MIE 270: Final (Part 2: Composite and Magnetic Materials)

1/40

Earn XP

Description and Tags

Chapters: 15 and 18 Does not include equations only theory

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

41 Terms

Composites

Multiphase materials

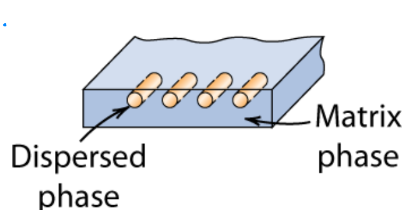

Composites: Matrix Phase + Dispersed Phase

Matrix helps retain shape and transfers stresses to the reinforcement

Matrix-based Classification

Polymer-matrix composites (PMC)

GFRP (Glass fiber)

CFRP (Carbon Fiber)

AFRP (Aramid Fiber)

Metal-matrix composites (MMC)

Ceramic-matrix composites (CMC)'

Carbon-Carbon composites

Hybrid Composites

Reinforcement-Based Classification

Particle - reinforced

Large (concrete)

Dispersion (TIny tiny)

Fiber - reinforced

Continuous aligned

discontinuous short

Aligned

Random

Structural

Laminate

Sandwich panels

Large-Particle Composites

Aggregate Size (water-cement)

both affect the strength of concrete

Problems

Very weak in tension

Thermal expansion

Water Permeability

Reinforced Concrete

Rebar/Wired Mesh

Fibers

Post-tensioning or Prestressing

Dispersion - Strengthened

Smaller particles

d = 10-100nm

Particles impede the movement of dislocations

Restrained plastic deformation

σy up, σts up, hardening up

Particles matrix interacuions

Strengthening at the atomic or molecular level

Example

Thorial (thorium dioxide) nickel-chromium, for thermal protection systems (TPS)

