Chapter 11 (Reaction Of Organic Compounds)

1/91

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

92 Terms

Alkane Combustion

Burn readily in the air - for an exothermic reaction (as such with hydrocarbons)

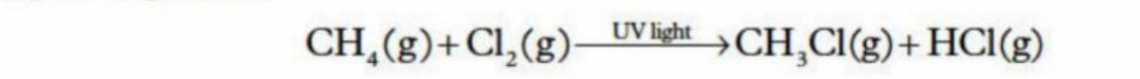

Substitution Reactions of alkanes

Atom or functional group is replaced by another atom or functional group

e.g. Creating halo alkanes (Replacing hydrogen with fluorine, nitrogen, CI)

Can only be initiated by UV light (the substitution reaction - cannot occur in darkness)

Explanation of example above

After single substitution, another substitution can also occur, until all hydrogens have been swapped out

Fractional Distillation

The process in which the different substituted products can be taken apart

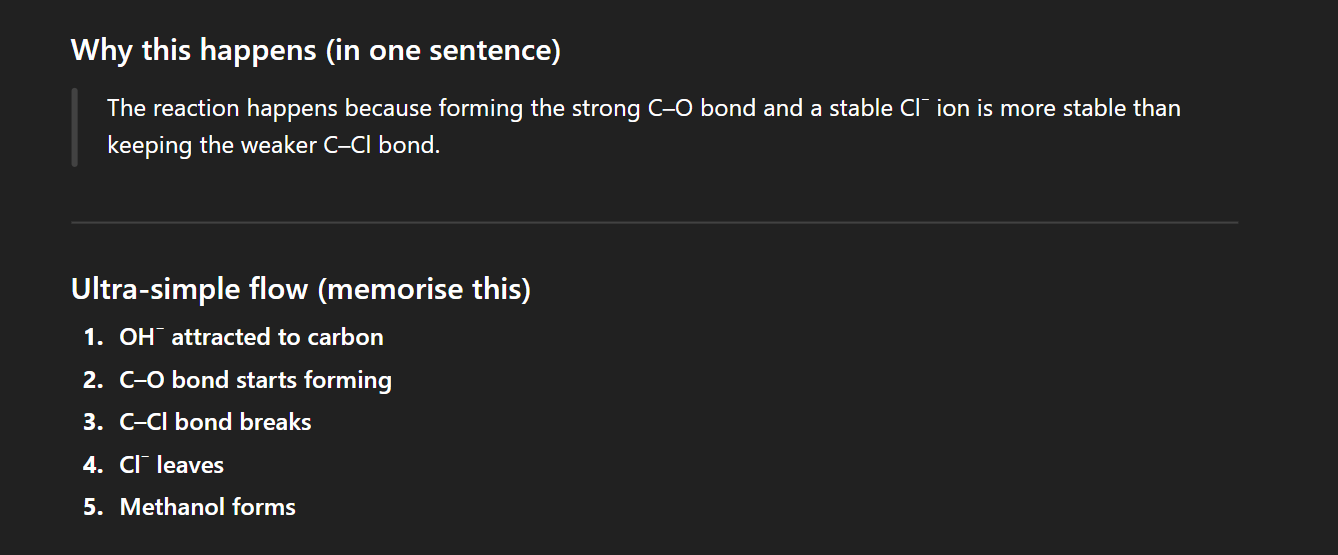

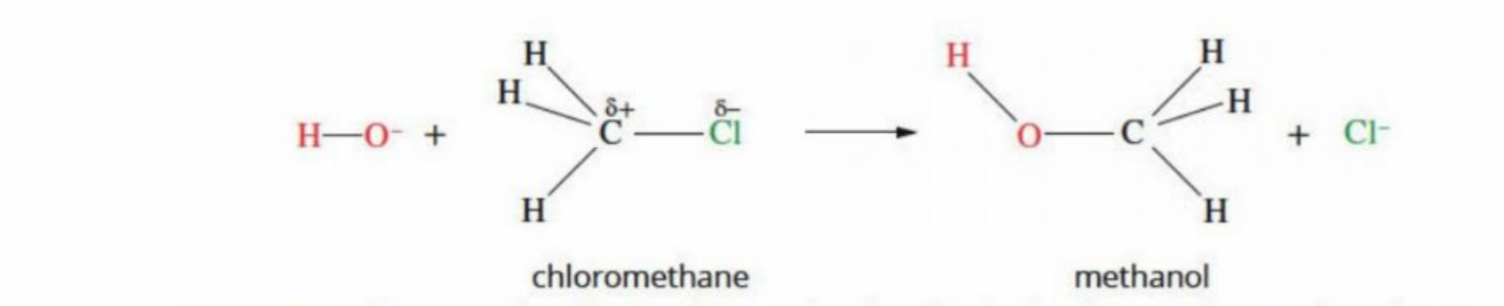

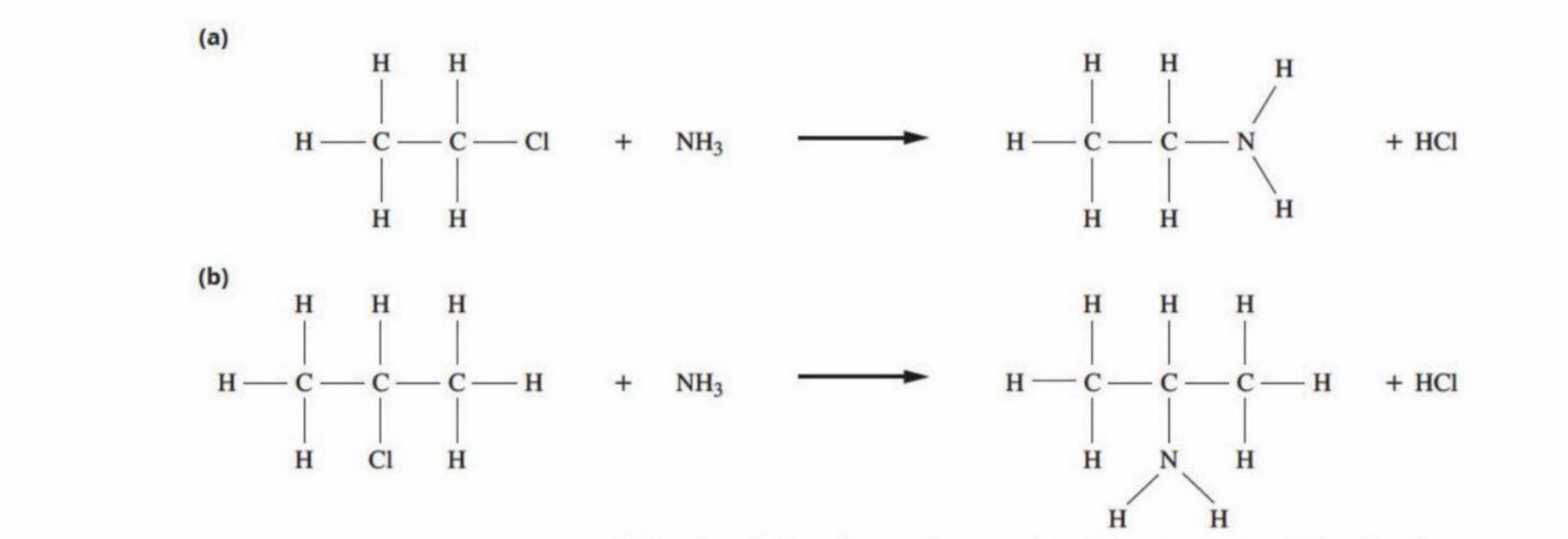

Substitution reactions within haloalkanes

Substitution reactions within haloalkanes - Example

Susbtitutions with Ammonia

Trick (Unclear)

If it is an alkane —> haloalkane (then is a substitution reaction)

Reactivity of alkenes

More reactive than alkanes (due to unsaturation)

The bonding that alkenes undergo

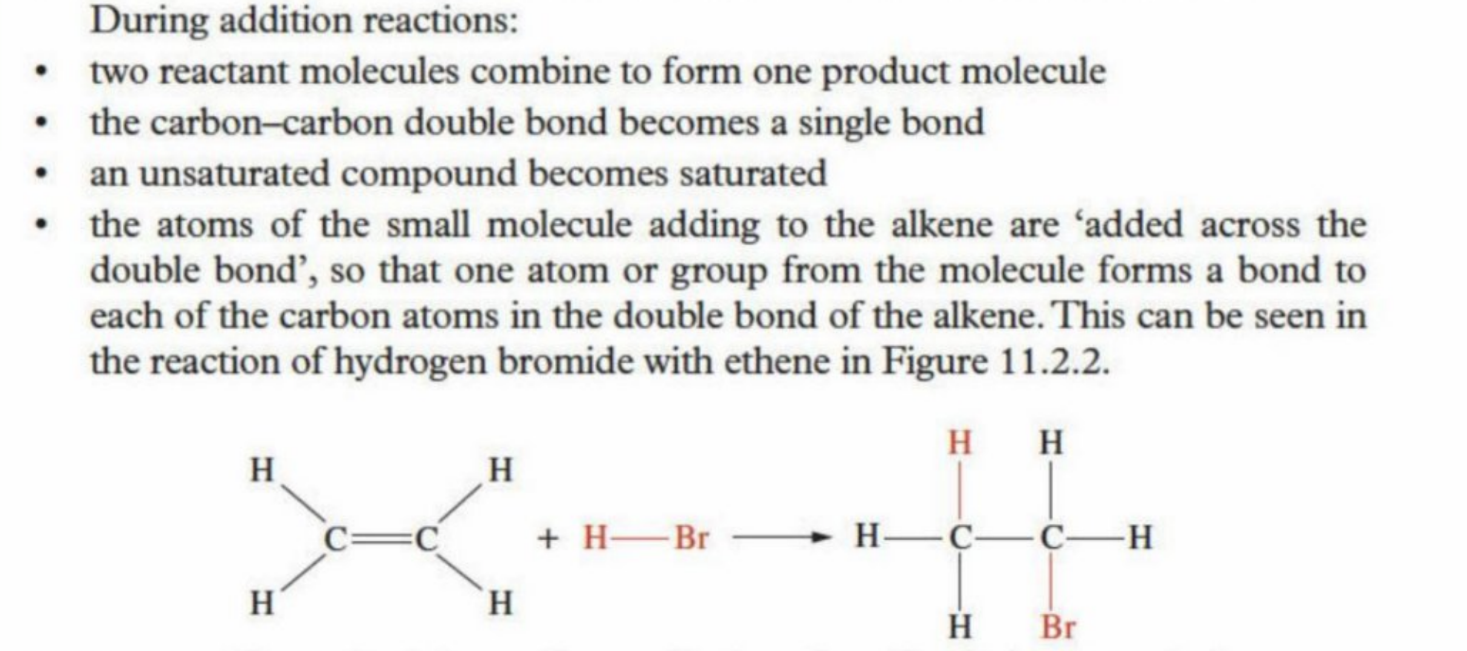

Addition reactions

(like how a monomer takes on additional bonds)

Makes no byproduct (everything is contained within the molecule) - no inorganic molecule formed

