FAA General: Inspections Concepts and Technique

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

32 Terms

When a 100-hour inspection is completed, if separate maintenance records for the airframe, powerplant(s), and propeller(s) are maintained, where is the entry for the inspection recorded?

In each record

What tool is used to determine the correct drill bit size?

A hole gauge and micrometer

Who is responsible for making the entry in the maintenance records after an annual, 100-hour, or progressive inspection?

A person approving or disapproving for return to service

The 100-hour inspection required by Federal Aviation Regulations for certain aircraft being operated for hire may be performed by

Appropriately rated mechanics and approve by them for return to service

Which of the following actions is/are appropriate concerning minor repairs performed on a certificated aircraft?

entries must be made in the aircraft maintenance record

If it is necessary to accurately measure the diameter of a hole approximately 1/4 inch in diameter, the mechanic should use a

small-hole gauge and determine the size of the hole by taking a micrometer reading of the ball end of the gauge

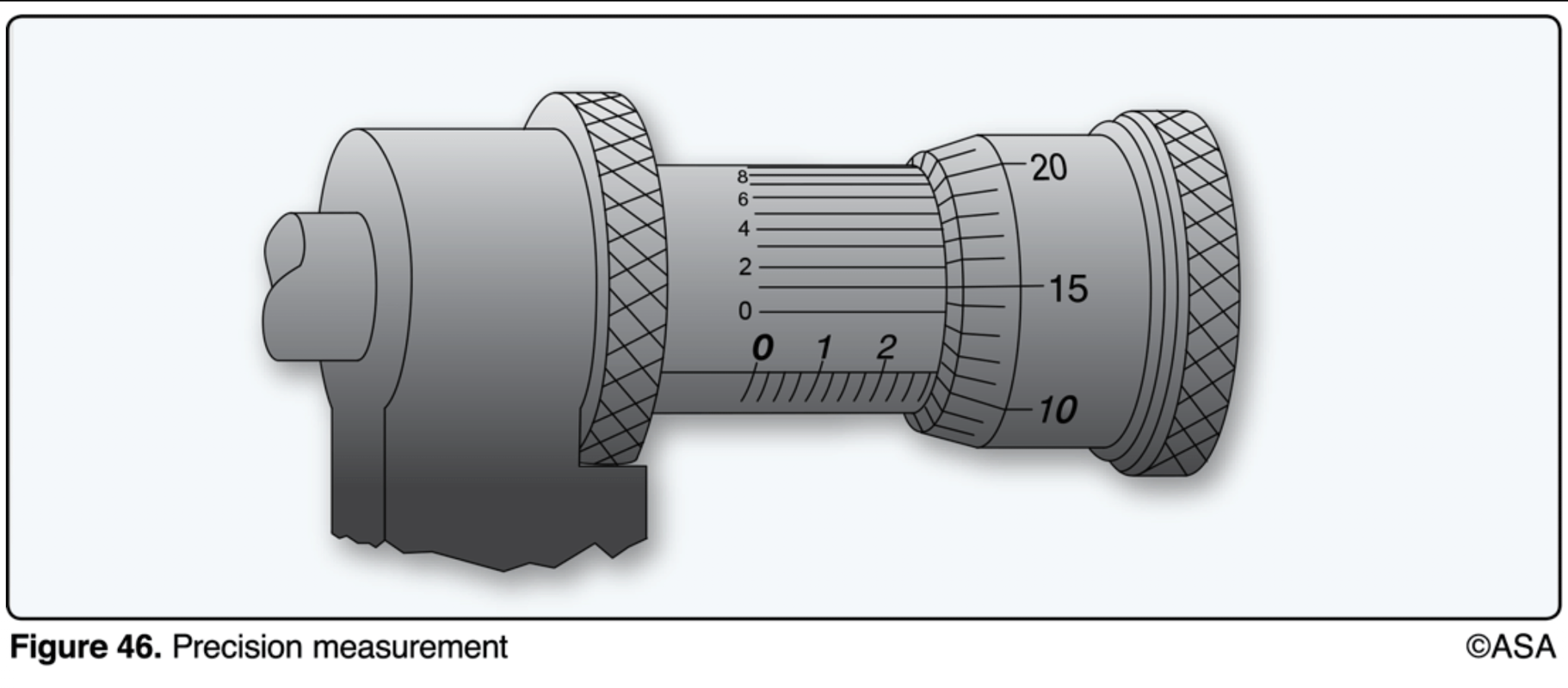

(Refer to Figure 46.) The measurement reading on the illustrated micrometer is

0.2851

Which tool is used to measure the clearance between a surface plate and a relatively narrow surface being checked for flatness?

