crystal synthesis

1/89

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

90 Terms

what is the shake and bake/ ceramic method?

what does it make?

reagents ground up and heated until they react

whole range of materials including metal oxides, sulphites, nitrides, aluminosilicates etc

how do ions move in shake and bake method?

what does this mean about temperature and speed

reaction ions migrate between and through solid starting materials

slow processes requiring lots of heat

what does high temperature methods give for ceramic method?

what does lower temperature give?

higher = thermodynamic product

lower = kinetic product - lower Ea = faster reaction

why is the ceramic method intrinsically slow?

reagents are not mixed at the atomic level

reaction occurs by solid state diffusion between particles of reactant materials

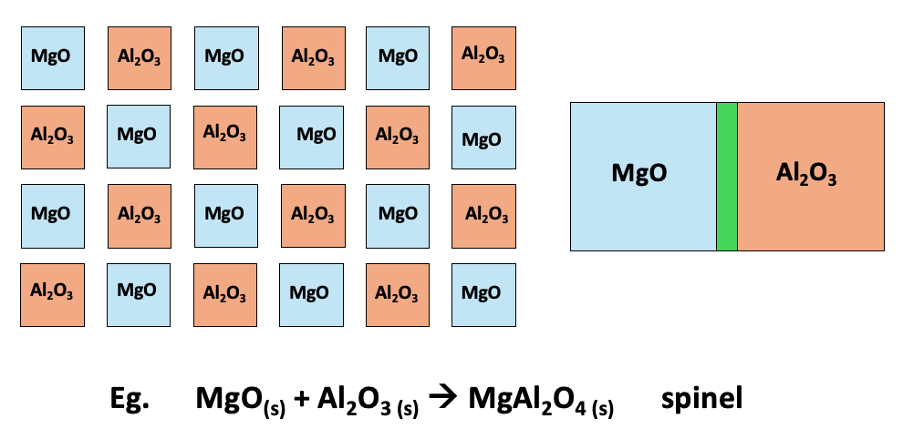

diagram of reaction under ceramic method

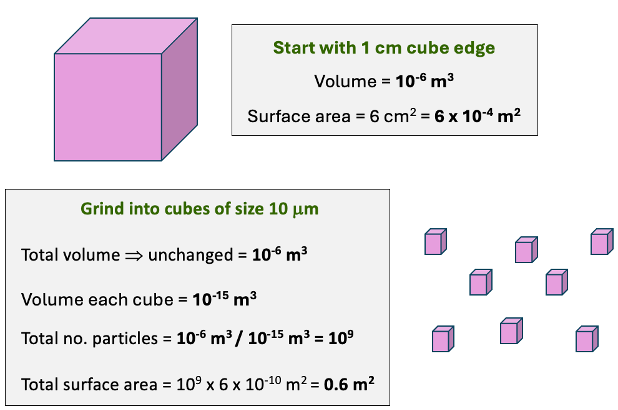

why are reactants ground up in ceramic method?

increases surface area

show volume and surface area for 1cm cube vs 10μm

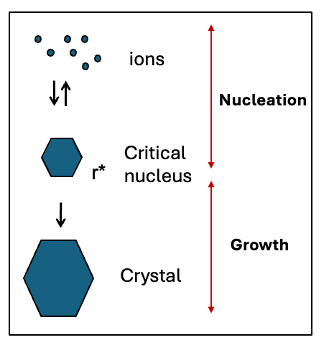

what are the 2 steps in the formation of crystals?

nucleation and growth

what is flow charge of nucleation and growth showing ions to crystal

what is nucleation?

when do nuclei propagate?

formation of stable nucleus of product (which can grow)

nuclei only propagate when they reach critical size (critical nucleus). smaller particles are unstable and redissolve

what can make nucleation occur quicker?

if nuclei can form on another favourable surface (heterogenous) - e.g. if structure of precursor resembles the product

e.g. MgO(s) + Al2O3 (s) → MgAl2O4 (s) spinel

how does growth from MgO support nucleation? what type of growth is it?

both MgO and MgAl2O4 are based on CCP oxide ion arrays

conversion occurs by maintaining same oxide packing

this is topotaxial growth

what is topotaxy?

when a solid state reaction occurs with 3D orientational and structural resemblance between reagent and product crystals

e.g. MgO(s) + Al2O3 (s) → MgAl2O4 (s) spinel

how does growth from Al2O3 affect nucleation? what type of growth is it?

