Food Service Final SG

1/131

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

132 Terms

Aesthetic factors of menu planning

flavor

texture

color

shape

preparation

management factors of menu planning

Food cost

Production capabilities

Type of service

Availability of food

Customer satisfaction

equipment needs related to menus

sustainability and menu planning

carbon footprint of food

Global hunger & malnutrition

Unequal economic access to nutritious food

Precariousness of fresh-water supplies for irrigation

Equity for food system workers

menu planning process

1. Dinner entrees 1st for entire cycle - balance between low & high cost items

2. Plan lunch entrees - don’t duplicate

3. Decide on starch for each item

4. Select salads, accompaniments, & appetizers

5. Plan desserts

6. Add breakfast after lunch & dinner are complete

7. Review completed menu for duplication and flow of

menu

challenges of purchasing

• Seasonality

• Volume

• Quality

• Specification & packaging consistency

• Competitive cost

pros and cons of fresh produce

• Good quality if in season

– Taste

– nutrition

• Good price if in season

• More storage

• More labor associated with it

• ↑ spoilage

pros and cons of frozen produce

• Convenient - available

• Low labor cost

• Less storage

• Less spoilage

• Lower food cost

• Good nutritive value

pros and cons of canned produce

• Quality

– Nutrient

– Taste

• Lower food cost

• Lower labor cost

• No spoilage

• Easy storage

pros and cons of convenience foods

• Higher food cost

• Lower labor cost

• Look at facility

• ↓ storage

• Uniform product

• ? Quality, nutritive value, variety

value analysis

Methodical analysis of all components of an existing product or service with the goal of discovering & eliminating unnecessary costs without interfering with the effectiveness of the product or service

Looking for best buy

Make or Buy decisions

quality, quantity, service, & cost

forecasting - time series model

moving average

Uniformly weighs past observations

All numbers are weighted evenly

exponential smoothing

Recent values are given more weight

forecasting - causal model

regression analysis

much more complex and expensive

look at several variable and the relationship between variables

selling price, packaging, # of items, temperature

food processing plants

forecasting - subjective model

naïve model

use when relevant data is scarce or when relationships between data do not tend to persist over time

Relies on opinions

Delphi technique

give to experts individually to complete questionnaires on a topic

Summarized

Revised for consensus

time consuming & expensive

informal purchasing

Purchasing small amount

Item only available by few sources

Need is immediate

Market is uncertain – prices fluctuating a great

deal, ? SupplySize of operation small

types

open market

blank check

cost plus

negotiated bid

open market buying

• cherry picking (line item bidding)

• bottom line (all or nothing bidding)

blank check buying

• risky, item in short supply

cost plus buying

• buyer purchases at cost + % markup or $ markup

formal buying

• Competitive Bids

• Large facilities or government

• Fixed for large # of items for a long period

of time

• Buyer draws up

– specifications

– method of delivery

– payment details

• types: line-item, all or nothing, contract

line-item bidding

– Time consuming

– Usually costs more for both buyer & seller

all or nothing bidding

– Bottom-line approach

competitive bids

Seller

submit sealed bids by certain date

open at one time

award contract

Binding Contract

agreement between 2 or more parties

• offer

• acceptance

• consideration

express warranty

Promises, specifications, samples, and descriptions of goods that are under negotiation. For a certain period of time promises are made

Implied warranty of merchantability

– Suppliers “puff ” the virtues of their products for the purpose of making a sale

– must reasonably conform to an ordinary buyer's expectations

Implied warranty of fitness for a particular purpose

Buyer relies on the supplier’s skill or judgment to select or furnish suitable goods. when a buyer relies upon the seller to select the goods to fit a specific request

central purchasing

cost center (just expenses)

Personnel in one office does all the purchasing for all the units in that organizations