Thickness gauge

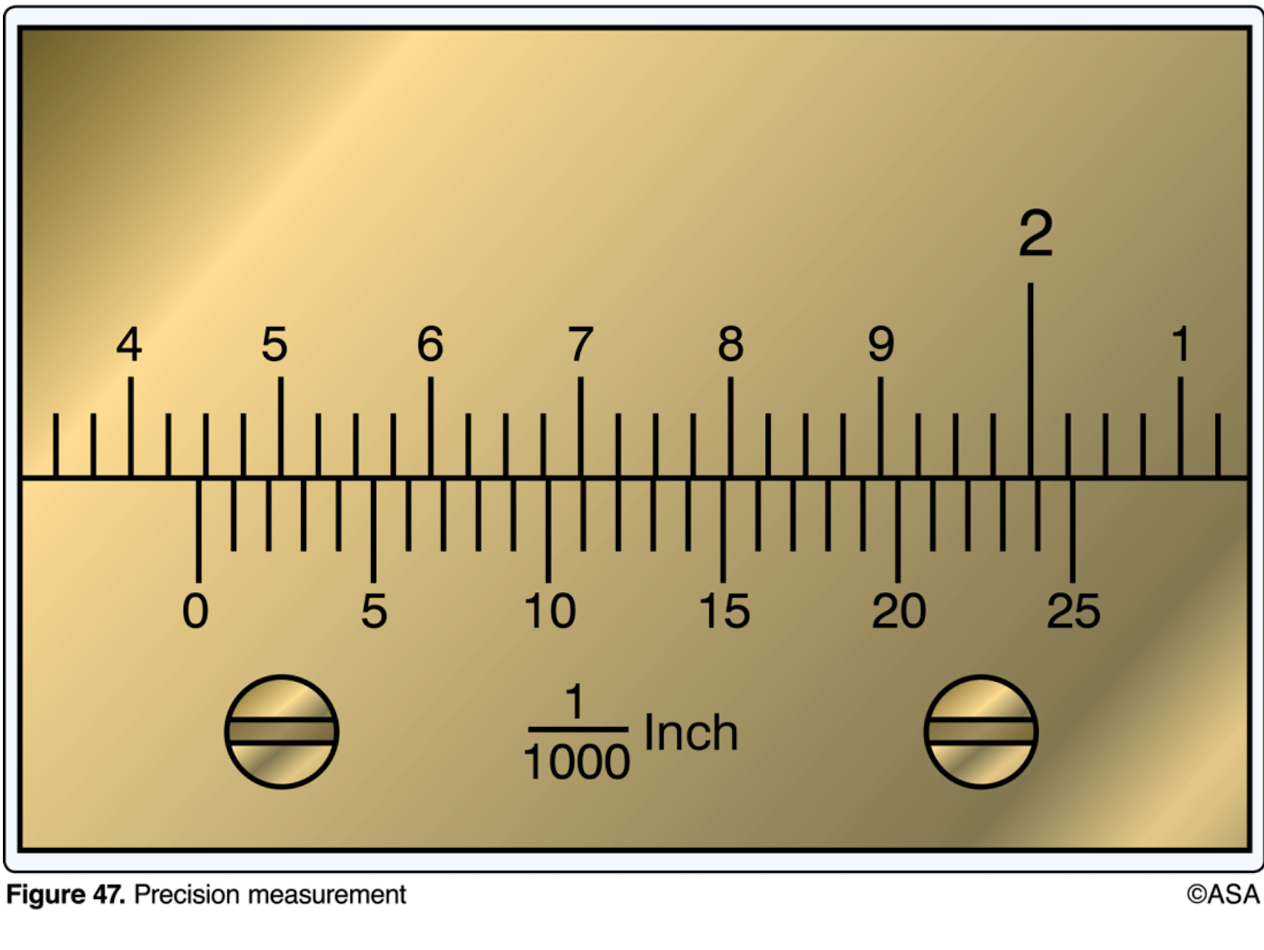

(Refer to Figure 47.) What is the measurement reading on the vernier caliper scale?

1.436 inches

What may be used to check the stem on a poppet-type valve for stretch?

Micrometer

Which tool can be used to determine piston pin out-of-round wear?

Micrometer Caliper

What precision measuring tool is used for measuring crankpin and main bearing journals for out-of-round wear?

