ANSC 240: Animal Production Exam #3

1/152

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

153 Terms

Pathogenic Organisms

Disease causing organism

Infection

Cell itself causes the illness

Intoxication

Toxins produced by bacteria causes the illness

Why are animal products high risk?

Due to a high expected microbial load

Why are muscle and milk from healthy animals considered sterile?

Skin, IS, and walls of GI tract providing protection

Contamination

Fecal, hide, hair, GI, and feather contamination

Harvest Procedures

Zero tolerance for hair, fecal, and milk; Antimicrobial washes

Temperature Control

Storage-refridgeration, perparation-cooking, hot holding, and cooling/reheating

Sanitation

Personal hygiene and equipment sanitation

Cross-contamination

The spreading of bacteria or other pathogens from one food to another

E. coli

Most strains are not pathogenic and common in animal GI tracts EHEC (STEC) and ETC are problem strains

-Symptoms: Bloody diarrhea, HUS, death

-Treatment: Not much, antiobiotics can cause a release of toxins

Shiga-toxins

Taken up by cells and inhibits protein production, linings of vessels breakdown=hemorrhaging, inability to reabsorb water

ETEC

Associated with beef products, colonizes rectum of cattle (no adverse affect on animal as it does not have shiga-toxin receptors), pathogenic but not as severe as ASTEC

ETEC Areas of Concern and Control

-Raw beef (ground beef), all other raw meat and milk are areas of concern

-Specific regulations like microbial testing required for beef carcasses and trim as well as proper sanitation and cooking

Salmonella

Found in GI tract, particularly of birds and has no real adverse impact on animals, is usually self limiting and extreme cases can result in hospitalization

Salmonella Areas of Concern and Control

-Raw meat, especially in poultry

-Proper sanitation and cooking

Listeria

L. monocytogenes and is a main concern and found in environment rather than species, grows at refrigerated temperatures, and dangerous for pregnant women and immuno-compromised people

Listeria Areas of Concern and Control

-Precooked items

-Proper sanitation, cooking, regulations for RTE, production testing, and interventions

Toxoplasma Gondii

Animal derived productions and contaminated drinking water, most immune systems keep in check (can stay in body for long period of time), dangerous for pregnant women and immuno-compromised people

Toxoplasma Gondii Areas of Concern and Control

-In raw animal products

-Proper cooking and sanitation

Campylobacter

Common foodborne pathogen in poultry and dairy, control usually involves sanitation and temperature control

USDA

-FSIS: Public health and meat/egg inspection

-APHIS: Animal welfare

-Food and Nutrition Service: Education and assistance with health

FDA

-Foods: Labeling, safety of food productions except meat and poultry

-Drugs: Human and vet

-Pesticides: Share with USDA and EPA

Inspection

Product dependent on animal health, processes, ingredients, etc. and also ensures products are as safe as possible for consumers before purchasing