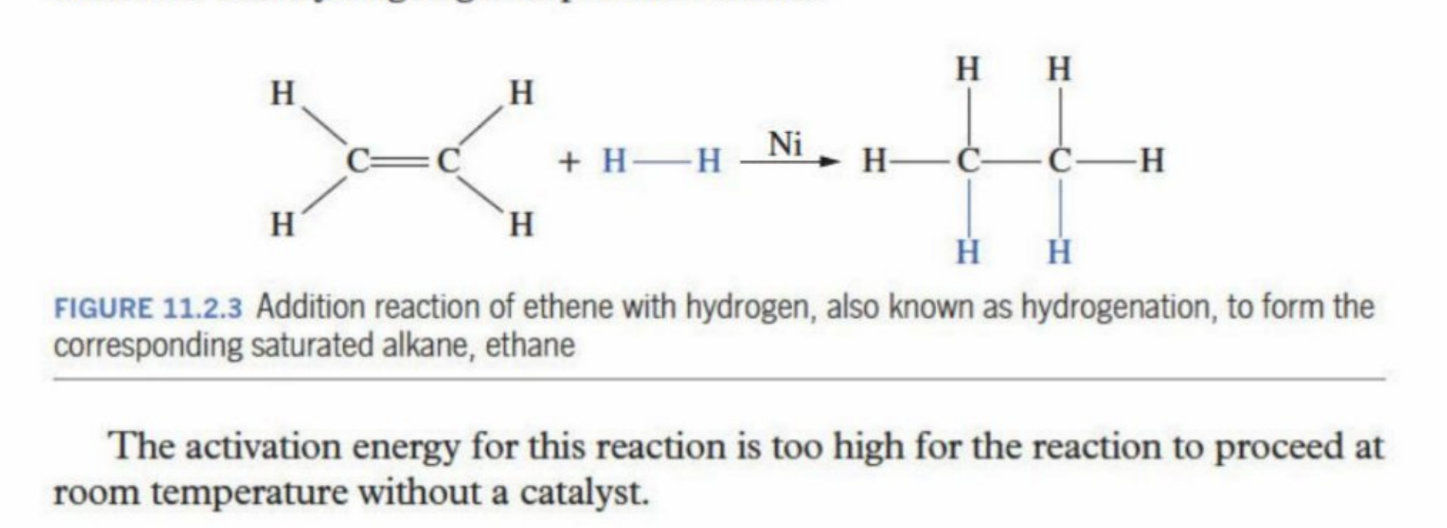

Reaction for alkenes with hydrogen (hydrogenation reaction)

Simply the addition of hydrogen atoms into the unsaturated alkene

Is done with a catalyst as the activation is too high for the reaction to proceed without a catalyst

Addition reactions with halogens

Alkene reacts with halogens to become saturated

Reaction with Bromine (halogen that is orange in color) can be used to distinguish alkane vs alkene - used to test for a C=C bond

Alkene - adsorbs bromine and the orange color, as it becomes fully saturated - solution becomes clear in color

Alkane - No change, as it is already saturated

Addition reactions with hydrogen halides

Halide - a halogen with a charge

Hydrogen atom + halogen - Both attach onto alkene, making it saturated

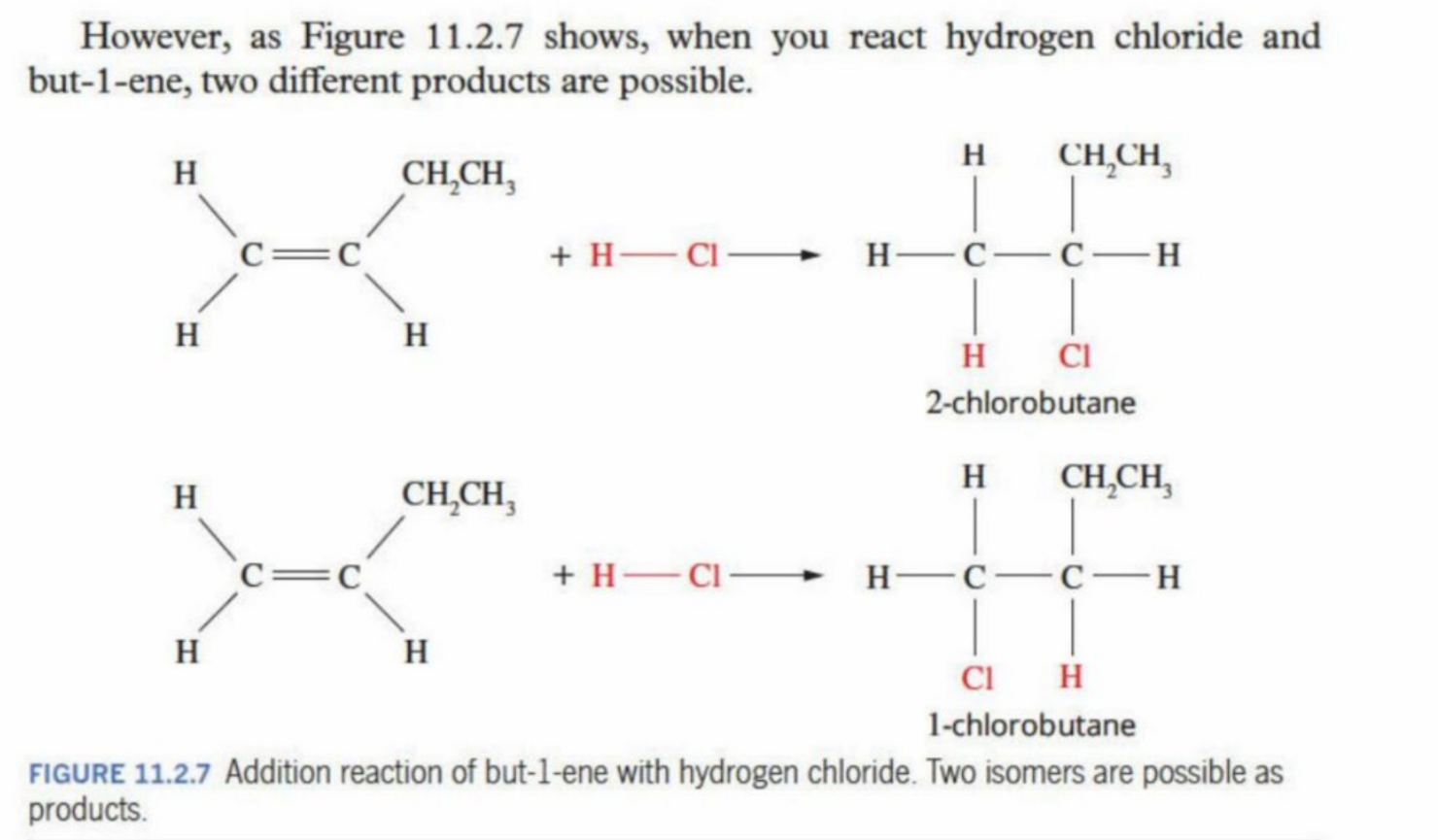

Can make isomers

Isomers made upon asymmetry of molecules

When an asymmetrical alkene bonded with an aysmmetrical reactant - isomers are produced

e.g. but-1-ene (C=C is is between C1 and C2 + HCI (is asymmetrical as the CI draws more electrons away from the H creating an imbalance)

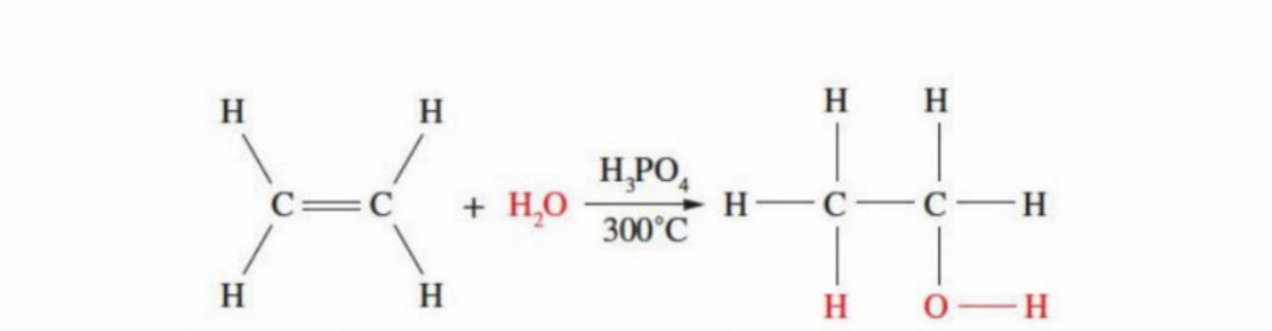

Alkenes with Water

Used to make an alcohol

Is used with an increase of heat and catalyst to speed up reaction

Is termed as hydration reaction

The making of ethanol using reactions with water

Explanation

Occurs at high temp (300oC) - reactants are passed over “bed” of the catalyst and gaseous ethanol is formed

Uses H3PO4 (Sulfuric Acid) as the catalyst

Commercial method of making ethanol - uses less energy (apart from initial heating), and is a one-step process

Solid-gas (heterogenous) nature of reaction - easy to remove product (ethanol as a gas) from reaction mixture, leaving catalyst (liquid)

Why having an hydroxyl group makes the hydrocarbon more reactive

OH bond - is highly polar and is very vulnerable to substitutions (with other atoms) and the lone pair on oxygen can also allow such additional reaction pathways

Alkene bond is non-polar - need higher activation energy

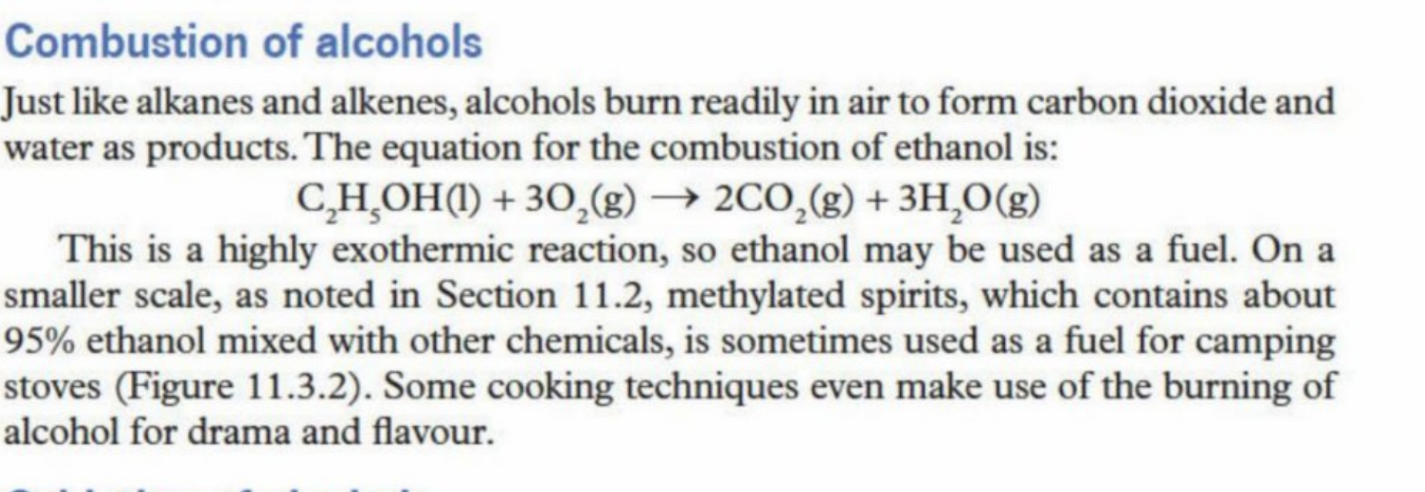

Combustion Of Alcohols

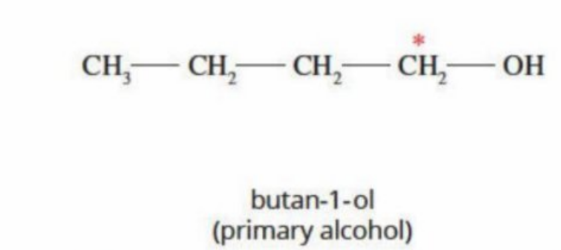

Primary Alcohols

The OH group is bonded to a carbon that is only bonded to one other carbon

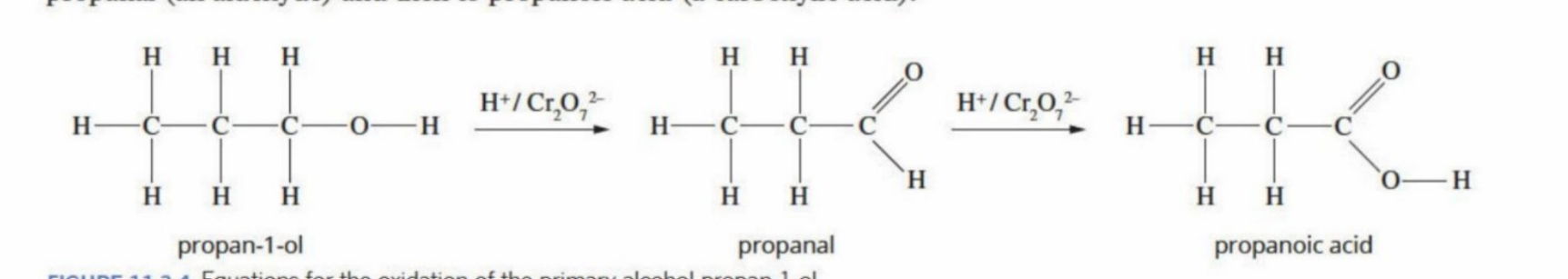

They oxidize to become aldehydes before oxidizing into carboxylic acids (is bonded to two hydrogens - can undergo oxidation twice)