Al2O3 structure is based on HCP oxide ions

nucleation of CCP MgAl2O4 on an HCP surface does not involve direct continuation of HCP lattice - however epitaxial growth occurs

what is epitaxy?

when crystal grows on crystalline substrate, with common in plane crystallographic orientation

there is a 2d correspondence

what is growth?

speed? distance?

after stable nucleus formed, ions diffuse into it from precursors so it can grow

slow but accelerated by high temperatures

even if reagents are finely ground, particles are large on atomic scale = ions diffuse long distances

what happens as grain of structure grows? (distance and speed)

distance the ions need to diffuse (path length) increases and reaction slows down

what is the advantage of the ceramic method?

easy: powder of starting material, combined in crucible

what are the disadvantages of the ceramic method?6

high temperatures needed (500-2000C)

may give incomplete reaction

compound may decompose at high T

little change of kinetic control as using high T (=thermodynamic product)

hard to control microstructure (crystal and grain size)

extremely pure starting materials - has to go completion = hard to purify

why are high temperatures required for ceramic method?

significant amount of energy to overcome lattice energy so cation or anion can diffuse into different site

what are the 4 ways of overcoming diffusion barrier/ intimately mixing reactants?

use reactants with small particle sizes

molecular precursor that has required elements in correct ratio

crystallise from gels (sol gel)

precipitate from solutions of metals (when no high T)

why are heated reactions carried out in sealed tubes? what are they made from?

starting materials/products can be sensitive to environments e.g. oxygen

sealed tubes made from fused silica, alumina or platinum

how are temperatures of 1300 reached?

electric furnaces

how are temperatures of 2300 reached?

electrical resistance heating in metal container - tantalum

passing electric current through sealed tantalum tube

how are temperatures of 4300 reached?

CO2 lasers

special atmospheres

how can higher ox state be prevented

how can higher ox state be formed

how can lower ox state be formed

argon can be used to prevent oxidation to higher ox state

may use oxidising gas (e.g. oxygen) to form high oxidation state

reducing gas (e.g. hydrogen) used to form lower ox state

how does microwave heating raise temperature?

what temp can it heat to?

raises temp of whole volume simultaneously - faster reaction

heated to over 1000C

do reactions need to be in solution for microwave heating?

what solids absorb microwaves well

carried out dry or in solution

V2O5, MnO2, Fe3O4, Co2O3, NiO, CuO, ZnO, WO3 and PbO2

what solids do not absorb microwaves?

CaO, Al2O3, TiO2, Fe2O3, La2O3, SnO and Pb3O4

what are the 2 ways a reactant can absorb microwave radiation?

conduction heating

dielectric heating

what is conduction heating?

electrons in lattice (high mobility) can move under influence of microwave field

resistance to movement causes energy to be transferred to surroundings as heat

what is dielectric heating?

material contains molecules with dipole - microwave field aligns them

oscillating field, the dipoles oscillate in sympathy (unable to follow rapid reversals in field)

power is dissipated in material which transfers heat energy to lattice

what is combustion heating?

heat generated by reaction is used to produce high temperatures

what are chimie-douche methods (soft chem)?

low temp methods of making solid materials

initial low temp, followed by firing at high temperatures

what are the advantages of chimie-douche methods?

products often higher purity

more uniform in texture and chemical homogeneity

what are the disadvantages of chimie-douche methods?

reagents are expensive

reaction conditions specific to given reaction and must be optimised

what are sol gel reactions? what are they an example of?

chimie-douche method

sol = colloidal suspension of particles in a liquid

gel = semi rigid solid in which solvent is entrapped in network of colloidal or polymeric material

how is sol and gel formed?

