Inhaled medicines

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

Physical perspective of the purpose of the air way

Heat and humidify the inhaled air (Conditioning).

Remove particles from the inhaled air by deposition (ie. act as a filter).

Where should particles ideally not reach

Alveoli - smaller particle <10um may

Why delivery to the lungs?

local effect: e.g. bronchodilators, corticosteroids, antibiotics, mucolytics

systemic effect: e.g. volatile anaesthetics (halothane), ergotamine tartarate (migraine), peptide drugs (insulin) (avoids first pass effect)

Rapid onset of action

Smaller doses than oral formulations and hence less systemic and GI adverse effects

Relatively comfortable

How to overcome the barrier of delivery/ penetrate into he airways

Drugs are delivered in the form of an aerosol

What is an Aerosol?

Suspension of liquid or solid particles in a gas → sufficiently small to remain airborne for a considerable time

•dispersion of solid particles or liquid droplets in a gas

In order to be effective the aerosol particles must

Deposit in the appropriate lung region

In the right quantity

Overcome physiological barriers and respiratory defence mechanisms

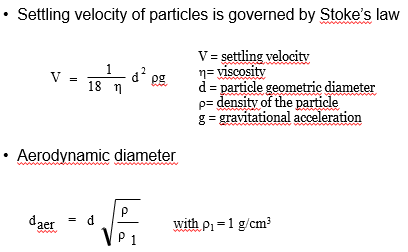

What is aerodynamic diameter?

Diameter of a (“pretend”) sphere with a density of 1g/cm3 that has the same settling velocity in air as the particle of interest

What settling velocity of particles is governed by…

Stoke’s law

Aerodynamic diameter fomula and stokes law

V = settling velocity

h= viscosity

d = particle geometric diameter

r= density of the particle

g = gravitational acceleration

Respirable fraction of an inhaled medicine definition

Percentage of drug present in aerosol particles less than 5 μm in size and hence likely to be deposited

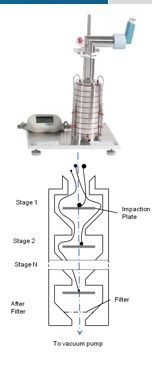

How to determine respirable fraction

Particle sixing techniques

Anderson Cascade Impactor

Next Generation Impinger

Next Generation Impinger

7 stages

Calibrated to flow rate required

Powder collected in cups after each stage

Size distribution information and prediction of site of deposition in the lung

Anderson Cascade Impactor

picture

3 types of inhalers:

Nebulisers

Pressurised metered dose inhalers (pMDI) → most used/convient

Dry powder inhalers (DPI)

Nebulisers

Aqueous drug solution/suspension aerosolised into droplets

Energy provided by compressed air or ultrasound

pMDI

Drug formulated in a liquefied gas under pressure

Aerosol formed by evaporation of the gas at atmospheric pressure

Issues with pMDI

Large proportion of patients are unable to co-ordinate actuation with inhalation

Particles leave the pMDI at a high velocity → high deposition in the oro-pharynx (back of throat)→ Consequence: low % deposition in the lung

Can improve with a spacer, but inconvenient

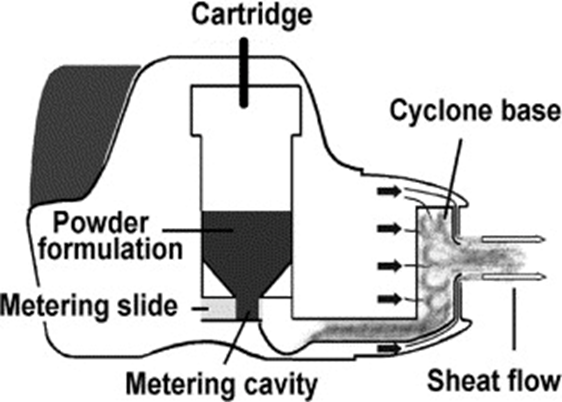

DPI

Drug normally with other solid excipients in a dry powder state

Aerosolisation by patient’s own inhalation

Delivers a dry powder, no solvent is involved

DPI as an alternative to pMDI

Breath actuated (no coordination required)

As a drug and excipients in a dry form tend to be more stable than drug dispersed in a solvent as in pMDI

Traditionally seen as difficult to formulate a suitable powder

Main components of DPI

Drug powder or blend of drug powder with excipients

Drug reservoir or pre-metered doses (cartridge, blister, capsule)

Body of the device

Cap to protect powder from dust, moisture

The patient’s inspiratory flow is used to: (DPI)

Fluidize the static powder blend

De-aggregate particle agglomerates into inhalable particles

•Dose delivered and deposited into the lungs depends on the patient’s inspiratory flow rate (hard to predict and reproduce!)