Fibre - Reinforced

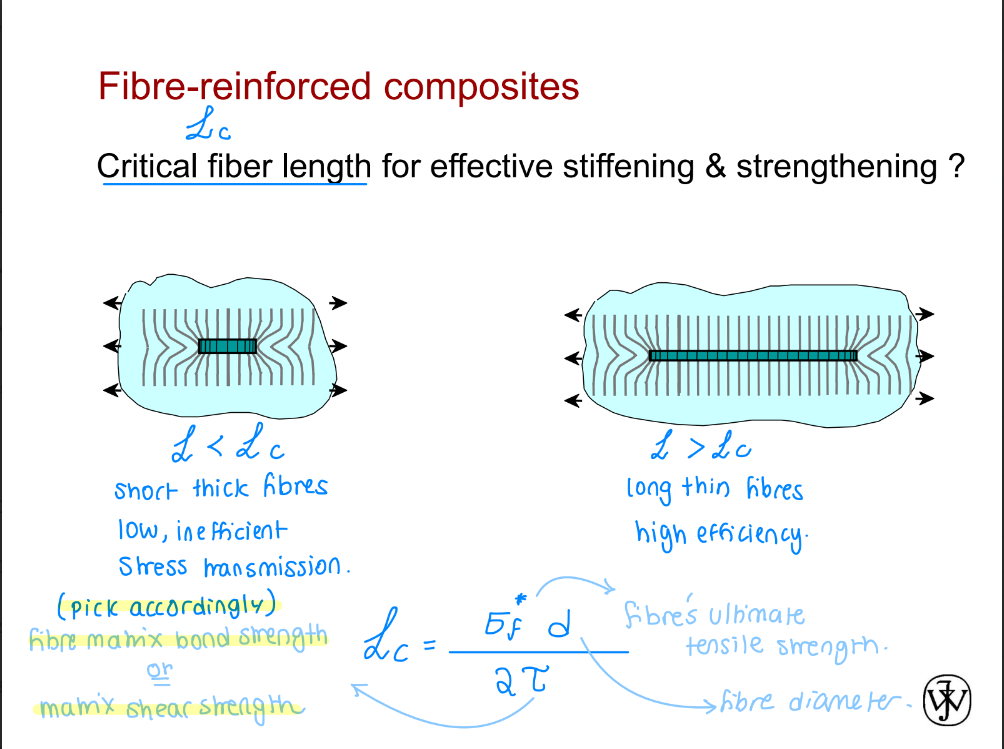

Critical Fiber Length

L < Lc

Short Thick fibers

low, inefficient stress transmission

L > Lc

Long thin fibres

High Efficiency

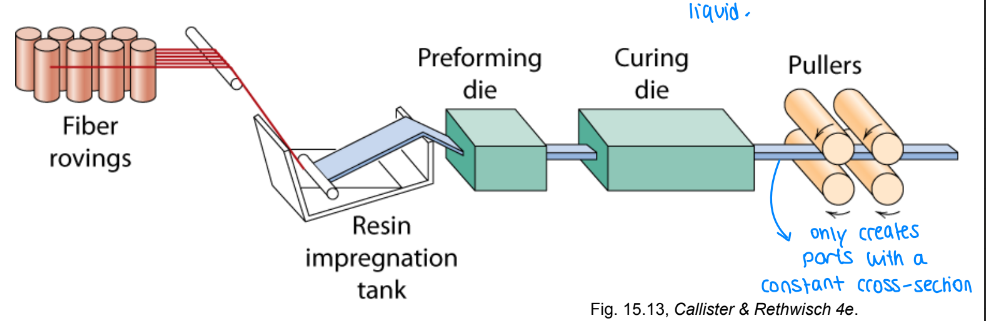

Pultrusion

Fibers pulled through a resin tank (thermosetting resin)

