturers

Steps for layout/design process

program

schematic design

blueprints

construction drawings

program

goals for the project

overview

project timeline

schematic design

preliminary plans, space drawings, proposed, electric, mechanical issues, costs

the basics

blueprints

specifics

mechanicals, electrical, plumbing

drawn to scale - usually ¼ inch = 1 foot

accompanied by a specifications book

sustainability in kitchen design/layout

increasingly important in design of future space, including foodservice operations

goal to be a “green building”

efficient use of energy, water, and materials, while reducing impact on human health and environment

LEED certification

sustainable certification process

designed to promote design/construction practices minimizing negative building impacts and improving internal environment

water conservation

sinks

toilets

foot petal sinks

high efficiency dishwashers

motion sensor sinks and lights

high velocity, high efficiency pre-rinse, spray nozzles

waste management

buy in bulk

pulpers

garbage disposals

recycling program

composting programs

receiving area materials

scale

table

sink

may want near manager’s office

dry storage

must be 10”-12” off floor for air flow

use vertical space

opaque windows

one door

secured

50-70 degrees F

3 types of storage

dry

refrigerated

frozen

preparation area

work table correct high

sinks for food prep

shelving

tool drawers

slicers

mixers

choppers

refrigeration

electrical capabilities

conduction

transfer of heat in direct contact with each other

convection

hot air circulating, fan, lower temp shorter time

radiation

energy transferred by waves of heat or light striking the food

induction

cooking vessel made of specific magnetic metal, copper coil in induction surface, electric current flows between, low voltage, faster and energy efficient

types of serving

banquet

restaurant

take-out

tray service

cafeteria

utensil dispense

used in cafeterias

clean up

garbage disposals

pulpers - works like a disposal but dehydrates the product into slurry by shredding and pressing out the water

waste is semi-dry

decreases solid waste by 85%

recycling

lighting

maybe 1/3 of energy cost

direct lighting - lighting aimed at a certain place

indirect lighting - shines over a space rather than at a certain place

incandescent lights

common light bulbs

a filament is encased in a sealed glass bulb

screwed into a socket

electric discharge lights

pass an electric arc through a tube with a special mixture of gasses

need an electronic or magnetic ballast

fluorescent

things to consider with lighting

ceiling height

wall color

floor finish

lumen

amount of light generated when 1 foot candle of light sines from a source

foot-candle

measurement of illumination equal to 1 lumen of light to 1 square foot of space

food code lighting level requirements

storage areas - 10 foot candles

hand/warewashing areas - 20 foot candles

food prep areas - 50 foot candle

layout and design books lighting suggestions

food prep areas - 70 to 100 foot candles

dining areas - 5-100 foot candles

guards over glass

prevent glass from falling

HVAC system

controls quality of air

indoor temp

humidity

air movement

room surface temp

produces comfortable work environment

HVAC equipment

furnaces or boilers - hot air

are conditioners or chillers - cold air

fans - circulate air

duct work - moves air

filters - clean air

supply air

air coming to the system through HVAC system

return air

air returning to the HVAC from the workplace

exhaust air

air that is removed form the workplace and building

makeup air

air being brought in to replace exhaust air

negative air pressure

more air removed than brought into space

slightly negative is good in kitchen

will prevent kitchen smells and odors going into dining room

positive air pressure

more air brought in than removed

Ventilation

circulation of fresh air

measure din cubic feet per minute

ventilation in different spaces

35 cfm per person in kitchen

15-20 cfm per person in DR

15-25 cfm per person in offices

hoods

ventilation system

heat, orders, grease, steam, and moisture generated

placed over cooking area to draw air out of the kitchen

20-30 total air changes in an hours

cleaned to avoid grease fires

automatic fire suppression systems

stainless steel

alloy of many metals

18-8 stainless steel - chromium (18%) and nickel (8%)

insert chemically, stain proof, strong and durables

#5 finish (bright satin) common

common gauge of stainless steel

20 gauge

1.5# per sq ft and 1/32 inch thing

higher the gauge…

thinner the stainless steel is

plastics

used for storage, less expensive

flooring considerations

ease of cleaning and maintenance

appearance

concrete floors

used in storerooms, receiving areas

Terrazzo floors

used in dining room, noisy

unglazed red clay tiles/quarry tiles

kitchen and heavily traffic areas

asphalt floors

light traffic, dining room

walls

glazed tiles 5"‘8” high

washable

impervious to moisture

ceilings

acoustically treated

higher in color than walls

14-18’ high

aisle space in kitchen

lane with one person - 36-42”

lane with more than one person or where mobile equipment passes 48-52”

main traffic lane 60”