Micrometer Caliper

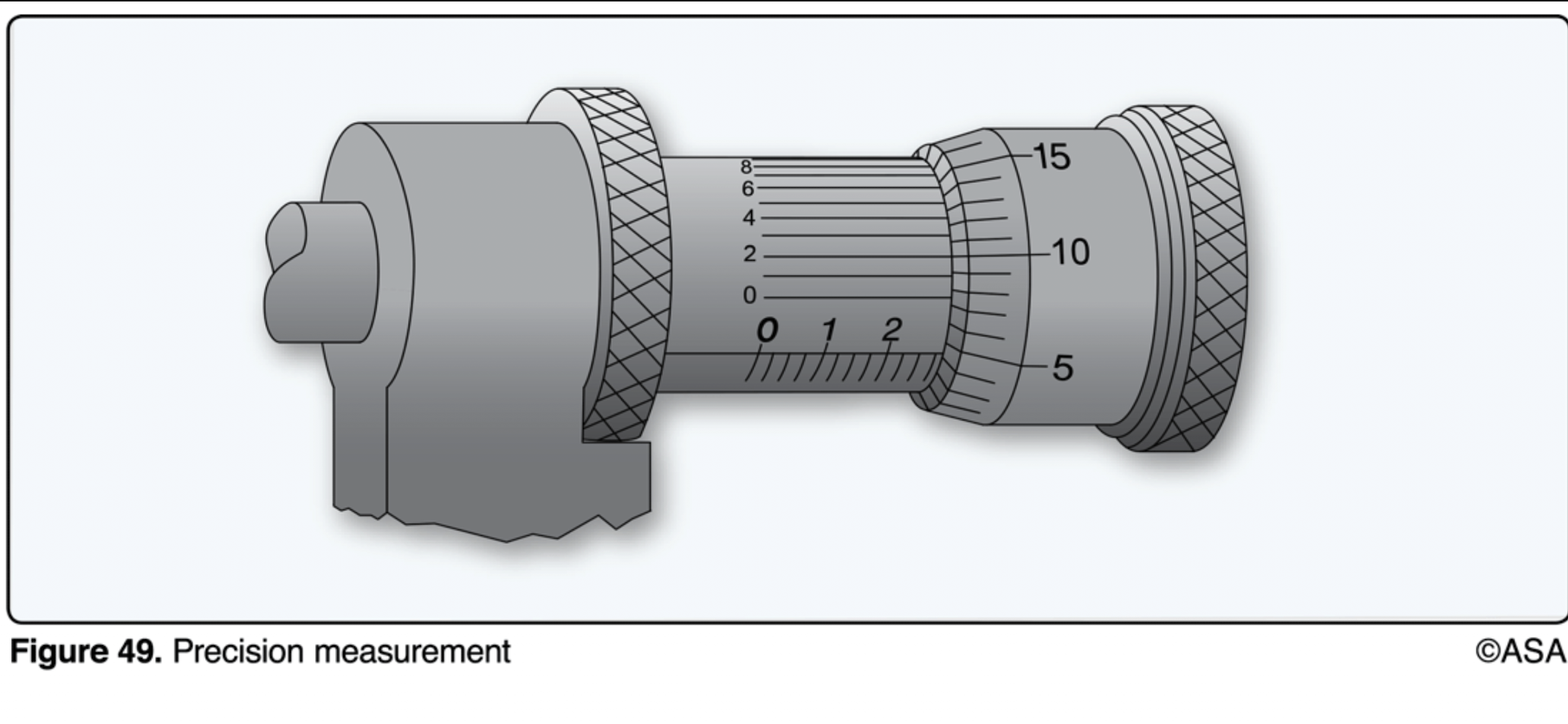

(Refer to Figure 49.) The measurement reading on the micrometer is

.2792

How can the dimensional inspection of a bearing in a rocker arm be accomplished?

Telescopic gauge and micrometer

Which of the following statements is true?

In nondestructive testing, a discontinuity may be defined as an interruption in the normal physical structure or configuration of a part.