pass through a steel die performing to the desired shape

pass through curing die

machined to the final part

heated to cure resin

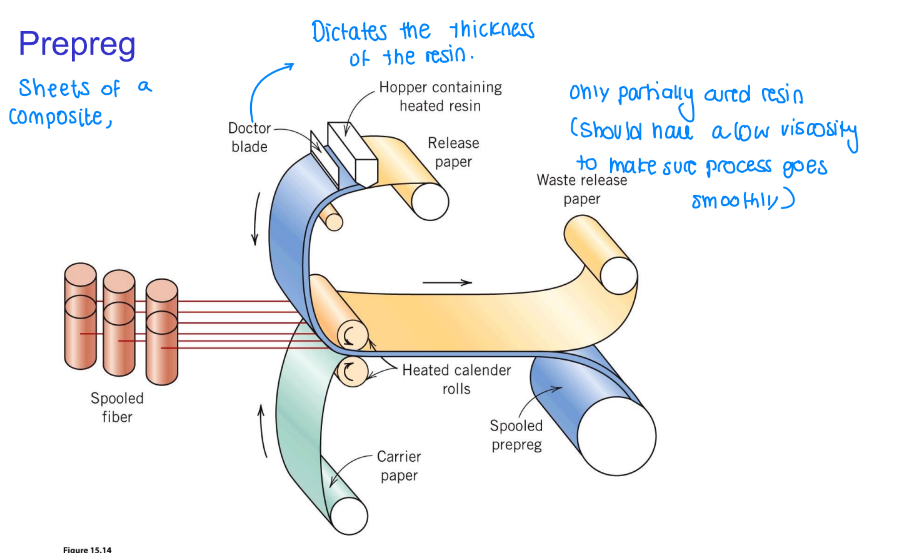

Prepreg - Sheets of a composite

—>

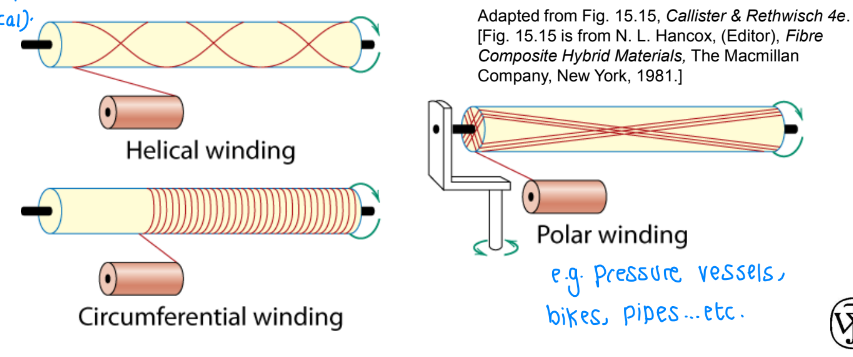

Filament Winding

Fibers are positioned in a predetermined pattern to form a hollow (usually cylindrical) shape.

Fibers are fed through a resin bath (thermosetting resin)

These fibers are then continuously wound onto a mandrel

After layering is complete, curing is carried in an oven or room temp

Mandrel is removed to give the final product

Con: Can’t get fibers to be longitudinal and is limited to closed convex shapes (cylindrical)

Laminates

Unidirectional: 0-degree angle between layers

notation: [0o]# of layers

Crossply: 0 then 90 angle between layers

[0o/90o]# of layers

Angle Ply: 45/-45

[45o/-45o]# of layers

Multidirectional:

[0o/90o/45o/-45o/]# of layers

![<ul><li><p>Unidirectional: 0-degree angle between layers</p><ul><li><p>notation: [0<sup>o</sup>]<sub># of layers</sub></p></li></ul></li><li><p>Crossply: 0 then 90 angle between layers</p><ul><li><p>[0<sup>o</sup>/90<sup>o</sup>]<sub># of layers</sub></p></li></ul></li><li><p>Angle Ply: 45/-45 </p><ul><li><p>[45<sup>o</sup>/-45<sup>o</sup>]<sub># of layers</sub></p></li></ul></li><li><p>Multidirectional:</p><ul><li><p>[0<sup>o</sup>/90<sup>o</sup>/45<sup>o</sup>/-45<sup>o</sup>/]<sub># of layers</sub></p></li></ul></li></ul>](https://knowt-user-attachments.s3.amazonaws.com/80ffcae8-b169-4748-be6c-8af7ccdd70d1.jpeg)

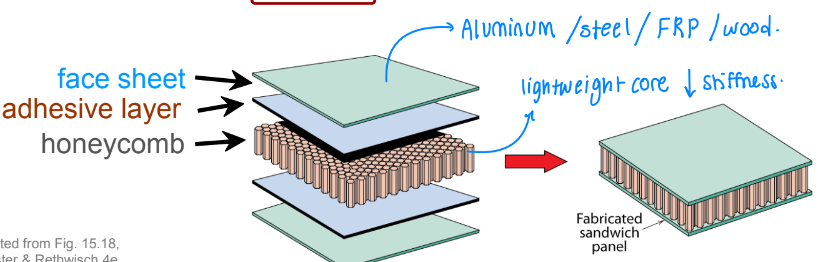

Sandwich Panels

The thickness of the core dictates the overall panel stiffness

With extremely large bending stiffness, it is lightweight and cost-effective

The purpose of the face sheets is to carry bending loads

The core

high shear strength of stiffness to withstand the transverse shear stress of buckling

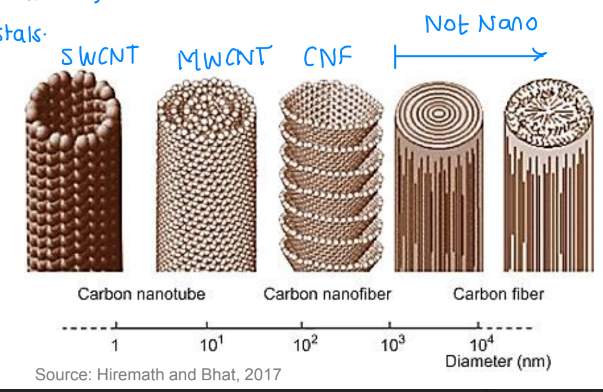

Nanocomposites

Types:

Nanocarbon: can be single-wall carbon nanotubes

Carbon nanofibers

Nanolayers (layered silicates)

Particulate nanocrystals

Nanoparticle Size

decreasing size can eliminate magnetic properties

decreasing size, the surface/bulk ratio increases, and surface phenomena dominates

Applications

Increase in mechanical properties

Challenges

It is hard to achieve adequate dispersion

price

risk of toxic exposure

Magnetic Properties - Concept

To some extent, all materials are influenced by the presence of a magnetic field.

Magnetism: the ability of a material to exert attractive or repulsive forces on a material

Magnetic Forces

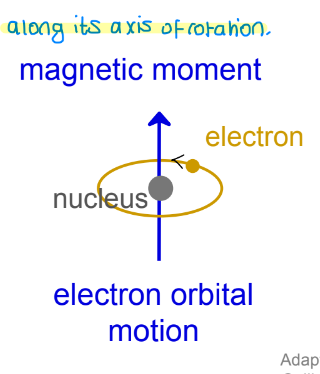

Generated by electrically charged particles

Electron Orbital motion

Electron Spin

Magnetic Field

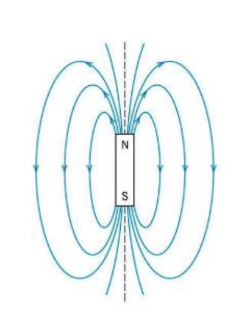

Distribution shown by lines of forces

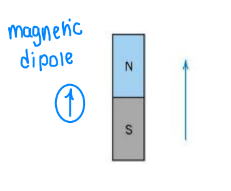

Magnetic Dipoles

Think of very tiny magnets that each have north and south poles

Magnetic induction

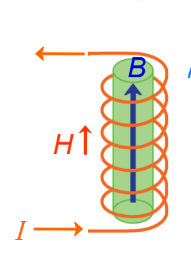

Applied Magnetic Field

Created by current through a coil

H

Externally applied magnetic field strength

B (Magnetic Flux density)

Is internally applied magnetic field due to the material inside the solenoid

Permeability (mu)

measure of the degree to which a material can be magnetized

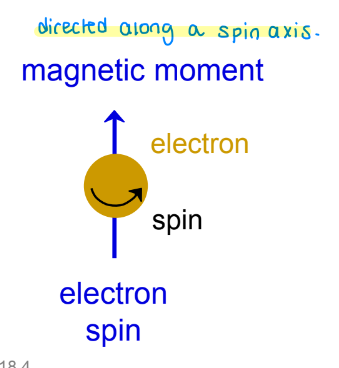

Magnetic Moment

As an electron movies in orbit it generates a magnetic moment. This magnetic moment is along the axis of rotation.

Electron spin

an inherent rotation or spin that electrons have, and it contributes to their overall magnetic properties. Denoted as mu s the magnetic moment is directed along the spin axis.

Net Atomic Magnetic Moment

Sum of all electrons (both spin and orbital)

Fundamental magnetic moment: Bohr Magneton

Types of Magnetism

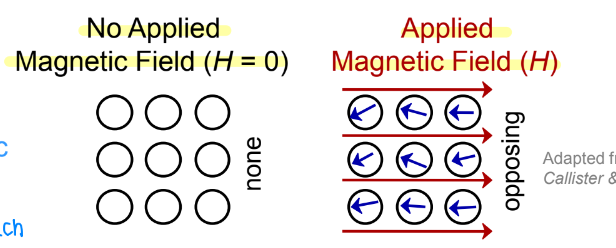

Diamagnetic

Xm < 0

mur <= 1 (just below)

