Fundamentals of Casting Processes in Engineering

1/56

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

57 Terms

Casting

Exploit the properties of the liquid as it flows and assume the shape of prepared container and then solidification process occur.

Materials removal (machining)

Remove selected segments from an initially oversize part.

Deformation

Exploit the ductility or plasticity of materials and produce the desired shape.

Consolidation

Building desired shape by putting smaller pieces together such as welding, soldering.

Powder metallurgy (PM)

Material components are made from metal powder.

Additive manufacturing

Successive layers of material form under computer control to create an object.

Casting process

Material is melted, heated to proper temperature, treated to modify its chemical makeup, molten material is poured into a mold, and solidifies.

Casting advantages

Complex shapes, parts can have hollow sections or cavities, very large parts, intricate shaping of metals that are difficult to machine, different mold materials can be used.

Casting disadvantages

Limitations on mechanical properties, poor dimensional accuracy and surface finish for some processes; e.g., sand casting, safety hazards to workers due to hot molten metals, environmental problems.

Pattern

A replica of the object to be cast, used to prepare the cavity into which molten material will be poured.

Mold cavity

Combination of the mold material and cores.

Riser

Additional void in the mold that provides additional metal to compensate for shrinkage.

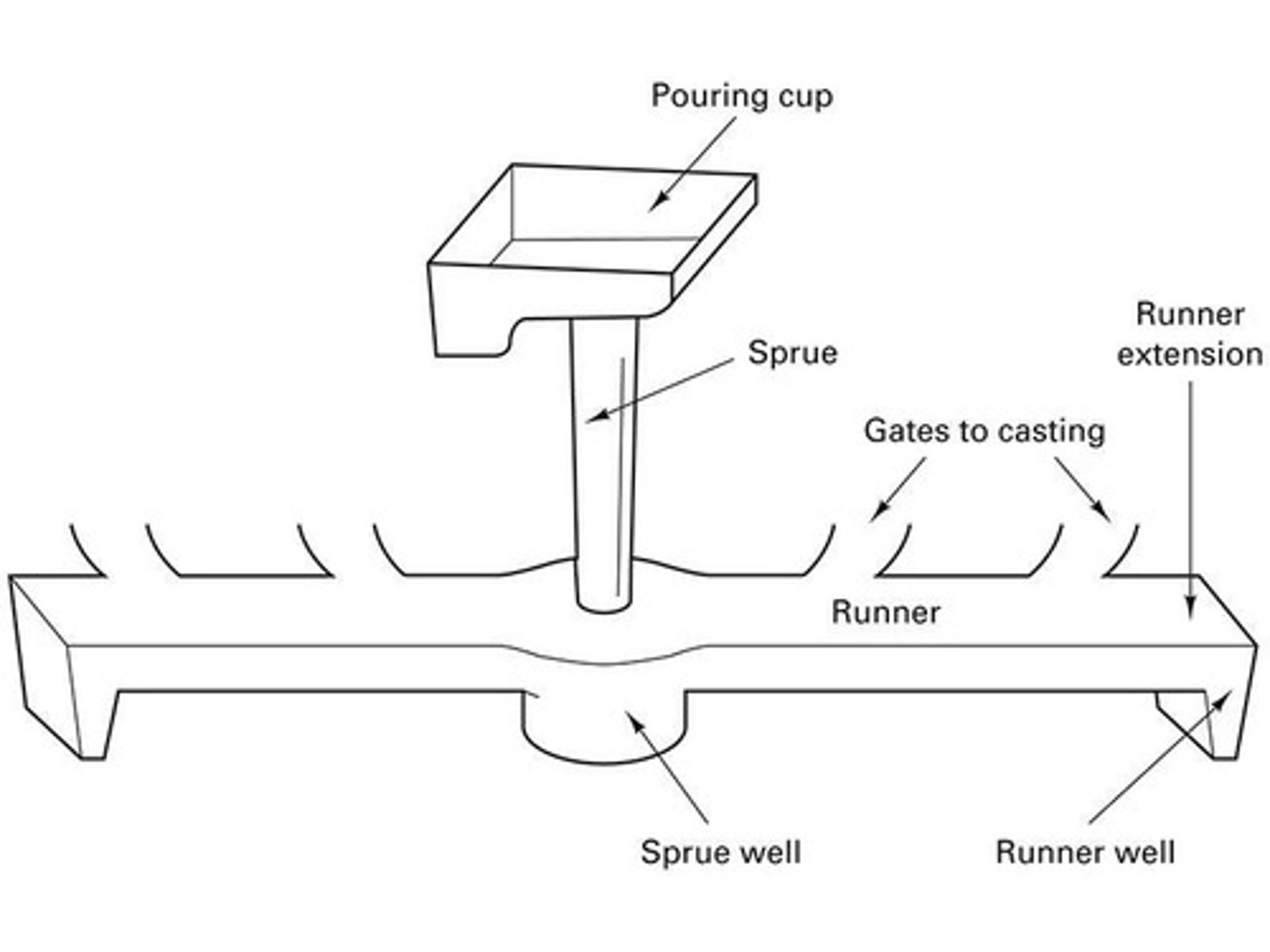

Gating system

Network of channels that delivers the molten metal to the mold.

Pouring cup

Portion of the gating system that controls the delivery of the metal.

Sprue

Vertical portion of the gating system.

Runners

Horizontal channels.

Gates

Controlled entrances.

Basic Requirements of Casting Processes

1. Mold cavity takes shrinkage into account; 2. Melting process provides molten material at the proper temperature in the desired quantity; 3. Pouring technique ensures that erosion and or defects are minimized; 4. Controlled solidification allows the product to have desired properties; 5. Mold removal ensures that the casting is removed from the mold.

Nucleation

Each nucleation event produces a grain.

Inoculation

The process of introducing solid particles to promote nucleation.

Growth

Occurs as the heat of fusion is extracted from the liquid.

Controlled Growth

Direction, rate, and type of growth can be controlled by the way in which heat is removed.

Nucleation Rate

Rates of nucleation and growth control the size and shape of the crystals.

Cooling Rates

Faster cooling rates generally produce finer grain sizes.

