PAES 201:2015

1/62

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

63 Terms

PAES 201:2015

This standard specifies the requirements for heated-air mechanical grain dryer used for commercial purposes. It does not include dryers for seeds.

PAES 201:2015

The grain in this standard refers to paddy and corn.

PAES 201:2015

Standard for Agricultural Machinery - Heated-Air Mechanical Grain Dryer - Specifications

batch type

mechanical grain dryer wherein the grain in fixed amount is held in the drying chamber in batches until the grain reaches the desired moisture content

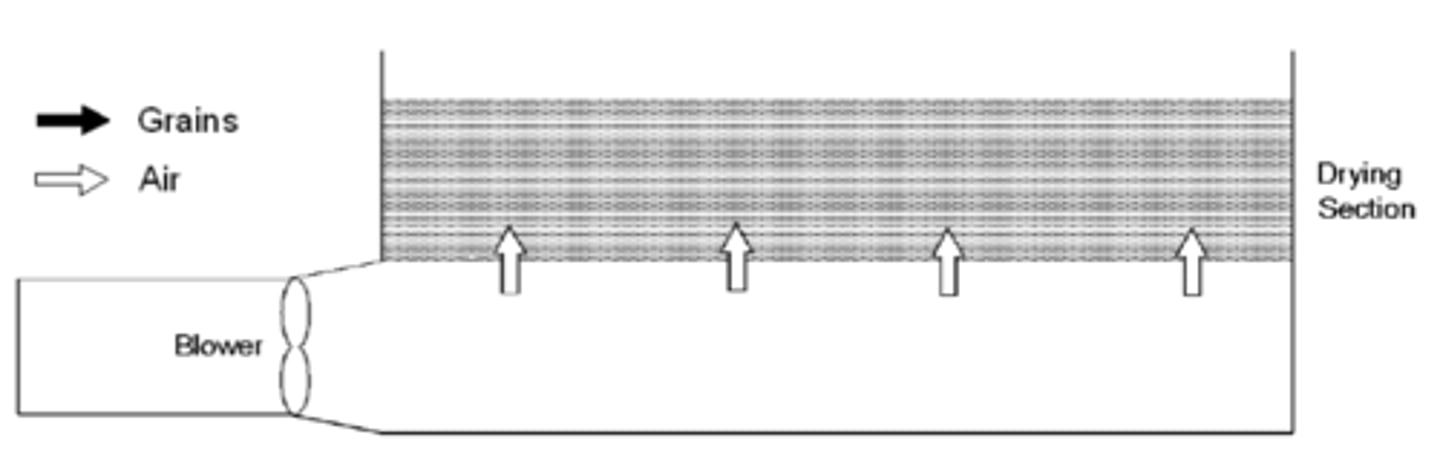

flat bed type

batch type dryer wherein a fixed amount of grain is held stationary in a horizontal grain holding bin

