(5-6) Physical Metallurgy | Properties of Metal

1/64

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

65 Terms

PHYSICAL METALLURGY

deals with the physical and mechanical properties of metals

PROPERTY

response of a material to any external stimulus such as stress, heat, electricity, magnetic field or the environment

example: strength of a material, which is the response of a material

STRUCTURE

arrangement of the components and at the different level-microscope, atomic, or even subatomic

PROPERTY = f(STRUCTURE)

PROPERTY = f(STRUCTURE)

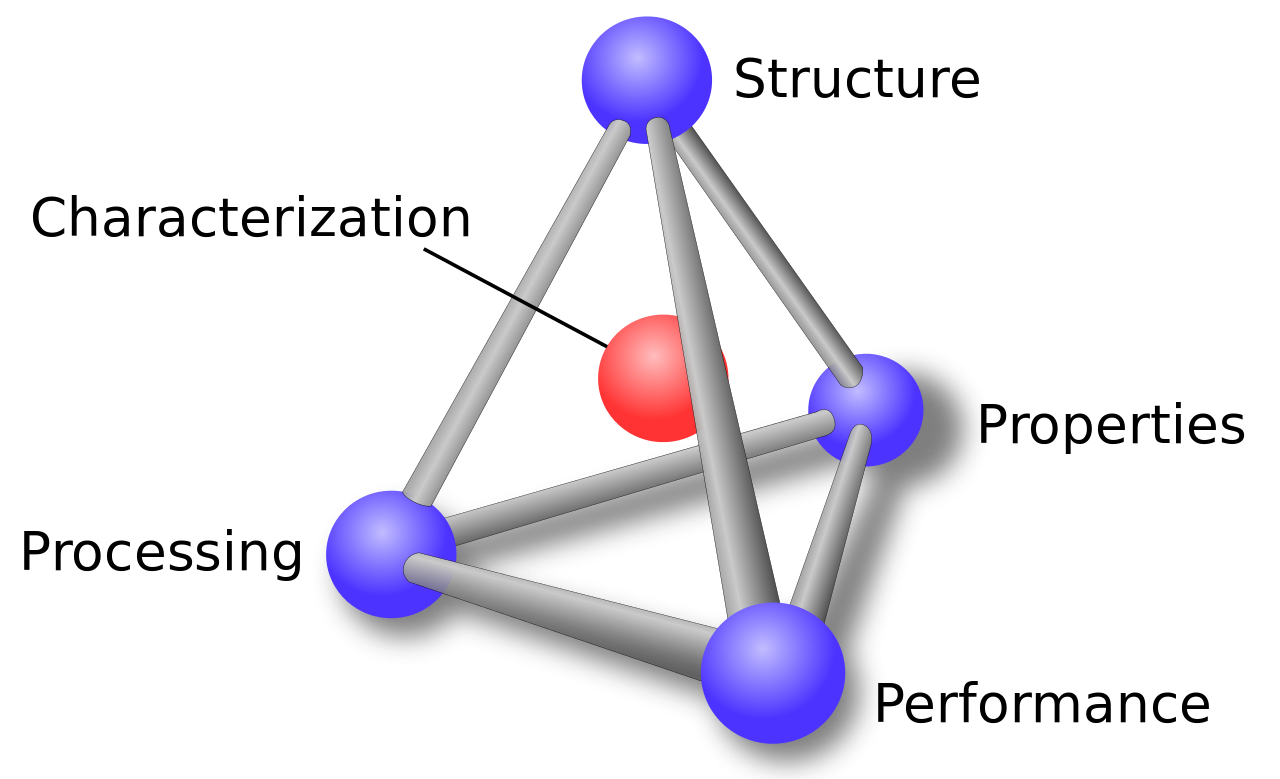

CHARACTERIZATION

STRUCTURE

PROPERTIES

PERFORMANCE

PROCESSING

Material Science Tetrahedron

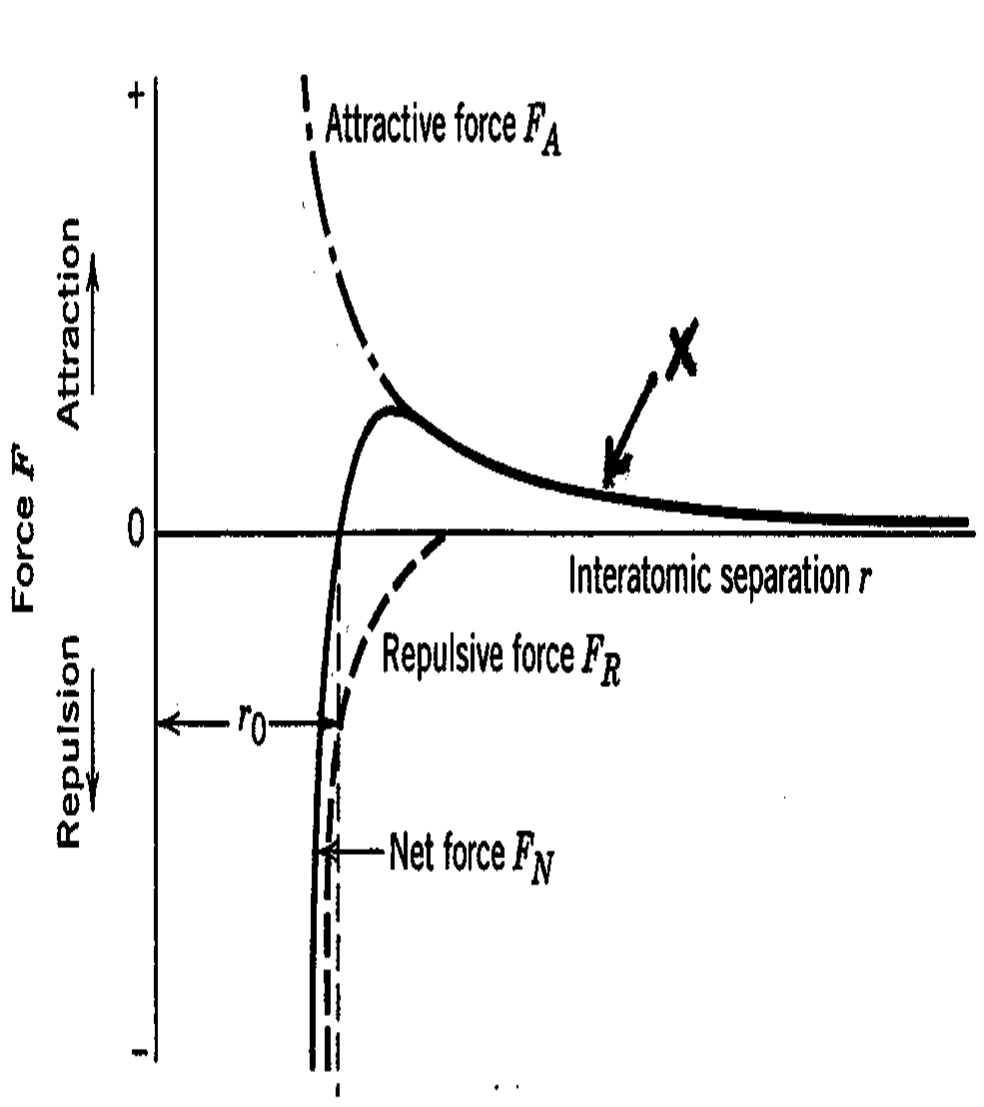

Atomic Bonding: Net Force

attractive and repulsive force merge at the center = equilibrium (Net Force)