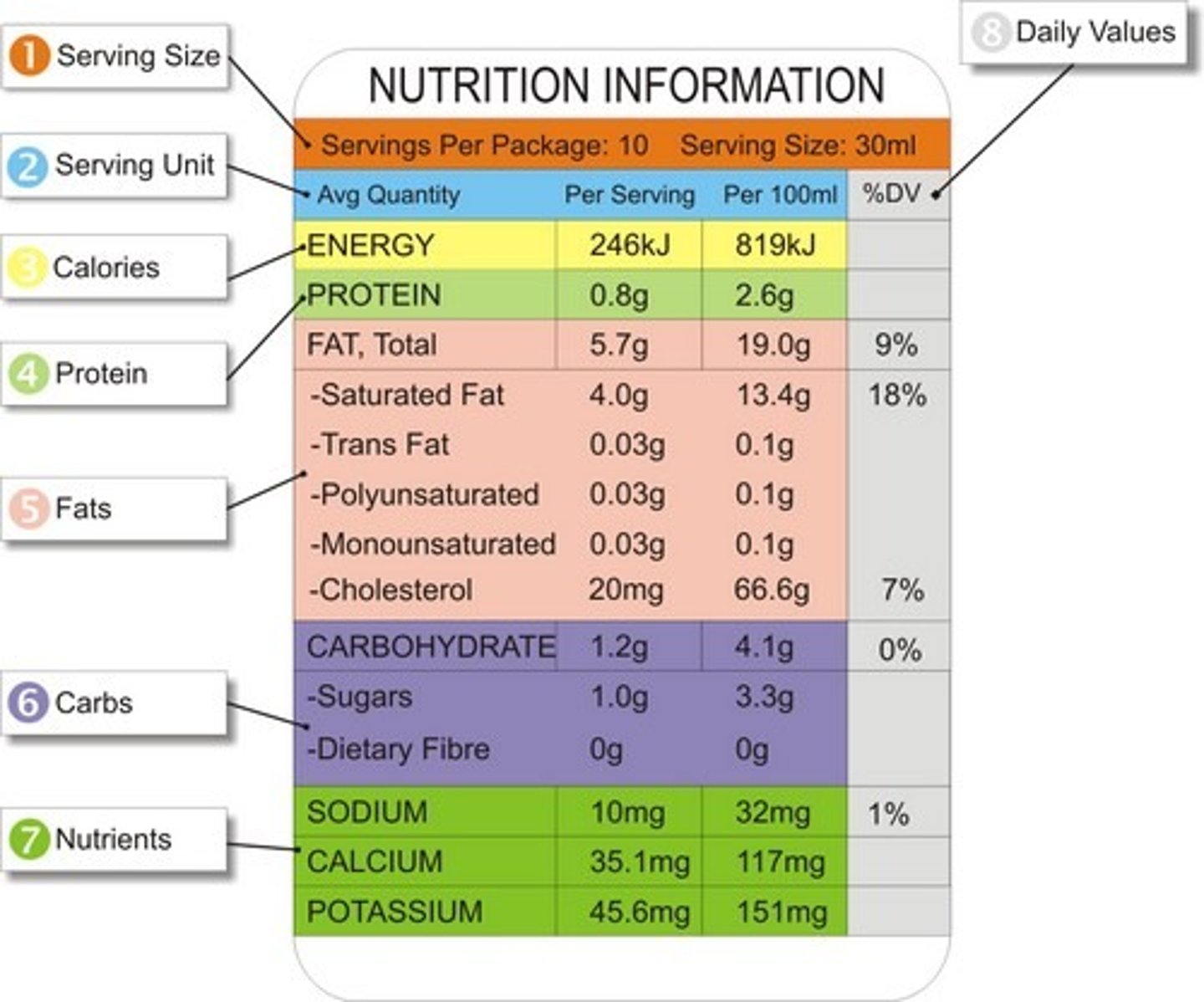

Labelling

Clear communication to consumers and process verification (everyone follows the same "rules")

How do people influence process verification?

People are willing to pay for things that contain certain attributes (real or perceived) and guarantee is needed for consumers to have trust

What does process verification allow for?

Consistent interpretations, assurances to consumers, but does not speak to other implied attributes

National Foods Protection Act of 1990

Final rule published in 2000, and arguably most stringent process verification and focuses on animal origin, feed, housing, healthcare, and processing

Meat and Poultry Products (Organic)

Livestock fed 100% organically grown feed and forage with no synthetic hormones and vaccinations, no pesticides on pastures, no sewage sludge, and must be raised from birth to organic standards

Meat and Poultry Products (Organic) Labelled

100% organic and contains organic ingredients

Antibiotics in Livestock Production

Treatment of infections, prevention of infections and performance (low levels in feed improves feed efficiency-gut health and ADG increase)

What does increased antibiotic use lead to?

Increase in population of antibiotic resistant bacteria (impacts drug efficiency)

US Companies and Antibiotics

Have begun to phase out antibiotics (big push for this in 2015) and poultry industry is the main industry to capitalize on this and every major broiler producer has segment of business antibiotic free and currently more than without

Halal

Islamic food laws

Kosher

Jewish food laws

Slaughter Practices for Religious Dietary Constraints

Religious practitioner present or performing harvest, stunning not allowed although animals are restrained, addition carcass inspection to make sure it meets criteria on purity

Why are CFO/CAFO controversial to communities?