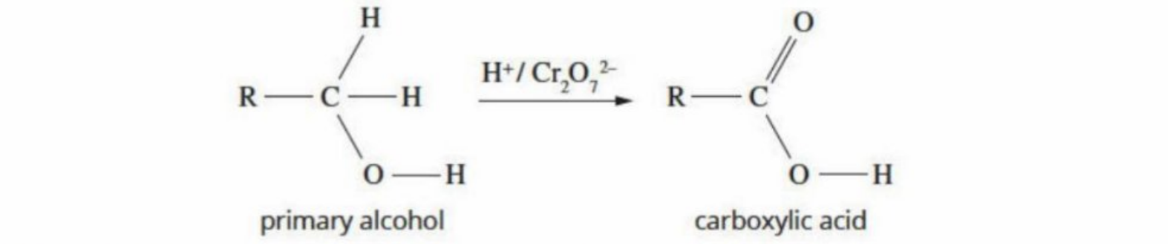

Oxidation of primary alcohols

Is first oxidised into aldehyde, and then into a carboxylic acid (group) - the carbon chain stays intact

An oxidising agent is used

Why an additional catalyst is used

Alcohols are not very reactive on their own

The C-OH bond is polar but strong, so the alcohol doesn’t easily give up hydrogens.

Catalyst provides the right environment

For example, in H+/Cr2O7-2

The acid protonates the alcohol (-OH → -OH₂⁺), making the oxygen a better leaving group.

Cr2O7-2 pulls electrosn from carbon as it is very “electronb-hungry” - disrupts C-H bond on alcohol carbon

This allows the oxidizing agent to accept electrons more easily.

Speeds up the reaction without being consumed

The catalyst lowers the activation energy, so the reaction happens faster and under milder conditions.

Primary Alcohols Oxidation (Visual)

General Primary Alcohols Oxidation Equation

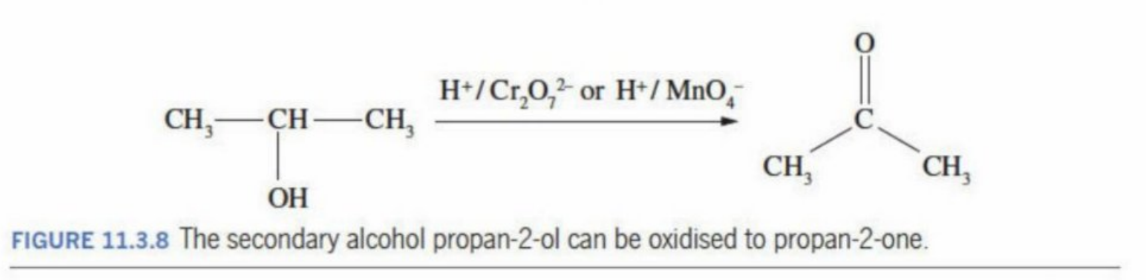

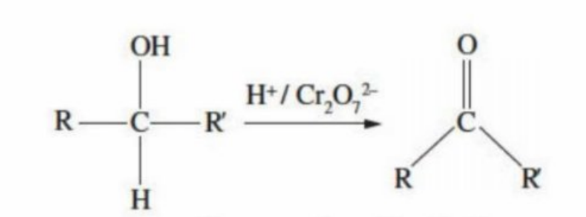

Secondary Alcohol

OH bonded Carbon is bonded to two other Carbon atoms

Produces a ketone in the presence of a strong oxidizing agent (reduces itself)

Secondary Alcohol Oxidation

Creates a ketone by the oxidation of the secondary alcohol

Secondary Alcohol General Reaction

Tertiary Alcohol Oxidation

As there are no hydrogens bonded to the carbon that is connected to the OH group, it cannot undergo oxidation (must loose a Hydrogen)

Tertiary alcohols are resistant to oxidation, no matter how strong the oxidation agent

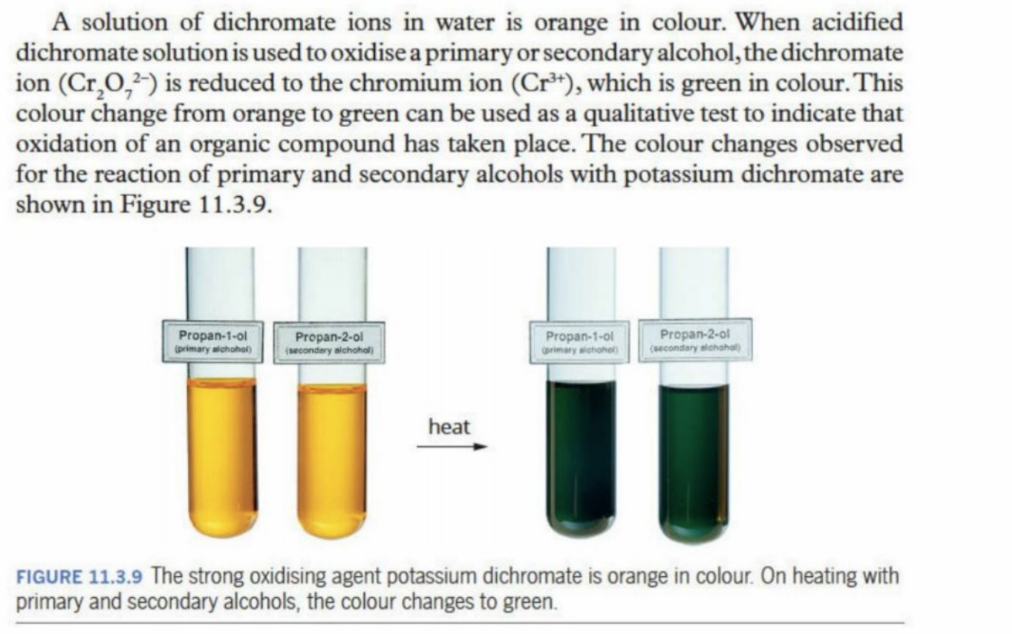

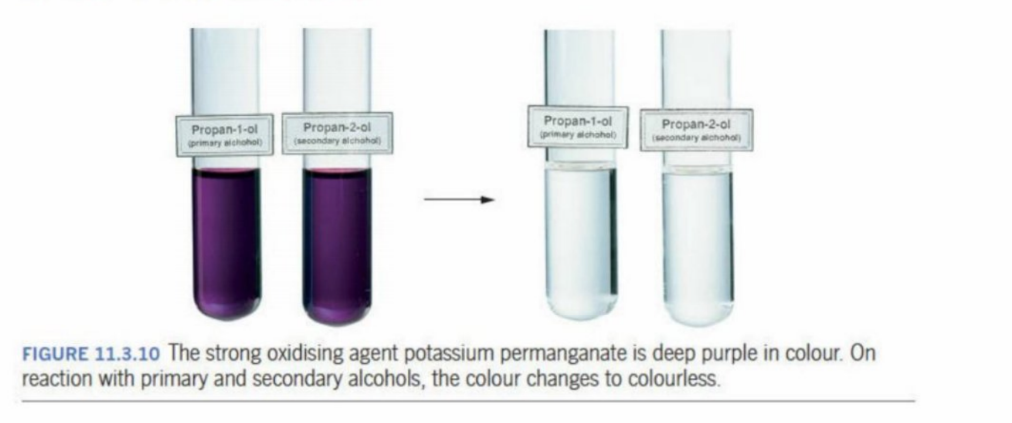

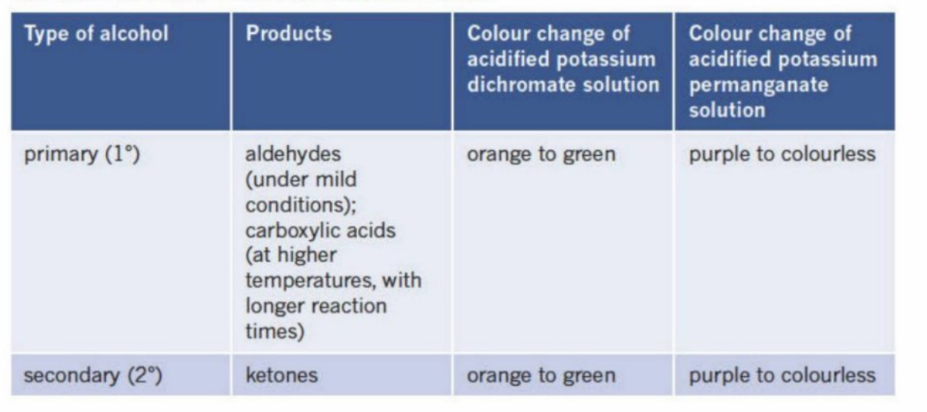

Using dichromate and potassium permanganate to indicate oxidation

When a primary or secondary alcohol is placed into these oxidising agents, they turn in colour, siganlling that oxidation has occured

The change in colour - shows gain in electrons

Dichromate

Cr —→ reduced to Cr+3 (its own charge - oxidation number)

If tertiary alcohol - no colour change is observed

Potassium permanganate

Changes from purple (MnO4-) to colorless (reduced to Mn+2), when secondary or primary alcohols are used.

Why is heat used

1. Overcoming Activation Energy (Ea)

Even though the reaction between an alcohol and potassium dichromate is "energetically favorable" (exothermic), it doesn't happen instantly at room temperature.

The Barrier: The molecules need a specific amount of kinetic energy to collide with enough force to break existing bonds (like the C-H and O-H bonds) and form new ones (C=O).

The Solution: Heat provides this "spark," increasing the speed of the molecules so that more collisions result in a successful reaction.

2. Controlling the "Oxidation Ladder"

Heat is the "throttle" that determines how far the reaction goes. This is especially true for primary alcohols, which can be oxidized in two stages:1

Alcohol —→Aldehyde

Aldehyde ——> Carboxylic Acid

Distillation (Gentle Heat): If you want to stop at the aldehyde, you heat the mixture gently and use a distillation setup.6 Because aldehydes have lower boiling points than alcohols, they evaporate and leave the reaction flask as soon as they are formed, preventing them from being oxidized further.7

Reflux (Strong Heat): If you want the carboxylic acid, you use a reflux condenser.8 This allows you to boil the mixture vigorously for a long time. Any aldehyde that evaporates hits the cold condenser, turns back into a liquid, and falls back into the flask to be "hit" by the oxidizing agent again until the reaction is complete.9

3. Increasing Reaction Rate

Organic reactions are notoriously slow compared to the "instant" reactions you see in inorganic chemistry (like acid-base titrations). Without heat, you might have to wait days to see the orange-to-green color change. By heating the mixture, you compress that time into a few minutes, making it a practical laboratory test.