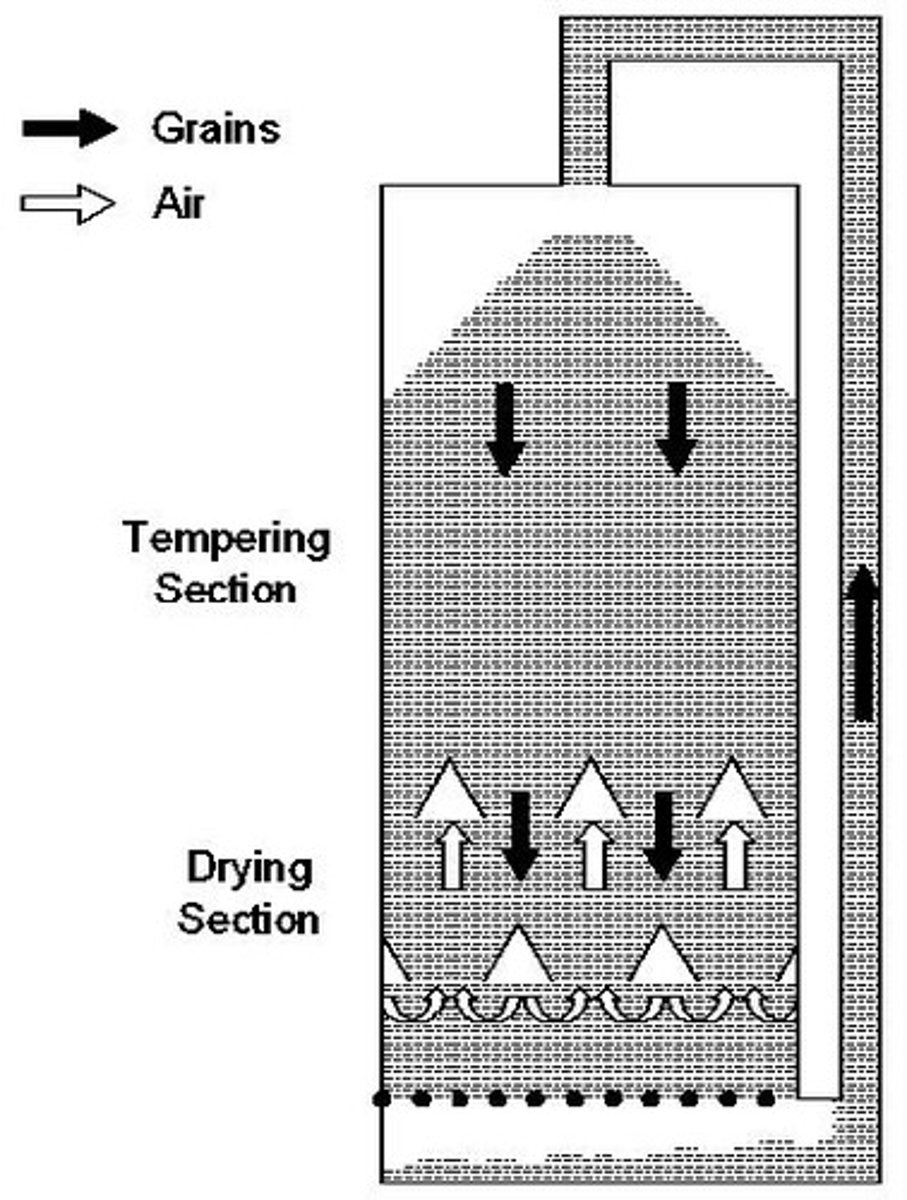

recirculating type

batch type dryer equipped to circulate and/or mixed fixed amount of grain during the drying operation

Flatbed Dryer

pic

Recirculating batch dryer

pic

biomass

organic materials used as renewable source of energy including but not limited to agricultural crops, feed and fiber crop residues, aquatic plants, forestry and wood residues, agricultural wastes, processing by-products and other non-fossil organic materials.

broken grains

pieces of grains smaller than three-fourths (3/4) of the average length of the whole kernel

