ChETE 3 - Shaping Plastic (Extruders)

1/51

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

52 Terms

Thermoplastic materials

are fuily reacted or polymerized products that, when subjected to sufficient heat, will soften.

Thermoset plastics

are polymers that have not fully completed their polymerization reaction, but do so when activated, usually by heat.

tooling cost

One of most important considerations when thinking of producing a plastic dimensional part is

tooling cost

the cost of molds and other devices that will be needed to shape the plastic into the desired form. The cost of tooling is directly related to the forces that will be required to create the form.

Profile extrusion

to make continuous solid profiles or tube simply requires a shaped aperture through which to push the plastic. Tooling cost is low

Thermoforming

is done with open molds using vacuum and compressed air at moderate levels.

Extrusion blow molding

__________________ of bottle forms requires a water-cooled mold consisting of two matched halves.

Injection blow molding

Which has higher cost, Injection or extrusion blow molding?

Resin type

Geometry of the finished part

Number of units required

Dimensional tolerance requirements

Container wall thickness

Other factors that need to be considered in molding are:

Melt flow rate

is a method of quantifies the behavior of plastics at elevated temperatures

(reference method ASTMD 1238)

Melt flow rate reference test method

thermoforming

The finished product of the extruder is also used for

heat, shear, and pressure

The purpose of an extruder is to use this to transform the solid plastic into a uniform melt

Regrind

Scrap from plastic processes converted into granular form

barrel

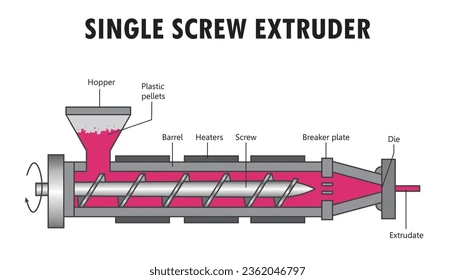

Most extruders contain a single screw inside a hollow tube called a

Hopper and feed port

Barrel

Screw

Motor

Screen packs/breaker plates

Instrumentation devices

Die

Machine elements of extruder:

Identify parts of extruder

Hopper and feed throat

This is where the pellets are placed

Barrel

Hollow tube which contains the screw and is equipped, on its exterior, with elements for heating and cooling

Screw

Has helical channels and acts to heat and melt the pellet to a liquid state and convey them to the die.

Motor

Also called the gear reduction system is used to turn the screw

Screen packs/ Breaker plates

Used to filter the melt and create back pressure

Die

Determines the shape of the extrusion

Instrumentation

Includes the thermocouples, pressure gauge valves, and other devices used to indicate and control machine variables like T, P, and screw rotation speed

Conveying/Feeding

Melting/Transition

Pumping/Metering

Mixing (optional)

The melting phase is broken down into three distinct steps:

Hopper

Are usually circular in cross section and the diameter gradually decreases as it nears the feed port

Bridging

A too rapid decrease in diameter can cause this where a compressed plug of material cuts off the flow to the extruder

Gravity

This is usually the driving force for the flow of the plastic into the extruder

Augers

Some hoppers have this to help force plastic material into the feed throat

Stirrer

Some hoppers have this to help wipe the material from the hopper walls

Hoppers

Extruders can have more than one _______

Starved

If the rate is too low, the screw is ____________. There will be less molten plastic in the other sections and output will be low

Melting will not be complete, and output may contain unmelted particles

What happens if rate is too high?

Melting of the plastic

What is the main function of the melting section?

Metering section

This is responsible for delivering the molten polymer at a desired and uniform rate to the die.

Single screw extruder

These are used to melt and convey the polymer but are not used to mix the polymer resin and other additives.

5-20 cm (2-8 in)

A typical extruder would have a barrel diameter of

20:1 - 30:1

Extruder sizes are described as the screw length to barrel diameter ratio. Most extruders fall in this range

Channel depth ratio

This is the ratio of the depth of the channels in the feed section to the depth of the channels in the metering section.

2-4, 3 (most common)

Typical channel depth ratio

Die

Where the melted plastic leaves in a desired shape

50C above melting point

Extrusion temperature for crystalline polymers

100C above Tg

Extrusion temperature for amorphous polymers

lower temperatures

Extrusion temperature for heat sensitive polymers

higher temperatures

Extrusion temperature for highly viscous polymers

Vented extruder

A vacuum is applied on the melt through a vent port on the side of the barrel

Vented extruder

Used for plastics with residual volatiles like PS

Twin-screw extruder

Contains two screws and can facilitate mixing

Twin-screw extruder

Can be rotating or counter-rotating