Concerns trace to manure: Environmental concerns, odor concerns, health concerns

Concerns with Manure Management

How much manure and storage, major concerns, manure managed to mitigate concerns, new tech/practices to prevent contamination and "odor events"

Operation and Manure Management

Must estimate how much manure is generated (EX: 1, 200 lb pig= about 75 square ft of manure per year)

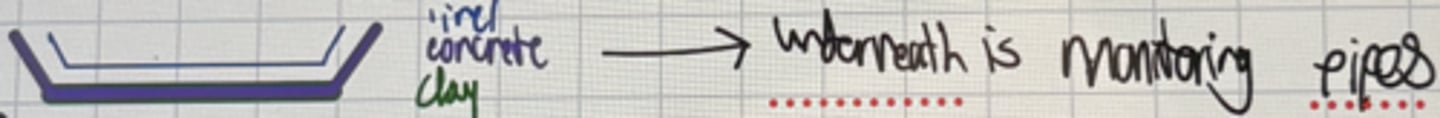

Lagoon

Traditional method, still used in new, especially dairy, operations, basin to store waste, decomposes, 2x year applied to field as fertilizer

Deep Pit

Pit immediately under floor holding animals- slotted floor, periodically pumped as fertilizer

Challenges with Manure Storage

Cracks in liner, potential spills when pumping, open top leads to odor (lagoon)

Positives to Manure Fertilizer

N, P, K, organic matter (increases soil stability, decreased erosion and water holding)

Drawbacks to Manure Fertilizer

Must be managed (too much of a "good thing"- N and P can be bad), must apply based on soil needs, soil testing needed (what does soil have/need and what are nutrient capacities), excessive manure could have runoff into water

Organic P and Animals

Not readily digested by animals and passes into manure= more P than plants need, use manure to get N can overshoot P, too much P leads to algae blooms which can use up unavailable O so fish die