B < Bo

No Magnetic Dipole orbital

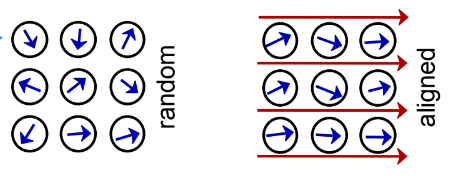

Paramagnetic

Xm > 0

mur >= 1

B > Bo

weak Magnetic Dipole spin

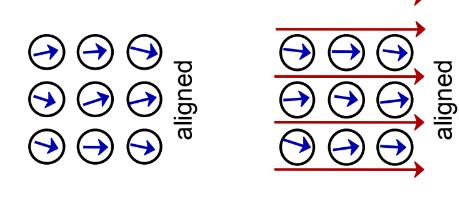

Ferromagnetic

Xm»0

mur»1

B = muoM M = Xr

Diamagnetic (Magnetic Responses)

Paramagnetic (Magnetic Responses)

Ferromagnetic (Magnetic Responses)

Diamagnetic Material

Have no unpaired electrons, hence magnetic moments are all canceled out

Weakly repelled by H

i.e. Au, Ag, Cu, Pb, water, humans, etc.

Paramagnetic Material

Have some unpaired electrons, hence magnetic moments are present

Weakly attracted by H

They lose their magnetization in the absence of a magnetic field

i.e., Al, Ca, Mg, Ti, etc.

Ferromagnetic Material

Spin of all electrons are parallel

Net(spin) magnetic moment

Coupling interactions: Magnetic moments of adjacent atoms to align

Domains: Mutual spin alignment happens over large volume regions

Strongly attracted by H

can be permanently Magnetized

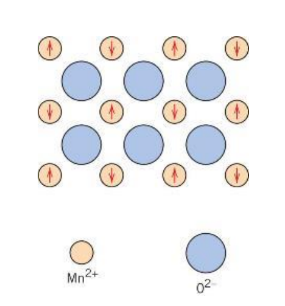

Antiferromagnetic Material

Coupling between adjacent atoms and ions occur in other materials too, but not parallel

aligned in opposite directions, so that the moments cancel out

Material has no net magnetic moment

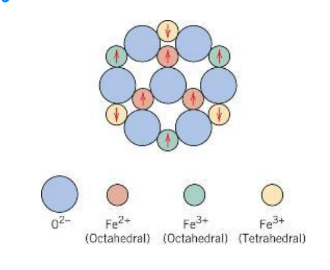

Ferrimagnetic Material

Cubic Ferrites (Fe3O4)

Some ceramics show permanent magnetization

non-parallel spin-coupling interactions

There is net magnetic moment since there is incomplete cancellation of the spin moments.