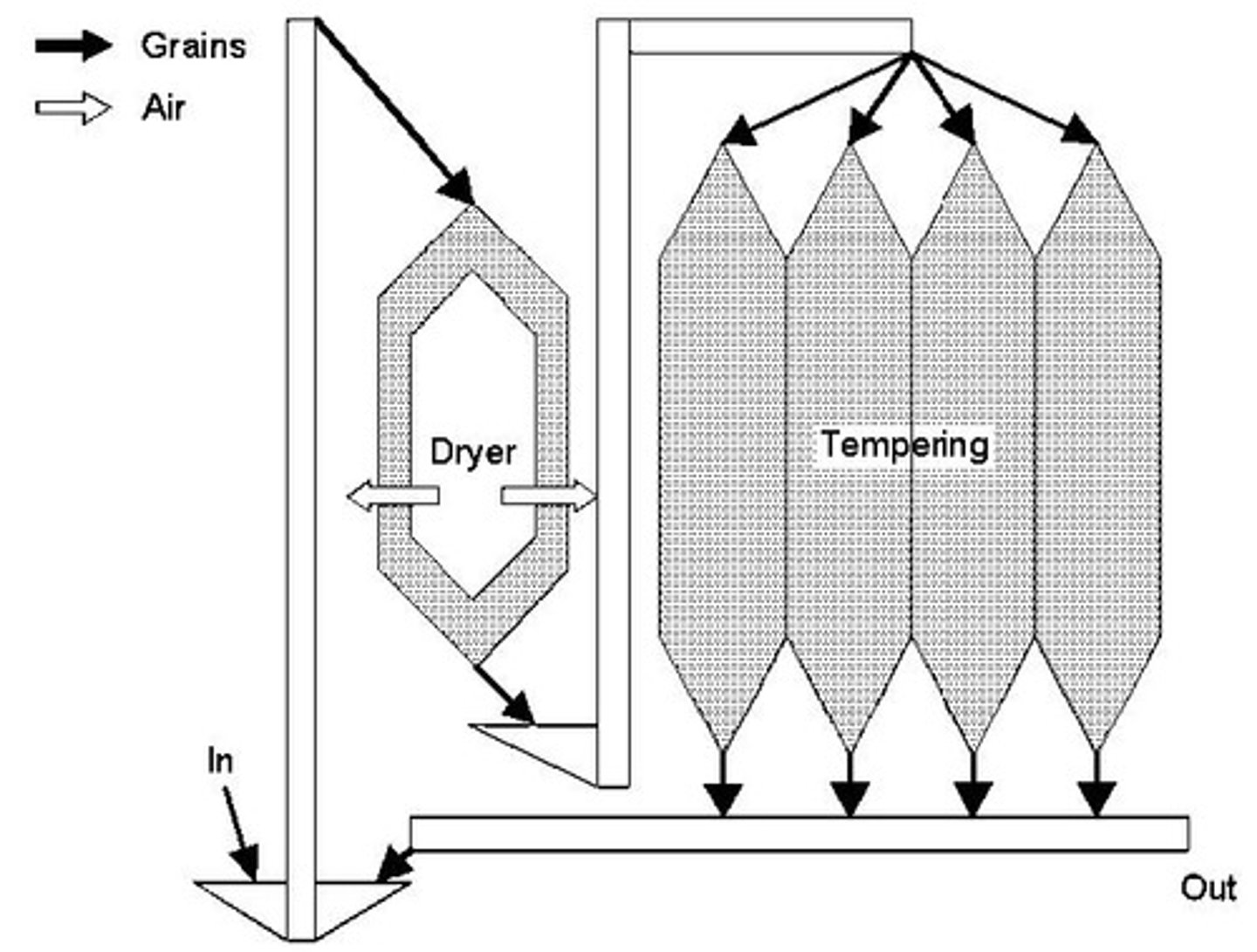

continuous flow dryer

dryer in which the material being dried moves through the drying chamber in a substantially continuous stream and is discharged without being recirculated and where the drying and tempering processes are accomplished in another holding bin or column

Continuous flow drying plant

pic

cracked grain

grains which show signs of fissures or fractures or splinters

dehusked corn

aka ear corn, corn on cob

dehusked corn

unshelled fruit of the corn plant where husk has been removed

dryer, direct-fired

dryer in which the products of combustion come into direct contact with the product being dried

dryer, indirect-fired

dryer in which the products of combustion do not come in contact with the products being dried

drying efficiency

aka heat utilization efficiency

drying efficiency

ratio of the total heat utilized to vaporize moisture in the material, to the amount of heat added to the drying air expressed in percent

dust collection system

device used to accumulate dust ( i.e. consist of aspiration fan, cyclone, etc.)