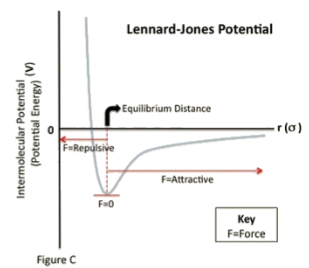

POTENTIAL WELL

equilibrium will be at the lowest point of well

the deeper the well, the better the equilibrium

deeper equilibrium is equal to higher energy needed to overcome that potential

Primary Bond

Ionic Bond

Covalent Bond

Metal Bond

Secondary Bond

Van der Waals

Hydrogen Bond

Types of Bond

IONIC BOND

type of bond where one or more electrons in the valence shell of an atom are transferred to the valence shell of another

between metallic and nonmetallic elements

COVALENT BOND

type of bond that involves sharing of electron

between nonmetallic elements

METALLIC BOND

type of bonding that occurs due to delocalized valence electrons

delocalized electrons can move freely within the solid in response to an electric field, creating a “sea of electrons”

VAN DER WAALS

type of bonding exists between virtually all atoms or molecules that arises from atomic dipoles or molecular dipoles

HYDROGEN BOND

special type of Van der Waals bonding

bond between a hydrogen ion and negatively charged ion

CRYSTALLOGRAPHY

arrangement of atoms within a structure of materials

Crystalline Solid

Amorphous Solid

Solid Structure is assembled into two:

CRYSTALLINE SOLID

contains regular and repeating atomic or molecular arrangements

includes metals and some ceramics and polymers

AMORPHOUS SOLID

non-dense, random ordering and packing

LATTICE

the 3D space filling repeating pattern on which atoms are placed

represents the arrangement of atoms, ions, or molecules in a crystalline material.

UNIT CELL

smallest unit and simplest portion of the structure that describes the crystal pattern

LATTICE CONSTANTS

edge length along major axes

INTERAXIAL ANGLES

angles between axes

denoted as α (alpha), β (beta), and γ (gamma)

CRYSTAL SYSTEM

a scheme by which structures are classified according to unit cell geometry

Simple Cubic

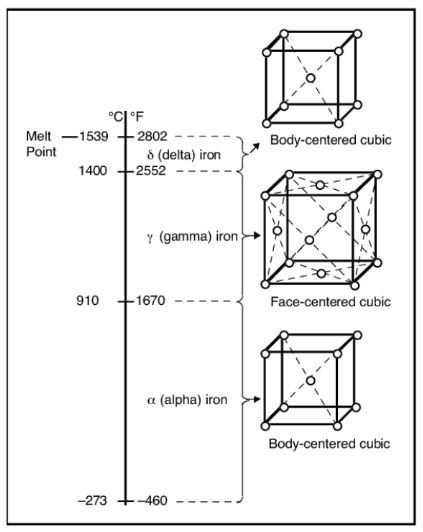

Face-Centered Cubic (FCC)

Body-Centered Cubic (BCC)

Hexagonal Close-Packed (HCP)

Types of Unit Cells

SIMPLE CUBIC

consists of atoms situated only at the (8) corners of a cube

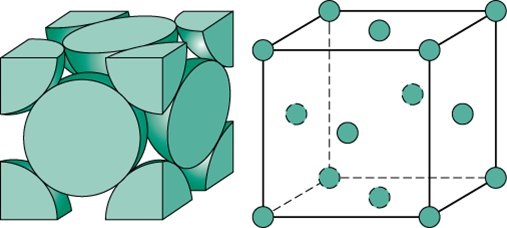

FACE-CENTERED CUBIC (FCC)

atoms are situated at the corners at the corners of the unit cell as well as the centers of each face

8 corner atoms, 6 face atoms

2 unit cells

Al (aluminum)

Cu (copper)

Ag (silver)

Au (gold)

Pb (lead)

