materials test 2

1/12

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

13 Terms

3 Stages of Fatigue

Initiation

Propagation

Final Fracture

Cyclic Loading

Application of repeated or fluctuating stresses and strains to a component

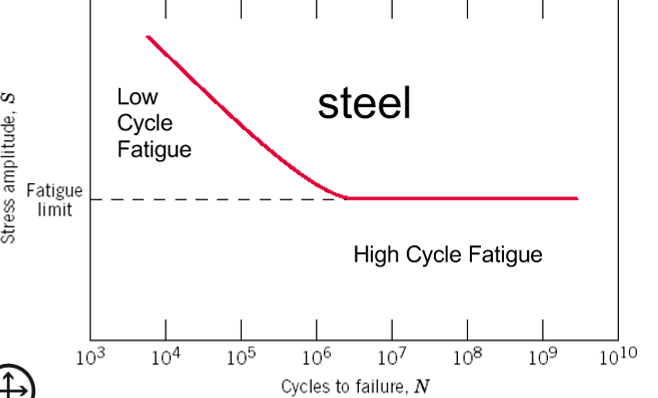

Fatigue Limit

the stress amplitude below which fatigue failure will not occur

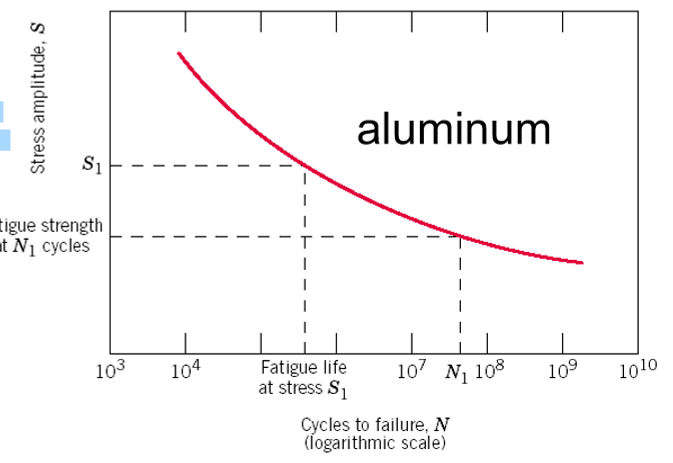

Fatigue Strength

The stress amplitude value for failure to occur in a specified number of cycles

Striations

micro-scale features indicating crack origin and growth characteristics

Beachmarks

macro-scale features visible by the eye, usually associated with periodic start-up and shut-down operation (one line per start-up and shut down). Does NOT reflect load cycles

Tensile stress is needed for crack growth

FALSE. Cracks will not grow if only compressive stresses are present.

3 Factors affecting Fatigue Life

Mean Stress

Surface Treatments

Design Factors (reduce stress concentration areas)

Surface Treatments

Case Hardening

Shot Peening

Case Hardening

Material maintains toughness but has a harder (wear resistant) surface

Shot Peening

Compressive surface stresses to delay crack initiation

Creep

time dependent plastic deformation at high homologous temperatures

Creep Strain

Primary

Strain which occurs after the first instantaneous change ( ɛ = ε_c + ε_E+ε_P)