CHEMMAT 121 EXAM PREP

1/127

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

128 Terms

Strength

Amount of force (stress) a material can resist before failure (permanently deformed and fractured

Stress

Sigma, Force over cross sectional area. Area decreases stress increases. Unit Pa or Nm-1

Strain

Change in length over original length. No unit or %

Tensometer aka Instron

Used to characterise mechanical properties. Measures F and change in length as material is pulled

What does the linear section of a stress-strain curve represent?

Elastic deformation, All strain is recovered upon unloading and stress < yield stress

What happens after yield stress but before UTS?

Plastice deformation (work hardening) and eleastic deforemation. Uniform reduction in area, some permanent dedformation when unloaded, but also some recovered.

What happens past UTS?

Necking, forms local reduction in area (neck). Still elastic deformation

What happens at fracture point? Stress-strain curve

! piece becomes more than one piece, and a gap forms, eleastic deformation is still recovered.

Youngs Modulus.

E, stiffness. change in stress/ change in strain. Unit is Pa. It is the gradient of the eleastic deformation section.

What is special about fully annealed steel stress strain curve?

Once yield stress is readched there is a discontinius yield before the graph continues. This only happens once, as the steel work hardens past this point.

Poissons ration

represented by "neu"(v). (-)strain in x axis/strain in y axis. Ratio how thin a metal needs to be when stretched by a certain amount. Most metal and polymers v = 0.5.

0.2% Proof stress

Geometric tool to use if there is no obvious yield point. Move gradtion line 0.2% (0.002) and take yield point as where the lines cross.

Safety Factor.

Either pretend material weaker than it is OR applied force bigger than it actually is. E.g. for SF of 4 w/100N force either 100 x 4 = 400N force OR yield stress = actual yiels stress / 4.

Engineering stress vs true stress

Egnineers only operate in eleastic def area. True stress is F/Instanaous area. engineering stress is F/init area. true stress increasess exponentially at UTS.

Ductility

How much plastic def before fracture. Described in:

%Elongation (%EL) = ΔL/init length * 100%.

%Reduction in Area(%RA) = ΔA/init A * 100

Toughness

Energy required to fracture a material. aka, area under the curse. unit: J/m^3 Usually something string is not tough.

BCC

Body Centered Cube:

atoms per unit cell: 2

Co Ordination number (how many atoms 1 atom is touching): 8

Unit Cell Dimension (a) = 4R/sqrt(3)

Atomic Pakcing Factor: 68%

E.g. chronium

Atomic Pakcing Factor

Vol of atoms/Vol of unit cell. aka hwo effciently unit cell filled with atoms. e.g. BCC 68% atoms 32% sea of e-

FCC

Face Centered Cube:

atoms per cell: 4

Co-ordination num: 12 (max possible)

-Unit cell dimension(a) = 4R/sqrt(2)Atomic Pakcing factor: 74%

FCC is close packed structure.

E.g. Copper

HCP

Hexagonal close packed:

atoms per unit cell: 6

-Co ordination num: 12

-Atomic Packing Factor: 74%

E.g. MAgnesium

Polymorphism

Materials have more than one structure. e.g.

IRON at RT = BCC

Iron at 912 degress = FCC

Ceramics

metals + nonmetals bonded ionic and covanlently. Arranged Crystalline.

Can be either Rock salt or Silicate Structure.

Determined by Balanced charges, relative size of ions (cations < anions. ions dont touch ion of same charge.)

Rock Salt

Two interlocking FCC structures.

Co ordination num = 6

a = 2(Radius anion) + 2(Radions cation).

Has ionic and covalent bonds, no sea of e- to conduct heat therefore thermally insulated.

Silicate (SiO4(4-))

Building block for rocks, soils, clays, sand. Base SiO4 join w/each other. NOT UNIT CELL.

Glasses vs ceramics

When atoms NOT regular repeating pattern (amporphus) form GLASS. When they ARE (crystalline) formm CERAMIC.

If SiO4 structure….

COOLED SLOWLY -> time atoms to rearrange -> CRYSTALLINE

COOLED RAPIDLY -> no time atoms rearrange -> AMORPHUS

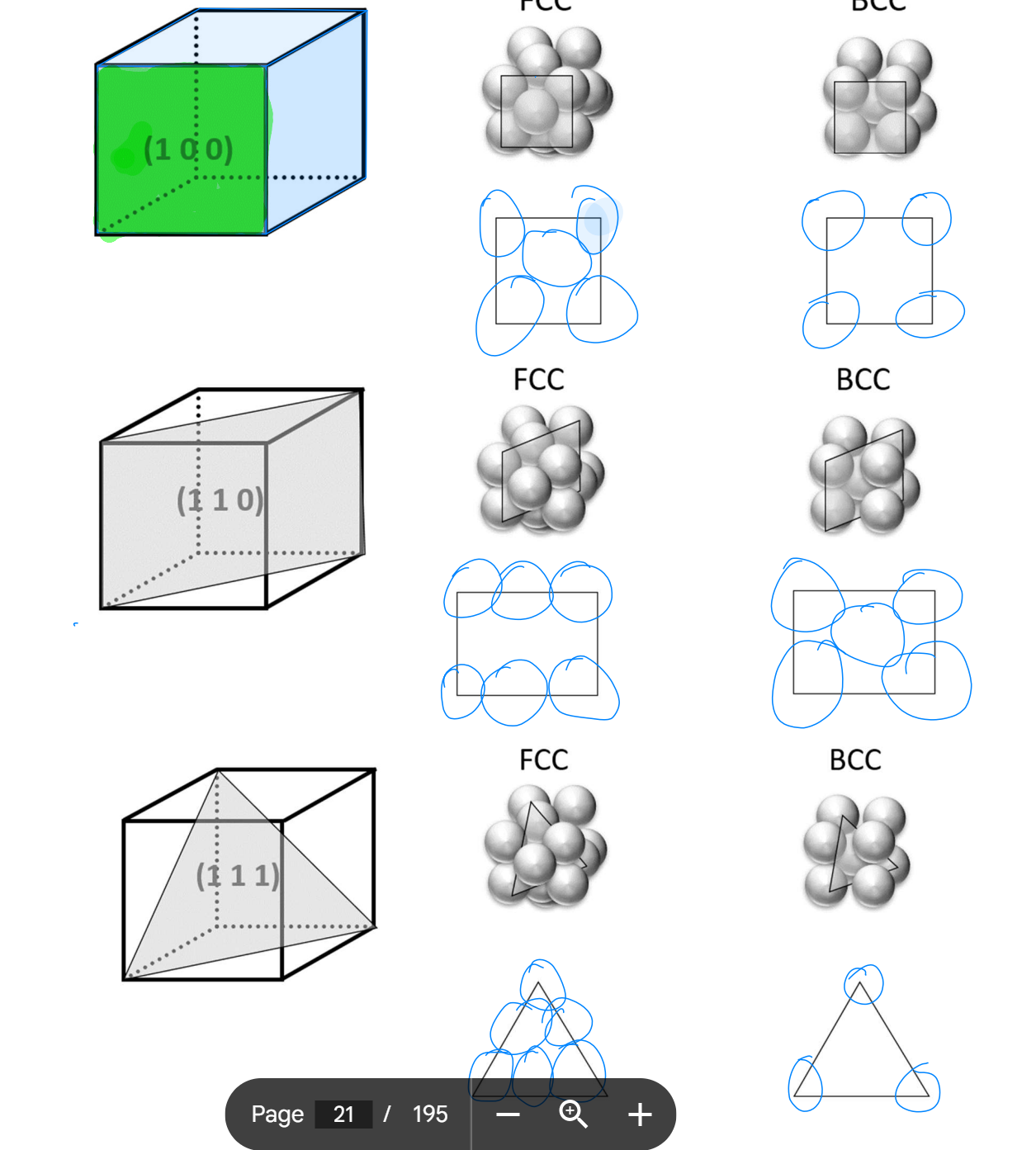

Naming directions

[u v w] <- direction

1) Draw vector for direction (origin @ start)

2) Project Length onto unit cell axes

3) Put in terms co effcients

4) Convert to integers (double for 1/2)

5) put in aquare brackets.