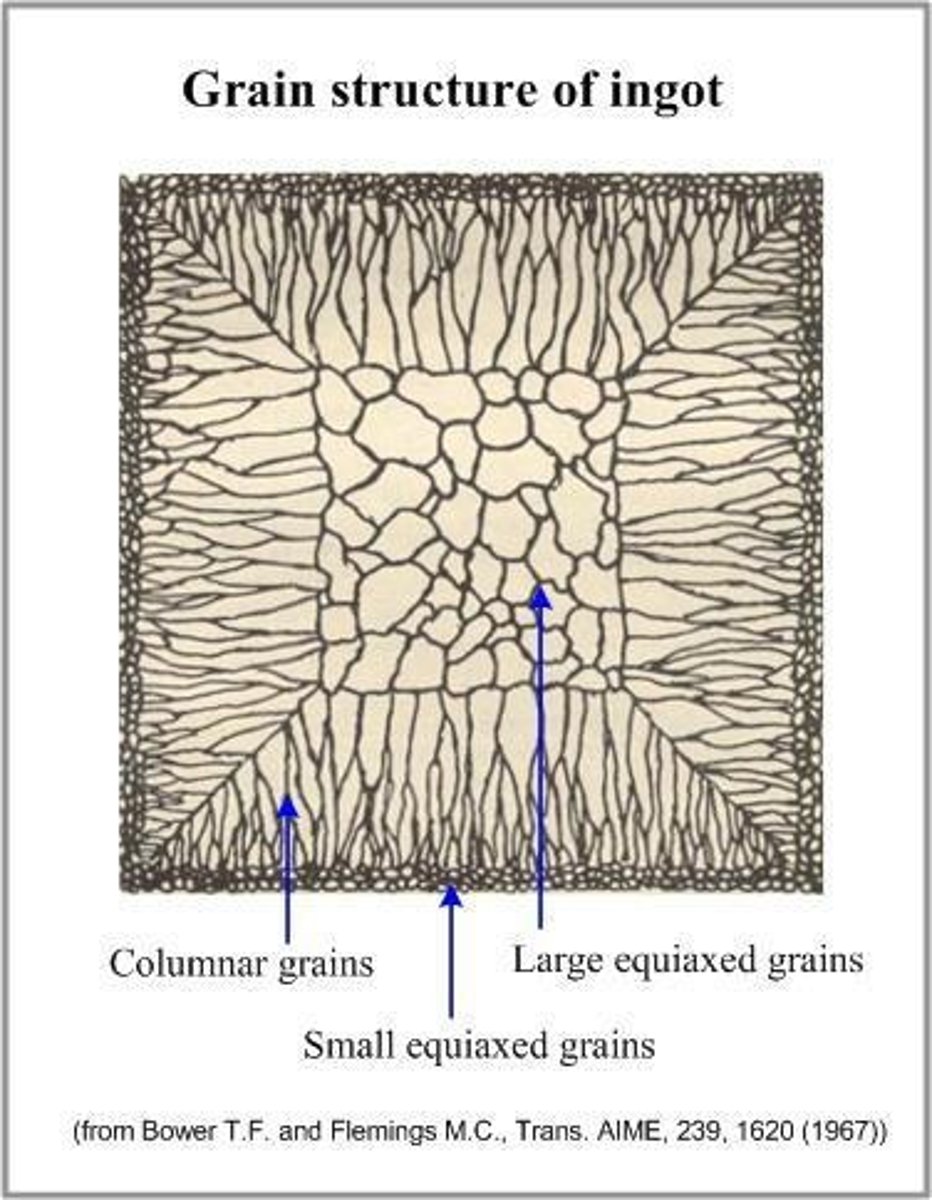

Chill Zone

Rapid nucleation that occurs when the molten metal comes into contact with the cold walls of the mold.

Columnar Zone

Rapid growth perpendicular to the casting surface, long and thin and highly directional.

Equiaxed Zone

Spherical, randomly oriented crystals in the interior of the casting.