Summary Of Reactions with primary and secondary alochols

Carboxylic Acids Reactions With Alcohols (Esterification - Forming Of Esters) - Why Catalysts are added

Are gently stirred with heat and with catalyst (e.g. sulfuric acid H2SO4 - adds hydrogen to carbonyl oxygen)

The H⁺ attaches to the oxygen of the carbonyl.

Oxygen now has more positive charge, so it pulls even more electron density away from the carbon.

Effect: The carbonyl carbon becomes more positively charged (even more δ⁺).

3. Why this matters

Alcohol attacks carbon by donating a pair of electrons (nucleophile).

Normally: the carbon isn’t positive enough → attack is slow.

After protonation: the carbon is more electrophilic → alcohol can attack much more easily.

Esterification (Visual)

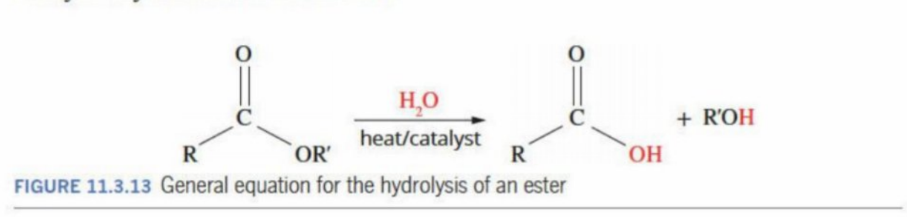

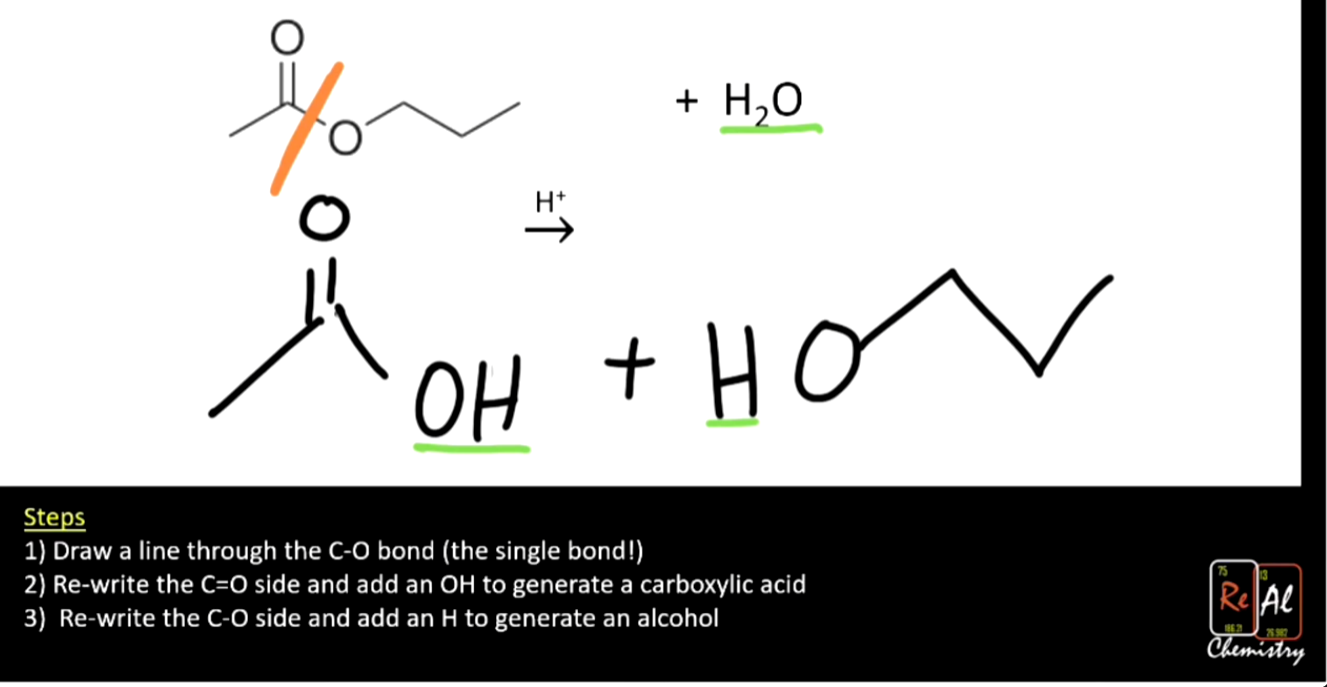

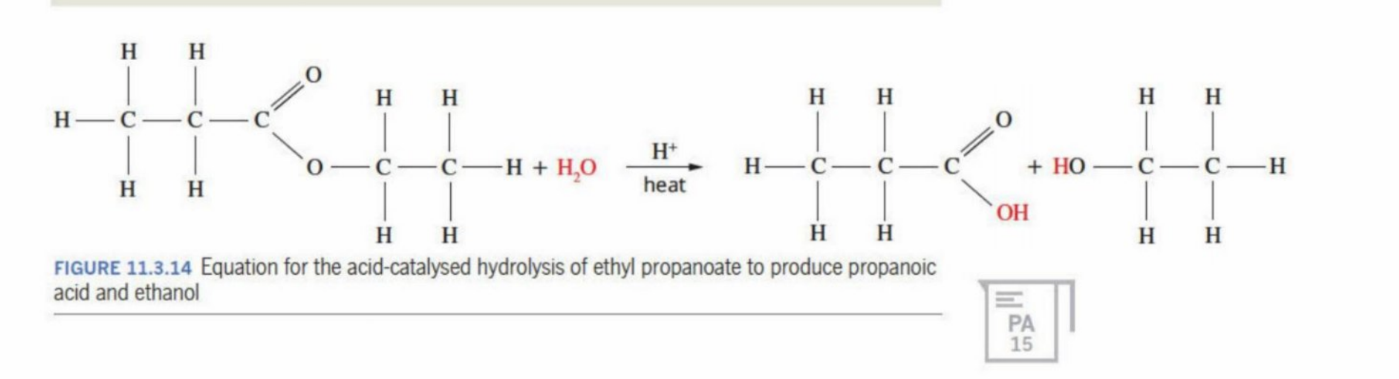

Splitting apart an ester (hydrolysis)

Goes back to carboxylic acid and alcohol by adding water (what was taken away during condensation)

Example

Example #2

When a catalyst like an alkali (e.g. NaOH) is used (unclear)

Salt is produced of the carboxylic acid, but can be turned into a solution through adding dilute acid solution

When using catalyst (what happnes)

The ion of the catalyst is added onto the molecule, preventing it becoming a carboxylic acid