For -ve directions put bar over num.

If spacing in one direction = another CYSTALLOGRAPHICALLY EQUIVALENT. e.g. BCC and FCC since both cubes

Naming Planes

(h k l) <- round brackets

1) Pick origin NOT on plane, usually plane is like roof to origin point

2) Work out intercepts (can be inf if // to axis)

3)Take reciprocals (e.g. 1/inf = 0)

4) Convert to integers if needed (1/2/ -> 2)

5) put in round brackets

What cases plastic & elastic def.?

ELASTIC → atomic bonds stretching

once past yield stress further def is permanent. This is caused by SLIP.

Slip

atoms sliding past each other, “block slip model”.

Close packed plane → less distance to next position → WEAKER material

Non-close packed plane → more distance to move → stronger material

Theoretical strength

Calculated energy req to break/make bonds.

ALWAYS LESS than measured strength due to IMPERFECTIONs.

In metals : dislocations

In ceramics: porosity

Point Defects

Vacancy → gap where atom should be

Interstitial atom → smaller in between other atoms

Substitutional atom → diff element than lattice.

Planar defects

aka dislocations

Edge dislocation → extra half plan in lattice

Screw dislocation → twist in lattice

Slip & dislocation movement

dislocation movement makes slip easer → bcuz of dislocations → bonds only need to break one at a time

This takes less energy/work → much weaker —> slip occurs easier

Slip can be thought of as dislocation movement w/in a lattice

Slip systems

occurs most easily on close packed planes in close packed directions.

e.g. BCC stronger than FCC as slip occurs easier.

FCC main slip system: {111} <110>

BCC main slip system: {110} <110>

Hcp has close packed planes BUT plane all in one orientation so slip very difficult → HCP metals very brittle (strong).

Ceramics & Glass properties

Ceramics:

Brittle, plastic def. improbably as when slip occurs cations line up together and repel

Stiff, due to strong ionic/covalent bonds

Glass:

very strong

very brittle

low toughness

Solidification

Polycrystalline → many crystals (molten metals solidify)

NOT ACCURATE: over decreaing temp, increasing time

baby crystal nuclei → nuclei grows each nucleus a single crystal, grain → keep growing bigger

EQUIAXED GRAINS → grains roughly equal

Homogenous Nucleation: solid in liquid

Hetrogenous Nucleation: with mould wall for solid to form on MORE COMMON

Grain Boundaries

Mismatch in lattice orientation → surface atoms have free bonds → bulk atoms formed all bonds → GB’s are high energy regions due to the surface atoms having free atomic bonds.

Grain structure development

“chill” cyrstals, small equiaxed grains on walls

Then columnar grains.

In the middle:

equiaxed grains OR columns meet OR hole/pore OR dendrite formation

The middle section makes the metal anisotropic (not the same in all directions).

How to get equiaxed structure?

use grain refiners (e.g. adding Ti particles when casting Al)

Annealing (heat treatment)

Metallography

Reveals Grain boundries

Grinding w/ sandpaper → removes big scratches, flat surface

Polishing w/diamond paste → removes more scratches (mirror like surface)

Etching w/ acid/alkali → reveals GBs

Polished metal → all light reflected so GBs not visable

Etched metal → GBs scatter light so they appear as dark.

Grain boundaries & dislocation movement

GBs stop dislocation movement bcuz of discontinuity in planes → makes material strong (but less ductile)

Big grains → fewer GBs → less GB density → weaker & more ductile

Small grains → more GBs → higher GB density → stronger & less ductile

Hall-Petch effect

yield stress = constant (friction stress) + k (hall-patch constant) * d(grain size mm)^(-0.5)

how GBs affect strength

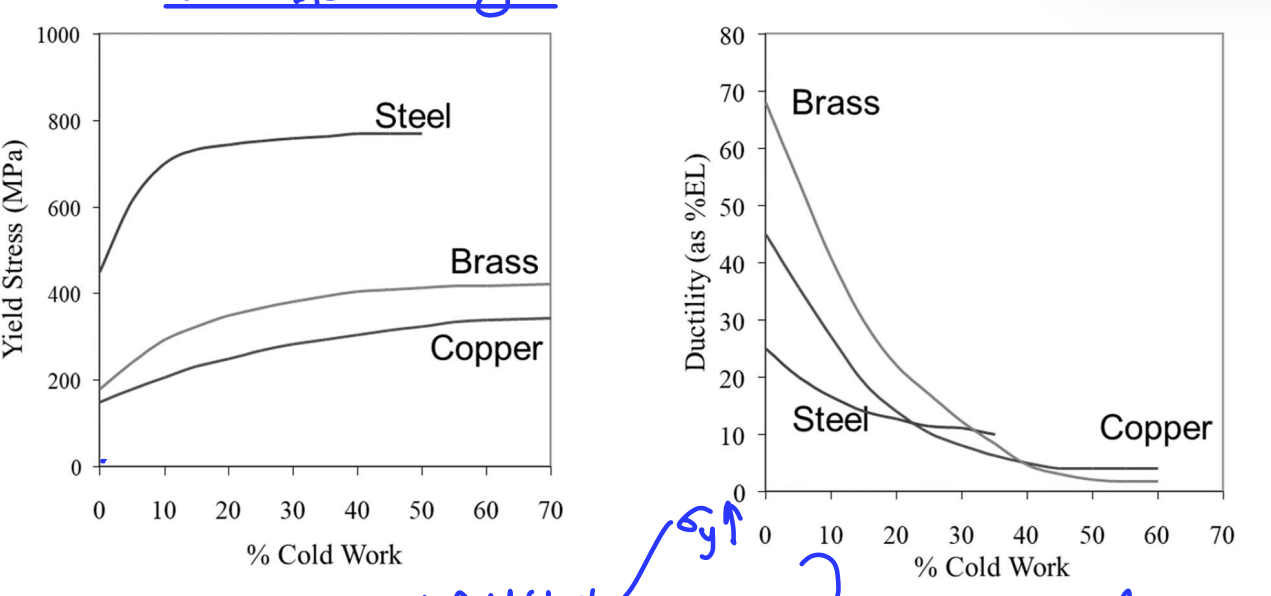

Work Hardening

Metal plastically deforms and becomes stronger:

dislocations move → multiple → dislocation density increases → inhibit each others movement → creates “traffic jam” → material is stronger but less ductile.

Aka cold working as plastically deformed below recrystallisation temp.

