AC STRUCTURES. WELDING PROCESSES

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

64 Terms

The two most prominent methods of welding aircraft structures and components are ____ and _____

fusion

non-fusion

The blending of compatible molten metals into one common part or joint

Fusion Welding

Fusing of metals is accomplished by producing sufficient ____ for the metals to melt, flow together and mix

heat

The heat is then removed to allow the fused joint to ____

solidify

Is the joining of metals by adhesion of one metal to another

Non-fusion Welding

The most prominent non-fusion welding processes used on aircraft are ____ AND ____.

brazing

soldering

IS THE SINGLE MOST IMPORTANT CHARACTERISTIC OF A GOOD WELD

PROPER PENETRATION

2 TYPES OF FUSION WELDING PROCESSES

• Gas Welding

• Electric Arc Welding

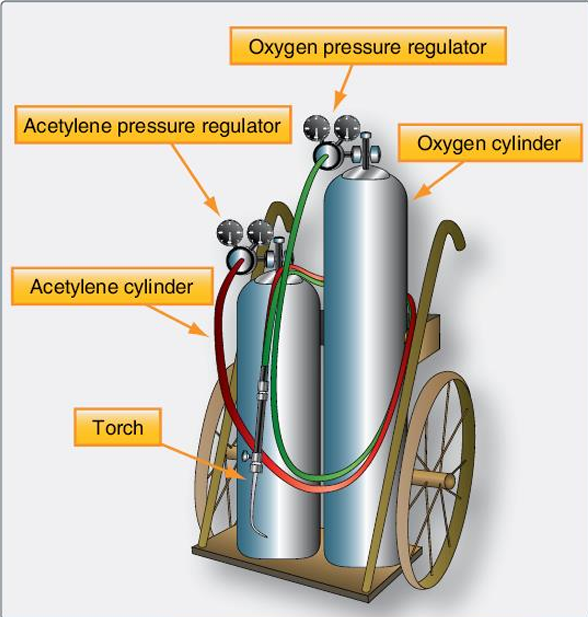

Often referred to as oxyacetylene welding, gets its name from the two gases, oxygen and acetylene, that are used to produce a flame

Gas Welding

______ is the fuel for the flame and _____ supports combustion and makes the flame hotter

The combination of these two gases results in sufficient heat to produce molten metal

Acetylene

oxygen

The temperature of the oxyacetylene flame ranges from _____ TO ______

5,600 to 6,300F

AIRCRAFT STEEL TUBINGS ARE WELDED USING WHAT TYPE OF WELDING

GAS WELDING

is used extensively by the aircraft industry in both the manufacture and repair of aircraft.

It can be used satisfactorily to join all weldable metals, provided that the proper processes and materials are used

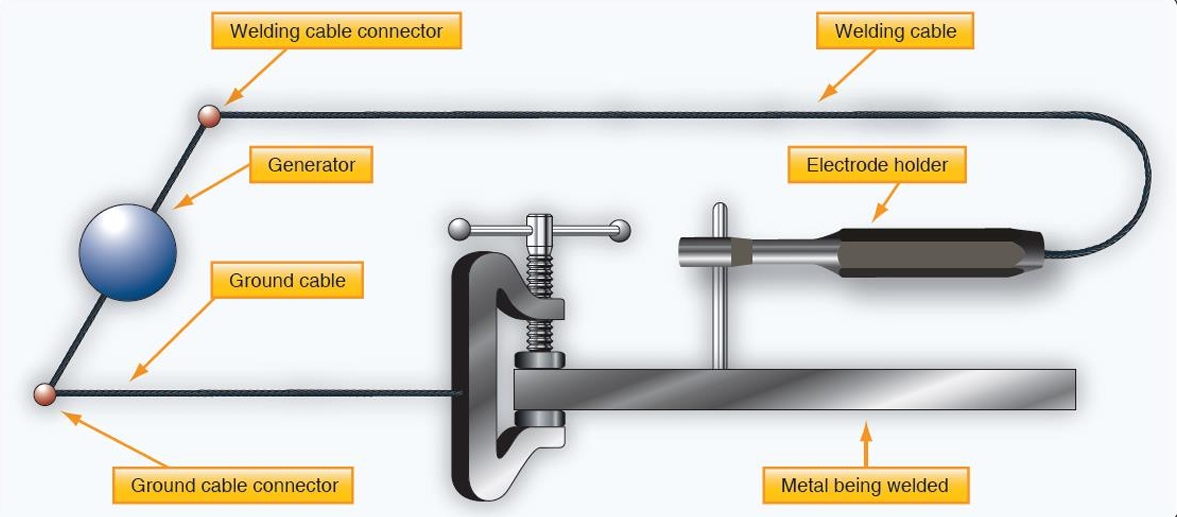

Electric Arc Welding

When electricity has sufficient voltage to ___ across the space between an electrode to an area of different electrical potential, heat is produced from the movement of electrons