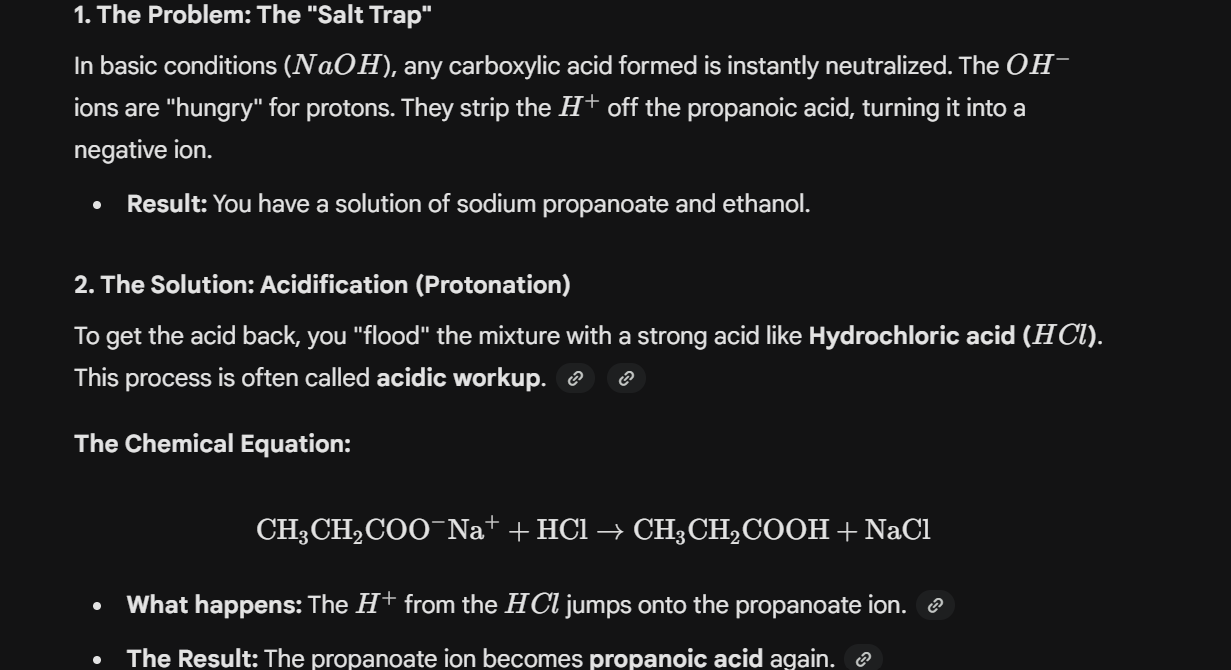

How to resolve this problem

HCI is used and creates the acid

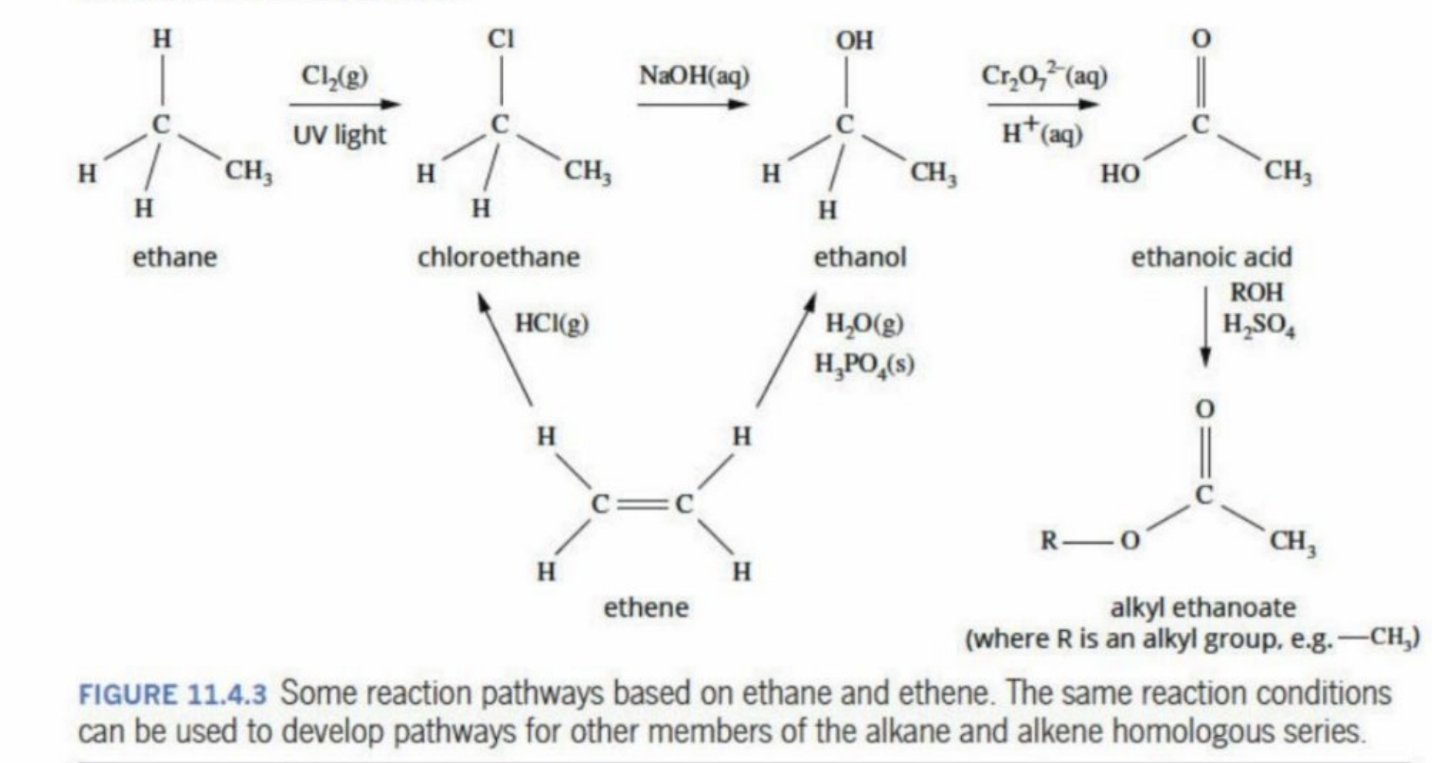

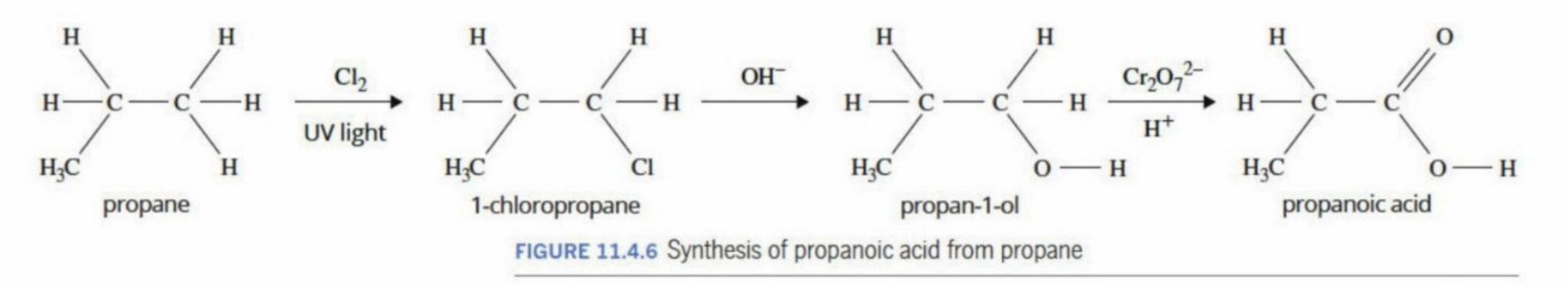

Reaction pathway

A series of one or more steps or reactions that are used to convert a reactant into a desired product with different functional groups

Can be done so in many different ways

Simple Reaction Pathways

With alkanes and alkenes, they generally produce the same products using the same inorganic reactants and reaction conditions

Because they share similar properties with one another

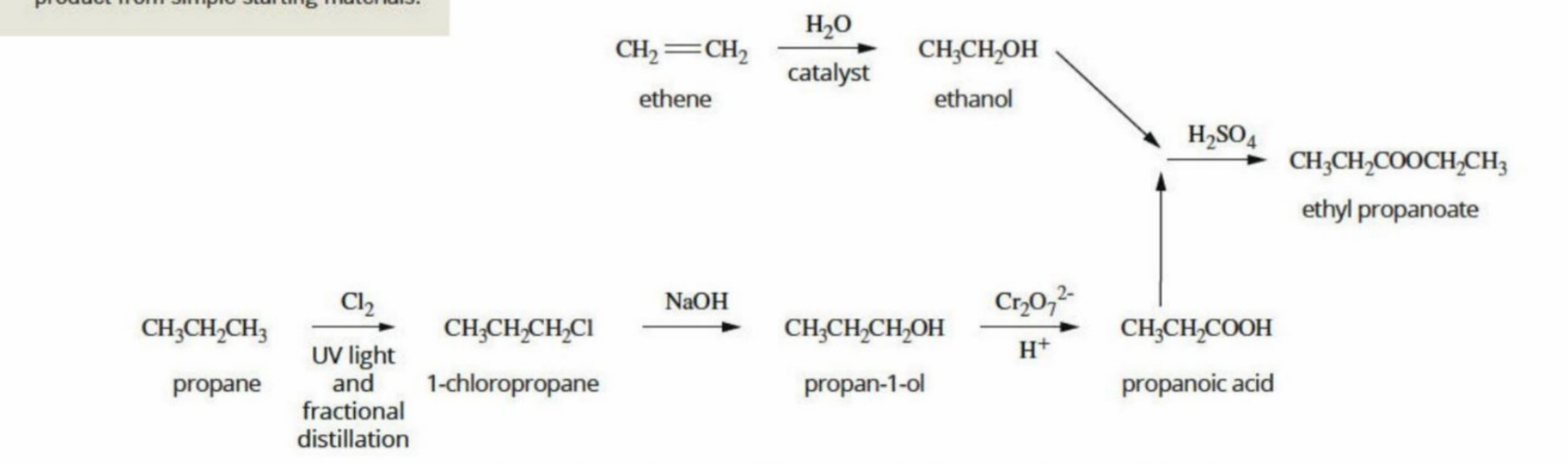

Example of reaction pathway (alkane)

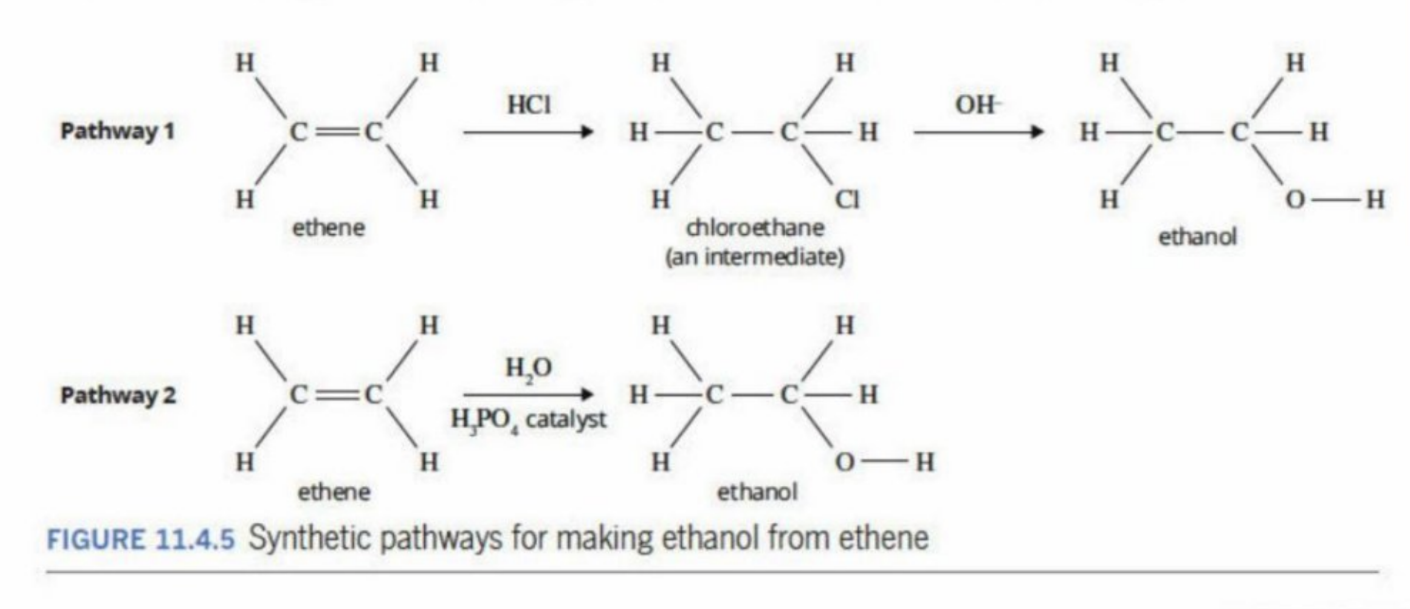

Making ethanol (complex reaction pathway) - in order to make an ester

Two pathways in creating ethanol

Uisng HCI to create Chloroethane, then using OH to create ethanol

Using water and phosphoric acid (H3PO4)

Why second method is better

a) Fewer steps = higher yield

Every extra step (like making a haloalkane) loses some product.

Direct hydration avoids the intermediate, so you get more ethanol from the same amount of ethene.

b) Simpler and cheaper

Using just water and an acid is cheaper than buying and handling HCl and a separate OH⁻ source.

Fewer chemicals, less purification needed.

c) Safer and cleaner

Haloalkanes like chloroethane can be toxic and volatile.

Direct hydration avoids creating hazardous intermediates.

d) Less energy-intensive

Direct hydration can often be done at lower temperatures and pressures than the two-step method.

Making propanoic acid (in order to make an ester)

Why does OH displace CI

Chlorine is displaced because it is a good leaving group, and OH⁻ is a nucleophile that can attack the carbon and form a stronger, stable bond with oxygen.

Electrophile

An “electron lover” which is attracted to electrons

Must be positive in charge, or deficient in electrons itself

In the same reaction: the carbon in C–Cl is partially positive → it is the electrophile

It accepts a pair of electrons to form a bond

Nucleophile

An atom that is negative in charge and is attracted to positive charge

is either negative or neutral

Must have a lone pair to donate

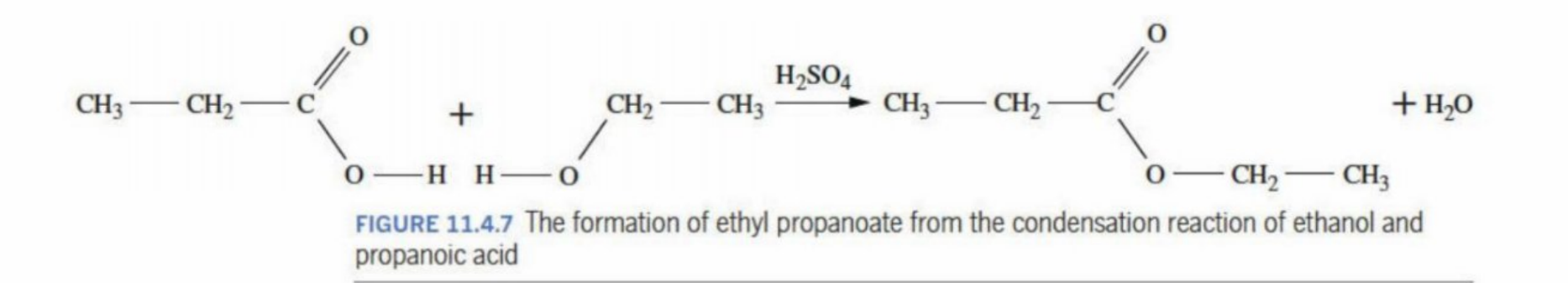

Ethyl Propanoate being formed through creating the acid and the alcohol (condensation reaction)

Purpose of a reaction pathway

To show the reactions required to produce a product from simple starting materials (to create a visual representation)