Cold working equations

Rolling:

% CW = (init thickness - new thickness)/init thickness * 100%

Assuming width doesn’t change much

Extruding:

%CW = (init area - final area)/init area *100%

As %CW increases, yield stress increases and ductility decreases

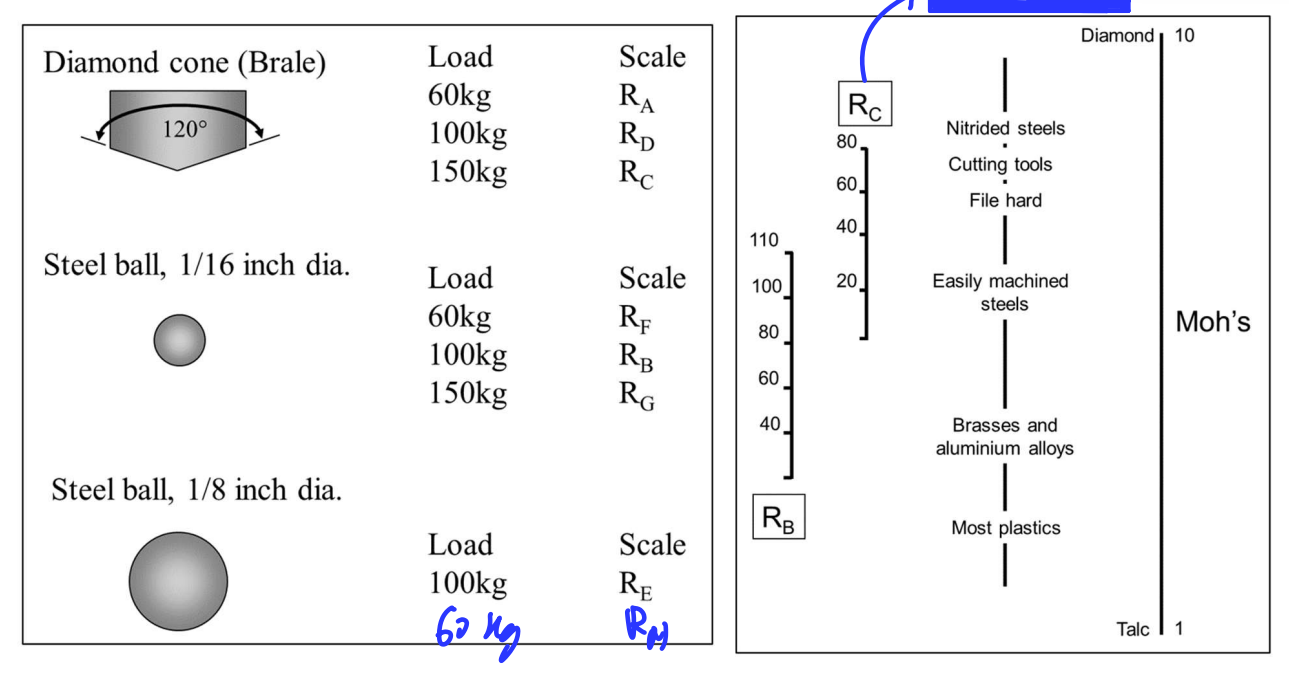

Hardness

Resistance to localised plastic deformation.

Use indent test indenter must be harder than tested material.

Harder material → small indent

Hardness proportional to strength, not equal to strength

Electrical properties

V = IR, R depends on material but NOT property

Resistivity (p) is a property p = R*A/L unit ohms meters

Metals good conducters → sea of e-

e- move → hit +ve core → stop (attracted by +ve) → resistivity INCREASEs

Ceramics + glass good inductors

no sea of e- → no e- movement

Electrical conduction in metals

On the graph electron drift velocity vs time:

Increases linearly until it hits a positive ion core, then falls, before repeating.

Middle is avg drift velocity. Vd = electron mobility (function of collision rate affected by atomic spacing) μ * electrical field strength

Electrical Resistivity in metals

Resistivity never 0, due to residual resistivity due to imperfections.

@ low temp:

less thermal vibrations

less resisitivity (less collisions)

@ high temp:

more thermal vibrations

more resistivity (more collisions)

While linear:

total resisitivity = resisitivity @ 0 * (1 + temp coeffcient * Temp)

CW vs Resistivity

Increasing CW → Increasing dislocations → resistivity (more collisions)

Linear relationship as %CW increases, but DOESNT start at 0.

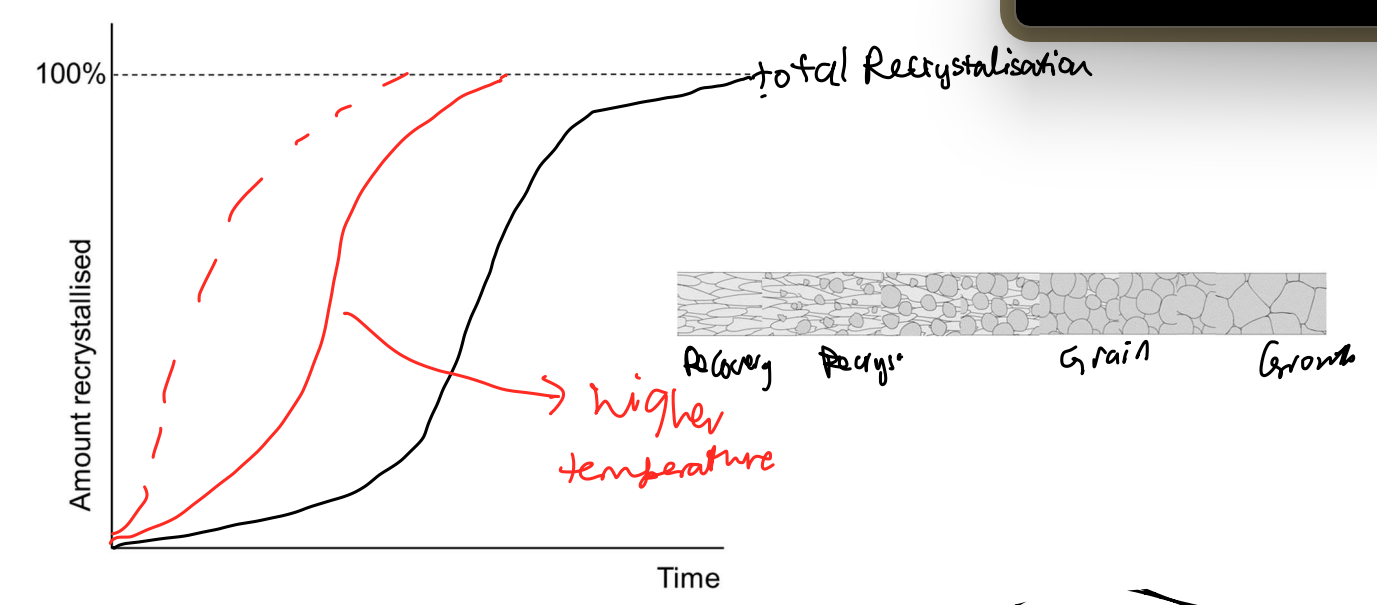

Annealing

heat treatment @ 2/3 melting temp, reverse effects of work-hardening

elongated grains (more dislocations, resistivity) strong and brittle.

THEN ANNEALING

equiaxed grains (less dislocations, resistivity) weak and ductile.