arc

The amount of heat is predominantly determined by the amount of ____ flowing across the gap

current

For all types of arc welding, a ____ OR _____ unit is used to produce and control electrical power

transformer/rectifier

this welding produces a blinding light, with infrared and ultraviolet rays, which can burn both skin andeyes

Electric Arc Welding

ELECTRIC ARC WELDING

3 types of electric arc welding

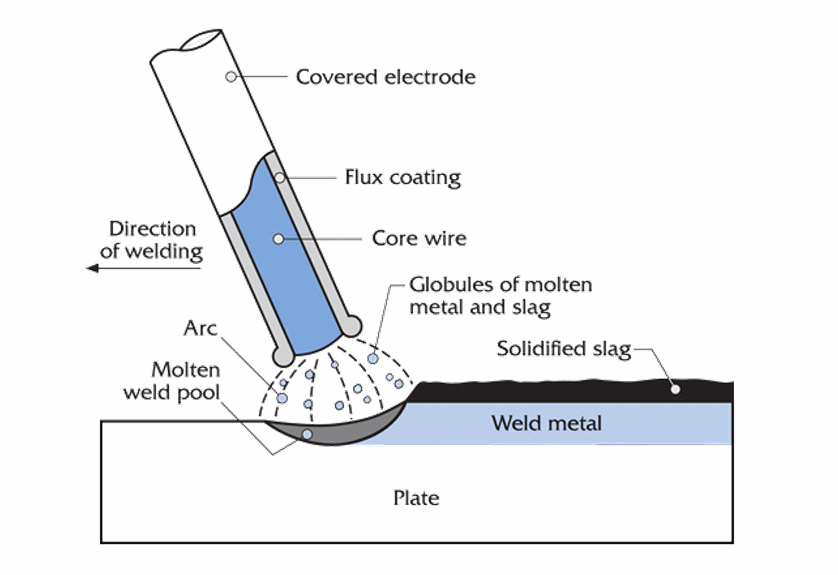

• Shielded Metal Arc Welding

• Gas Metal Arc Welding

• Tungsten Inert Gas Welding

Shielded metal arc welding (SMAW), or_____, is the most common type of arc welding.

You may find stick welding useful for fabricating tools and shop equipment, but it is not generally used for the fabrication or repair of aircraft

stick welding

In SMAW welding, a metal wire rod, which is composed of approximately the same ______ as the metal to be welded