sol - formed by dispersion of insoluble particles in solvent or through reaction of precursor with solvent

gel - formed from sol by methods including concentration solution (eg eval), ageing or heating

how is aerogel and xerogel formed from sol-gel?

supercritically extracted - aerogel

evaporated to form xerogel

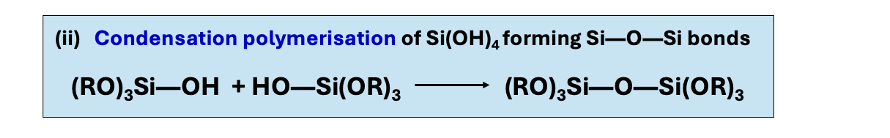

how is silica sol made? what is the precursor?

what are the 2 steps?

silica alkoxide (Si(OR)4) precursor

hydrolysis of alkoxide precursor to form Si(OH)4

condensation polymerisation of Si(OH)4

hydrolysis of Si(OR)4 equation

condensation polymerisation of Si(OH)4 equation

what are the 5 steps of silica optical fibres from sol-gel

sol prep

gel formation

drying

purification and densification

fiber fabrication

how is gel formed? silica rxn

sol is cast into mould (often tube) and gelled

reducing pH = silica particles to aggregate/combine and form gel

what happens in drying? silica sol gel

wet gel is dried to remove liquid = giving porous silica gel

what is purification and densification? silica sol gel

porous gel heated to remove organic impurities and hydroxyl groups

sintered to create dense, transparent glass

what is fibre fabrication? silica sol gel to make optical fibres 2

preform creation : dense silica glass is used to create preform - larger thicker version of intended fibre

fibre drawing : preform heated and drawn into thin fibre with desired diameter and properties

what are the 4 benefits of sol gel of silica optical fibres?

compositional flexibility

purity - minimise impurities that can affect optical fibre performance

cost effectiveness

can create microstructures fibres - complex geometries with unique optical properties

how does the sol gel method give compositional flexibility?

allows dopants to be easily incorporated - controls optical properties of fibre

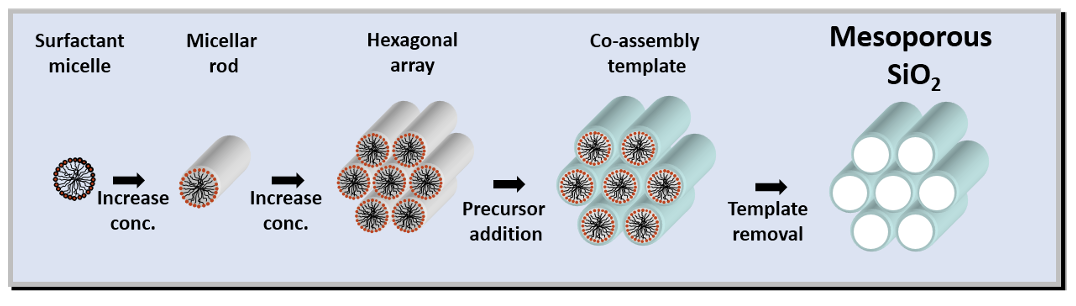

what are mesoporous solids?

how are they made?

pores of size 2nm-50nm

synthesised using templating methods

what is templating?

a scaffold is used to direct the formation of the solid = condense solid around it

template is removed to give product

why might you use an organic scaffold for templating?

what method can you use in conjunction with it?

can remove it at low temperatures

can use sol gel as low temp

what are thermotropic surfactants?

surfactants that change phase due to temperature

what are surfactant/solvent systems called?

what do surfactants do in solution?

lyotropic

surfactants self assemble to give different structures/phases

how to make mesoporous materials (e.g. silica) using surfactant

what does larger surfactant give

condense silica around surfactant

burn away surfactant to give mesoporous product

larger surfactant = larger pores

what is hydrothermal synthesis used for?

when you want to carry reactions out in solvents

at temperatures above their BP

what vessel would you use for hydrothermal synthesis? pressure? heating?

how is pressure controlled?

teflon lined cylinder or bomb - sealed/connected to pressure control

bomb is heated to 100-500C

p controlled either by degree of filling or externally

what is hydrothermal reactions but for organic solvents called

solvothermal reactions

what are zeolites?

what technique could you use to make them?

microporous aluminosilicate framework structures

use hydrothermal synthesis/sol gel reaction

what is the advantage of hydrothermal synthesis compared to other methods?

lower temp than ceramic / sol gel methods

what are the poles like in zeolites?

what are the applications?

well defined, interconnected

intersect at cavities / cages

used for many applications e.g. catalysis and molecular separation

what is the difference between zeolites and mesoporous substances?

zeolites are naturally occurring

what is the general formula for a zeolite? what is M for?