Good electrical insulators

Ms = Magnetic Saturation, Smaller than in ferromagnets

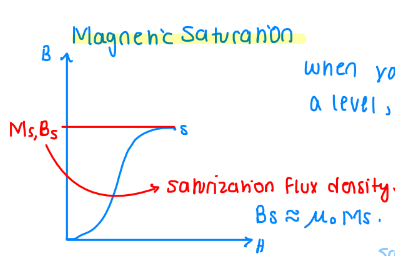

Magnetic Saturation

When you increase H beyond a level, increase in magnetization plateau

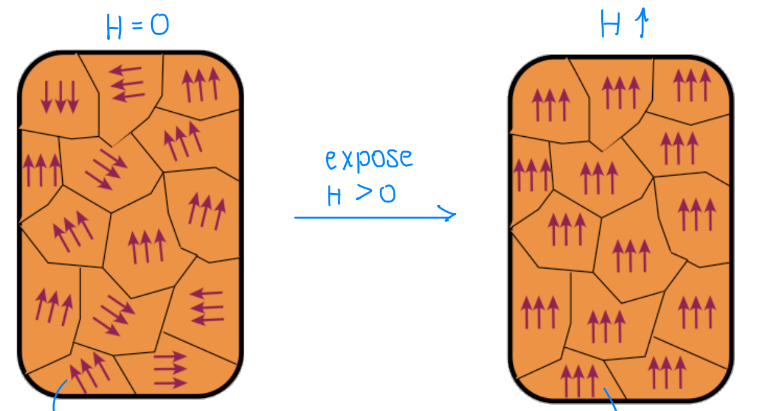

Domains in Ferro and Ferri-magnetic Materials

Before applied H

Mutual alignment of all magnetic dipole moments

After

At Ms , a single domain is oriented with H

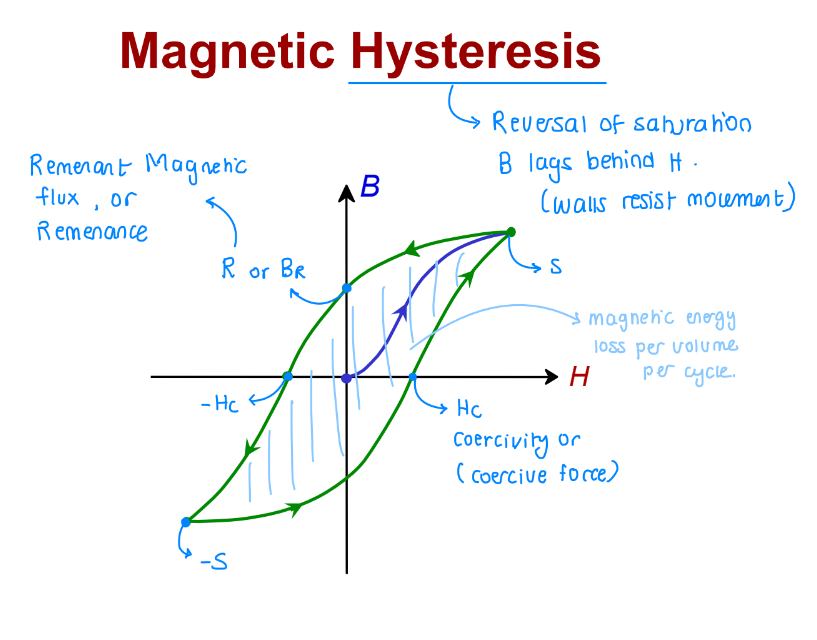

Magnetic Hysteresis

The tendency of a material to retain its magnetization even after the removal of an external magnetic field. It causes a lag between the changes in the applied magnetic field and the resulting magnetization.

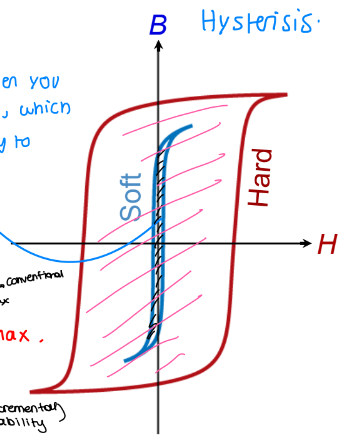

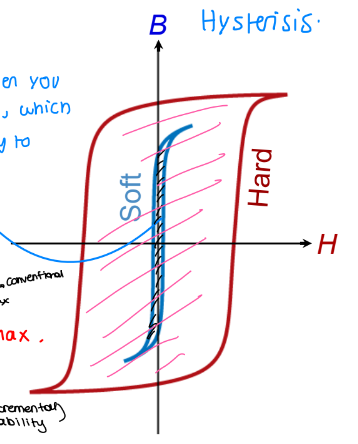

Soft Magnetic Materials

Low energy loss

High initial magnetic permeability

Low H conductivity

Can easily be magnetized and demagnetized with low energy loss

Hard Magnetic Materials

High energy loss

High resistance to demagnetization

Low magnetic permeability

High Hc, Br, Bs (Saturation magnetic flux density)