Annealing steps

Recovery

dislocations rearrange to lower energy config.

dislocation density unchanged. goes from pile up/traffic jams → spread out arrangement (less energy)

Recrystallisation

New grains (less dislocation density & equiaxed) nucleate at pre-existing grain boundaries. new gains grow @ GBs → when new grains meet → recrystallisation. Thermodynamic driving force: stored strain energy, from high energy state to low energy state.

Grain Growth

nucleated new grains grow bigger. goes from high energy small grains to low energy big grains. Thermodynamic driving force: reduction in GB energy.

How does annealing change metal properties?

RECOVERY:

strength and ductility constant

Resistivity decays exponentially

RECRYSTALLISATION:

strength decreases linearly (new grains w/ less dislocations)

ductility increases linearly

resistivity decrease exponentially but slower than before

GRAIN GROWTH:

all keep continuing lines, plateuing of. Strength due to hall-petch effect.

Rate of Recrystallisation

Increasing temp increases rate of recrystallisation.

Recrystallisation Temp

temp at which 50% CW metal will fully recrystallize in one hour.

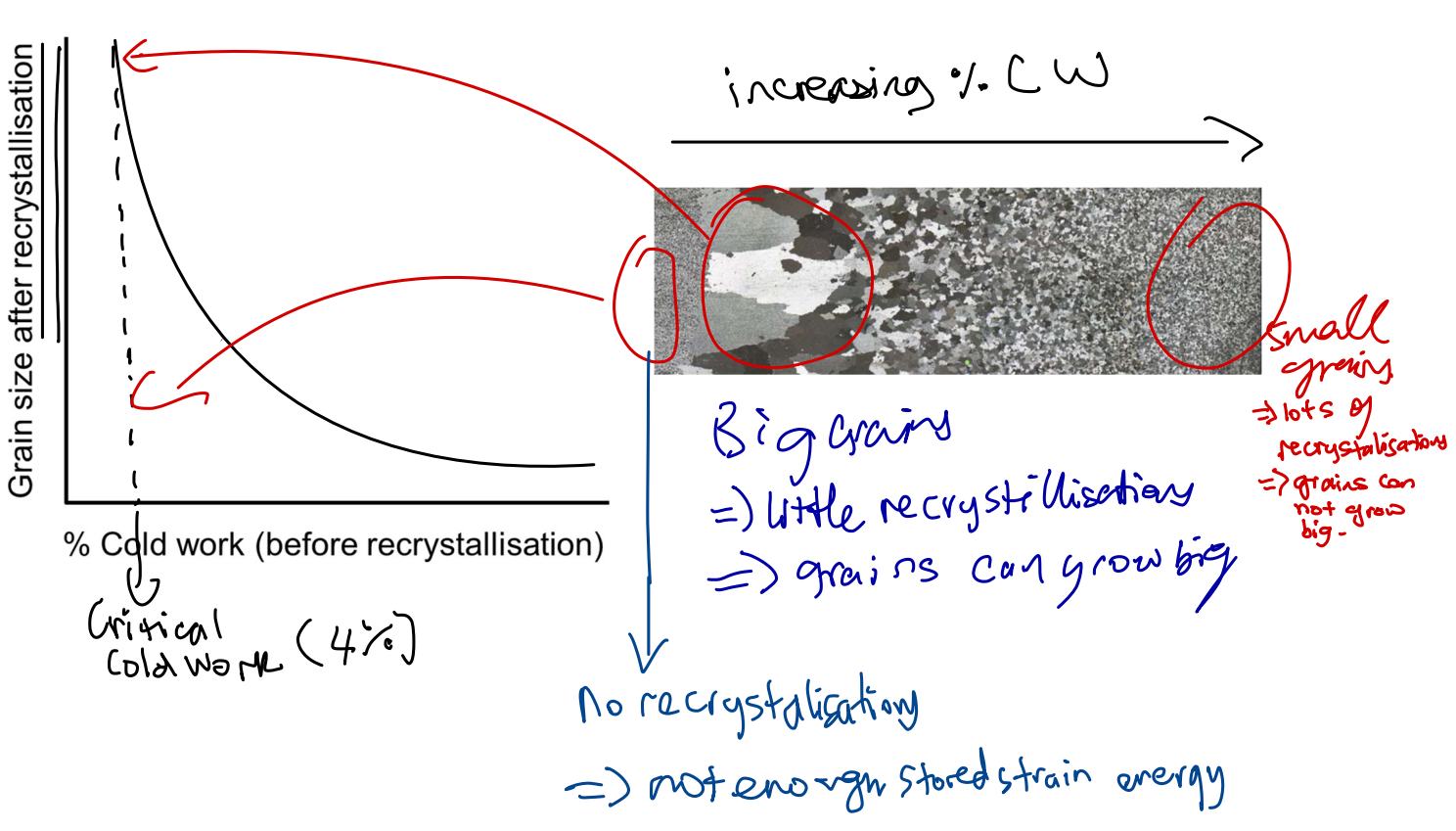

Grain size effect on recrystallisation

Hot Work

plastic deformation done above recrystallisation temp. Work hardening and recrystallisation happen same time.

Solid state diffusion

atoms move within solid crystal lattice.

vacancy diffusion → atoms move to empty space

interstitial diffusion → smaller atoms move w/in lattice

To move to next stable equilibrium position, energy barrier Q must be overcome (activation energy). Overcome by force or heat

Arrhenius equation

rate increases with temp

Rate = A*e^(-Q/RT)

A =constant, Q = activation energy (J/mol), T = Temp (k), R = universal gas constant

Diffusivity

measure how easy atoms move w/in crystal lattice.

D = init D *e^(-Q/RT)

Phase Equilibria

Phase → component w/in a system with uniform physical characteristics.

Metal dissolved in another metal (alloy)

Interstitial Solid Solution

diff element atoms in interstitial sides of parent crystal lattice. Interstitial atoms must be smaller than parent lattice. ALWAYS limited solubility. Solubility limit changes w/ temp.

Substitutional Solid Solution

diff element atoms are substituting some atoms in parent crystal lattice. Can have limited (Al-Cu) OR unlimited (Cu-Ni) solubility