Ni (nickel)

metals with FCC structure

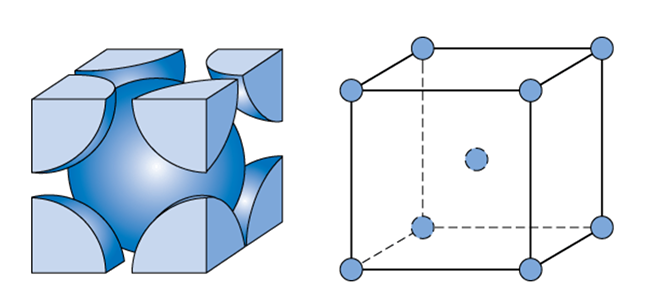

BODY-CENTERED CUBIC (BCC)

atoms are situated at the corners of the unit cell and at the center of the cube

Cr (chromium)

Fe (iron)

W (tungsten)

Metals with BCC structure:

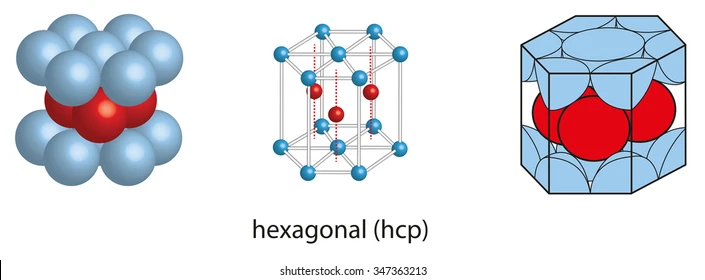

HEXAGONAL CLOSE-PACKED (HCP)

has 2 basal planes in the form of a regular hexagon and one atom at the center

12 coordination number, 6 atoms

Cd (cadmium)

Co (cobalt)

Ti (thallium)

Zn (zinc)

Metals with HCP structure:

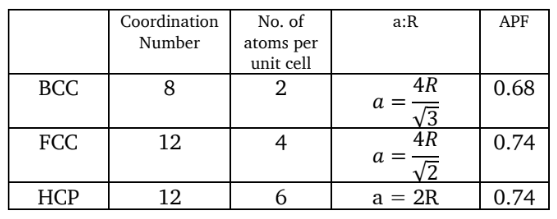

Atomic Radius

Coordination Number

number of nearest neighboring atoms

Number of atoms per unit cell

Ratio of lattice constant to atomic radius (a:R)

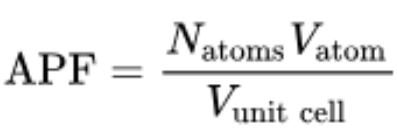

Atomic Packing Factor

fraction of space filled by spherical volume

Unit Cell Parameters

Atomic Packing Factor (APF) formula

Unit Cell Parameters

SINGLE CRYSTAL

has perfect periodic arrangements of atoms that extends throughout the entire specimen

exists in nature but is very difficult to grow

quartz

POLYCRYSTALLINE

consists of many small crystals or grains

separated by grain boundaries

POLYMORPHISM

capability of some material to possess different crystal structures

Graphite vs Diamond

Polymorphism in Fe (Iron) with Carbon

ANISOTROPY

dependence of properties with crystallographic direction

degree increases with low structural symmetry

ISOTROPY

independence of properties with crystallographic direction

observed for polycrystalline materials even if individual grains are anisotropic

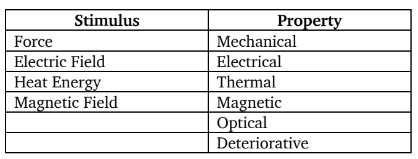

Stimulus and its Property

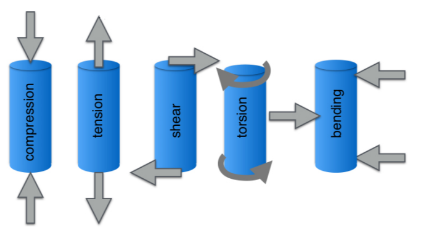

MECHANICAL PROPERTIES

external force is applied

Tension

Compression

Shear

Torsion

Types of Loading (4)

