MME 231 Quiz 3

1/61

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

62 Terms

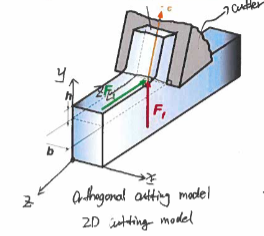

Orthogonal Cutting

the cutter edge is perpendicular to the cutting direction

2d cutting

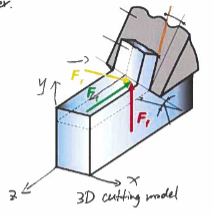

3d cutting

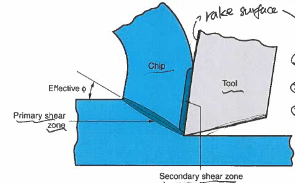

chip formation

Conditions of generating continuous chips

ductile workpiece material, high constant cutting speed

Continuous Chip Advantage

good surface finish

Continuous Chip Disadvantage

tends to entangle around cutting tool

Continuous chip strain hardening

chips are harder and stronger than original workpiece

Chip breaker

integral part of the cutter

Continuous chip with build up edge

material from workpiece deposits on tool forming BUE

Continuous chip with build up edge Conditions

ductile materials, medium cutting speed

CC BUE is affected by

adhesion of workpiece material to rake face of tool

CC BUE can be reduced by

increase cutting speed and decrease depth of cut

Serrated Chips

chips with the appearance of saw teeth

Conditions for generating discontinuous chip

lack of cutting fluid

Cutting tool characteristics

High toughness, wear resistance

Right Hand Cutting Tool

high hardness and wear resistance, only replace insert

Tool life

the duration of time a cutting tool can be used before it becomes ineffective

Tool wear

determines tool life

Three modes of tool failure

fracture failure, temp failure, gradual wear

Gradual wear

preferred as it leads to the longest possible use of the tool

Gradual wear occurs at

both rake surface and flank surface

Flank wear

a prevalent wear that is measured as the average flank bandwidth of wear

Flank wear reasons

sliding of the tool along machined surface which causes abrasive tool wear

Flank wear side effects

loss of dimensional accuracy, deteriorated surface finish

Crater wear reasons

sliding of the chip up the rake face, high localized stress

Notch wear

excessive localized damage on the rake face and flank face

Notch wear reasons

tool rubs against the shoulder of the workpiece causing a small amount of the cutter to adhere to the workpiece

Edge chipping

sudden breakage of a piece from the cutting edge of the tool

Causes of chipping

mechanical shock and thermal fatigue

Catastrophic failure reason

tool made with brittle material

Catastrophic failure solution

cutting fluid

vT^n = C

ln(v) + n ( ln(T) ) = ln(C) -> ln(v) = - n ( ln(T) ) + ln(C)

Cutting fluids

any liquid or gas applied directly to the machining operation to improve cutting performance

Main functions of cutting fluids

Cooling, lubrication, chip removal

Cutting fluids advantages

reduces cutting force and temp of workpiece

Cutting fluid coolant

reduces the effects of heat

Cutting fluid lubricants

reduces tool chip and tool workpiece friction

Methods of applying cutting fluids

flood cooling, mist cooling

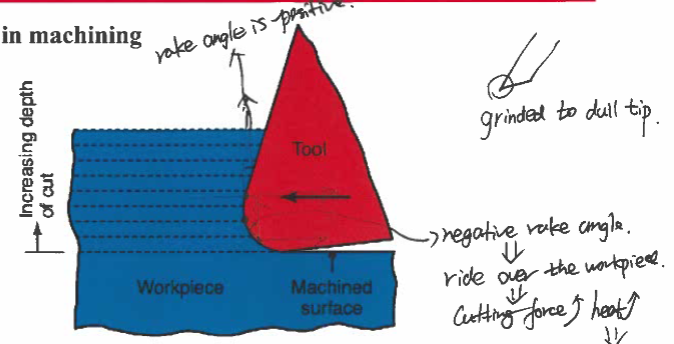

surfaces in machining

Negative rake

rides over the workpiece leading to an increase in the cutting force and workpiece temp

Negative rake angle leads to

cracks and residual stress

surface roughness, top areas = bottom areas

Rz (Rmean)

highest point - lowest point

Ra

arithmetical mean roughness

Ra =

( integral 0 L abs [ z(x) ] dx) / L

Rmax =

f^2 / 8R

Ra (arithmetic average) ≈

f^2 / 32R

Process parameters surface roughness factors

low cutting speed leads to discontinuous chip formation which cracks surface

Unstable continuous chip w/ BUE surface roughness factors

heavily strain hardened fragments are welded to the surface

Edge chipping, tool wear and dull cutter tip leads to an

increase in surface roughness in transverse direction

Vibration/chatter

introduces variation in surface geometry

Surface integrity

pertains to properties that effect the generated surface

Surface integrity improvments

small depth of cut

Machinability

the ease at which the material can be machined

High Machinability Effects

long tool life, good surface finish

Poor machinability factors

high hardness, strength and ductility

Forced vibrations

the sustaining alternating forces exist independent of motion

Chatter

the alternating force that sustains the motion is created by the motion itself

Forced vibrations solutions

isolate and remove forcing elements

Chatter solutions

damping

Damping

The rate at which vibrations decay