FILM SCREEN P1

1/145

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

146 Terms

darkroom;

this is the place where the film is

processed and made useful for viewing.

processing room

is perhaps

the most important single room

in the radiology department

latent image,

processing room is the place where the ___ placed on the film by

radiographic equipment, is

converted into a useful visible

image.

DARKROOM

specially designed and constructed

room

–Used for the proper storage and

maintenance of radiographic films, as well

as for the handling of films in the process of

loading and unloading cassettes and the

processing of the exposed radiographic

film.

Processing Tanks

Used on the wet side of the darkroom.

Contain developer, fixer, and wash water.

Allow manual processing of radiographic

films.

Proper temperature and time control are

essential to avoid image errors.

Warning Light Outside the Room

Located outside the darkroom entrance.

Indicates when the darkroom is in use.

Prevents accidental opening of the door

and film fogging.

Lockable Door

Ensures the darkroom is completely light-tight.

Prevents unauthorized access.

Helps maintain radiation department safety and workflow

control.

Film Bin

Located on the dry side.

Used for temporary storage of

unexposed and exposed films.

Protects films from light, heat,

and humidity.

Loading Bench

Found on the dry side.

Used for loading and

unloading films into

cassettes.

Must be kept clean and dry

to prevent artifacts.

Pass Box

A light-tight transfer

compartment.

Allows films to be passed

between the darkroom and

X-ray room.

Prevents light exposure

while maintaining workflow

efficiency.

Safelight

Provides safe illumination

during film handling.

Uses appropriate filters (e.g.,

GBX, Wratten 6B) depending on

film type.

4 feet

Safelight Positioned at least__ feet from

work areas to prevent fogging.

Darkrooms can be smaller if distributed all throughout the X-ray Department but should not be less than 8 feet along any wall. The size of the darkroom will depend on the overall size and activity of the department. Minimum of 10m sq

Ceiling height must be at least 2.5 - 3m

Darkrooms can be smaller if distributed all throughout the X-ray Department but should not be less than ___ feet along any wall. The size of the darkroom will depend on the overall size and activity of the department. Minimum of —- m sq

Ceiling height must be at least—- m

DARKROOM

Minimum area: 10 m2

Minimum wall length: 8 feet

Ceiling height: 2.5–3 m

DARKROOM

Minimum area: ___

Minimum wall length: ___

Ceiling height:___

1:2

RATIO OF darkroom to radiographic rooms

: Barium plaster

Alternative wall shielding material used in X-ray rooms

Lead ply sheet

Material used to line X-ray room doors

• 6 inches thick concrete

Standard concrete thickness for radiation protection

1.5 mm aluminum equivalent lead lining

Required wall lining equivalence for radiation shielding

5 mR

Stored radioactive materials should be located as

remotely as possible from the darkroom because even as little as__ mR total exposure from x- or gamma rays causes detectable fog.

Windows

should be avoided because they are

extremely difficult to render lightproof.

Plastic tiles)

Type of flooring recommended in darkrooms for durability and easy maintenance

Walls are generally light gray or ivory

color to provide reflection from

the “safe” lighting system.

Walls are generally ___or ___

color to provide reflection from

the “safe” lighting system.

Note that the darkroom walls do not

have to be painted black.

Note that the darkroom walls do not

have to be painted ___

40-60%

darkroom Relative humidity :

▸Low humidity- increase static marks

▸High humidity- increase fogging

▸Low humidity- increase ___

▸High humidity- increase ___

10

VENTILATION

Minimum of __ air changes per hour

18-20 degrees C

darkroom – Room temperature

Single Door Type

Double Door Type

Revolving Door Type

Maze Labyrinth Type

TYPES OF DARKROOM ENTRANCE

SINGLE DOOR

The simplest type of door.

• This type of entrance , although the

least expensive and requiring minimal

space , is also the greatest potential

source of light leaks into the darkroom.

DOUBLE-DOOR

• A less costly entrance is a in which access to

the darkroom is accomplished by opening an

outer door enabling you to enter a darkroom

anteroom.

An electrical system of locks is used to

prevent you from opening the inner door

leading into the darkroom itself until the

outer door is completely closed.

The locking devices are arranged to prevent

both doors from being opened at the same

time.

maze

•Because of the high cost

of the required floor

area, ___ are rarely

used today.

LABYRINTH/ MAZE TYPE DOOR

• Used in larger departments.

• This eliminates the need for doors

and the possibility of extraneous light

leaks but takes up considerable space

and increases the cost of

construction.

• The ideal darkroom entrance,

because of no door and air can freely

circulate in the room.

Safelight System.

•The special illumination for a radiographic darkroom is

called

1. Safelight

2. General

3. Radiographic

A properly designed darkroom should have three

types of illumination:

1 meter (3 feet)

Minimum working distance from the safelight

no

is “SAFE'' lighting totally safe?

Amber filter – blue-sensitive film

Red filter: green and blue-sensitive film

__ filter – blue-sensitive film

___ filter: green and blue-sensitive film

KodakWratten6-B safelight filter

specific brand for ‒ For Blue-sensitive Film

• Ortho G and GBX Filter

specific brand for ‒ Sensitive for Both Blue and Green

The standard safelight system used in many departments is a

7.5- 15-watt bulb with a Kodak Wratten 6B filter. (Red orange)

The standard safelight system used in many departments is a

____ watt bulb with a_____ filter. (Red orange)

Exposed radiographic film// Twice as sensitive

what is More sensitive to safelight illumination, exposed or unexposed film

latensification.

This increased sensitivity of film to exposure to safelight

illumination is called

post-exposure fog.