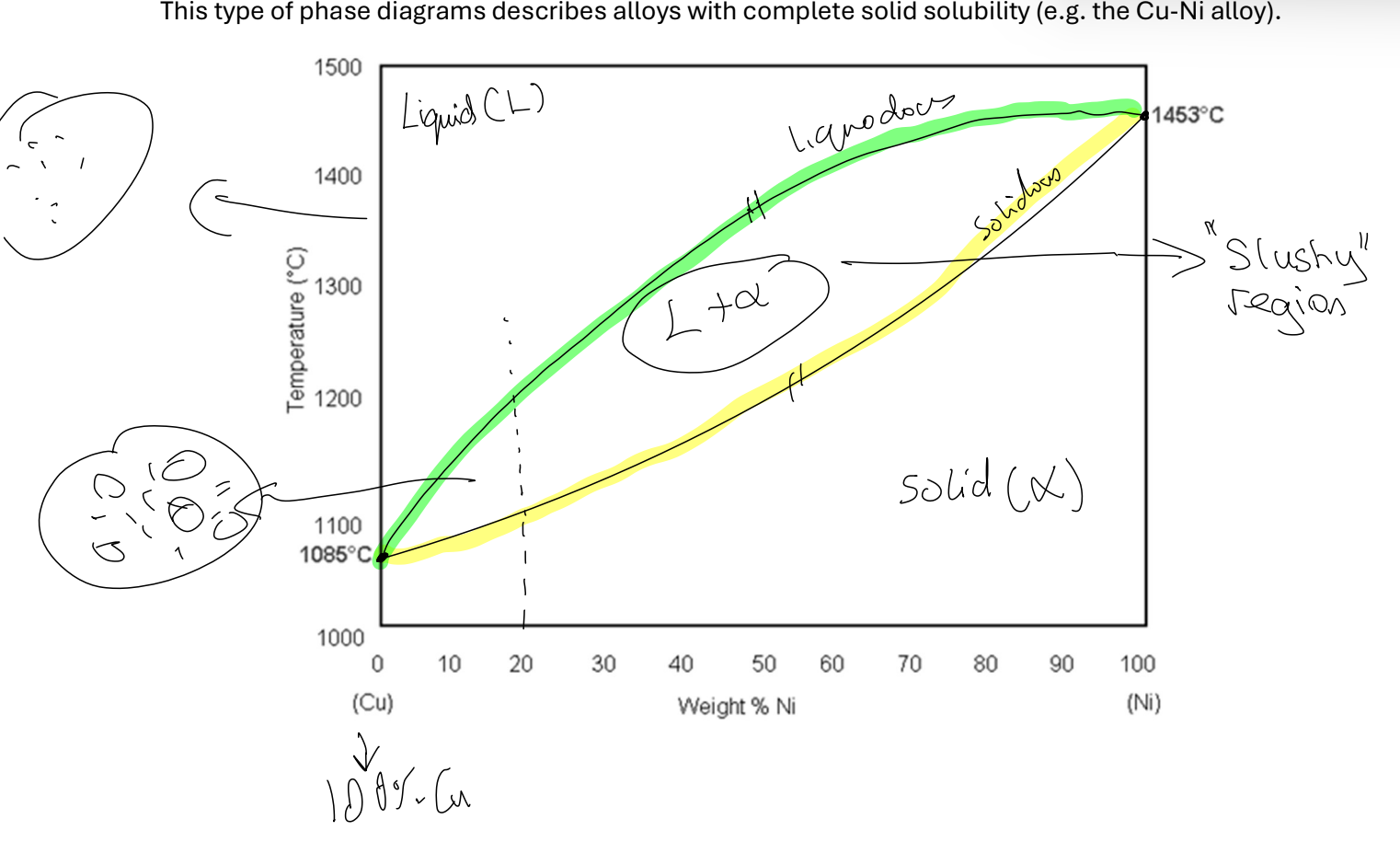

Binary Isomorphous alloys

consists only 2 diff elements. W/ complete/unlimited solubility only 2 phases formed:

Solid phase α

Liquid phase

Phase diagrams can tell us:

- What phases exist in equilibrium

How many phases

How much of each phase

Composition of each phas

Lever Rule

Answers how much of each phase? at certain comp

Plot point at chosen temp and overall composition

Draw tie-line through point to phase boundaries

Find % of lengths of tie line on either side.

% phase in material = % length OPPOSITE side of point

To answer composition of each phase:

read off where tie-line intersects phase change line. Intersection tells composition

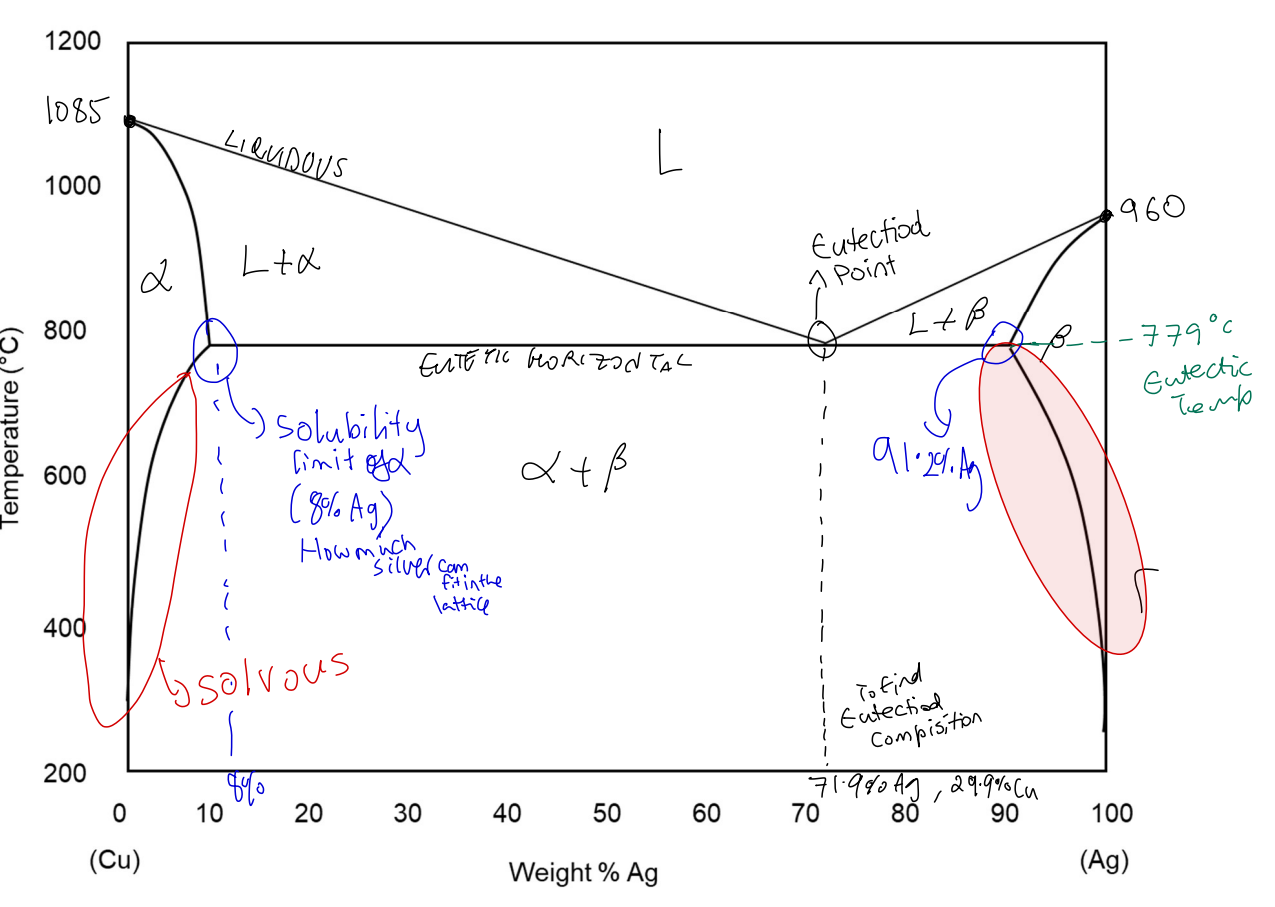

Binary eutectic alloys

when it has limited solubility

solid phase α - 1 in 2

solid phase β - 2 in 1

a liquid phase

when temp changes solubility limit changes.

Eutectic reaction

At eutectic point:

alloy melts at single temp

single liquid phase turns into 2 solid phases

L_eutectic →add cool/heat→ alpha + beta

This reaction produces layered 2-solid phase structure called eutectic solid

NOT A PHASE, combination of 2 phases.