Mx/n[(AlO2)x(SiO2)y].mH2O

M present to neutralise negative charges on aluminosilicate framework

what does changing Si/Al ratio change in zeolites?

changes the cation content

what are zeolites with high Si content like?

hydrophobic

how are zeolites made?

why does gel form? why is it heated and in what?

reactive silica and alumina reagents under hydrothermal conditions - high pH

gel forms due to copolymerisation of silicate and aluminate ions

heating gel in autoclave generates zeolite (few days)

what is chemical vapour deposition? how are reactants and products delivered?

reactants are delivered in gas phase

product phase is deposited as thin film on substrate

what can chemical vapour deposition be used to make?

high purity thin films

what starting materials are used for chemical vapour deposition?

how are they transported? where do products form?

volatile - typically hydrides, halides and organometallic compounds - heated to produce vapours

mixed and transported to substrate using carrier gas

product deposits as thin film

what are the properties of diamond?5

hardness

chemical inertness

optical transparency

thermal conductivity at room temp

electrical insulation

what is a problem that arises when making diamond thin films using chemical vapour deposition?

how is this avoided?

graphite forms under ordinary conditions

in diamond chemical vapour deposition, need to deposit carbon while suppressing formation of graphitic sp2 bonds

establish high concentration of non diamond etchants e.g. atomic H

how are large single crystals of Si made?

what conditions? how is silicon prepared?

Czochralski process

normally performed in vacuum under inert atmosphere of Ar in inert chamber e.g. quartz

Si melted in crucible and then single crystal is position on surface of melt

crystal acts as seed which continues to grow, slowly withdrawn

how is large single Si crystal withdrawn?

pulling an ever lengthening crystal in same orientation as original seed

what are single crystals of potassium dihydrogen phosphate (KDP) used for?

how are they grown?

special optical properties - converting laser beams from IR to UV

grown from large 0.3m seeds. placed in tanks containing aq KDP. temp lowered to make supersaturated solution = driving force

what are the 3 problems stopping rapid crystal growth of KDP?

impeded transport of dissolved KDP from bulk of solution to crystal

insufficient supersaturation of solution

inaccurate measurement of supersaturation as can’t control it

what are the 3 solutions for KDP rapid crystal growth problems?

improved transport of dissolved KDP by putting seed in middle of slowly rotating turbine

improved model of crystal growth rates

turbine to give better mixing and suppress undesirable spontaneous nucleation

what are the two approaches for making nanomaterials?

bottom up

top down

what is bottom up nanomaterial synthesis?

when nano materials are made from smaller compounds

chemical synthesis or forming arrays of nanoparticles by self assembly

what is top down nanomaterial synthesis?

formed by the processing of larger (macroscopic) strucutres

e.g. etching through a mask or ball milling

is bottom up or top down more powerful?

