Porcelain Fused to Metal Restorations

1/54

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

55 Terms

metal-ceramic restoration

what combines the strength and accuracy of cast metal with the esthetics of porcelain; known for predictable esthetics and sound physical properties, most popular in 1970's and 80's

porcelain fused to metal

consists of a complete cast metal substructure and porcelain veneered for esthetics --> aggressive restoration to mask metal substructure

- esthetics

- long span fixed partial dentures (due to strength at the connectors)

- abutment teeth for removable partial dentures

what are the indications for a PFM

- patients with untreated perio disease

- young patients with large pulp chambers

- bio-incompatibility: some patients are allergic to metals

what are the contraindications for a PFM

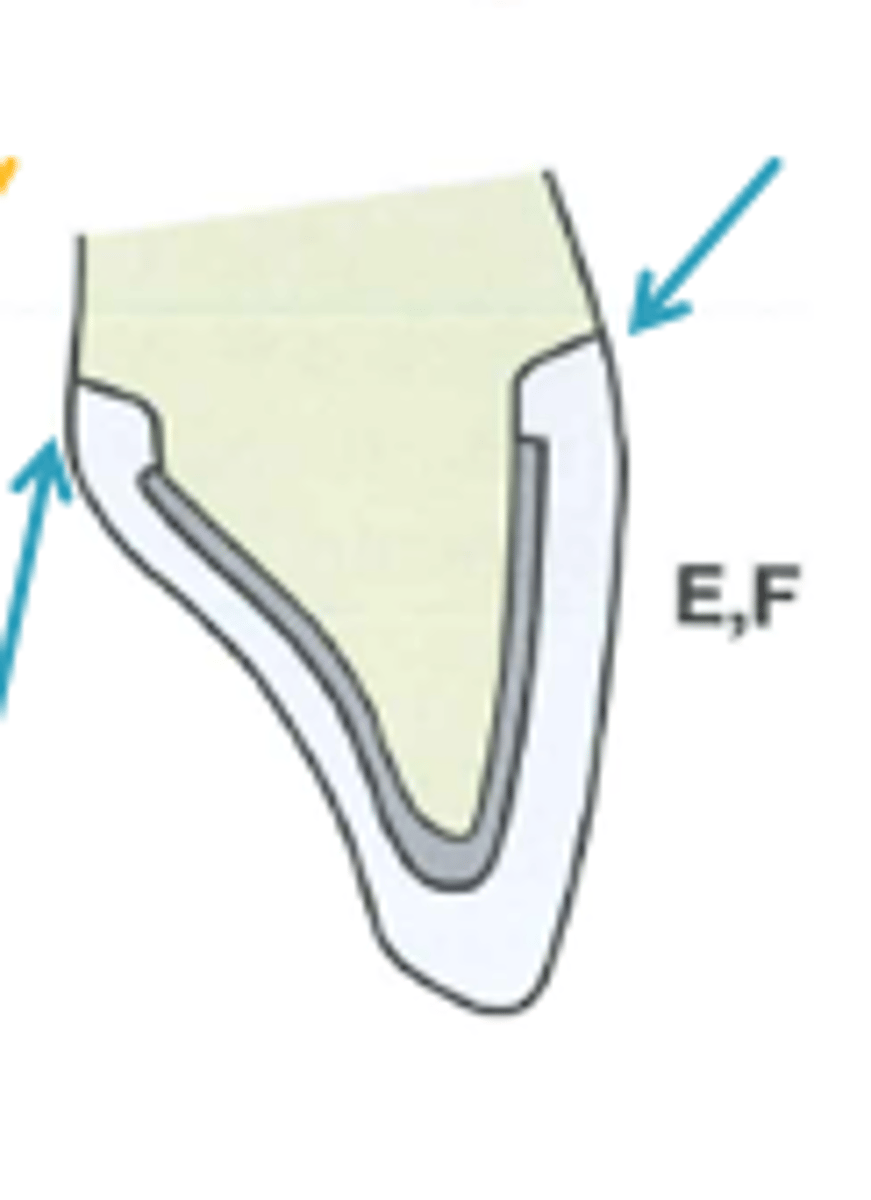

0.3-0.5mm

how thick is the metal coping layer of a PFM

opaquer

layer of a PFM the conceals the metal and develops bond between metal and porcelain