fan

air moving device that is used to force heated air through the mass of grains at the desired air flow rate and pressure

grain dryer

device for reducing excess moisture from the grain, with or without introduction of heat

head rice

grain or a piece of a grain with the length equal to or greater than three-fourths (3/4) of the average length of the whole kernel

heated-air mechanical grain dryer

device used to remove grain moisture by forcing heated air through the grain mass until the desired moisture content is attained

heating system efficiency

ratio of the amount of heat added in the air to the heat available in the fuel

moisture gradient

difference between the maximum and the minimum grain moisture content randomly sampled after drying

plenum

chamber maintained under pressure for uniform distribution of the heated air through the grain mass

safety device

any device that is used to avoid human accident related to drying operation and/or damage to the parts and components of the dryer during the operation and automatically shuts-off the operation of the dryer in case of malfunction

shelled corn

"maize"

shelled corn

aka corn grain

shelled corn

corn kernels, mainly of either dent or flint varieties of the plant Zea mays

tempering bin

chamber wherein the grains are temporarily held after drying chamber or to the storage bin

Batch type, Continuous Flow

Classification of heated-air mechanical grain dryers according to system of operation

Flat Bed, Recirculating

Classification of batch type heated-air mechanical grain dryers

Renewable, non-renewable

Classification of heated-air mechanical grain dryers according to fuel source

4%

maximum moisture gradient of rice for batch type heated-air mechanical grain dryer

4%

maximum moisture gradient of corn for batch type heated-air mechanical grain dryer

2%

maximum moisture gradient of rice for recicrulating type heated-air mechanical grain dryer

2%

maximum moisture gradient of corn for recicrulating type heated-air mechanical grain dryer

0.8%/h

drying rate of rice for batch type heated-air mechanical grain dryer

1%/h

drying rate of rice for continuous flow heated-air mechanical grain dryer

2%/h

drying rate of shelled corn for heated-air mechanical grain dryer

0.4%/h

drying rate of ear corn for heated-air mechanical grain dryer

3% increase

maximum cracked grain of rice for batch type heated-air mechanical grain dryer

2% increase

maximum cracked grain of rice for continuous flow heated-air mechanical grain dryer

10% increase

maximum cracked grain of corn for heated-air mechanical grain dryer

5% decrease

maximum head rice for heated-air mechanical grain dryer

2% increase

maximum hulled/damaged grain of rice for heated-air mechanical grain dryer

7% increase

maximum broken/split corn kernels for heated-air mechanical grain dryer

1%

maximum drying loss/spillage of rice for heated-air mechanical grain dryer

1%

maximum drying loss/spillage of corn for heated-air mechanical grain dryer

75%

minimum drying efficiency of rice for heated-air mechanical grain dryer

75%

minimum drying efficiency of corn for heated-air mechanical grain dryer

90%

minimum heating system efficiency of rice and corn for petroleum-based fueled direct-fired heated-air mechanical grain dryer

75%

minimum heating system efficiency of rice and corn for petroleum-based fueled indirect-fired heated-air mechanical grain dryer

65%

minimum heating system efficiency of rice and corn for biomass fueled direct-fired heated-air mechanical grain dryer

50%

minimum heating system efficiency of rice and corn for biomass fueled indirect-fired heated-air mechanical grain dryer

0.05 m3/min/kg (1750 ft3/min/ton)

blower flow rate of rice and corn for heated-air mechanical grain dryer

25 mmH20 (1 inH20)

static pressure of rice and corn for heated-air mechanical grain dryer

thermometer, pressure gauge

The dryer shall be provided with ___ to measure the actual air temperature entering the grain mass and a ___ to measure the working static pressure in the plenum.

92 dB (A)

The noise emitted by the heated-air mechanical grain dryer shall not exceed ___.

one (1) year

The construction shall be rigid and durable without major breakdown of the following major components: burner, fan, bin and conveying equipment within ___ after the date of acceptance of the unit by the end-user.

one (1) year

Warranty shall be provided to parts and services within ___ after the date of acceptance of the unit by the end-user except on fast moving and easy to wear parts such as fan belts.