HYPOEUTECTIC → less than eutectic composition

HYPEREUTECTIC → more than eutectic composition

PROEUTECTIC → solid phase before eutectic solid

how much eutectic solid would there be in the final microstructure when a certain alloy is cooled down slowly from its liquid phase?

CANNOT apply lever rule. look just above eutectic temp

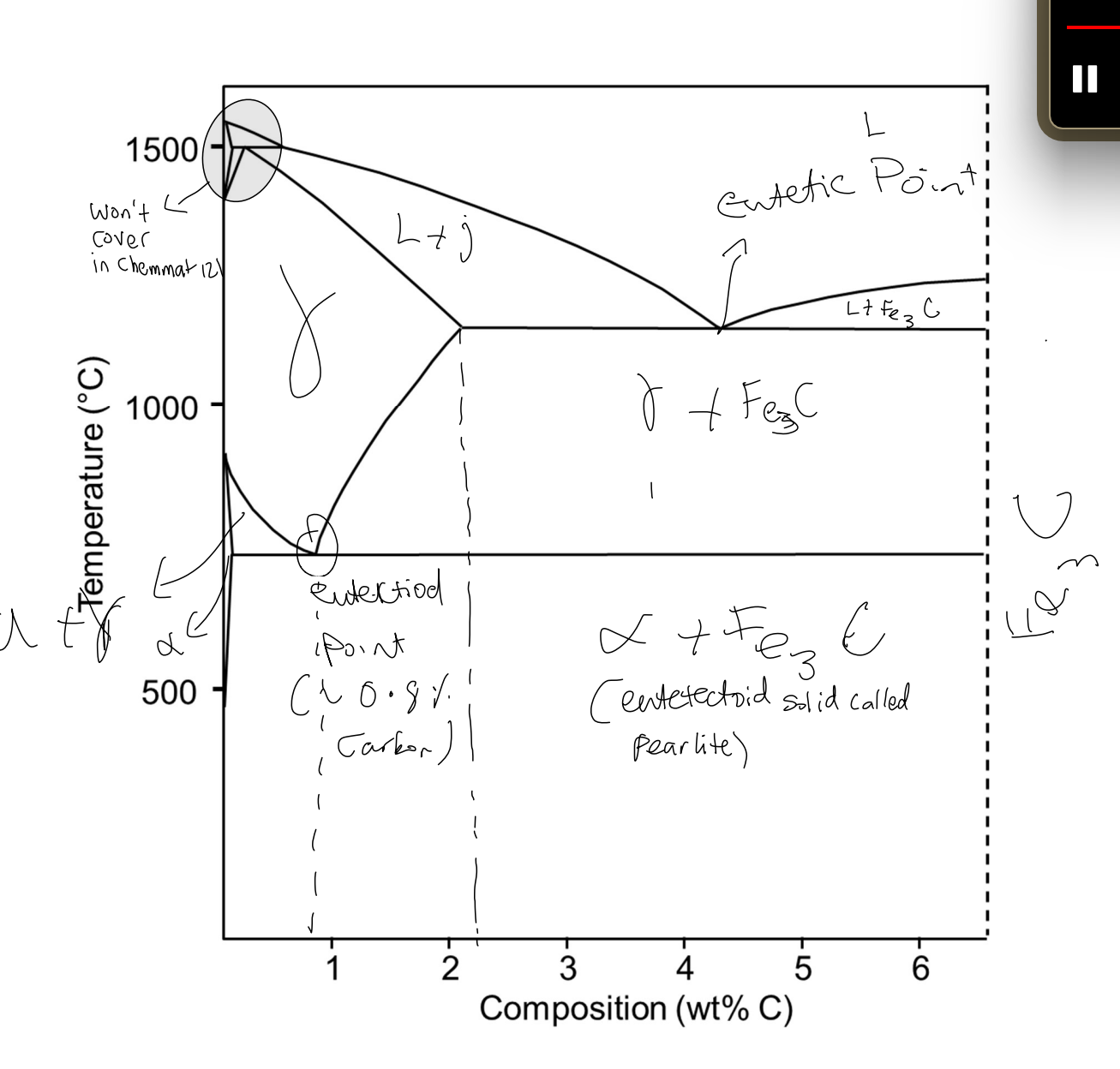

Steel wt% C

Low carbon steel: up to 0.25%C

Med carbon steel: 0.3-0.5%C

High carbon steel: 0.55-0.95%C

Cast irons: up to 4%C

Phases in Fe-C system

Gamma iron (γ) or austenite

FCC iron parent lattice accommodate up to 2.1wt%C

Exists above 723

Ductile (many slip systems) non magnetic

Alpha iron (α) or Ferrite

BCC iron parent lattice up to 0.02%C

between RT-910

Ductile (several slip systems) magnetic

Cementite (Fe3C) or iron carbide

not solid solution, compound of fixed composition (6.67%C)

Can be thought of as ceramic

orthorhombic strcture a ≠ b ≠ c

no slip systems very brittle and hard

Fe-C phase diagram

Eutectoid reaction

γ(eutectoid) → cool/heat → alpha + Fe3C

Takes place 0.8 wt%C and 723

Produces eutectoid solid called PEARLITE, only formed slowly cooling eutectoid reaction

Steel w/

LESS eutectoid composition → hypoeutectoid & proeutectoid alpha + pearlite

MORE eutectoid composition → hypereutectoid & proeutecoid Fe3C + pearlite

first solid phase before pearlite is called proeutectoid solid.

Strengthening mechanisms for pure metals

Work hardening

any plastic def. increases strength of crystalline material

Grain Boundary Strengthening

smaller grains → stronger. To get small grains → do lots of CW → anneal

To get big grains → let grain growth happen

Rule of thumb strengthening mechanisms in metals

If dislocations can move easily → weak and ductile

OR

to increase strength stop dislocation movement.

Solid solution strengthening

WITH ALLOYS can be substitutional or interstitial. atoms of diff elements have diff sizes.

both big and small solute atoms hinder dislocation movement as they have more distance to travel.