chemical composition

is normally used for welding heavy gauge steel

it is seldom used in aircraft construction or repair

SMAW

SMAW

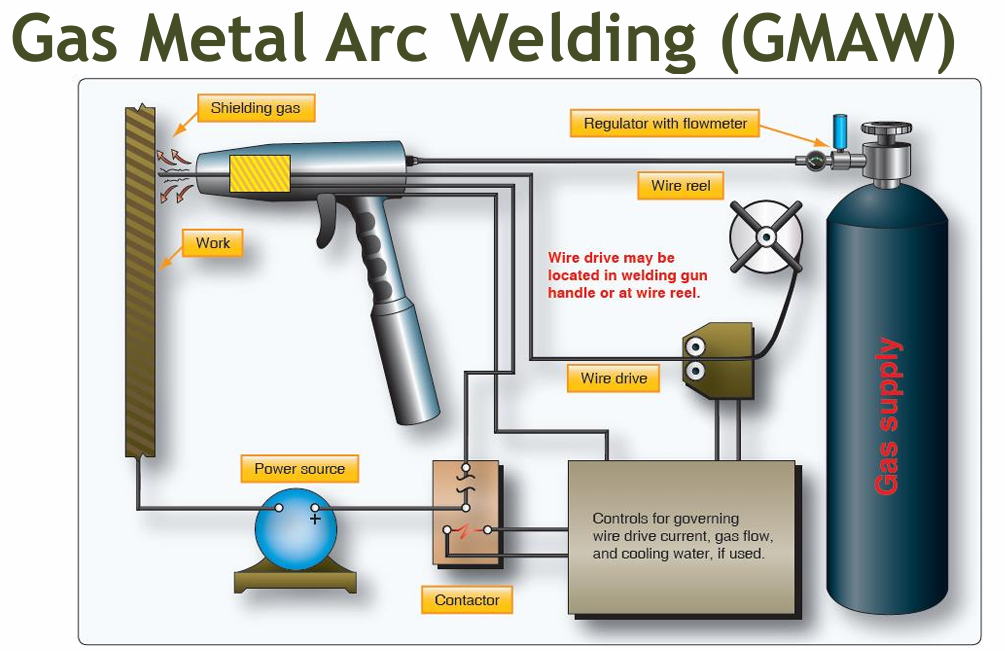

Gas Metal Arc Welding (GMAW) AKA

Metal Inert Gas (MIG)

Used primarily in large volume production work.

Gas Metal Arc Welding (GMAW)

GMAW

WHAT IS THE ADVANTAGE OF GMAW TO SMAW

no slag is deposited on the weld bead

An ______ acts as the electrode.

uncoated filler wire

An inert gas such as ____, ______ or ______ flows out around the wire to protect the weld zone from oxygen

argon

helium

carbon dioxide

When power is supplied to the electrode, and it is brought into contact with the work, it produces an arc, which melts the ____ and the _____

metal

filler wire

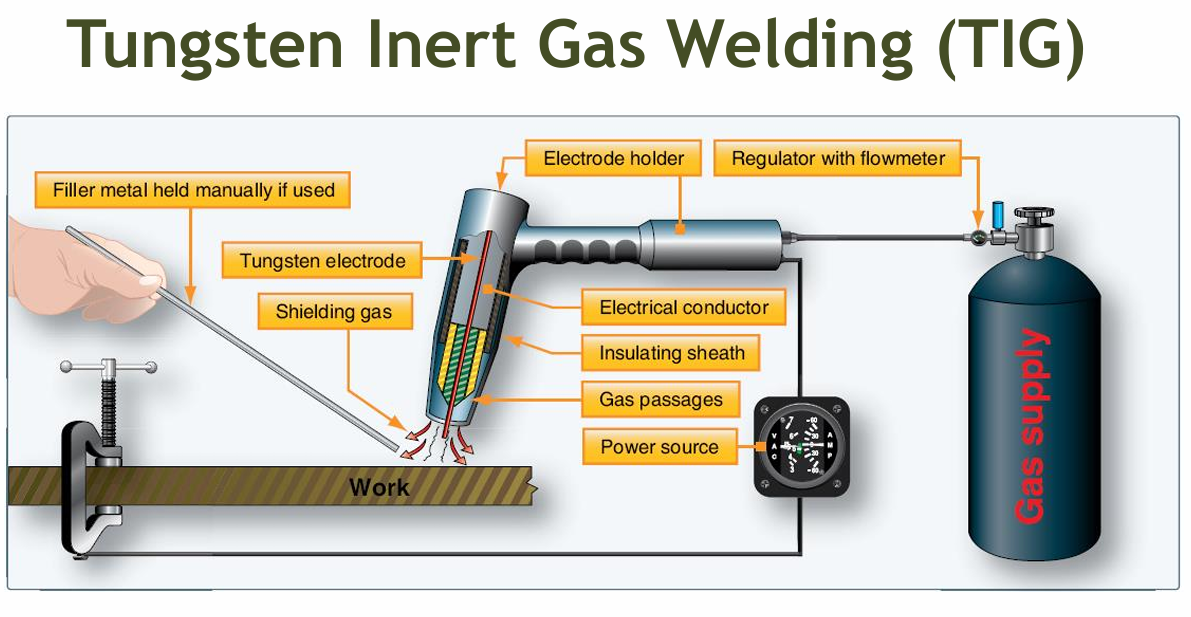

Tungsten Inert Gas Welding (TIG) IS ALSO KNOWN AS

gas tungsten arc welding (GTAW)

TIG

2 TRADE NAMES OF TIG WELDING.

These trade names were derived from the fact that the inert gas originally used was helium

Heliarc

Heliweld

TIG is the preferred method to use on______, ______, and most forms of thick ______.