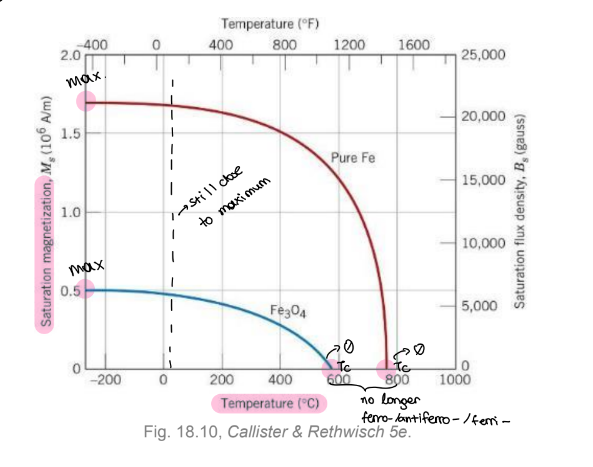

Effects of Temperature on Magnetic Properties 1

When temp increases, the magnitude of thermal vibrations of atoms increases, aligned directions turn to random directions and don’t get magnetized easily.

Ferro, AntiFerro, Ferri magnetic materials

Thermal motions counteract coupling forces between adjacent atoms or dipole moments causing dipole misalignment.

Ms is max when T = 0K

Effects of Temperature on Magnetic Properties 2

At Temp above Tc (curie)

Ferro and Ferri magnetic materials become paramagnetic

Tc (oC)

Fe 768

Co 1120

Ni 335

For antiferromagnetic materials

Tneel (equivalent to Tc)

Magneto strictive

Magnetostrictive: A property of certain materials that exhibit a change in shape or dimensions when subjected to a magnetic field.

used as Sensors

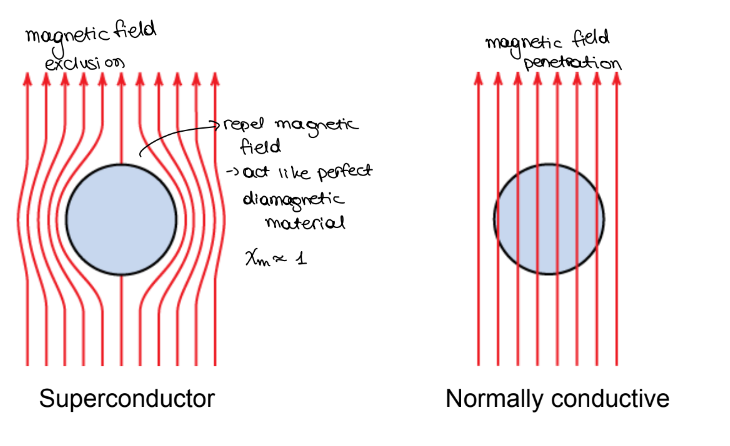

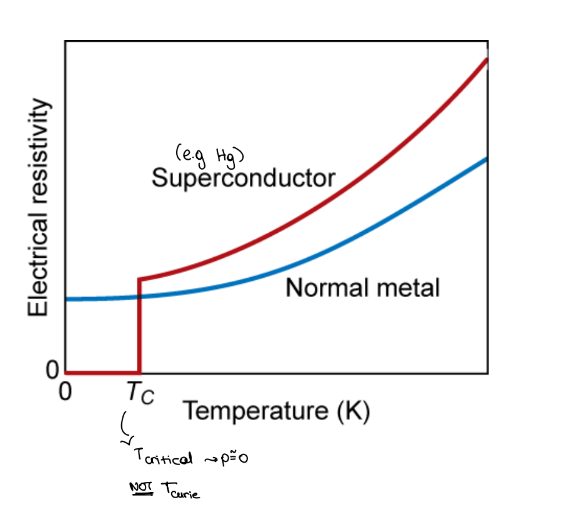

Super Conductivity

The phenomenon where certain materials exhibit zero electrical resistance when cooled below a critical temperature, allowing for the efficient flow of electricity.

Meissner Effect

A phenomenon where a superconductor expels magnetic fields from its interior when cooled below its critical temperature, causing it to levitate above a magnet.