0.8-1mm

how thick is the body and incisal (or occlusal) porcelain layer of a PFM

1.1-1.5mm

what is the overall required thickness for porcelain veneered surfaces

dentin

what does body porcelain represent that is more opaque

enamel

what does the occlusal porcelain represent that is more translucent

no function on the junction

what is the saying to determine where the junction of metal and porcelain should be placed in reference to occlusion

1.5mm

how far away should the metal-ceramic interface be from all centric occlusal contacts

color of the underlying body and opaque porcelain

what significantly influences the perceived color of the PFM restoration

gold based

palladium based

what are the noble metal casting alloys for PFM that have good corrosion resistance due to inherent nobility

nickel

cobalt

chromium

titanium

what are the base metal casting alloys for PFM

nickel

cobalt

what are the principal elements of base metal casting alloys for a PFM

chromium

titanium

what base metal casting alloys oxidize rapidly and prevent diffusion of oxygen into the underlying metal (protects it from corrosion) but these oxides could cause greenish color of porcelain

silver

copper

gallium

what may also be included in base metal casting alloys that are not noble metals and could cause greening of porcelain if present

oxide layer

what forms during casting and should be partially removed (either by acid or airborne particle abrasion with aluminum oxide)

controlled oxide layer

what creates surface irregularities to help with mechanical bond besides chemical bond between porcelain and metal (want this to be thin after partially removing)

manufacturers incorporate small amounts of certain base metals that form ___ to aid chemical bonding to metal-ceramic adherence

linear coefficient of thermal expansion

what must closely match between the metal and ceramic to achieve a strong interfacial bond

porcelain-alloy bonding

"wetting" the alloy surface by the porcelain slurry at the firing temperature (opaque layer)

dental porcelain

chemically speaking are glass:

- quartz (SiO2)

- Feldspar (potassium aluminum silicate, orthoclase, sodium aluminum silicate albite)

- other oxides

- a firing temp well below the melting range of the metal

- a significantly high thermal expansion compatible with the metal

what are 2 requirements for porcelain that will be fused to a metal for a PFM

if oxide layer not formed

what is a mode of failure of porcelain-metal restorations

fracture during bisque bake

what failure is caused by:

- improper condensation

- improper moisture contol

- poor framework design

- incompatible metal-porcelain combination

bubbles

what failure is caused by:

- too many firings

- air entrapment during buildup of restoration

- improper moisture control

- poor metal preparation

- poor casting technique

unsatisfactory appearance

what failure is caused by:

- poor communication with technician

- inadequate tooth reduction

- excessive thickness of opaque porcelain

clinical fractue`

what failure is caused by:

- excessive firing

- poor framework design

- centric stops too close to metal-ceramic interface

- improper metal preparation

1.5mm

how much occlusal reduction is necessary for a metal occlusal PFM

2.0mm

how much occlusal reduction is necessary for a porcelain occlusal PFM

1.5-2mm

how much occlusal reduction is necessary for combination occlusal PFM

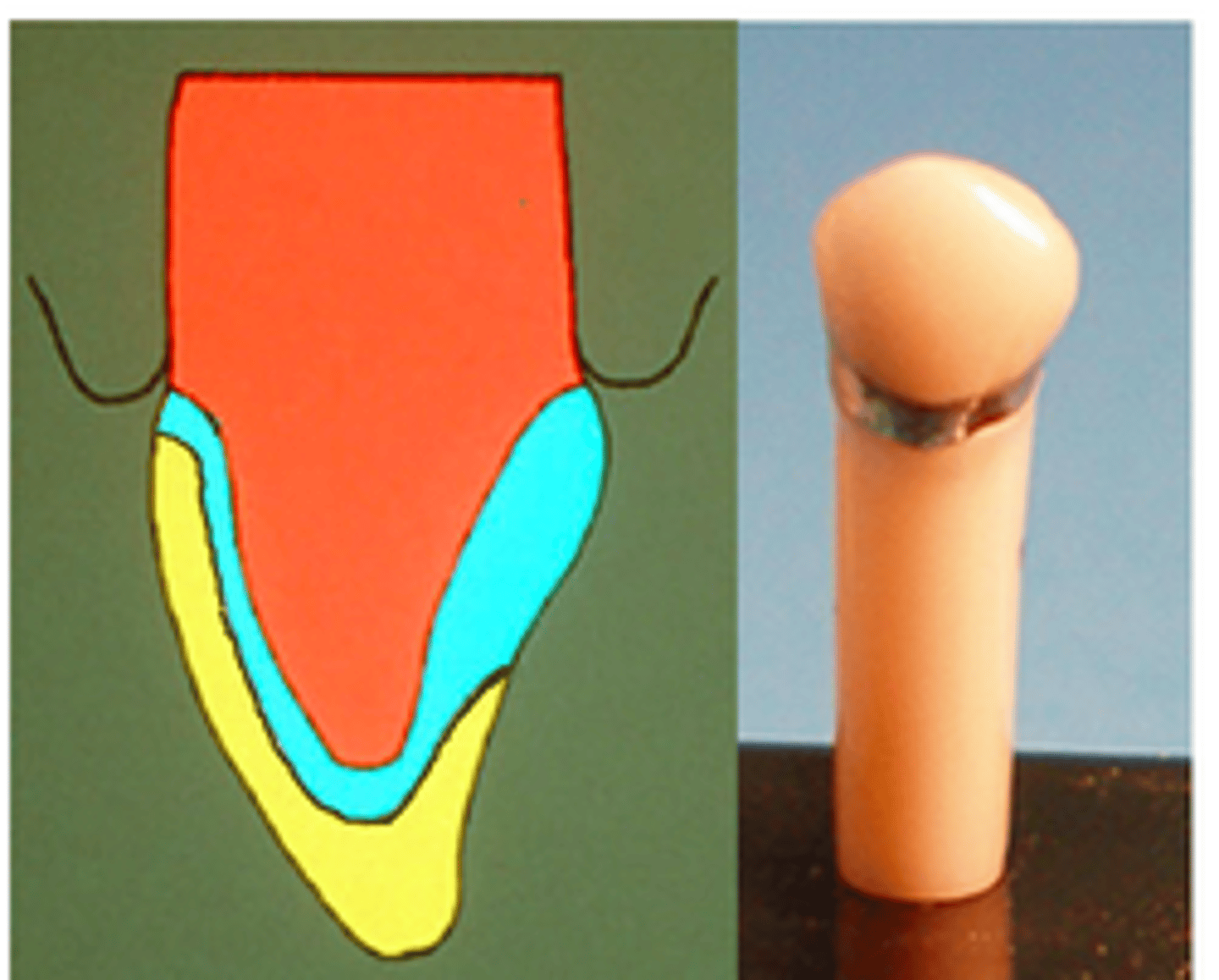

metal collar margin

what type of PFM margin is this called (usually on the lingual)

- disappearing metal margin

- porcelain margin

- metal collar margin (on lingual usually)

what are the 3 kinds of margins for a PFM

disappearing metal margin

what PFM margin has a combination of metal and porcelain that should have a 120 degree sloped shoulder margin

- usually on the buccal to conceal the metal portion of a PFM

120 degrees

how sloped should the shoulder of a disappearing metal margin be?

90 degrees

how sloped should the shoulder of a porcelain margin be?

porcelain margin

what PFM margin is used when better esthetics are desired

conservation

avoid weakening of the tooth

resistance

prevent dislodgment apical or obliquely directly forces

retention

prevent displacement along the path of insertion or long axis of the tooth

structural durability

provide adequate reduction for material strength

margin

proper finish line for close adaptation; minimize leakage

periodontium

provide proper shape and contours for optimal periodontal health

1/3 buccal axial wall

how large is the aesthetic bevel and where is it placed

878-012

878-014

878-016

What are the numbers for a chamfer bur?

chamfer margin

what margin is used for the lingual margin of the #4 PFM prep

functional bevel

what provides adequate space and thickness of the restorative material on the area of significant functional loading

mesial contact

how far in the buccal margin extended interproximally since its more visible?

847-016 (flat end taper)

what bur is use to establish the 120 margin for a disappearing metal margin

10839-012

10839-014

10839-016

what are the codes for end cutting burs to establish your 120 degree sloped margin

just lingual to the contact

where is the mesial shoulder to chamfer transition for the 14 PFM prep

just lingual to the DB line angle

where is the distal shoulder to chamfer transition for the 14 PFM prep

847

what bur do you use for the facial margin of a PFM prep

878

what bur do you use for the lingual margin of a PFM prep