stainless steel

magnesium

aluminum

The result of a weld is a

joint

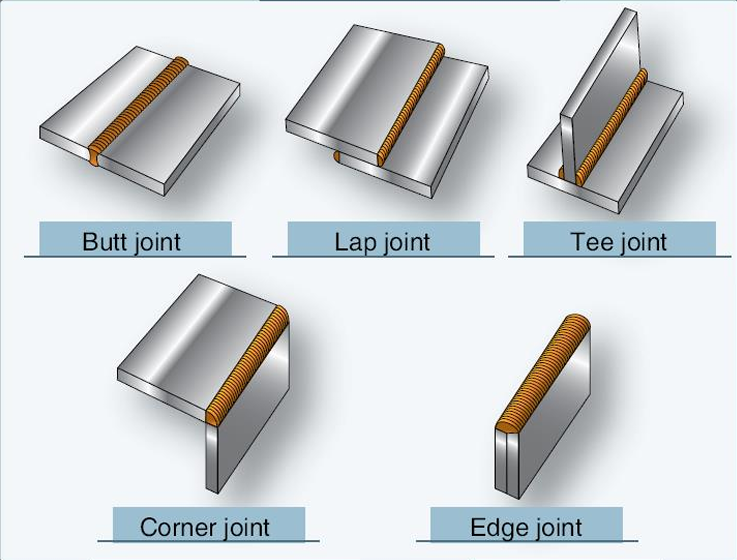

5 Types of Welded Joints

BUTT JOINT

TEE JOINT

LAP JOINT

CORNER JOINT

EDGE JOINT

Made by placing two pieces of material edge to edge, without overlap, and then welding

Butt Joint

joints generally are not used for joining tubing because they are too weak for aircraft structures

Butt Joint

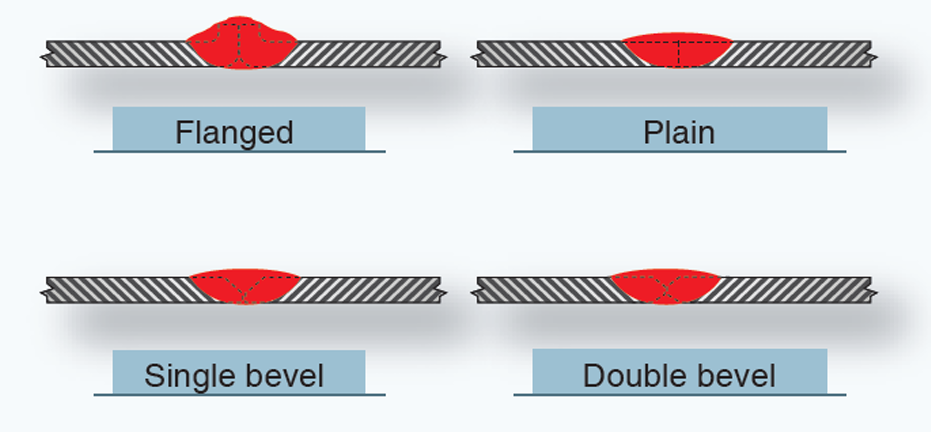

A plain butt joint is used for metals from ___ inch to ___-inch in thickness.

1/16

1/8

The flanged butt joint can be used in welding thin sheets, _____

1/16- inch or less

Abevel butt joint is used for metals thicker than ___-inch

1/8

4 TYPES OF BUTT JOINT

Seldom used in aircraft structures when welding with oxy-acetylene, but is commonly used and joined by spot welding

Lap Joint

joint has very little resistance to bending, and cannot withstand the shearing stress to which the weld may be subjected under tension or compression loads

SINGLE LAP JOINT

2 TYPES OF LAP JOINT

Formed when the edge or end of one piece is welded to the surface of another

Tee Joint

These joints are quite common in aircraft construction, particularly structures

Tee Joint

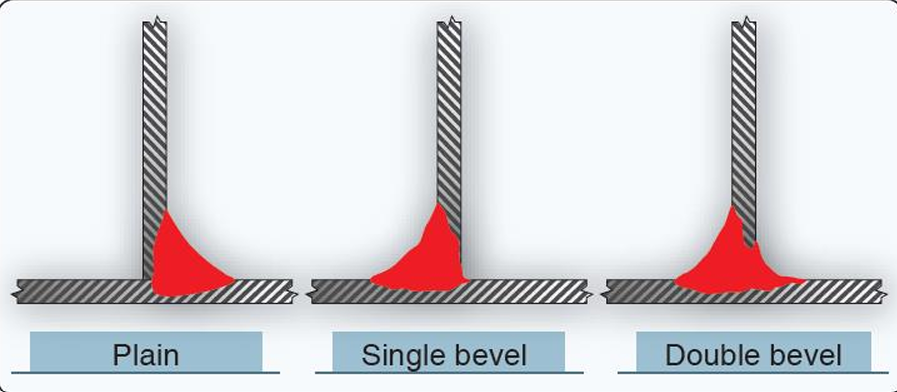

The______ is suitable for most thicknesses of metal used in aircraft, but heavier thicknesses require the vertical member to be either ___ or ____ to permit the heat to penetrate deeply enough

plain tee joint

single OR double beveled

3 TYPES OF TEE JOINT

Made when twopieces of metal are brought together so that their edges form a corner of a box or enclosure

