L6: Abrasion

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

17 Terms

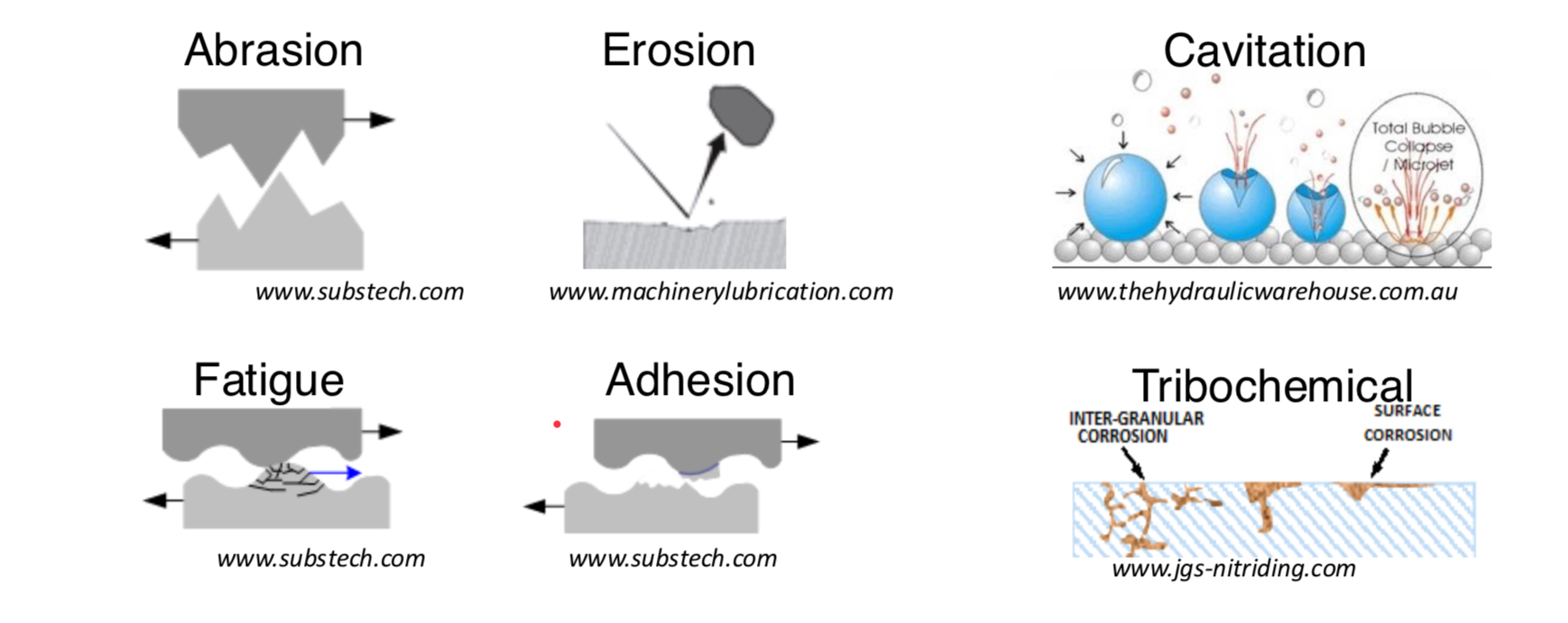

Abrasion

contact between 2 solids resulting in a loss of matter/physical integrity of the weaker surface

Abrasion Hazards

accidental contact with rough surfaces, normal wear; affected by surface roughness, hardness, and presence of a 3rd medium

Wear

material is lost/displaced from a solid to an atomic level

Polymer Abrasion

displacement of surface materials in relative motion

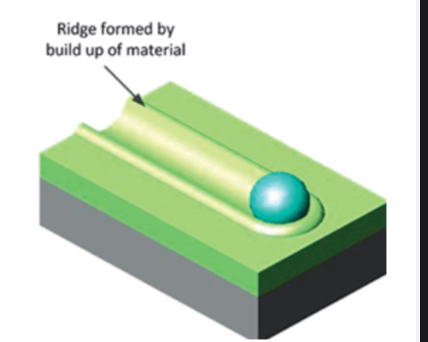

Microploughing

ridge formed as material moves along a surface; material displacement

Microcutting/Microshearing

material chipped away as a channel is produced; material loss

2 body abrasive wear

3 body abrasive wear

Abrasion of Elastomers

mechanical abrasion caused by mechanical failure from local stress concentrations; basic wear - characteristic wave pattern

Abrasion of Yarns/Fibres

Abrasive surface adheres to the fibre, junction is formed, surfaces slide, junctions shear, one surface left attached to the other