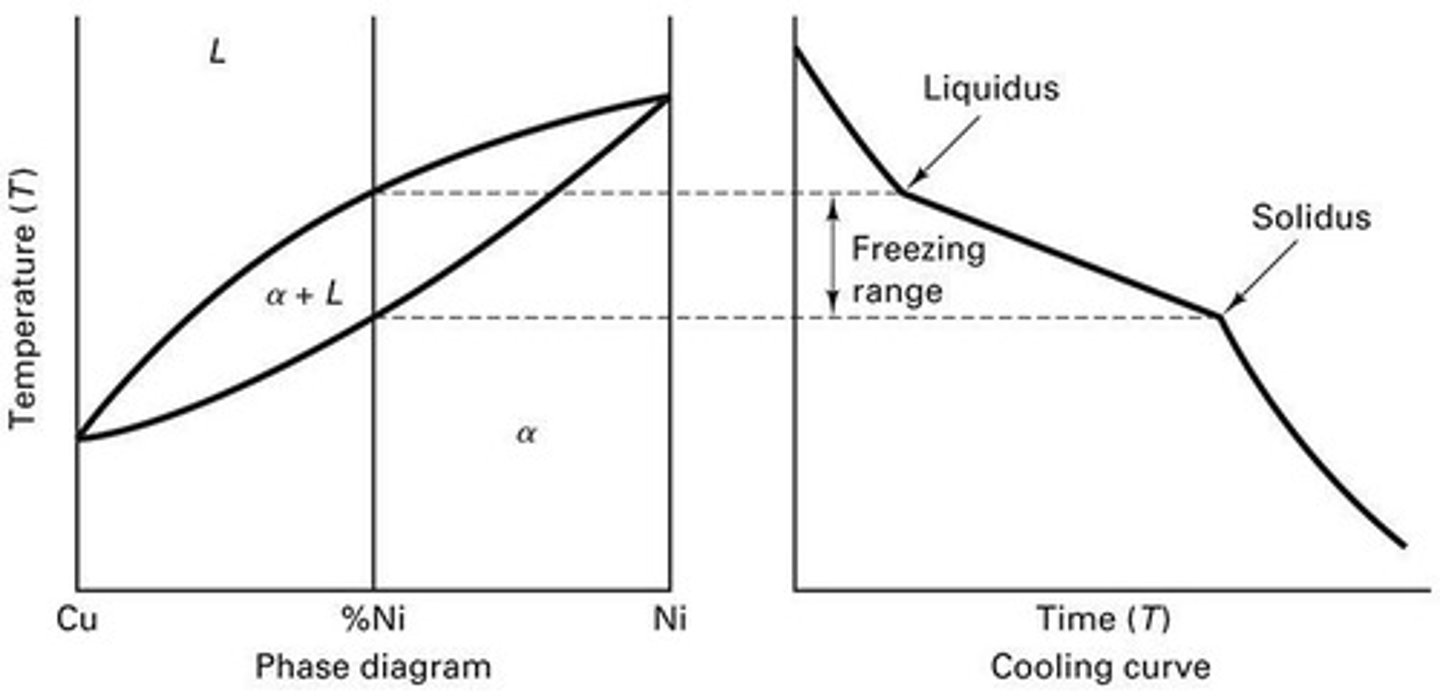

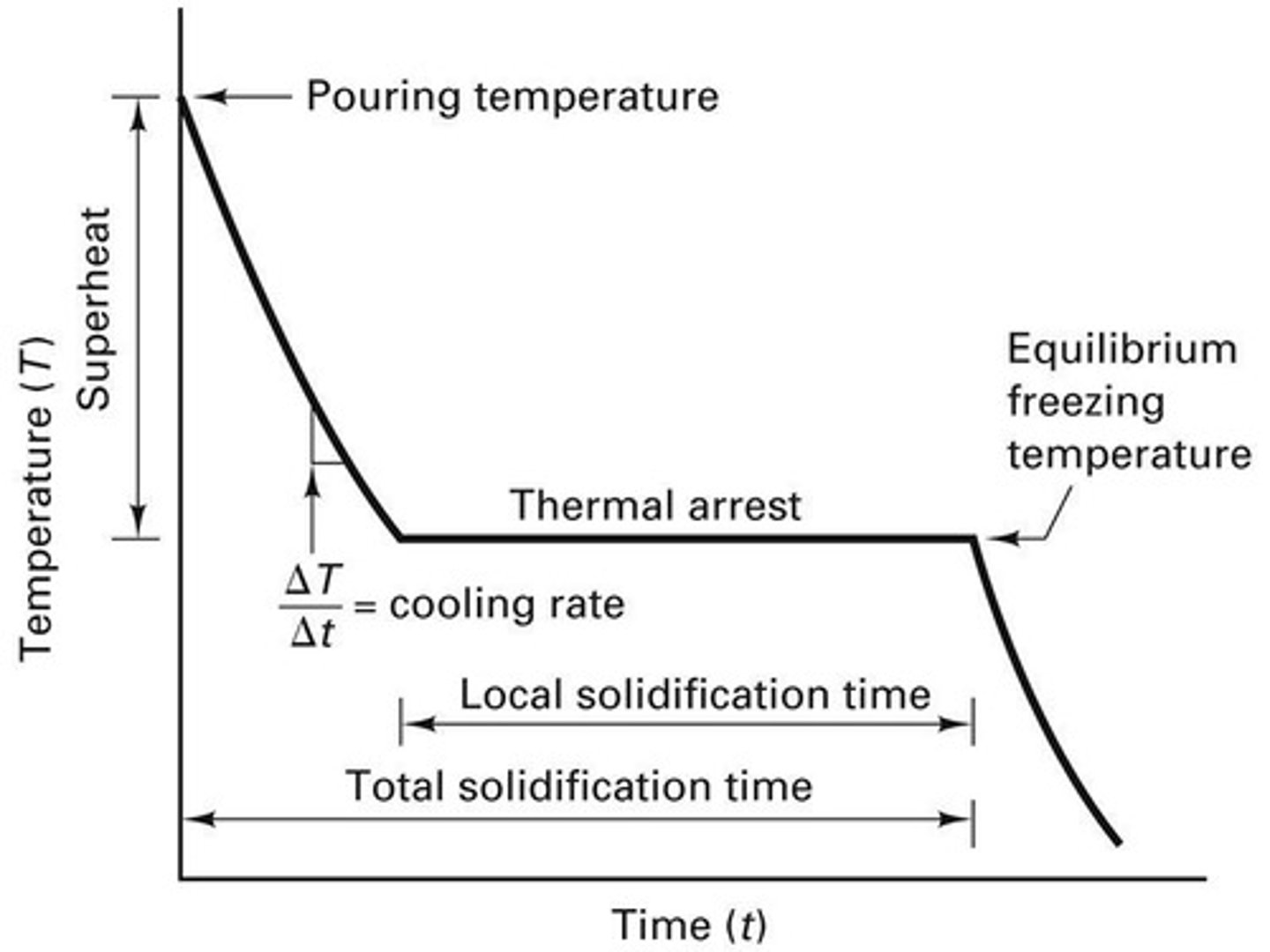

Solidification Process: Cooling Curve

Characteristic grain structure in an alloy casting, showing segregation of alloying components in center of casting.

Pure Metal Casting

Characteristic grain structure in a casting of a pure metal, showing randomly oriented grains of small size near the mold wall, and large columnar grains oriented toward the center of the casting.

Chvorinov's Rule

The amount of temperature that must be removed from a casting to initiate solidification depends on superheat and volume of the materials in the cast.

Superheat

Difference between pouring temperature and freezing point.

Total Solidification Time Formula

Total solidification time is calculated using V= volume of the casting, A= surface area through which heat is extracted, n= 2.0, B= mold constant.

Mold Constant in Chvorinov's Rule

Known to be 4 min/cm² for certain mold conditions.

Casting Dimensions

For the flat plate, length l= 30 cm, width w= 10 cm, and thickness h= 2 cm.

Solidification Time Calculation

Determine how long it will take for the casting to solidify using the given mold constant and dimensions.

Area

Area= 2 (Lh)+ 2(LW)+2(Wh)= 2(3010)+ 2(302)+ 2(10*2)= 120+ 40= 760 𝑐𝑚2

Volume

Volume= LhW =30102 = 600 𝑐𝑚3

Molten Metal Problem

Chemical reactions can occur between molten metal and its surroundings.

Metal Oxides

Metal oxides may form when molten metal reacts with oxygen.

Dross or Slag

Dross or slag is the material that can be carried with the molten metal during pouring and filling of the mold.

Pouring Temperature Control

This can be controlled by lowering pouring temperature.