Corner Joint

3 TYPES OF CORNER JOINT

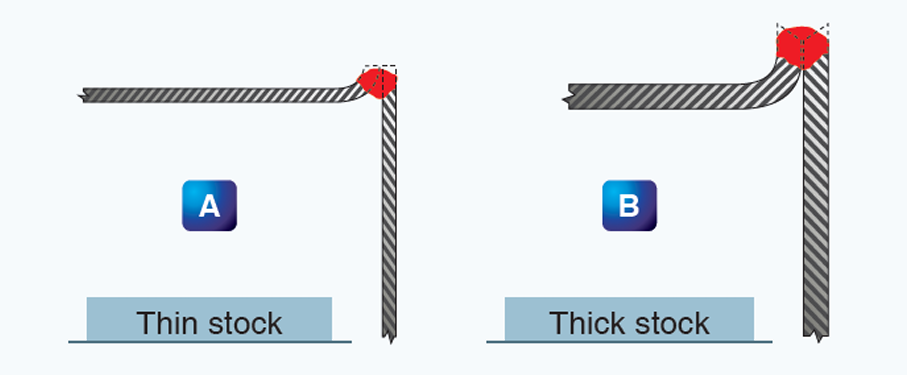

Figure 5-44A used where the load stress is not important

The type shown in Figure 5-44B is used on heavier metals, and filler rod is added for roundness and strength

If a higher stress is to be placed on the corner, the inside is reinforced with another weld bead. Figure 5-44C]

![<p>Figure 5-44A used where the load stress is not important</p><p></p><p>The type shown in Figure 5-44B is used on heavier metals, and filler rod is added for roundness and strength</p><p></p><p>If a higher stress is to be placed on the corner, the inside is reinforced with another weld bead. Figure 5-44C]</p>](https://knowt-user-attachments.s3.amazonaws.com/bbe7b24f-2bfe-4693-b33c-0ba360a1f38f.png)

Used when two pieces of sheet metal must be fastened together and load stresses are not important

Edge Joint

are usually made by bending the edges of one or both parts upward, placing the two ends parallel to each other, and welding along the outside of the seam formed by the two joined edges

Edge Joint

2 TYPES OF EDGE JOINT

The joint shown in Figure 5-43A requires no filler rod since the edges can be melted down to fill the seam.

The joint shown in Figure 5-43B, being thicker material, must be beveled for heat penetration; filler rod is added for reinforcement

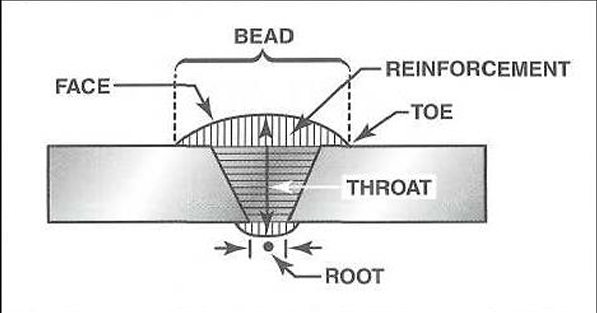

IS THE METAL THAT IS DEPOSITED AS THE WELD IS MADE

BEAD

IS THE EXPOSED SURFACE OF THE WELD

FACE

IS THE DEPTH THAT FUSION PENETRATES INTO THE BASE METAL

ROOT

IS THE DISTANCE THROUGH THE CENTER FROM THE ROOT TO THE FACE

THROAT

IS THE EDGE FORMED WHERE THE FACE OF THE WELD MEETS THE BASE METAL

TOE

IS THE QUANTITY OF THE WELD METAL ADDED ABOVE THE SURFACE OF THE BASE METAL

REINFORCEMENT

Parts of Welded Joints

IS THE QUANTITY OF WELD METAL ADDED ABOVE THE SURFACE OF THE BASE METAL

REINFORCEMENT