Light Metals, Non Ferrous alloys (Aluminium)

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

45 Terms

Advantages of Al for plastic deformation and forming

FCC crystal structure

Good formability

Low hot-strength

Mill products

Flat rolled products

Rod bar wires

Tubular products

Extruded shapes

Two classes of Al wrought products

Mill products

Forging

Flat rolled products divisions

Foil

Sheet

Plate

Foil thickness

Less than 0.2mm

Sheet thickness

0.2-6mm

Plate thickness

Over 6mm

Flat product production

Ingot casting and Hot and Cold rolling

Strip casting and finish rolling

Ingot casting and hot and cold rolling

ingot casting and homogenization

hot rolling

cold rolling

Strip casting and finish rolling

Dont solidify metal completely

Solidifies when it is plastically deforming at the same time

Only for certain Al alloys

International Allot Designation System (IADS)

PUT IN TABLE

Designation system for aluminum alloys

Can you age harden pure Al?

No → no secondary phases

Only certain Al alloys are age hardenable

Non heat treatable Al alloys (Strain hardened)

Al

Al-Mn

AL-Mg-Mn

Al-Mg (5000 series)

Work hardening

High corrosion resistance

Reduces ductility

Weldable

Work hardened Al-Mg have 4 times higher yield strength than pure Al

Work hardening rate is not the same for every alloy.

Heat treatable Al alloys

AL-Mg-Si (6xxx)

Al-Cu-Mg (2xxx)

Al-Zn-Cu (7xxx)

Al-Cu-Mg (2000 series)

If cold worked some of the 2000 series alloys respond better to ageing.

High strength good ductility.

Often stored in a fridge to slow down age hardening to keep the metal in a workable condition.

Aluminium wrought alloys

Aluminum casting alloys are specific types of aluminum alloys that are designed to be used in the casting process.

Molten aluminum is poured into a mold to form a desired shape.

Ability to be melted and cast into complex geometries while maintaining desirable mechanical and physical properties.

Maintains strength, ductility, corrosion resistance, and heat tolerance.

Can aluminium alloys be cast by any of the casting processes?

Yes

Casting affects properties mainly porosity through solidification rate → which determines grain size. (dendrite arm spacing.

Most important casting processes for Al

Sand

Permanent mold

Die casting

Sand casting

Disposable sand mold, slow cooling rate

Permanent mold

Metallic permanent mold, gravity cast or low pressure assisted, medium cooling rate

Die casting

Metallic permanent mold, high pressure injection, very high cooling rate.

Aluminium

FCC crystal structure

MP → 600 degrees celcius

Maleable → 12 slip systems

Low yield strength → 7-17MPa

Strain hardenable

G → 70Gpa

Excellent corrosion resistance

high electrical and thermal conductivity

Most effective strengthening mechanism for Al?

Age hardening

Two types of Aluminium alloys

Wrought alloys

Casting alloys

Advantages of Al for casting

Low melting temps

Relatively goof fluidity

Excellent melt-oxidation resistance

Negligible solubility for all gases bar hydrogen

Relatively good surface finish

Disadvantages of Al for casting

Shrinkage

Hydrogen porosity

Hot-tearing / hot-cracking

Reactivity with steel tools

Shrinkage in Al

Volumetric shrinkage: (3.5-8%) occurs during solidification due to density difference between liquid Al and solid Al

Linear shrinkage: (~1.3%) occurs during cooling from solidus to RT

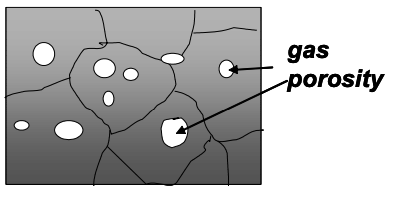

Hydrogen porosity in Al

Effects impact and ductility

Due to the difference in liquid and solid solubility of H in Al.

H2 precipitates out and produces rounded gas holes with smooth internal surfaces.

can be reduced by argon degassing

Hot-tearing or hot-casting (Disadvantage of Al for casting)

Macroscopic tears or cracks in the casting

Occur due to thermal and mech stresses during solidification

Die design and hot-strength of the alloy are important

What elements may casting alloys contain?

Si, Mg, Cu, Zn, Fe, Li, Mn, Ni, Sn, Ti

Why is Silicon important for casting alloy systems?

Increases fluidity

Reduces Coefficient of thermal expansion.

Good weldability

Good corrosion resistance

Aluminium 3xx series

Aluminium-Silicon with magnesium and/or copper (Most important alloys)

Most important alloy system

Al-Si

Al-Si hypoeutectic

A356

Main alloy used in automotive applications.

Contains some Mg

Si particles (phase) are pointed and coarse.

Adding sodium or strontium can can modify Si shape from coarse to fine → Increasing strength and ductility.

Al-Si Hypereutectic alloys

Excellent wear resistance

Contains some Cu

Phosphorus modifies silicon shape to spherical precipitates → inscreasing ductility.

F (Temper designation for aluminium casting alloys)

As-cast condition.

T1 (Temper designation for aluminium casting alloys)

Quenched from casting temperature and naturally aged at room temperature.

T4 (Temper designation for aluminium casting alloys)

Solution heat treated

Quenched

And naturally aged at room temperature.

T5 (Temper designation for aluminium casting alloys)

Quenched from casting temperature

Artificially aged.

T6 (Temper designation for aluminium casting alloys)

Solution heat treated

Quenched

Artificially aged

T7 (Temper designation for aluminium casting alloys)

Solution heat treated

Quenched

Artificially overaged (stabilized)

Aluminium 8xxx series

Aluminium-Lithium Alloys

Properties of lithium in al alloys

Light

Reactive with moisture

Problems with Al-Li

Low thermal stability

High anisotropy (directionally dependant ) of properties.

Susceptible to local deformation

Scattered values of fracture toughness

With increasing lithium → Density decreases and youngs modulus increases