Main issues with DPI

•Particles < 5 µm (AS NEEDED TO PENETRATE THE LUNG) are extremely cohesive (due to large surface area compared to mass)

Moisture increases agglomeration (ensure powders stay dry)

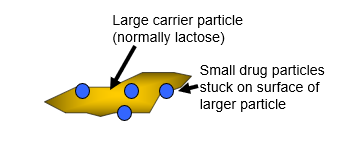

Solution to DPI

•Drug blended with a carrier powder with large particle size (typically lactose). This means drug must be separated from this carrier particle to be inhaled.

•Spherical particles (eg. spray-dried powders) can reduce particle contact area and hence aggregation.

•Protection from moisture (blister pack, use of desiccant)

DPI formulation

Carrier particles (50-100μm) are needed to stop small (< 5μm) drug particles aggregating (this is known as an ORDERED MIX).

To be effective for delivery the small drug particles must be separated from the carrier during inhalation

Large lactose particles deposit in the oro-pharynx

Drug deposits in the lungs

Types of DPI

unit does devices

Multiple unit does devices

Reservoir devices

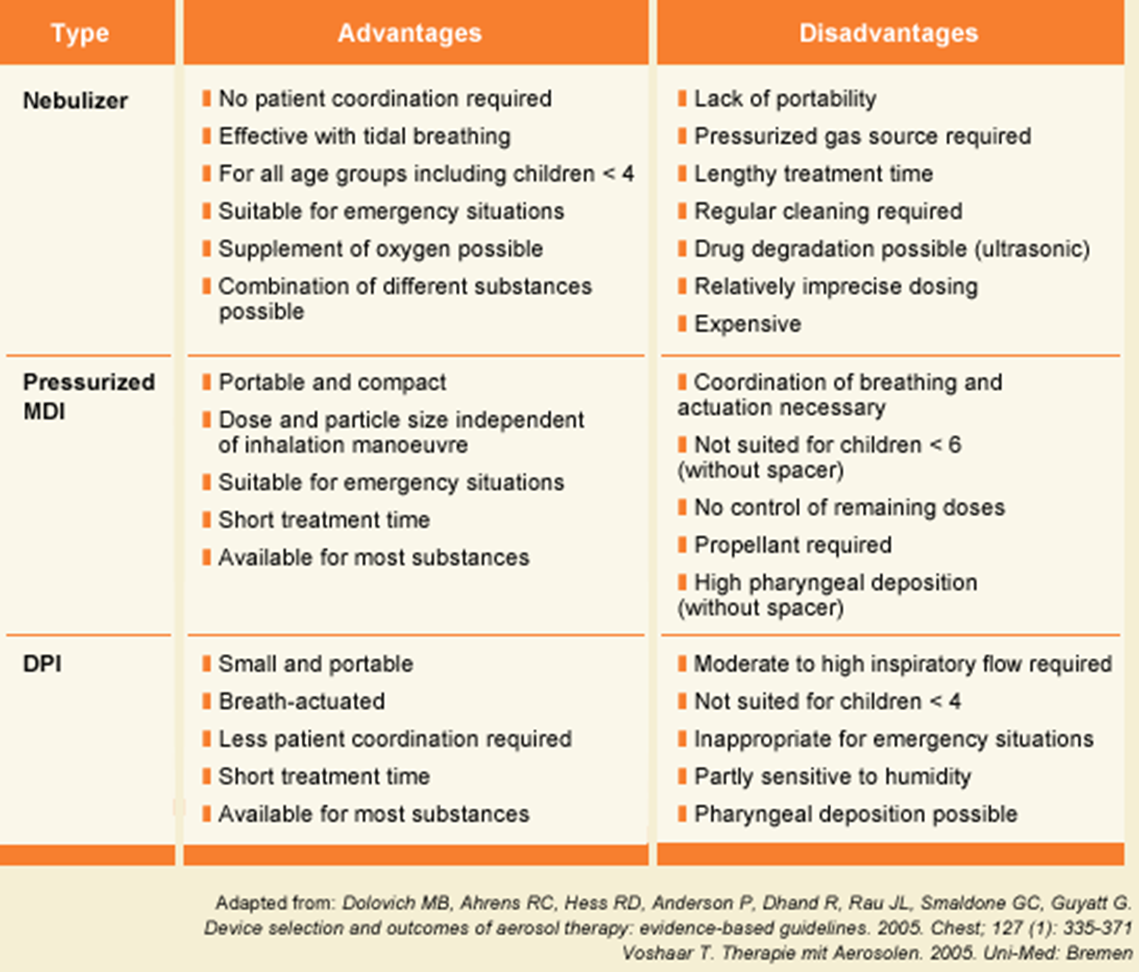

advantages and disadvantages of inhaler types