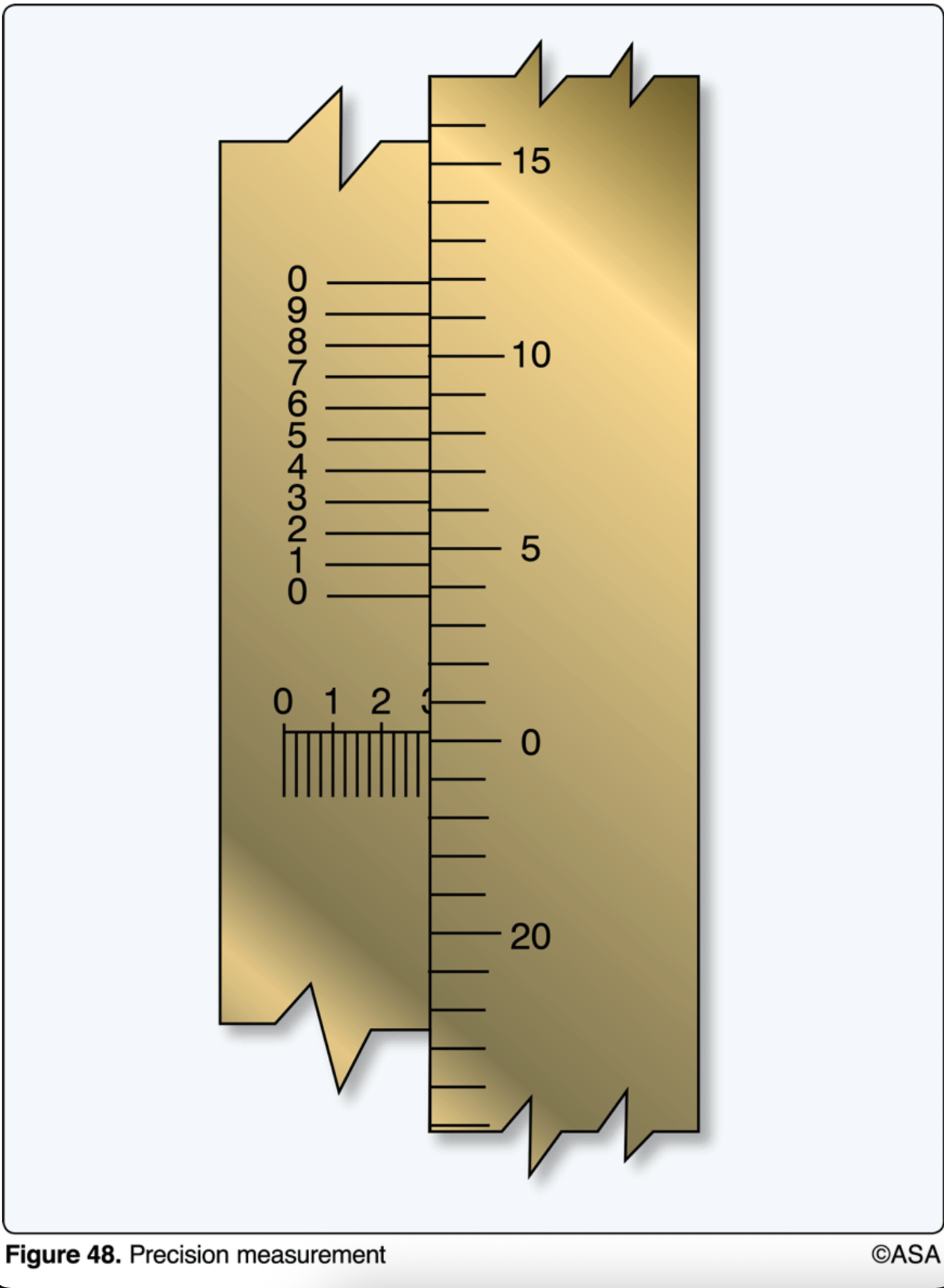

(Refer to Figure 48.) What does the micrometer read?

.3004

A certificated airframe and powerplant mechanic is required to have an Inspection Authorization rating to perform which of the following inspections and approve the aircraft for return to service?

An annual and progressive inspection

What tool is generally used to set a divider to an exact dimension?

Machinist scale

What tool is generally used to calibrate a micrometer or check its accuracy?

Gauge Block

During an annual inspection, if a defect is found which makes the aircraft unairworthy, the person disapproving must

provide a writting notice of the defect to the owner

Which number represents the vernier scale graduation of a micrometer?

.0001

The side clearances of piston rings are measured with a

thickness gauge

What nondestructive testing method requires little or no part preparation, is used to detect surface or near-surface defects in most metals, and may also be used to separate metals or alloys and their heat-treated conditions?

Eddy current inspection

After a mechanic holding an airframe and powerplant rating completes a 100-hour inspection, what action is required before the aircraft is returned to service?

make the proper entries in the aircraft’s maintenece record

Who has the authority to approve a propeller for return to service after a 100-hour inspection?

a certificated mechanic with a powerplant rating

Which inspection method can be used on a variety of materials?

Ultrasonic inspection

If an aircraft owner is provided a list of discrepancies on an aircraft that was not approved for return to service after an annual inspection, who may correct the discrepancies?

An appropriately rated mechanic

A mechanic has completed a bonded honeycomb repair using the potted compound repair technique. What nondestructive testing method is used to determine the soundness of the repair after the repair has cured?

Metallic ring test

An aircraft was not approved for return to service after an annual inspection and the owner wanted to fly the aircraft to another maintenance base. Which statement is correct?

the owner must obtain a special flight permit

The twist of a connecting rod is checked by installing push-fit arbors in both ends, supported by parallel steel bars on a surface plate. Measurements are taken between the arbor and the parallel bar with a

thickness gauge

Identify the correct statement.

Dividers do not provide a reading when used as a measuring device

Each person performing an annual or 100-hour inspection shall use a checklist that contains at least those items in the appendix of

14 CFR Part 43