IED EoC Study

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

14 Terms

6 steps of design process

define the problem

generate concepts

more just research

NVM use decision matrix here

develop solution

, drawing

construct / test prototype

evaluate solution

reflect and improve from testing

present solution

design brief

This concise document (no more than one page) identifies the client, clearly states his/her problem or need, details the degree to which the engineer will carry out the solution, and lists the rules and limits within which the engineer must perform.

deliverables

Project deliverables are the output you expect to have at the end of your project. Deliverables can be anything—a new product, marketing campaign, feature update, sales deck, a decrease in churn, or an increase in NPS.

project portfolio

Used to document the project and given to the people who offered the Design Brief (problem)

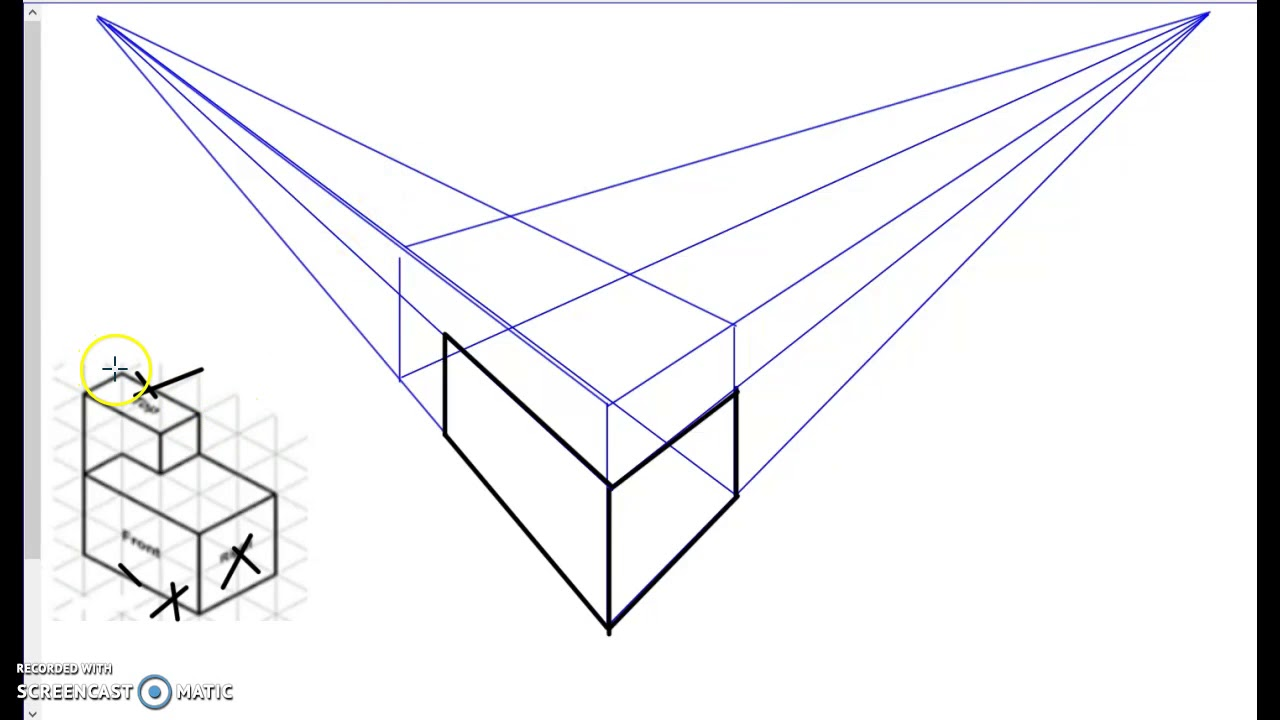

perspective sketch

A type of pictorial drawing in which vanishing points are used to provide the depth and distortion that is seen with the human eye.