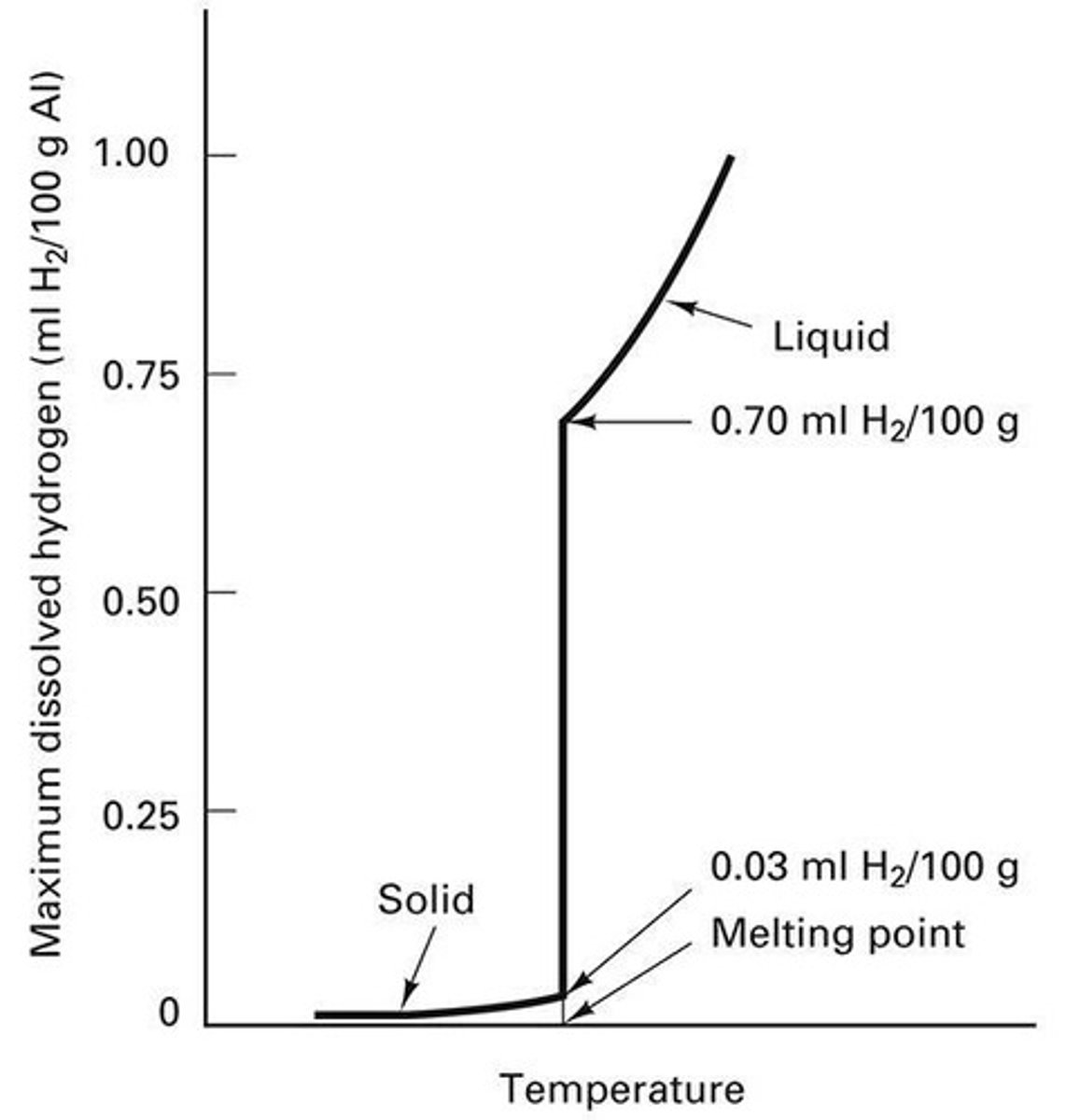

Gas Porosity

Gas that is not rejected from the liquid metal may be trapped upon solidification.

Techniques to Prevent Gas Porosity

Several techniques to prevent gas porosity include melting in a vacuum, melting in environments with low-solubility gases, minimizing turbulence, and vacuum degassing.

Gating System Design

Gating system should be designed to minimize turbulent flow, which tends to promote absorption of gasses.

Short Sprue

Short sprue are desirable: minimize the distance must fall.

Rectangular Pouring Cup

Rectangular pouring cup: prevent vortex formation.