Tensile Stress

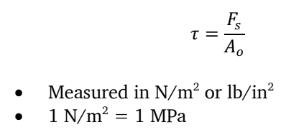

Shear Stress

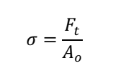

Engineering Stress

Engineering Strain

Types of Stress (4)

Tensile Stress

Shear Stress

Engineering Stress

instantaneous force divided by the original cross-sectional area

Engineering Strain

instantaneous deformation divided by the original length

the effect of stress

Universal Testing Machine (UTM)

Necking

Types of Stress-Strain Testing

Universal Testing Machine (UTM)

used to uniaxially load as sample until material failure

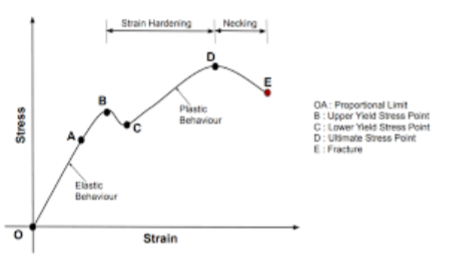

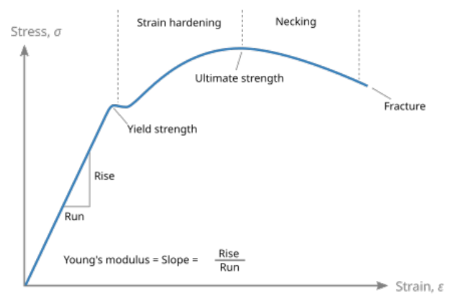

Stress-Strain Diagram

to present data from UTM

Necking

localized reduction in cross-sectional area, begins after UTS

Elastic Deformation - reversible

Plastic Deformation - irreversible

Tensile Properties

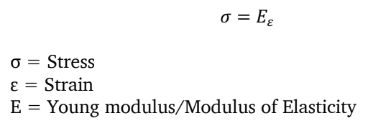

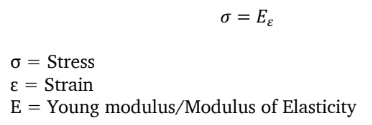

Hooke’s Law

used for Elastic Deformation

linear properties between stress and strain

Proportional Limit

Yielding

Ultimate Tensile Strength (UTS)

Fracture Stree

Elastic Behavior (4)

Proportional Limit

point wherein departure from linearity of stress-strain curve starts

Yielding

phenomena wherein it starts to transition from elastic to plastic

Ultimate Tensile Strength (UTS)

before necking

maximum stress a material can withstand while being stretched or pulled before it breaks

Fracture Stress

stress at the point of breaking of fracture

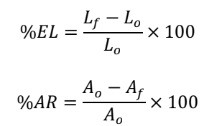

Ductility (%EL)

degree of plastic deformation that have been sustained at fracture

expressed as %elongation

Resilience

capacity to absorb energy when it is plastically deformed, and to have its energy recovered upon unloading

strain energy per unit volume required to stress a material from an unloaded state

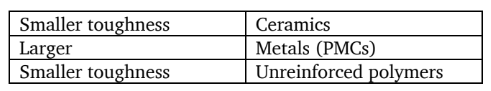

Toughness

energy to break a unit volume of a material

approximately by the area under stress-strain

Hardness

a property that described the resistance to permanently indenting to the surface or localized plastic deformation

higher hardness means resistance to plastic deformation

Rockwell

Brinell

Knoop

Hardness Tests

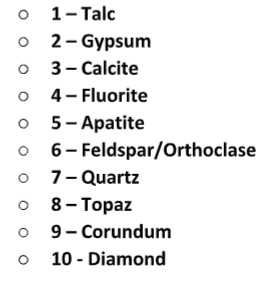

Mohs Scale of Hardness

most are solid at normal temperature

relatively high density

some are very good conductors of heat and electricity

magnetic properties

Macroscopic Physical Properties of Metals (4)