Full Reaction pathway of ethyl propanoate

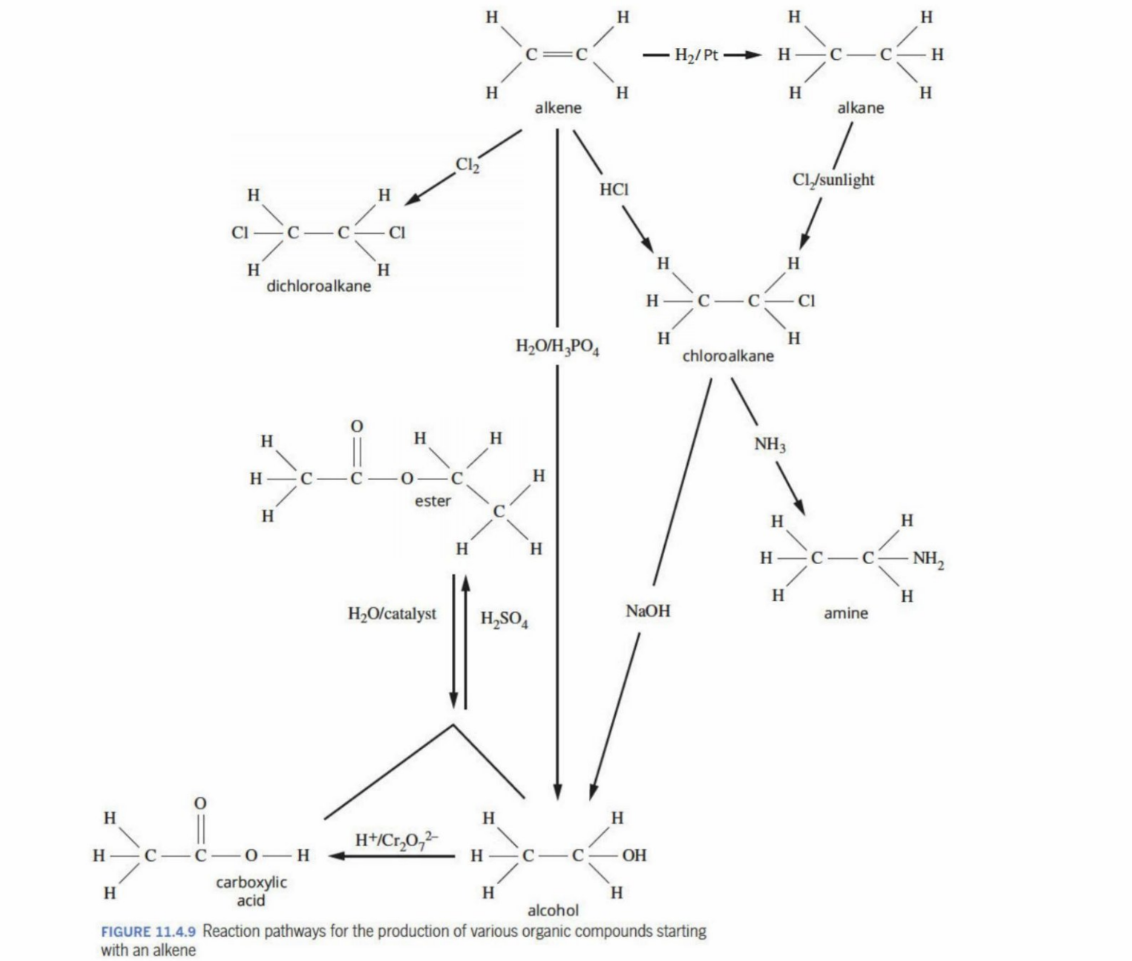

Reaction pathways - Overview of what can be made using different reagents and catalysts

Steps in devising an appropriate plan for a reaction sequenc

1) Functional groups and the required molecule are identified

2) A synthetic pathway is made based on the existing knowledge of functional groups - may require intermediate stages (compounds)

3) Isomers need to be considered as they could also be produced (you may aim for one specific molecule, but isomers may form as well) - more than possible pathway is to be made - product can be made through many different ways

4) Methods of separation from intermediates and other isomers must be determined

5) Final product must be purified and evaluated

6) Must consider yield - not all reactants may turn into products

Yield

The amount of product obtained through respective reaction pathways

Efficiency - can be derived through calculations

3 types: Theoretical yield, Actual yield, Percentage yield

Theroretical yeild

The mass of product obtained If the limiting reagent reacts according to the stoichiometric ratios of the equation - the theoretical output of product (reactants 100% convert into products)

Actual Yield

Lower than theoretical yield (what is desired) due to a number of factord

Reasons why actual yield is lower than theoretical yield

1) If reaction reaches equilibrium - reactants are being turned into products; however, products are also being turned into reactants (never attains full product output)

2) If the reaction rate is slow - cannot be fully completed in the bound time, creating less product

3) Changing between vessels, separation, purification, and filtration result in smaller amounts of product formed

4) Competing reactions - reactants may form another reaction instead of the intended one.

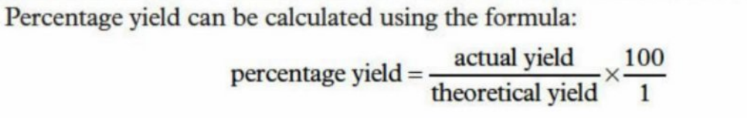

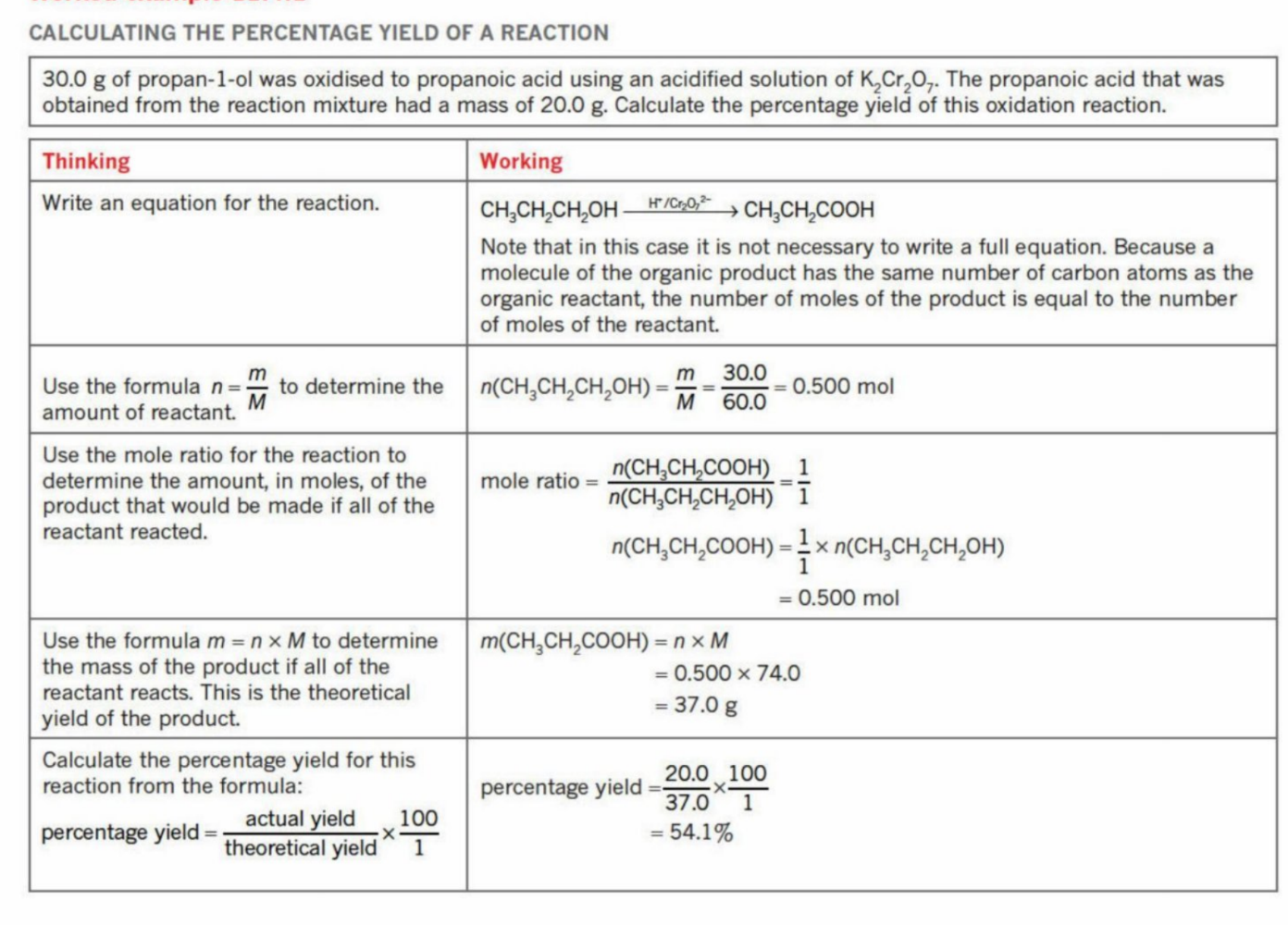

Percentage Yield

Compares actual yield to theoretical yield

Example

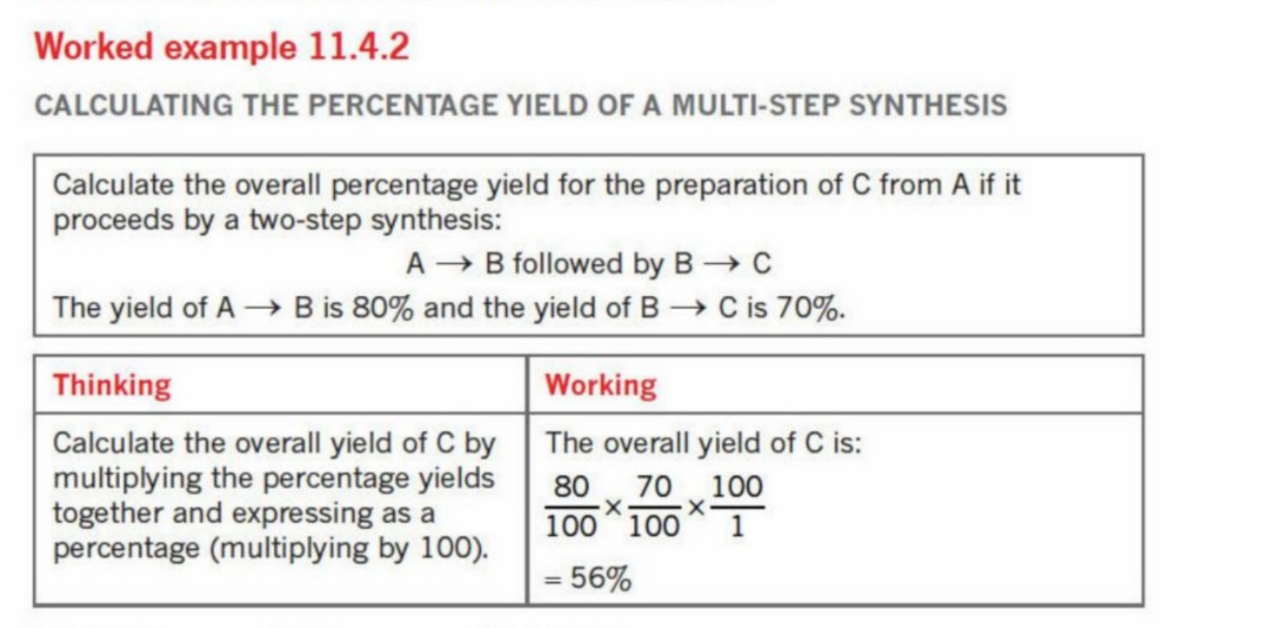

Percentage Yield in multi-steps

Yield is lost in every step of a reaction pathway

A lower yield in one of the intermediate reactions can cause a massive effect in the amount of product obtained

