Materials Science Exam II

1/42

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

43 Terms

Heat treating a metal that has been cold work means the effects of the cold work are __________.

Nullified

The word for heat treating a metal that has been cold worked.

Annealing

Three annealing stages

Recovery, Recrystallization, Grain Growth

During the recovery stage of annealing, there is a reduction and then annihilation of….

Dislocations

Form of shear, includes a drive shaft

Torsion

Torsion equation

Moment x 1/Area x 1/Radius

Simple Compression Equation

F x 1/Area

Tensile strain is in what direction?

y

Lateral strain is in what direction?

x

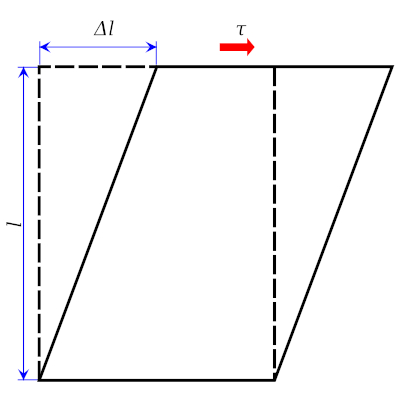

This is what type of deformation?

Shear strain

Reversible type of deformation

Elastic

Type of deformation with a linear stress/strain curve

Elastic

The slope of a stress/strain curve, E

Modulus of Elasticity

The elastic modulus of a material depends on what?

Interatomic bonds

Elastic moduli for materials are related only if those materials are what?

Isotropic

Permanent, nonrecoverable deformation

Plastic

Name for the maximum stress on an engineering stress-strain curve.

Tensile strength

For metals, the maximum on a stress-strain curve appears at the onset of noticeable…

Necking

The name for the amount of plastic deformation at failure.

Ductility

Ability of a material to absorb energy during elastic deformation

Resilience

Modulus of resilience for a linear stress-strain curve.

½ x stress x strain

The amount of energy absorbed before fracture.

Toughness

True Stress Equation

Stress(1 + strain)

True Strain Equation

ln(1 + strain)

True Stress, by definition

Force x 1/Instantaneous Area

True strain, by definition

ln(li / lo)

True stress in terms of true strain

True stress = K(true strain)^n

A material with a larger n (strain-hardening exponent) will experience (more/less) true stress compared to a material with a smaller n.

More

Reasons why ceramics are brittle

Dislocation motion (difficult when highly ionic)

Few slip systems

Resistance between like anions/cations

Order these from most ductile to least ductile.

Polymer, Elastomer, Plastic

Polymer, Plastic, Elastomer

Decreasing temperature (increases/decreases) modulus of elasticity.

Increases

Decreasing temperature (increases/decreases) tensile strength.

Increases

Decreasing temperature (increases/decreases) elongation %

Decreases

Increasing strain rate has what effects, as compared to decreasing temperature?

Same

Measure of resistance to surface plastic deformation (dent or scratch)

Hardness

GO OVER ROCKWELL VS BRINELL HARDNESS

Tm and Tg ___________ with increasing chain stiffness

Increase

Increasing chain stiffness

Bulky side groups

Polar groups

Double bonds and aromatic chain groups

The more random a polymers structure is, the _____ it is to form its crystalline structure.

Harder

Regularity of repeat unit arrangements affect (Tm or Tg) only.

Tm

Larger crystals are closer to ideal, and therefore have a _____ melting point.

Higher

Polymers with many imperfections are less crystalline and therefore have a _____ melting point.

Lower

Thermoplastics

Little crosslinking

Ductile

Soften with heat (remolding)