Fundamentals of Metal Forming(rolling)

1/15

Earn XP

Description and Tags

Metal forming operations which cause significant shape change by deforminh metal parts whose initial form is bulk rather than sheet

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

16 Terms

What are the starting forms of bulk deformation?

cylindrical bars and billets, rectangular billets and slabs and similar shapes

Two main functions of rotating rolls

Pulls the work into the gap between them by frictions between work parts and rolls, simultaneously squeeze the work to reduce its cross section

Two types of rolling based on workpiece geometry:

flat: used to reduce thickness of a rectangular cross section, shape: square cross sections is formed into a shape such as an I-beam

Two types of rolling based on temperature:

Hot: most commons due to large amount of deformation required, cold: produces finished sheet and plate stock

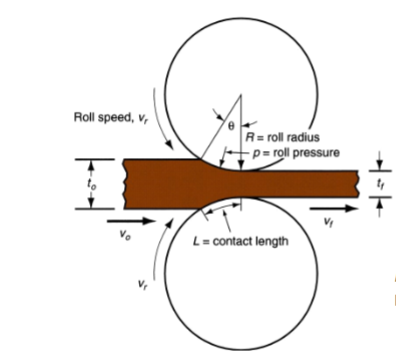

What is this a diagram of? Also what is draft?

Flat Rolling, draft: thickness reduction

Shape Rolling

Work is deformed into a contoured cross section rather than flat. Accomplished by passing work through rolls that have the reverse of desired shape

Types of rolling mill configurations:

2-high: two opposing rolls, 3-high: work passes through rolls in both directions, 4-high: backing rolls support smaller work rolls, cluster mill: multiple backing rolls on smaller rolls , tandem rolling mill: sequence of two-high mills

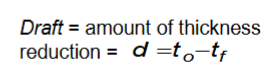

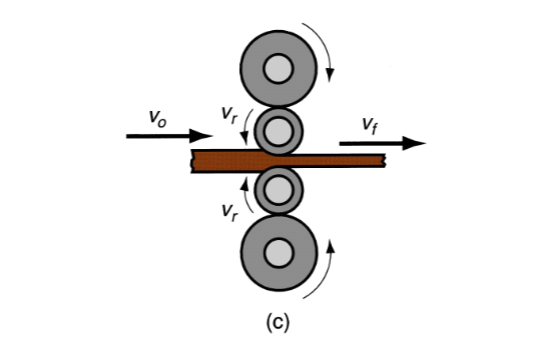

What milling configuration is this?

Two-high rolling mill

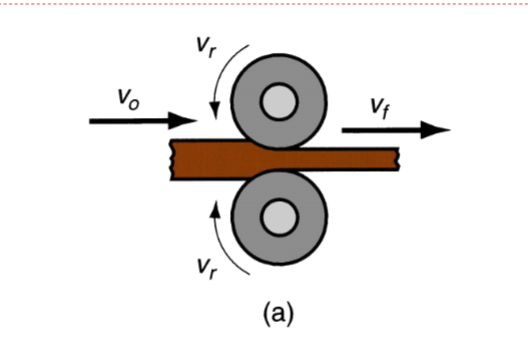

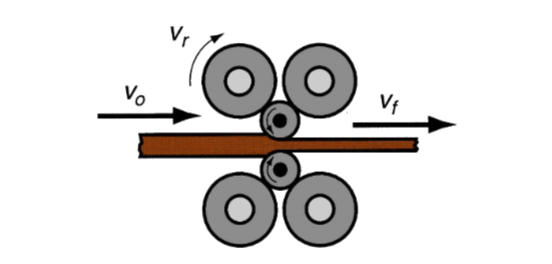

What milling configuration is this?

Three-high rolling mill

What milling configuration is this?

Four-High rolling mill

What milling configuration is this?

Cluster mill

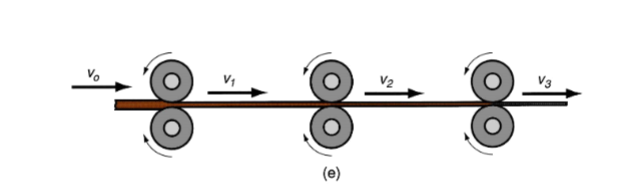

What milling configuration is this?

Tandem rolling mill

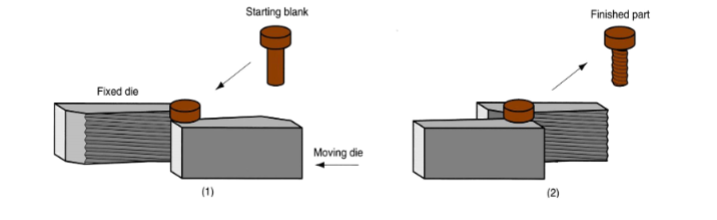

What type of rolling is this?

thread rolling rolled between two-dies

Thread Rolling

production of bolts and screws, performed in cold working, advantages over thread cutting include high production rates, better material utilization, stronger threads and better fatigue resistance due to work hardening

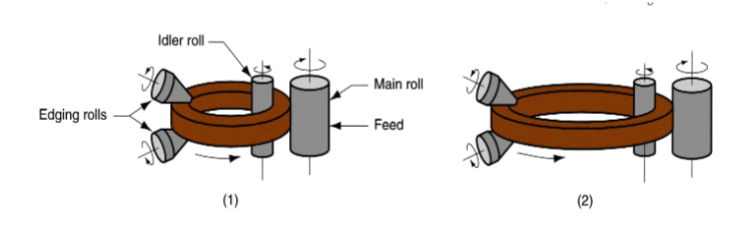

What type of rolling is this?

Ring Rolling: thick-walled ring of smaller diameter is rolled into a thin-walled ring of larger diameter

Ring Rolling: process and advantages

As thick-walled ring is compressed deformed metal elongates causing diameter of ring to be enlarged. Hot working for large rings and cold working for smaller rings. Advantages: material savings, ideal grain orientation, strengthening through cold working