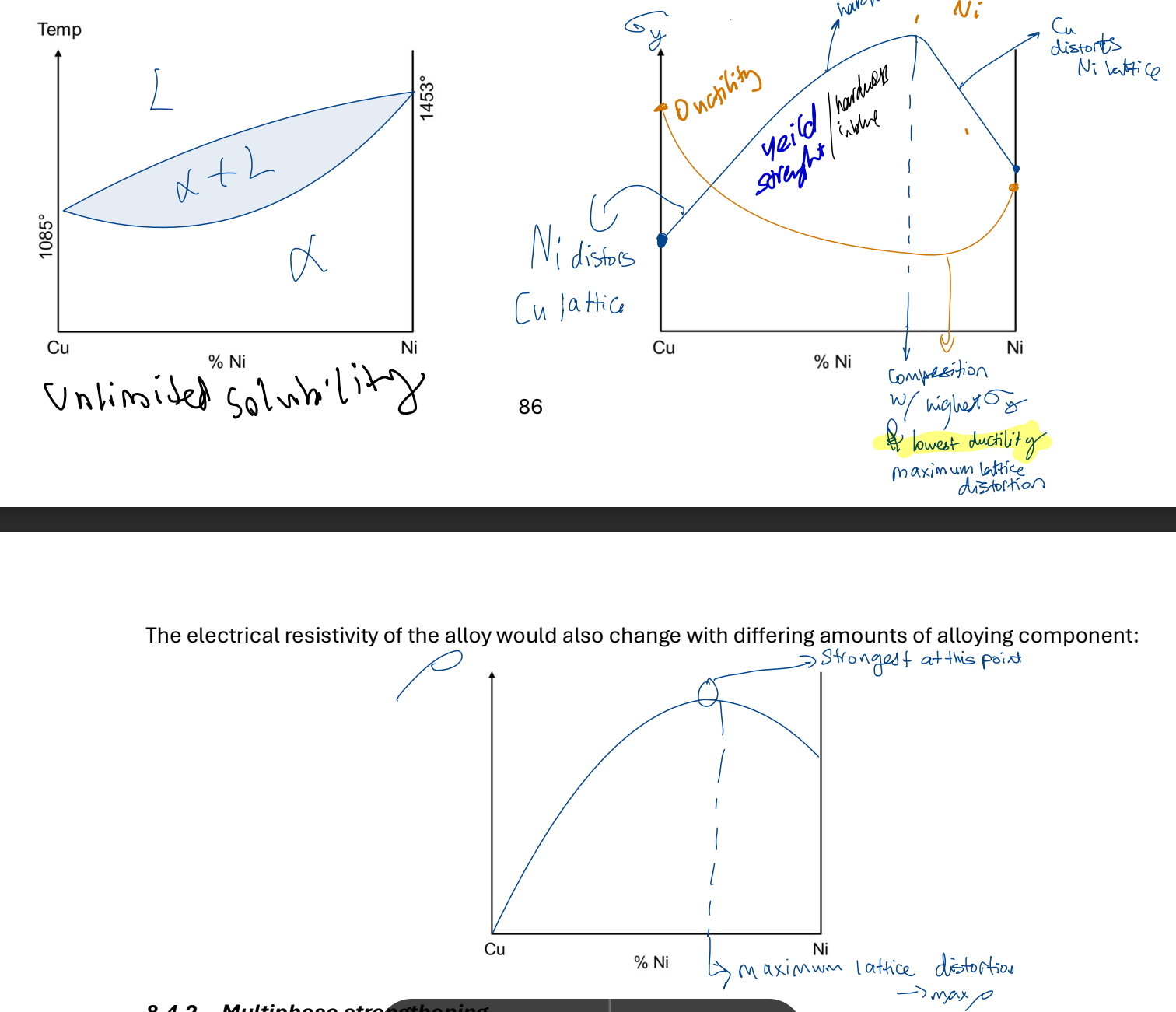

w/ complete solid solubility (e.g. Cu-Ni)

describe graphs

Multiphase stengthening

boundaries inhibit dislocation movement in crystal lattice includes phase boundaries, grain boundaries etc.

looking at phase diagram → max num boundaries → max yield stress → increase % eutectic solid.

alpha phase (solid solution of 1 in 2):

FCC - lots of slip systems

weak and ductile

Theta (compound e.g. CuAl2):

BCT (aab) - no slip systems

strong and brittle

Multiphase strengthening microstructures

when slowly cooled down from liquid phase:

L → L+alpha → alpha + theta:

proeutectic alpha and eutectic solid

low strength, high ductility

Straight through eutectic point:

100% eutectic solid

moderate strength, not very ductile

L → L + theta → theta:

proeutectic theta + eutectic solid

very strong VERY brittle BAD

due to brittle theta at grain boundries

Dispersion strengthening

aka age hardening/ precipitation hardening

having lots small hard ppts in ductile matrix (increases num boundaries). Two mechaisms:

discontinuity in slip systems → dislocation gets stopped by ppt

Distorts parent lattice → dislocations have further to travel

small ppts are more effective stopping dislocations than big ones (more finely dispersed).

Steps to get good microstructure for age hardening.

Solution heat treatment

heat alloy above solidus line to dissolve all Cu atoms.

Quenching

rapid cooling to room temp, doesn’t allow for diffusion. get supersaturated alpha phase (metastable)

Ageing

heat below solidus, allow for diffusion. get theta ppt within alpha matrix.

effects of time and temp on 3rd step of age hardening

Since its diffusion based it depends on time and temp.

If they aged at HIGHER temp, SHORTER aging time. This means less time to reach max strength so the max strength will be lower.

Overaging (leaving for too long, past peak) causes big incoherent theta ppt.

Requirements for alloy to be age hardened

phase diagram must show decreasing solid solubility with decreasing temp i.e. must be able to quench from single solid phase to a 2-solid phase region

parent matrix → soft & ductile. strengthening ppt → hard and brittle & finely dispersed through softer parent phase/ Soft ppt will break when hit by dislcoation.

ppt should be coherent w/ parent matrix & distort it to create srain fields. makes dislocation movement diffcult

alloy should be able to survive quenching process. Sudden temp change causes thermal shock & shape distortion & cracks.

Strengthing mechanisms - pearlite

layered structure, effective multiphase strengthening. austenite → cool + heat → alpha + Fe3C. formed when austenite at eutectoid comp cooled slowly under eutectoid temp. formation depends on solid state diffusion of C atoms. @ high temps ~700 - COURSE PERALITE @ low temps ~500 - FINE PERALITE

Martensite

austenite quenched instead of slow cooled, ssd does not occur, pearlite not formed, instead martensite.

Has BCT structure formed through shear/displacive transformation, diffusion not required. made from 2 austenite unit cells

a supersatureated solid solution of C & Fe | @ RT alpha has 0% C. BCT → no slip system → hard & brittle

a metastable structure | not on Fe-C phase diagram, transform into alpha + Fe3C is solid state diffusion allowed

increasing hardness with C content of steel | solid solution strengthening, more carbon → more lattice distortion