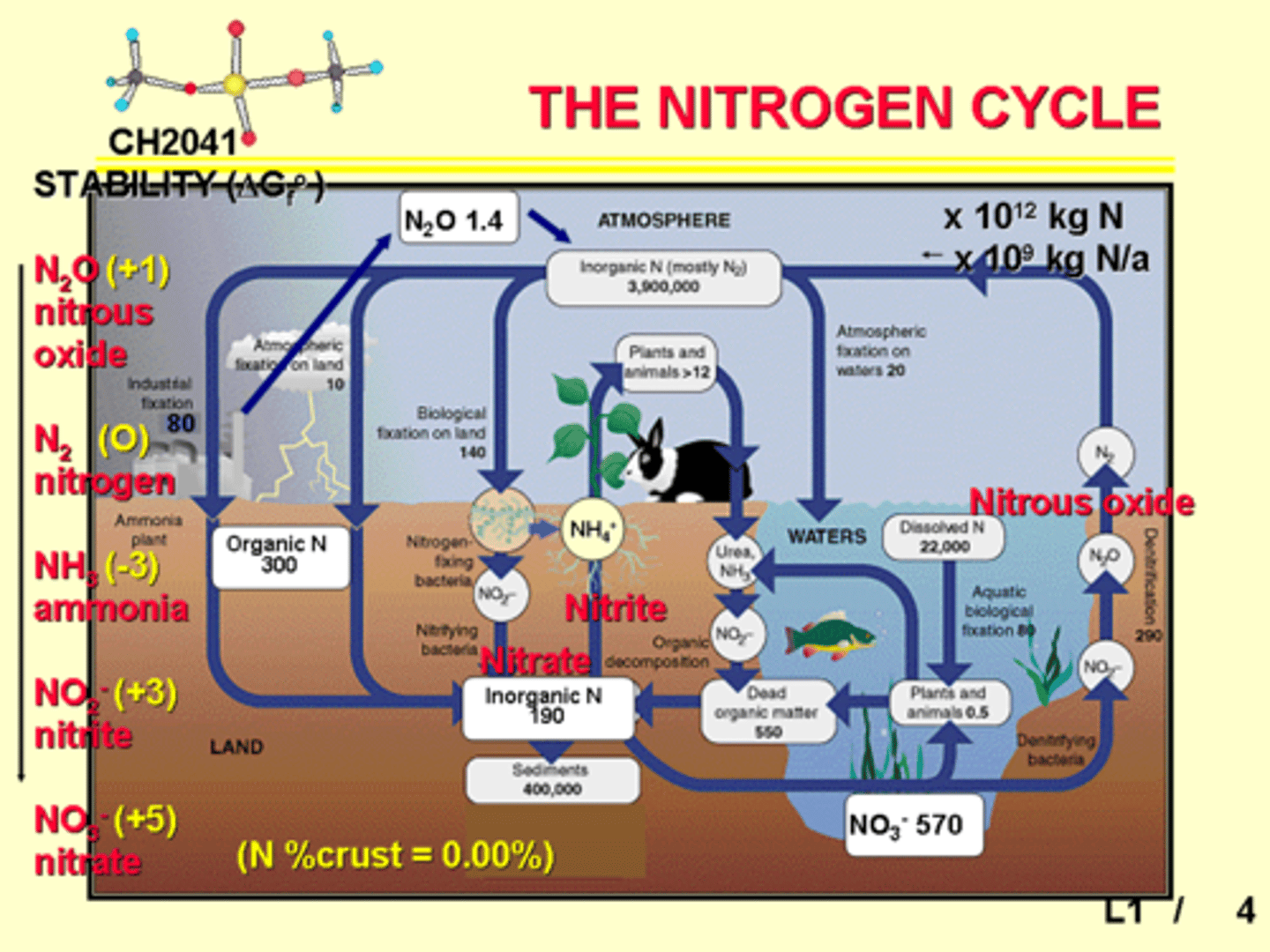

N in Manure

Very active and can escape so mineralization process of N is key (organic N to inorganic N), organic N is not always available to animals, inorganic is although volatile

N Cycle

Challenge with N

As N loss increases, P concentration/issues increase

Retaining N

Microbes use organic N and N in AA in soil, then microbes will get N from wherever they can (inorganic N) impacts C in soil and ration to C is important (too little C= microbes trap inorganic N and make it unavailable to plants; too much C= volatility and odor increase)

N in Lagoons and Spraying Manure

-P and K will settle to bottom, increased N in top= more N loss, agitation can reduce this

-Surface= increased N loss, soil incorporation can reduce

IDEM Regulations

Confined feeding control law, confined feeding operation rules, concentrated animal feeding operations rule

-Focus is more on manure management to protect water

Define Setback (minimum distance structure can be from certain point)

-Water on surface: 100-300 ft

-Public water: 1000 ft

-On-site water supply: 100 ft

-Off-site residential or public building: 400 ft

Other Rules

Public notification, waste storage capacity, plot and farmstead map, nutrient management plant, soil and manure testing plan

Office of the Indiana State Chemists

Fertilizer use, distribution, and record keeping, focus is on protecting water, rules on how and where manure can be applied, must use licensed applicator (some special rules for CFO) and county level might have more regulations

County Level

More regulations like use of buffers, minimum lot sizes, odor standards, transportation standards, additional application standards, and distance solves most conflicts except odor

Modelling Odor Management

Can be modeled and determine distance (buffer) for neighbors but difficult to estimate

Odor Causes

Fresh manure (high concentration of intestinal bacteria which produce metabolites, gases, etc. decompose organic matter and other things), agitated manure (bacteria population change)

Main Gases

Methane (odorless and made by methagenic bacteria and knock out in high quantities), CO2 (odorless and asphyxiant), CO (odorless and poison), Amonium (pungent and irritant), H2S (pungent and poison), several trace metabolites

What affects odor?