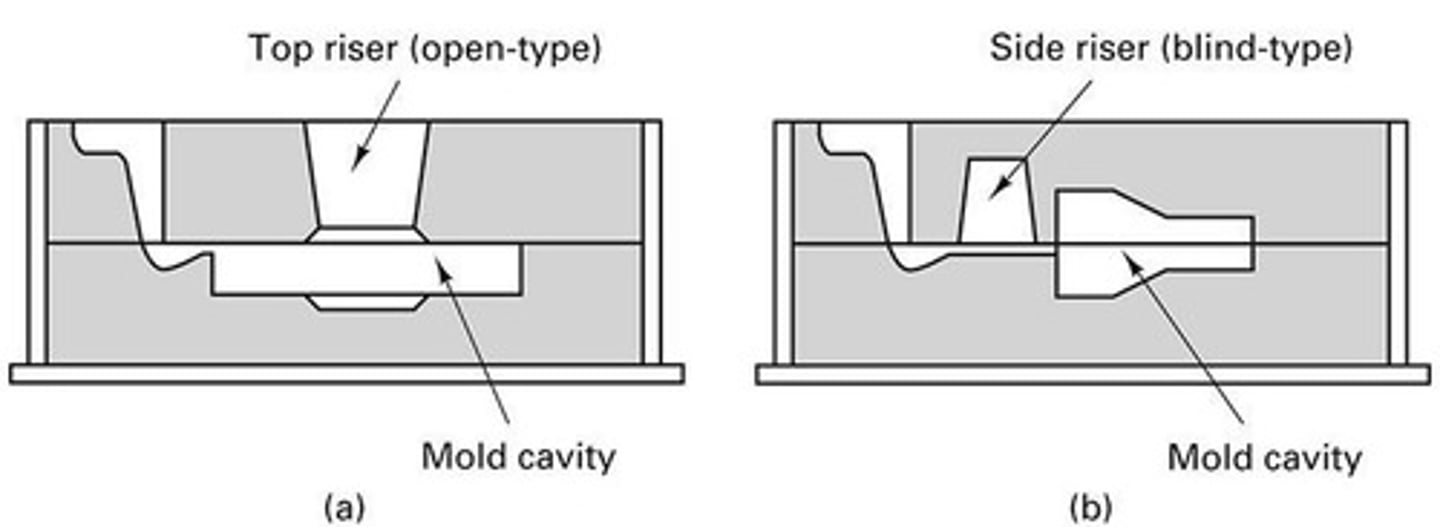

Risers

Risers are reservoirs of liquid metal that feed extra metal to the mold to compensate for shrinkage.

Riser Design

Risers are designed to conserve metal and should feed directly to the thickest regions of the casting.

Blind Riser

Blind riser- contained entirely within the mold cavity.

Live Riser

Live riser- receive the last hot metal that enters the mold.

Good Riser

Good riser=long frozen time.

Chvorniov's Rule

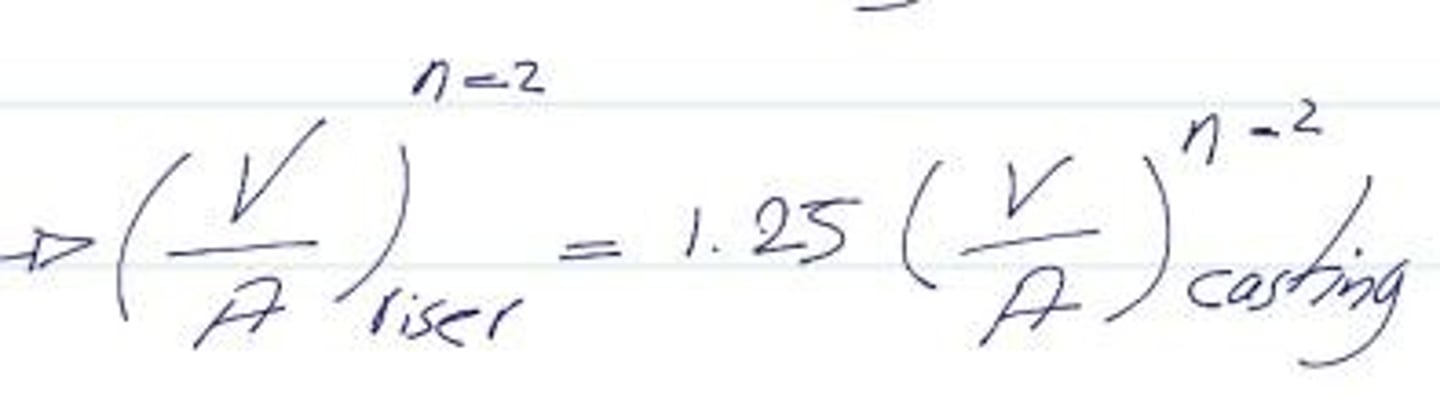

The minimum size of riser can be calculated from Chvorniov's rule.

Riser Dimensions Calculation

Using Chvorniov's rule with n=2 calculate the dimensions of an effective riser for a casting rectangular plate.

Riser Height to Diameter Ratio

Riser is a cylindrical of height to diameter ratio 1.5.

Volume of Riser

V riser= 𝜋𝐷2𝐻 = 𝜋(3.22)2(4.83) = 39.33 𝑐𝑚3.

Volume of Casting

V casting = 48 𝑐𝑚3.

Casting Weight Fraction

Vcasting/Vcasting+Vriser= 48/ (48+39.33)= 0.55.