natural looking and no distortion

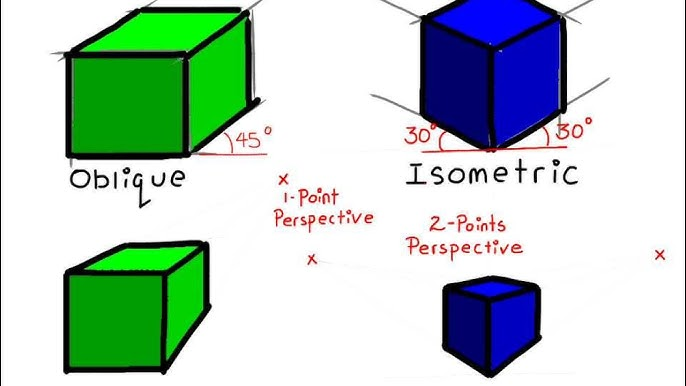

oblique drawings

▪start with a straight-on view of the one of the object's faces, which is often the front face

▪angled, parallel lines are drawn to one side to represent the object's depth. common oblique angles include 30°, 45°, and 60°

pictoral sketch

▪2D illustrations of a 3D object

▪shows 3 faces of an object in one view

▪3 types:

-isometric

-obliques

-perspective

dimensioning rules

dimensions are actual size not scaled size

overall dimensions: width, height, depth

Include all dimensions necessary to produce or inspect the part.

Do not include unnecessary dimensions

Dimensions should be attached to the view that best shows the contour of the feature to be dimensioned. (usually front view)

A dimension should be attached to only one view; for example, extension lines should not connect two views.

Whenever possible, locate dimensions between adjacent views.

don’t dimension hidden lines

don’t place inside object

don’t cross dimension line with another dimension line or extension line

don’t cross with leader lines

leader lines cant be straight and must point to center

dimension values should be centered but staggered when stacked dimensions

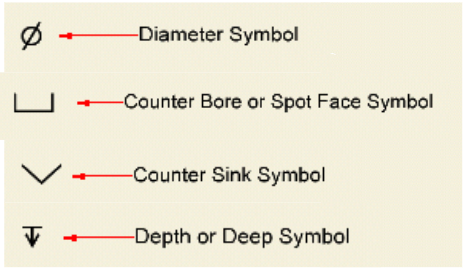

a circle is dimensioned by its diameter and an arc by its radius

holes should be located and sized in the view that shows a circle

holes are located by their centerlines which may be extended and used as extension lines

types of lines

object

Lines are thick and dark

used to define the object

Construction

Very lightly drawn lines

used as guides to help draw all other lines and shapes properly.

hidden line

dashed

used to show interior detail that is not visible from the outside of the part.

center line

Lines that define the center of arcs, circles, or Symmetrical parts. They are half as thick as an object line.

section line / break line

Lines are used to define where there is material after a part of the object is cut away.

extension lines

Lines used to show where a dimension starts and stops on an object.

leader lines

Leader lines are used to show dimensions of arcs, circles and to help show detail.

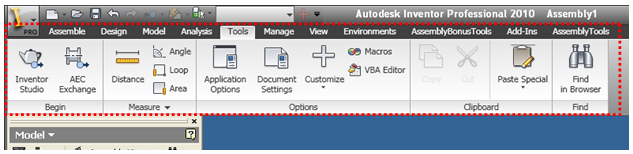

ribbon

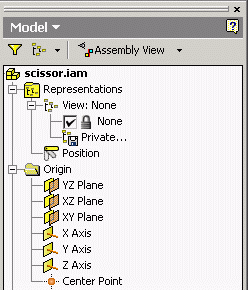

browser

geometric constraints

perpendicular

parallel

tangent

smooth

makes continuous curvature between curves

coincident

constrains geometries together

concentric

makes have same center point

collinear

makes lie on same line

horizontal

vertical

equal

makes have same radius or samelength

fix

fixes in position

symmetry

place features symmetrically on part

precedence of lines

Object lines take precedence over hidden and center lines.

Hidden lines take precedence over center lines.

Cutting plane lines take precedence over all others.

hole types

clearance

Hole large enough to allow screw head (and driver) to pass through

blind

Hole does not cut through entire thickness

countersink

Conical-shaped recess around hole at surface

Often used to accept tapered screw

counterbore

Cylindrical recess around hole at surface

Often used to receive a bolt head or nut

tapped

hole has internal threads