bottom up is more powerful

-control material structure from atomic level

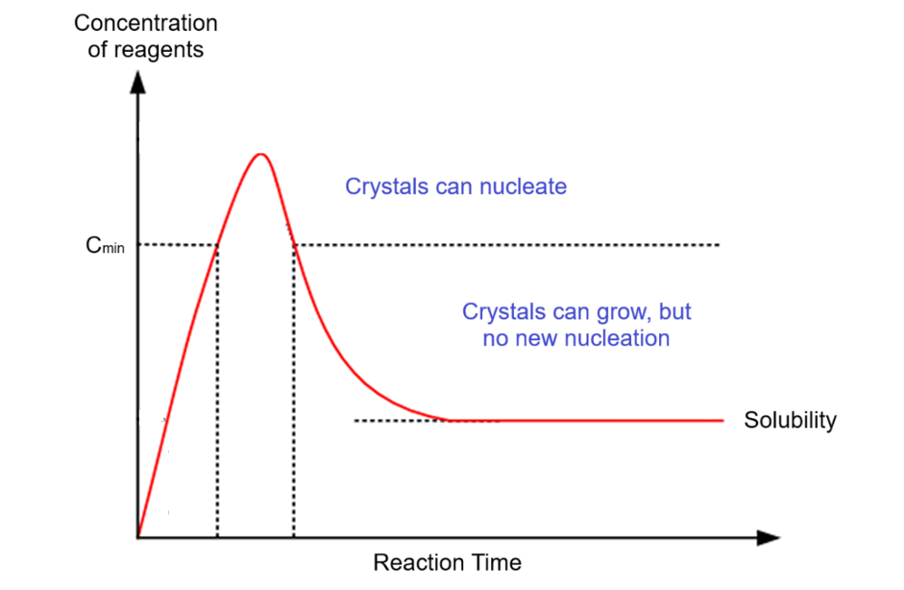

how is CdSe nanoparticles made?

how does nucleation occur?

hot injection methods

dissolved in tri-alkyl phosphine. solution injected into hot trioctyl phosphine oxide (TOPO). nucleation occurs in a burst

injection causes solution to cool. nuclei can grow but no knew can form.

in nanoparticle synthesis, what controls growth of nanocrystals after injection?

surfactant molecules control growth

aggregation is suppressed by the presence of surfactants on the particle surface

growth of nanoparticles - concentration of reagents vs reaction time graph

how does a burst of nucleation form a narrow size distribution?

all nuclei form at same time - reduces conc of reactants to a level where no new nuclei form

NCs continue to grow. since all formed at the same time and no new nuclei can form later, they all have same size

how can existing lattices be modified?

how is charge neutrality maintained? what must the reactant material be?

adding extra ions into vacant sites (intercalation)

removal of ions (de-intercalation)

electrons must be added or removed - reactant material must be a conductor to allow flow of ions or electrons

how is potassium graphite formed?

melting potassium over graphite power in inert atmosphere

intercalated ions in AxWO3

intercalated ions are mobile

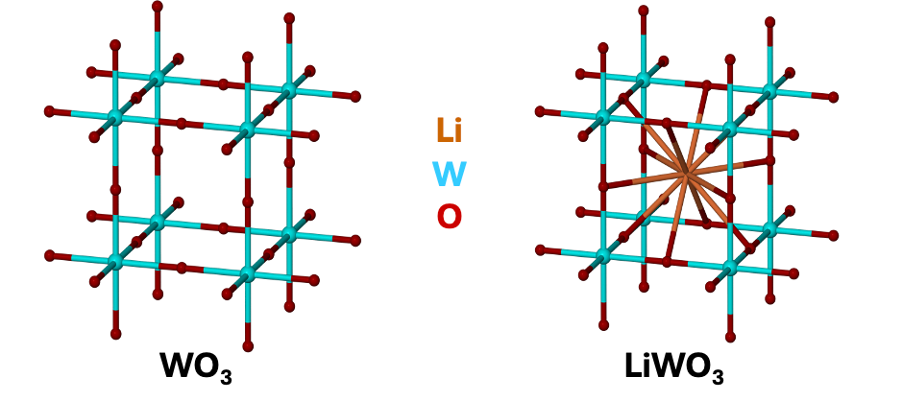

how can LixWO3 be prepared 3

what is reducing agent

reacting WO3 with BuLi (Bu- red agent)

reacting WO3 with lithium vapour (Li0 red agent)

electrochemically reducing WO3 in presence of Li+

what is structure of WO3 and LixWO3

how does structure change as x increases?

edge centred cubic lattice

Li+ intercalates into centre of cubes

as x increases, turns into perovskite lattice

what is tungsten bronze made up of?

solid solution of perovskite LiWO3 in simple cubic WO3