Comparison of percentage yields can indicate which pathway is most efficient - is paramount to prevent wasting of valuable reactants

Example

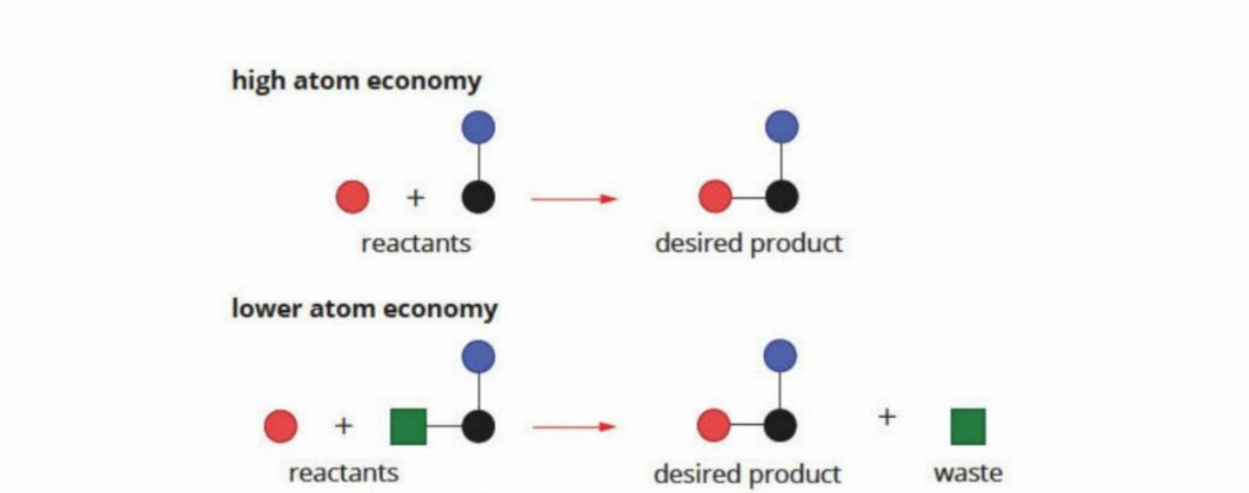

Atom economy

A measure of how many atoms in the reactants end up in the products

The higher the atom economy, the less wastage produced and higher yield is established

Visual Representation

If only one product, then atom economy is 100%

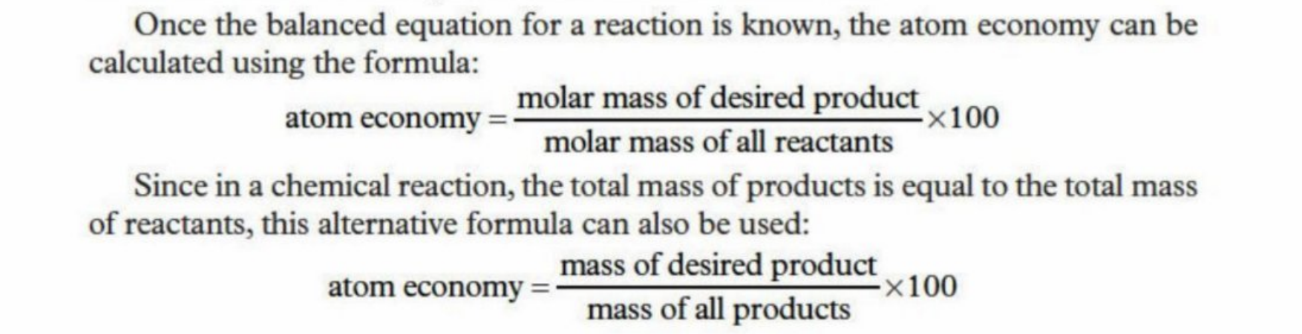

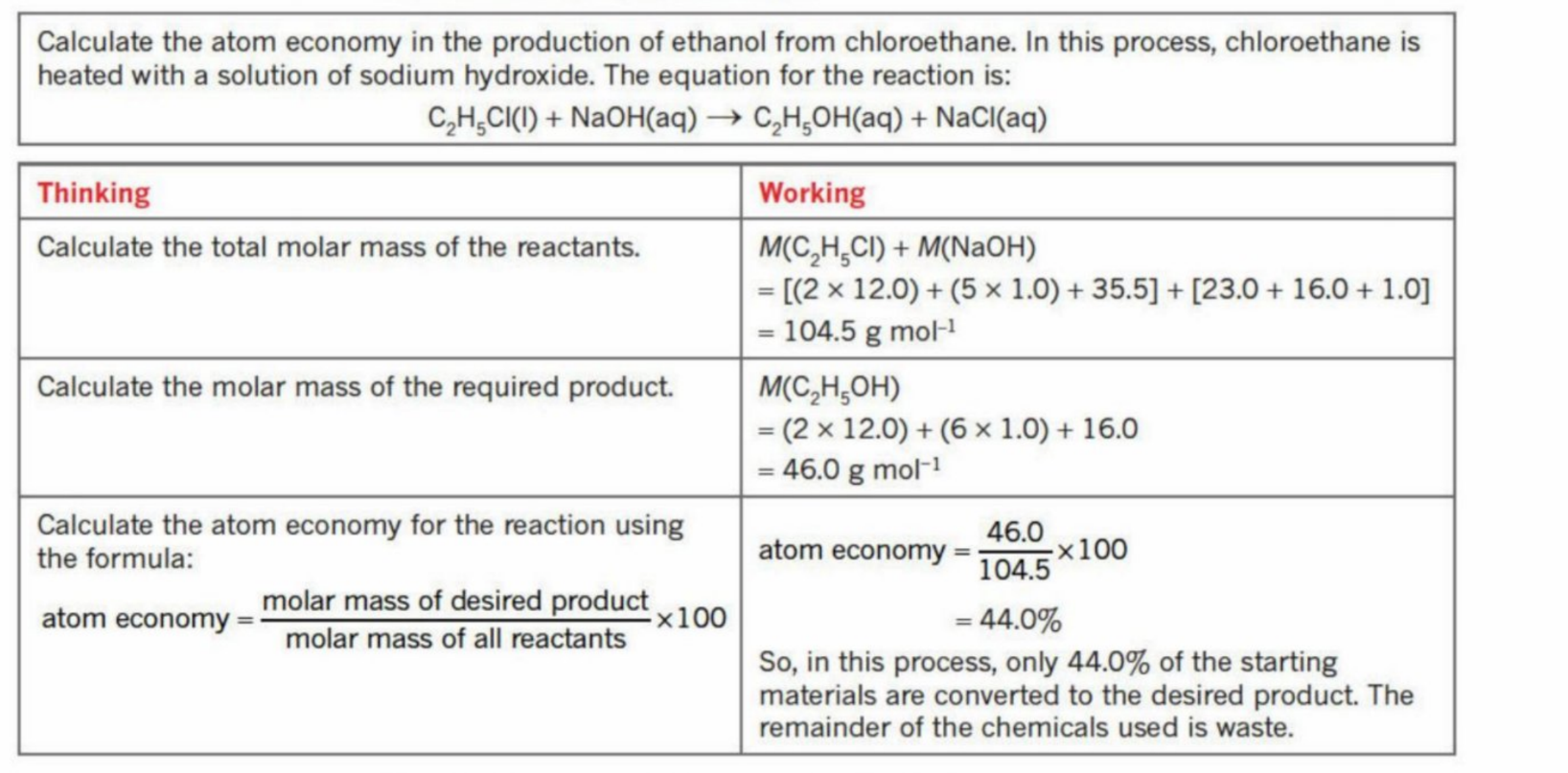

Finding atom economy

Example

Benefits of high atomic economy

Produces less waste

Uses reactants more efficiently

More atoms end up in the desired product

Lower costs for raw materials

Lower disposal costs for waste

Easier purification of product

Reduced environmental impact

Aligns with green chemistry principles

Radical

An atom or molecule with a single unpaired electron

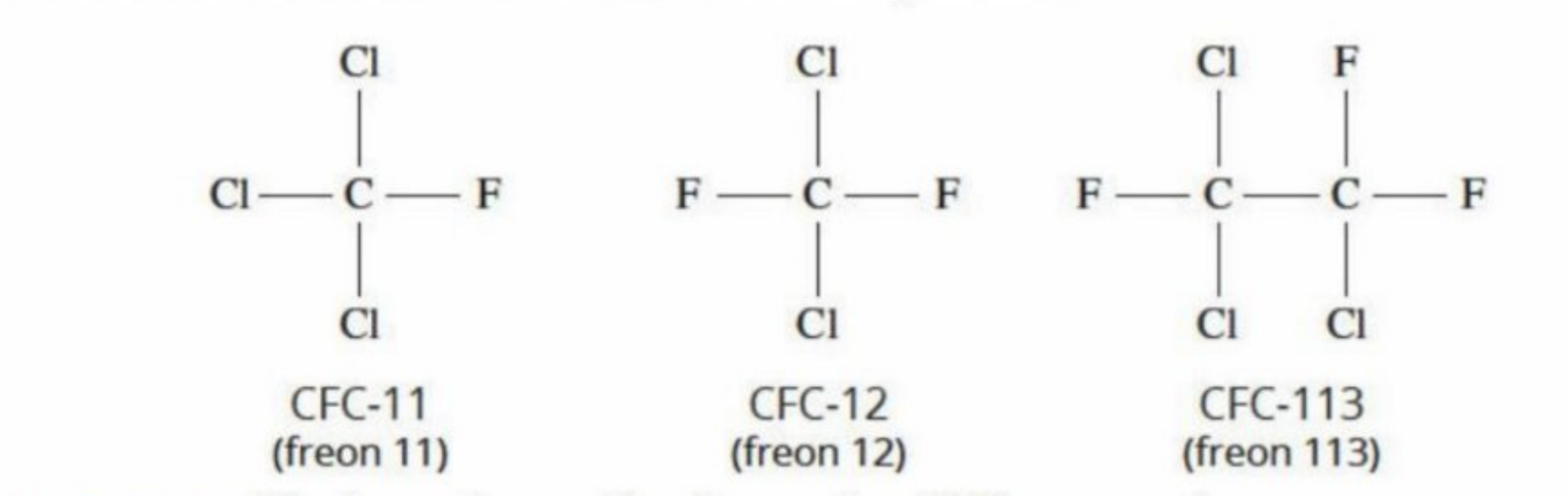

CFC Compounds

Chlorofluorohydrocarbons (hydrocarbons contained fluorine and chlorine)

Were responsible for the decrease in the concentration of the ozone

Structure —→

Montreal Protocll

The agreement of scientists and authorities from around the world is slowly phasing out the usage of CFC’s in aerosols and refrigerants

Occurred in 1987

Now, levels have stabilized through using alternatives - by 2050 ozone levels will have stabilized to pre-1987 levels

