Bearing Life (ONLY rolling element so ball or roller)

1/5

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

6 Terms

Bearing Life

Bearings are designed to facilitate motion between 2 components, rolling element bearings are superior in terms of friction reduction due to the shape and reduced contact area (high stress))

Mechanical Fatigue

This is the primary source of bearing failure, this is the cracking in material

Mechanical fatigue will be the only source of failure if (bearing is properly lubricated, bearing is free of contamination, and the temp is reasonable)

Surface spallation - fragments seperate at surface

WHat is the bearing life

This is the total number of revolutions or hours at a speed until failure

Bearing failure is defined as spalling or pitting of a surface area of 0.01 in² or greater

First evidence of mechanical fatigue that leads to component failure.

Two Bearing life problems

Radial Loading ONLY (less common)

Combined (Radial and Axial)

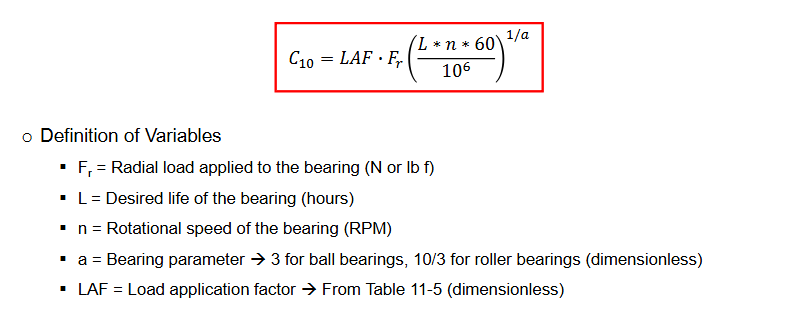

Radial Loading

The load application factor is the safety parameter used for bearing selection

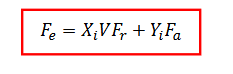

Combined Loading (Fe)

For combined loading the radial and axial loads are combined to an equivalent load Fe

Fr- radial load

Fa- axial load

V- rotation parameter (1 if inner ring rotates, 1.2 if outer ring rotates)

Xi and Yi - equivalent load factors (From table)

Have to figure out depeneding on calculation of e wheter u use X1 and Y1 or X2 and Y2