counter height

heavy work - 36”

light work - 37-41”

work centers

smallest area planned in the facility

area where related tasks are performed

cold or hot food prep

volume to be prepared

# of employees

kind and amount of equipment

measuring productivity of workers

payroll cost per day

payroll cost per meal served

payroll cost per pt. day

meals served per labor hour

work design

program of continuing effort to increase the effectiveness of the work system

industrial engineers

material handling

movement of materials and products as they go through the system

good flow leads to increased efficiency

Frederick Taylor

father of scientific management

belief if design best work situation will decrease conflict between res

Gilbreths

principles of motion economy

aimed at reducing the effort and energy required to do a job

items easy to pick up, right height, better design of tools and equipment

work measurement

method of establishing equitable relationship between amount of work performed and human input needed to accomplish the task

what do you expect of production

activity analysis

work sampling

quality circles

Began in Japan in ‘60’s

small group of employees (3-25) 10 works best

have meetings during work hours

look at project as a whole

input from all

increased productivity, ee morale, product quality,

better work distributiondecreased absenteeism

determining space

Heaviest customer load

speed of service - average 5 people/minute in a straight-line system; less time with scatter system more efficient

menu variety - more items on line slower service

seat turnover - how many times in an hour do seats turn; hospital 30 min. turnover rate 2

length of serving period

the longer the serving period the fewer seats required

space allocation/seat

check w/ state & local building codes

width of service area

~14 ft. Space from back wall to customer line

length in hospital usually 30 ft.

plan in advance

do feasibility study to see if should go ahead or abandon it

architect, foodservice consultant, financial people in addition to manager or owner

prospectus

costs

income

expenses

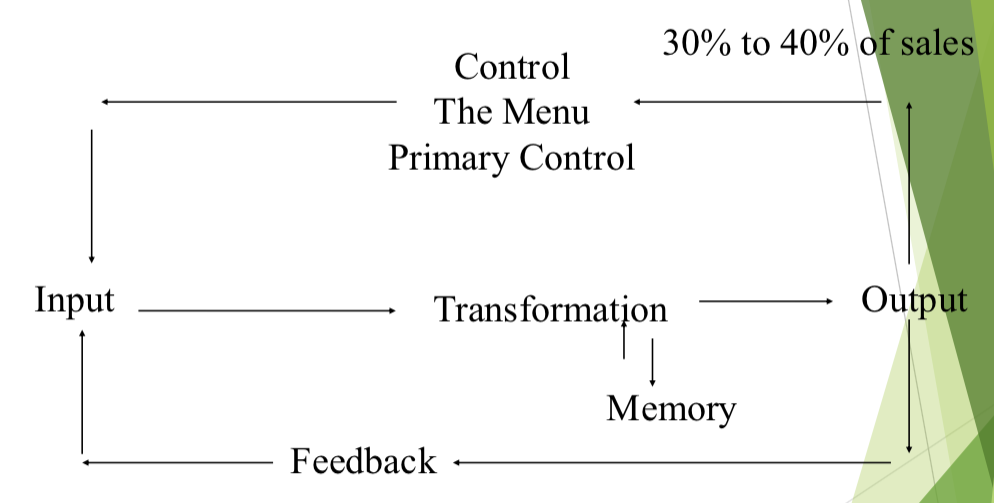

menu planning flow chart

menu psychology

design and layout of a menu is such a way to influence the sale offends served on the menu

eye gaze on 3 page menu

primacy and recency

items you want customers to buy 1st and last in category

front size and color

increase the size of font to attract customer, decrease to deflect, easy to read

color and brightness

increase color, brightness, and shading to draw attention

spacing and grouping

borders to draw attention

menu types

no choice

limited choice

choice restaurant

commercial (profit centered)

non-commercial (hospitals, schools, military)

no choice menu

very uncommon

serves those whoa re unable to or do not have a desire to choose

allows for greater forecasting and control

long-term care facilities

limited choice menus

may be able to choose side dishes, dessert, beverage

static menus

same menu items offered every day

usually restaurants but now institution food services - restaurant style menu

room service menus

cycle menus

series of menus offering different items daily

weekly, bi-weekly, or some other basis

could have different seasonal cycles

seen in schools, long-term care, hospitals

simplifies purchasing, standardizes preparation, gives more constant, and even workload distribution

choice menus

single use

planned for use on a particular day and not used in the same form

monotony breakers

usually non-commercial

aren’t these daily specials in commercial

catered events

degree of choice

the less choice the easier it is to forecast production needs

increase choices increases customer satisfaction

two tier menus

upscale menu items made for those willing to pay extra for them

table d’hote

several food items grouped together and sold for one price