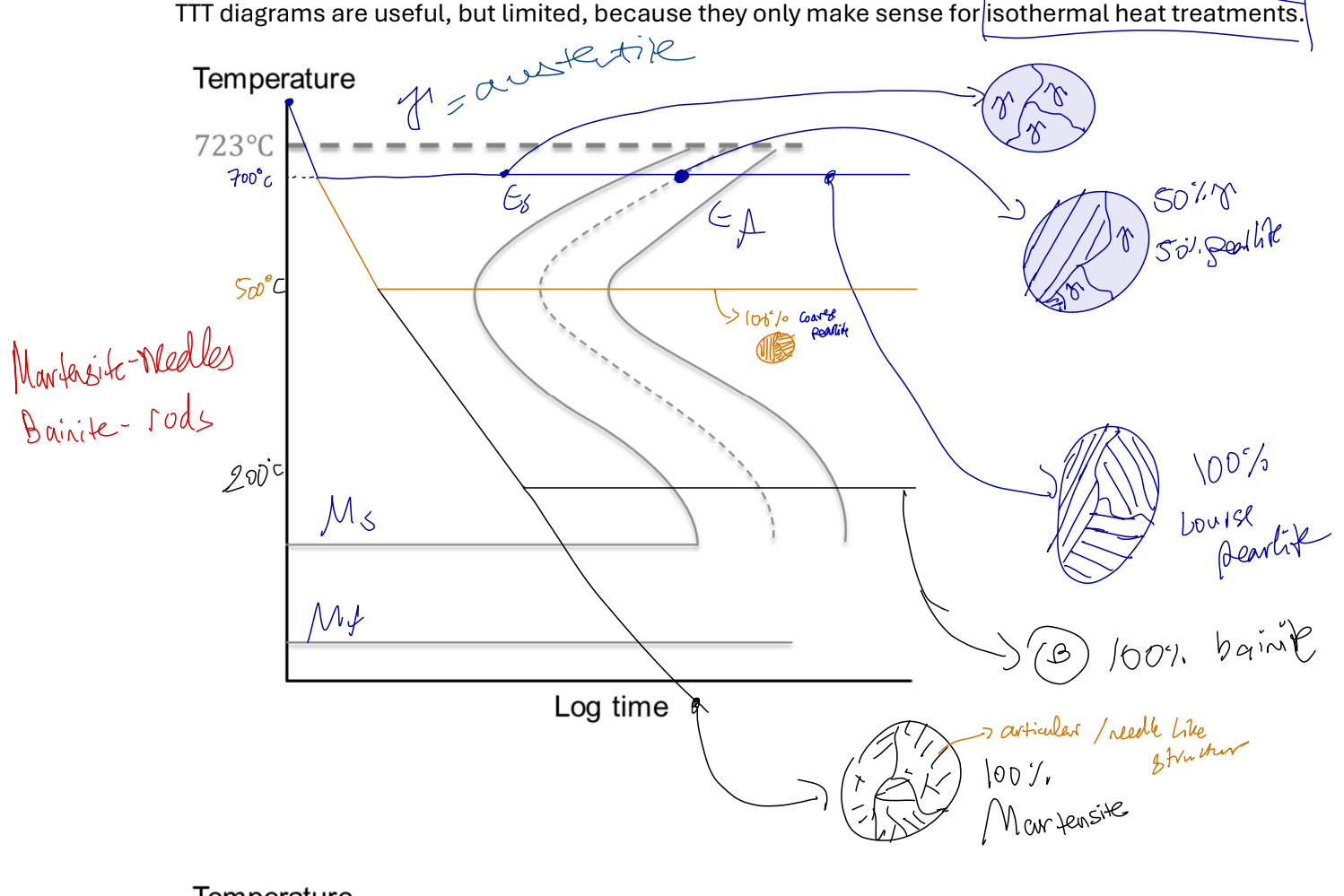

TTT curves

Time-Temp-Tranformation

only make sense for isothermic heat treatment (constant temp).

earliest eutectoid comp at “nose” of curve.

Tempered Martensite

temper martensite to get alpha + Fe3C (NOT PEARLITE). tempering → reheat then cool slowly, get Fe3C ppt in alpha matrix. Tempered martensite optimium strength w/ suffcient ductility & toughness.

Tempering effects size & dispersion of Fe3C ppt in ferrite matrix.

IDEAL: fine ppt

if ppt TOO BIG less strength, caused by increases temp & time.

What happens if quenching of steel is not done properly?

causes structural variation problems. usually:

martensite closest to edge → then banite → then fine pearlite → then course pearlite

Can be fixed by adding other elements than slow carbon diffusion e.g. 1wt% Mn

Spheroidised steel

weakening mechanism, slow cooled high C steels have lots hard & brittle Fe3C phases. They wear tools quickly. Can be made softer by spherodising, transforming Fe3C layers into spheres.

heat to ~700 then hold for several hours

Thermodynamic driving force:

reduction in Fe3C surface area (or energy)

Influence of carbon content on hardness/strength of steel

Quenched steel (martensite):

- more c → more distortion

Quenched and tempered:

more C → more ppt

Slow-cooled steel (pearlite):

more c → more strength

Polymerisation

double bonds in monomer between 2 cs open up and are replaced by single covalent bond, allows c atom to bond to another one. This is repeated and forms a polymer chain.

Degree of polymerisation (DP)

(avg molecular weight of chains in polymer)/(molecular weight of repeating unit)

aka avg num repeating unis/monomers in each chain.

since polymerisation produces chains of varying length, molecular weight is always avg.

Shape of Molecule

not straight → zig zag config. bcuz carbon tetravalent (forms tetrahedral shape)> 109.5 degree angle between all c atoms. C atoms can occupy any pos rotating around bonds.

rotational movement + thermal vibrations = diff shapes and configs.

Micro chain structure: blocks

Bulk chainstructure: like spagitte

Effect of DP on polymer strength

degree of tangling increases w/ chain length (increases DP). as weaker 2ndary bonds between chains.

Shorter chains (less DP)

less 2nd bonds, easy to break & chains to slide = less strength

Long Chains (More DP)

more 2nd bonds, difficult to break & hard chain slides = more strength. also more chain tangling increases strength

At max strength due to 2nd bonding + tangling

failure occurs by breaking of covalent bonds w/in chain

Polyethylene (PE)

4 small H atoms

LDPE

recycling num 4, grocery bags, cling film, bubble wrap.

Branches of PE grafted onto main chain, prevents close packing, less crystalline regions, 2nd bonding, strength

HDPE

recycling num 2, milk bottles, cleaning product bottles.

Linear chain → segments line up easily

high crystalline, 2nd bonding, and strength

Polyvinylchloride (PVC)

small Cl atom + 3 H atoms. recycling num 3

Unplasticised (Hard)

spouting, plumbing products

Plasticised (Flexible)

hoses, cleaning product bottles

Polytetrafluoroethylene (PTFE)

“Teflon” 4x small F atoms, white/opaque in pure form

chemically inert, low friction, high melting point

Flourine small reactive atom, forms symmetrical chains, high: crystallinity, 2nd bonding, strength, density, melting point.

Strong C-F bonds: high chemical inertness, slipperiness.

Doesn’t melt normally

Polypropylene (PP)

Large CH3 side groups 3x small H atoms

transparent in pure form, recycling num 5

rope, bottle caps, garden furniture, takeaway containers.

Can have atatic or Isometric forms. Isotactic forms stronger.

Polystyrene (PS)

Very large side group transparent in pure form, recycling num 6

Expanded PS

protective packaging, takeway containers

Conventional PS

disposable cutlery, polymer “Glassware”

Polymethylmethacrylate (PMMA)

Very large side group, AND CH3 side group

Perspex or Acrylic

aircraft windscreens, safety glasses

Completely amorphous. Large side groups prevent close packing.

Polymer chain structures

Homopolymers

same monomer repeating

Co-polymer

2 or more chemically diff monomers

Alternating; block; random; graft (side group B attached to A)

Linear polymers

monomers joined end-end, no branching

long flexible chains, pack close together, HDPE

Branched polymers

main polymer chain w/ connected side branches, branching reduces chain packing = low density LDPE

Cross-linked polymers

linear chains joined covalently bonded chain segments from 3-d structure

Cross links prevent chains move relative to each other → stiff hard and strong

Thermoplastic polymers (thermoplastics)

Linear branched polymers w/ weak 2nd bonds

soften with increasing temp

heat → increased thermal vibrations → decreased 2nd bonds → allows relative movement under stress

cooling → decreases thermal vibrations → increases 2nd bonds → original properties return

process reversible, polymer can be reheated & reshaped, good for recycling

Thermosetting polymers (Thermosets)

crosslinked polymers

strong covalent bonds prevent flow relative to each other (no chain sliding)

harder & stronger than thermoplastics

can’t be melted or recycled

at high temp burn, degrade, and char