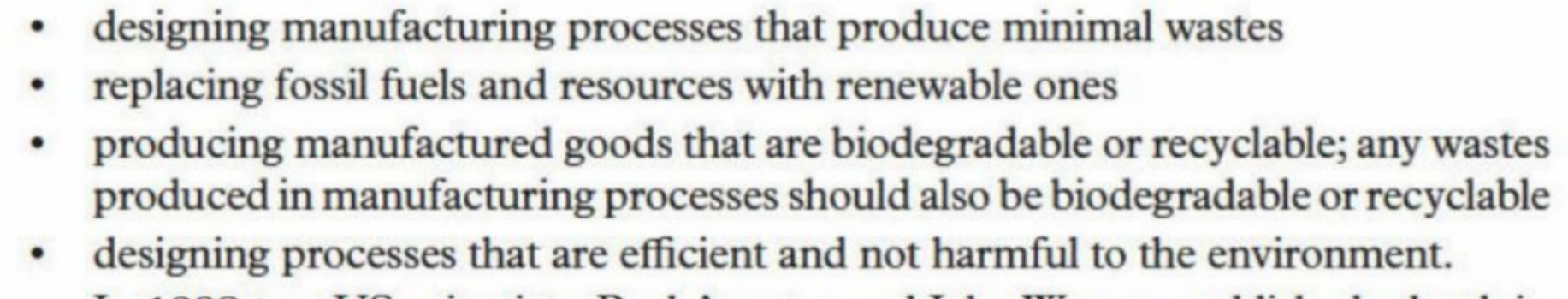

Green Chemistry

Creating a new approach to the design and manufacturing processes of chemicals required, mitigating the effects upon the environment and human health

Examples Of Fundamental aims - green chemistry

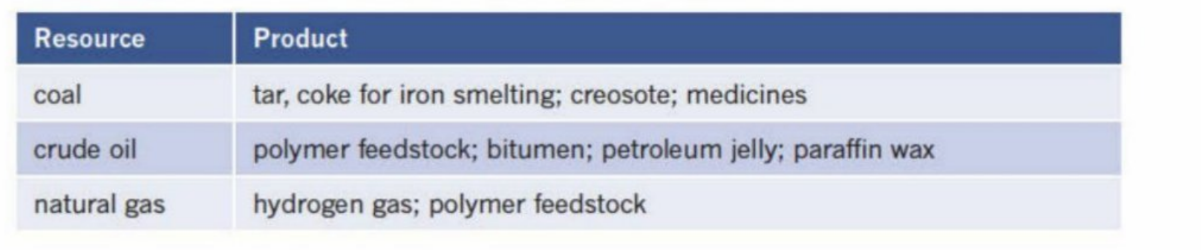

Feedstock

A raw material used in the preparation of other products

e.g. oil is used for biodiesel

Uses of coal crude oil and natural gas

Are non-renewable - are pollutants and cannot be replenished for constant manufacturing

Are also non-biodegradable - will persist in environment

There are alternatives being developed

Biopolymers

Are made from feedstocks (the raw materials) that are derived from plants and celluloid and cellophane - both were derived from cellulose

Were used in 1920s - now are primarily made from fractional distillation of crude oil (non-renewable)

The polymers do not decompose easily

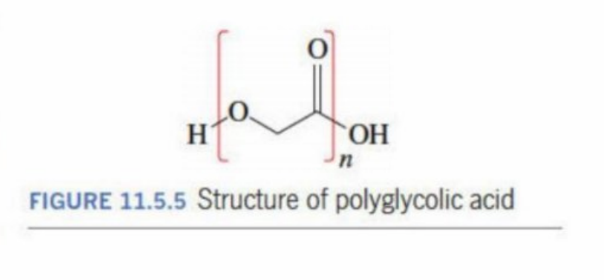

Polyglycolic acid

Is a biopolymer that is good at biodegradability

Has a fast degradation rate

Has a high stiffness (performs like heavy-duty plastic but is lightweight)

Is biocompatible (used in surgeries as stitches)

does not leak -Prevents leakage

Polyglycolic acid (structure)

Biosolvents

Are derived from biomass and use renewable feedstocks as opposed to non-renewable feedstocks

Example of a bio solvent

Glycerol - Used in the production of biodiesel - also used in cosmetic space

Turpentine - a grease solvent and paint thinner - is derived from the resin of trees (renewable)

Solketal - Polar compound and is used in ink and paint manufacturing - derived from glycerol (a renewable feedstock)

Advantages of biopolymers and biosolvents

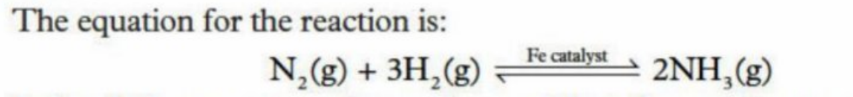

Haber Process - Catalysts

Used to make ammonia from nitrogen and hydrogen gas in the presence of an iron catalyst

Is an exothermic reaction

High pressure is used to favor the reaction that produces the lower amount of atoms (the forward reaction - produces ammonia)

A medium (450 degrees) temperature is used to speed up the reaction, despite not attaining all of the yield

A catalyst - Iron - is used to lower the activation energy, resulting in much lower energy required for teh energy to occur

Enables enormous savings in heating - reduces consumption of fossil fuels

Haber process (link)

Enzymes

Are biological catalysts

Reduce the need for chemicals to carry out reactions - resources are saved and heating cost and wastes are reduced

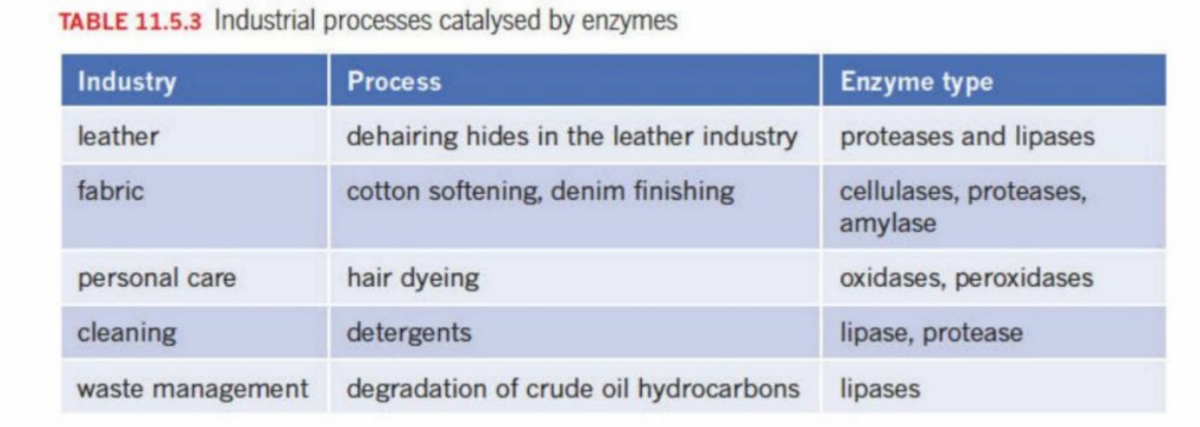

Industrial Processes using enzymes

Catalyst Advantages (Overall)

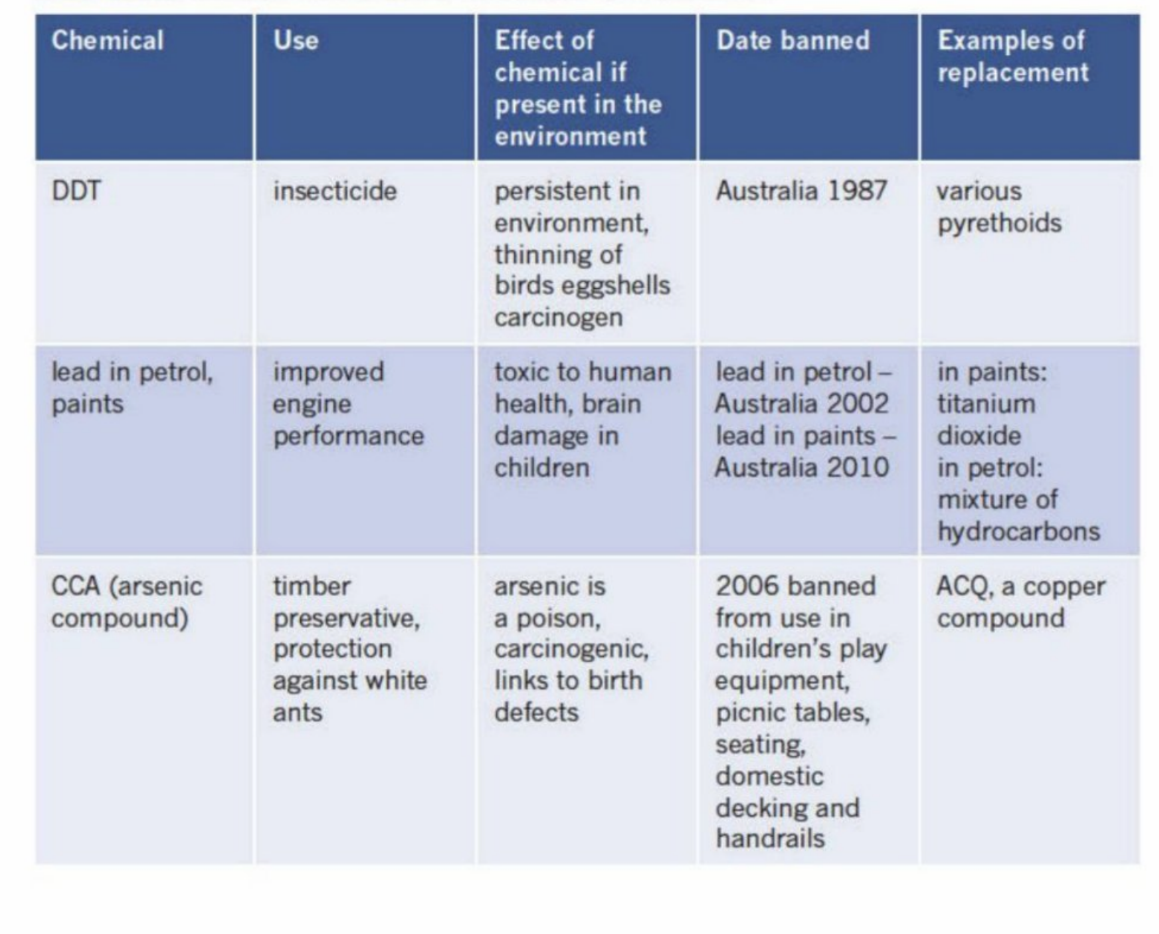

Designing safer chemicals

Banning/prohibiting certain chemicals due to the damaging impact they have on the surrounding environment and the harm they pose to human health

Chemicals that have been banned

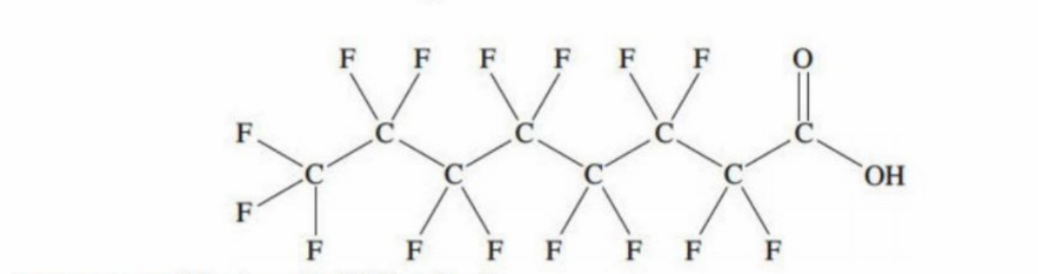

PFAS - Perfluoroalkyl compounds (fire-fighting foams)

Have a long chain of carbons bonded to fluorine atoms

Why PFAS is banned

The C-F bonds are very strong

Have high heat resistance and stability

Are banned as they don’t break down readily and can build up concentration in waterways, soil and groundwater - become pollutants to the environment

Alternatives to PFAS

Using non-fluoro containing mixtures - non-toxic and biodegradable - will break down in the environment in a short time