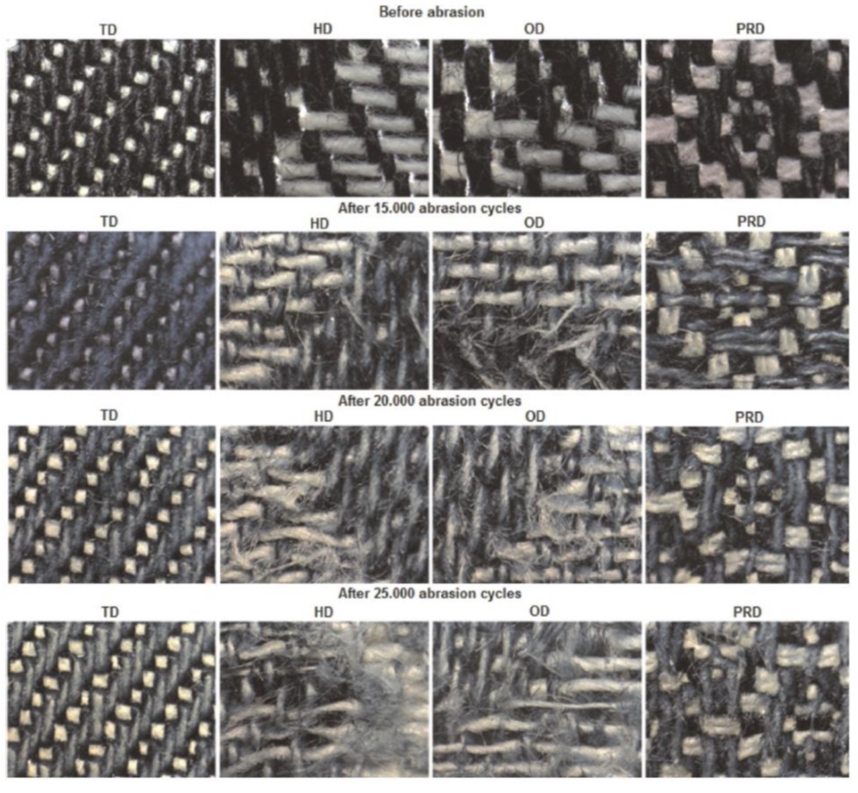

Abrasion of Fabrics

fibre breakage and entanglement, strong effect of weave pattern, surface flattens and may become fuzzy

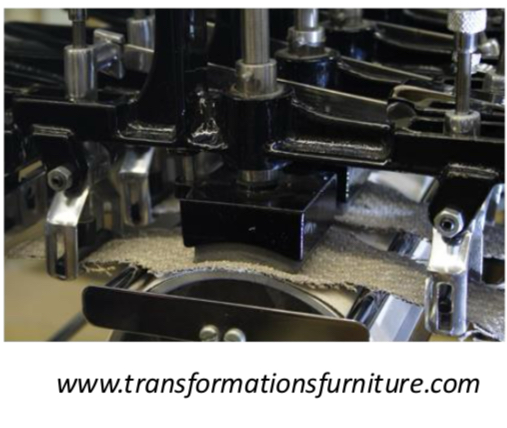

Martindale abrasion tester

38 mm specimen in circular holder: measure number of cycles before endpoint

Wyzenbeek tester

cylinder moves back and forth over fabric, tested in warp and weft direction: endpoint is when 2 broken yarns or noticeable wear

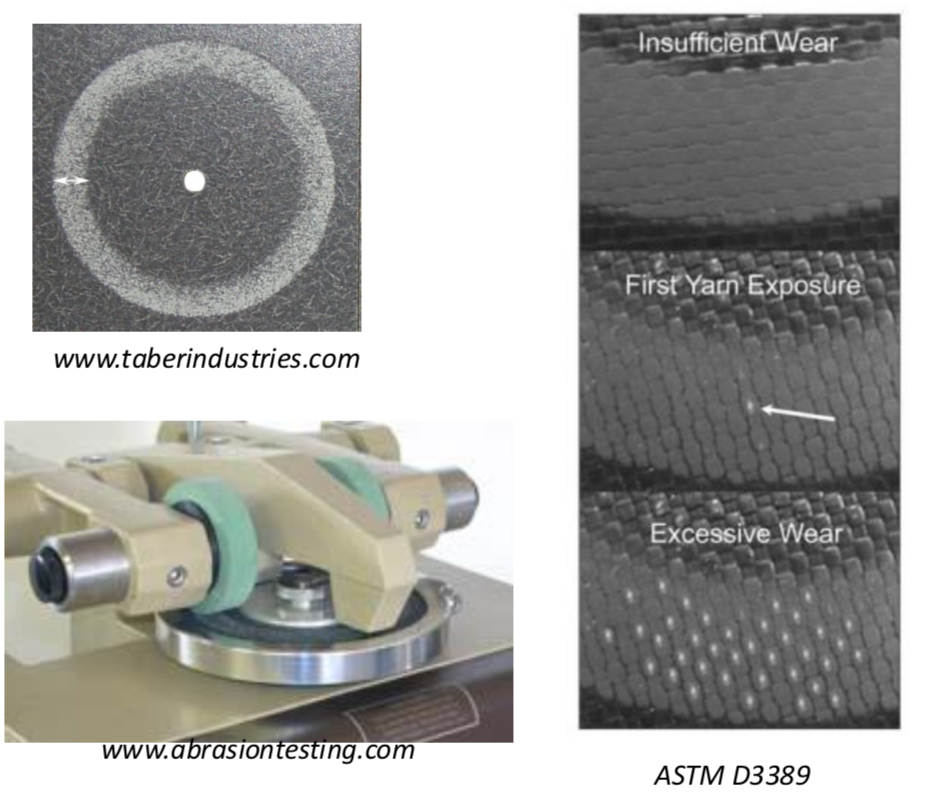

Taber abrader

2 wide discs of abrasive material: measure number of cycles to end point

Impact Abrasion

Used for motorcycle protective(EN 13595-2, 13594, 13634)

Specimen secured to a sensor and dropped onto a 30 km/h abrasive belt

Measure time to complete abrasion

Challenges with abrasion testing

lack or correlation between test methods

degradation proceeds differently according to test method

sensitivity to other factors

lack of precise endpoint evaluation

not correlated with real use conditions

Hard surface coatings

Plastic: Superfabric

Ceramic: Schoeller ceramic coated textiles

Elastomers

Polyurethane

Nitrile rubber

Natural rubber

Leather

Excellent abrasion resistance compared to textiles

Depends on tanning process to improve strength and wear resistance

Full grain leather has the best resistance

Preferred in impact resistance applications