Wind frequency, topography factor, orientation and shape factor, building odor emissions, animal #, odor emission factor, building design and management factor, manure removal frequency, manure dilution (swine), dry (poultry) or residue (dairy) factor, odor emission from outdoor storage, animal weight, abatement in and out of building

Methagens

Bacteria in manure that make methane that can survive in anerobic conditions and connects H to CO2 to make methane byproducts, found in rumen and microbes create energy and protein and digests fibrous feed, and some methane escapes via belches and the farts of monogastric animals

Methane

Major greenhouse gas related to animal agriculture and in 2006 UN stated livestock GHG emissions=18% (higher than transportation) although later many issues were found with this estimation like the math being off

Greenhouse Emissions in Developed Countries

-Energy: 31%

-Transportation: 26%

-Livestock/Food: 3.4% (cattle=1.4%)

GHG Research

Global warming potential (ability of gas to trap heat and methane is produced and used at different rates, and methane impact on the environment has been overestimated 4x), CO2 (stock gas stays in environment, CH4 is a flow gas that is produced and then destroyed), GWP* (new metric accounting for short livespan)

Reducing GHG

Using it with anerobic/methane digesters (decompose manure, microbes break down to biogas and digested solid), biogas (60% methane, 40% CO2, 0.3% Hydrogen Sulfide, 1/4 of the heating value of propane, highly corrosive, storage not practical)

Covered Anerobic Lagoons

Dairy and swine industry, needs impermiable flexible cover and manifold to collect gas, manure with less than 2% solids and needs warm climates with cold climates mainly using it for odor control

Complete Mix

Engineered tank above or below the ground, manure can be 3-10% solid, can operate in all climates

Plug Flow

Manure can be 11-13% solids and manure can operate in all climates, has not been used well in swine operations

Distillers Grains

From producing ethanol

Hooves and Horns

Adhesives, plastics, plant food, pet food, lamination, gelatin

Swine- Internal Organs

Insulin (pancreas), heart valves

Sheep- Lanolin

Cosmetic products (name brands), adhesives, printing ink

Poultry- Eggshells

Cleaning applications, soil amendments

Poultry- Feathers

Pillow stuffing, plastics, feather meal

Poultry- Comb and Shell Membrane

Hyaluronic acid (traps moisture)

All Livestock- Fat and Fatty Acids

Solvents, gum, paint, lubricants, cream and lotions

All Livestock- Skin/Hide

Leather, sports equipment, gelatin

All Livestock- Hair

Brushes, air filters

Blood

Cultural bacteria, glue, adhesives

Intestines

Sausage casings, instrument strings, sutures

Horizontal Integration

Each entity is owned by a different company (Price keeps going up- EX: beef)

Vertical Integration

Owned by 1 company (2 or more segments) and primarily used for poultry (meat and layers) and swine

Integrator

Owns multiple production portions (feed mill and transport)

Grower

Actually raises animals and contracts with integrator

Market Contract

Common in the swine industry, less farrow-to-finish and more grower/finisher operations, grower agrees to sell set # of animals at set time for set price (animals are owned by grower)

-Contract based on future market and assumption of prices

-Guarantees market timing and price is set and avoids market volatility (real price goes up or down... no change to payment)

Production Contract

Common for poultry industry, and grower agrees to raise animal and provide housing, equipment, labor/husbandry, and manure management according to standards set by integrator (think: renting service- animals owned by integrator)

-Producer provides everything but animals and feed

-Contract is usually base/guaranteed price but premiums are possible (total # of animals to market, F:G, competition between growers to meet metric)

-Pay out based on performance, contract, and # of buildings/animals you contract

Pros to Production Contracts

-Decrease some risk as it is spread out among entities

-Decrease initial investment and good for starting operations

Cons to Production Contracts

-Integrator has great deal of control (metrics, practices, expansion)

-Producers can't contract with 2 integrators at once

-Housing standards may= re-investments

-Imbalanced negotiations

Ovine

Refers to sheep family

FEC

Measurement of internal parasite burden in ruminant animals

Parasite Resistance

Ability of parasites to survive and reproduce despite exposure to anthelemintic treatments

Shearing

Act of cutting off wool

Genetic Component

Animal specific basis

Ewe

Female sheep any age

Broad Ewe

Female sheep of advanced age

Ram

Intact male sheep for breeding

Wether

Castrated male sheep

Lamb

Sheep of any sex under 1 year of age

Birth

Called lambing, 8-12 lb live weight, processed 2-5 days (introduced to flock), tail docked, castrated via hot knife, band, or surgical means

Weaning

Weaned at 60-90 days of age

Feed Lot

Finishing weight 120-140 lb