The effect on previously exposed x-ray film of an exposure to a safelight

is known as

Kodak Wratten 6B

: Older safelight filter used for blue-sensitive films

GBX

Modern safelight filter for green-sensitive (orthochromatic) films

Wratten 6-B

Safelight filter not suitable for orthochromatic-sensitive films

Low latensification, decreased contrast, gross fog

Negative effects of using Wratten 6-B on green-sensitive film

5-

minute

Maximum safelight exposure time for green-sensitive film using GBX without significant fog

is 120cm (4 feet)

Recommended minimum safelight distance from working surface

distance

or the bulb wattage or both.

correct intensity can be obtained by adjusting either

: 20 – 45 secs

‒ Maximum time a film can be exposed to safelight during

the procedure without causing any appreciable degree of

fogging.

Screen–film radiography

is an imaging

system in which X-ray photons interact

with intensifying screens, converting X-ray

energy into light, which then exposes a

radiographic film to create a latent image

that becomes visible after chemical

processing.

Image forming X-rays:

‒ x-rays that exit the patient and

interact with the image receptor

Exit X-ray beam:

X-rays that remain as the useful

beam exits the patient

Scattered X-rays, Image-forming X-rays

Components of the exit X-ray beam

IMAGE RECEPTOR

• The medium that converts the x-ray beam into

a visible image

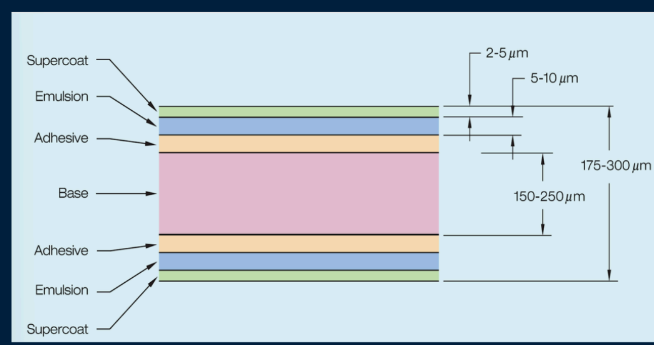

‒ Base

‒ Emulsion

Radiographic film has two parts:

double

emulsion film

• The emulsion is coated on both sides:

OVERCOAT/ SUPERCOAT

Protects emulsion from

scratches,

pressure, contamination during

handling, processing, and storage.

• Prevent damage to the sensitive

emulsion layer underneath

150 to 300 μm.

The thickness of radiographic

film is

approximately

ADHESIVE LAYER

Between the emulsion

and the base

BASE

Foundation of radiographic film

• Properties:

‒ Transparent and clear

‒ Provide a rigid structure

‒ Slight blue tint

‒ Flexible and sturdy

‒ Fracture resistant to allow easy

handling

‒ 150 to 300 μm thick,

base is how thick

polyester

base is made of

(Dimensional Stability)

Should be sturdy/ strong to maintain size and shape during use

and processing

(Uniform

Lucency)

Should be nearly transparent to light so there will be no unwanted

pattern or shading on the film caused by the base

1. Glass plate

2. Cellulose nitrate

3. Cellulose triacetate

4. Polyester

TYPES OF FILM BASE

Original base

‒ Plates coated with emulsion

‒ Difficult maintenance

‒ Exposure factors with plates

very high

‒ Origin of term “flat plate” of

abdomen

1. Glass plate

CELLULOSE NITRATE

• Replaced glass plates during

World War I glass shortage

CELLULOSE NITRATE

• Highly flammable film base

World War I

CELLULOSE NITRATE

• Replaced glass plates during ___

glass shortage

CELLULOSE TRIACETATE

• Safety base introduced in 1920s

• Less flammable than Cellulose Nitrate

• Disadvantages:

‒ Films would warp with age

‒ Not as resilient as today’s polyester films

POLYESTER

Base of today’s modern film

• Introduced in 1960s

• Introduced in 1960s

POLYESTER

• Introduced in ___

1920s

CELLULOSE TRIACETATE

• Safety base introduced in

Dye

Component added to radiographic film to reduce eyestrain and fatigue

Dimensional stability

Property that allows radiographic film to maintain size and shape during use and processing

EMULSION

The heart of radiographic film.

Gelatin

Component of emulsion that holds crystals

Silver halide crystals

Component of emulsion sensitive to X-rays

3 to 5 μm

Thickness of the emulsion

Binder

Component that holds the recording medium on the base and provides a form of material easier to work with

cows

The binder is a gelatin, which is extracted from

collagen, a protein found obtained from the

flatbones of

gelatin

The binder is a

Colloid

Substance which, in solution, fails to settle out but not dissolve; at higher temperatures it will and has some degree of porosity

Gelatin

Properties: clear & porous, provide mechanical support for silver halide crystals by holding them uniformly dispersed

SILVER HALIDE CRYSTALS

Active ingredient of emulsion

98% silver bromide; 2% silver iodide

composition of silver halide crystals in SF film

Tabular

Commonly used shape of silver halide crystals

1 μm

Approximate diameter of silver halide crystals

cubic form or cubic lattice.

Inner structure of silver halide crystals

Silver Nitrate (AgNO3)

Made by dissolving metallic silver (Ag) in nitric acid (HNO3) to form

Silver Bromide (AgBr)

Formed by mixing silver nitrate with potassium bromide (KBr)

Sensitivity Center/ sensitivity speck

Physical imperfection in the lattice of the emulsion layer

Silver Sulfide

Chemical contaminant responsible for the physical imperfection of the silver halide crystal

: ZBr = 35

Atomic number of Bromine in silver halide crystals

ZAg = 47

Atomic number of Silver in silver halide crystals