group purchasing

– Union of separate units (hospitals) not related to a single management

– Large volume purchasing- economical

warehouse purchasing

buying in bulk to store in a warehouse

Just in Time (JIT) purchasing

– Purchase products as need for production & immediate consumption

– $ not tied up in inventory

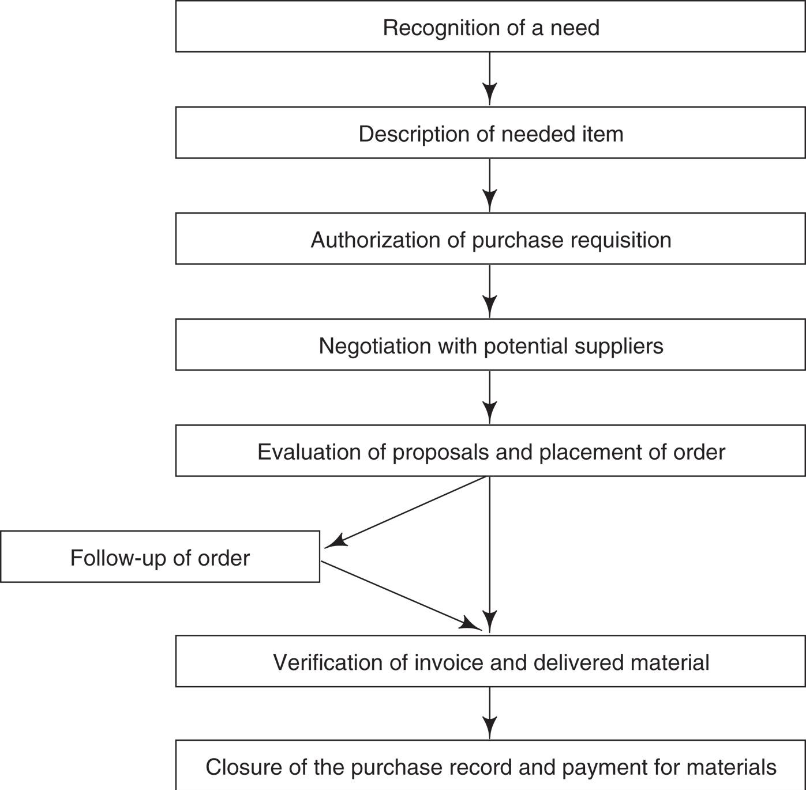

flow of purchasing

requisition

Form used by foodservice manager to request items from purchasing manager or department

purchase order

– made by buyer

– written record of items ordered

– item, quantity, specifications, prices, delivery date

invoice

– made by vendor

– delivery slip list items & prices

– extension

– check against items received & PO

– check extensions & total

direct issues

items directly from receiving to production

storeroom issues

written record when food is removed from storerooms

physical inventory

– actual count of goods on hand at the end of an accounting period

– usually do 1X/month

– put prices on products and extend to determine value

perpetual inventory

• Running record of each item in the storeroom, add purchases, subtract issued items

• At any time can value inventory

• Still must do physical inventory

• Daily or Direct Issues + Storeroom Issues = Food Cost

inventory turnover ratio

• How many times the inventory turns over in a year

• Total Cost of Food Sold / Average Food Inventory

• High # - small inventory- $50,000 ÷ 500= 100 times/year

• Low # - large inventory - $50,000 ÷ $2,000 = 25 times/year

• 2-4 times per month is often desirable

par stock ordering method

• Bring stock up to the par level EVERY time an order is places regardless of how many you have in inventory

• Par is 10 cases and you have 8 cases, order 2 cases

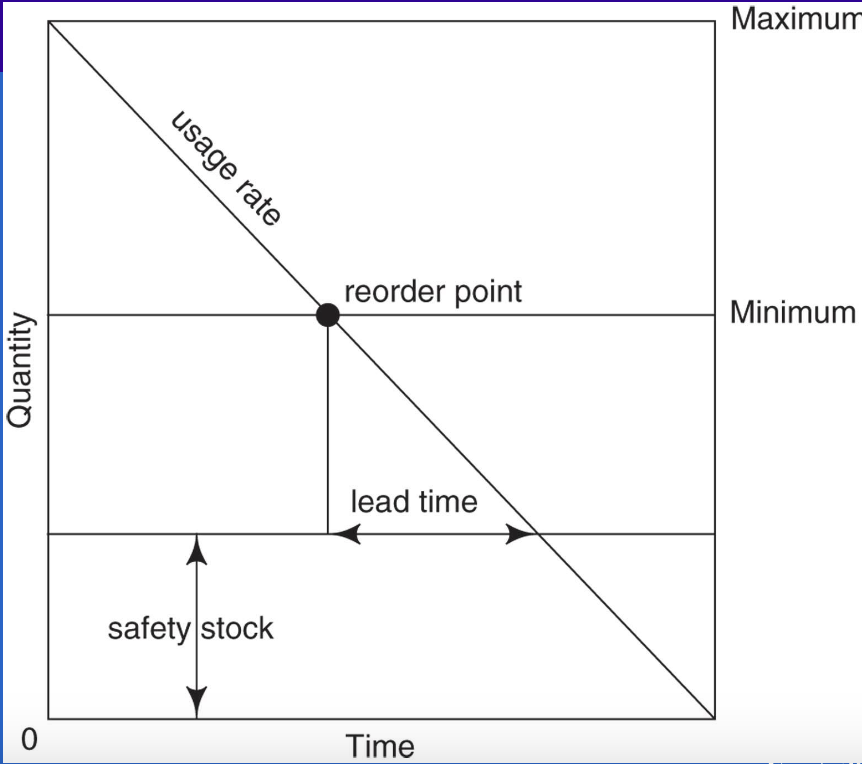

Fixed order quantity inventory system

Determine the order point

(Average daily use) (lead time) + safety stock

– Lead time= # of days from placing the order until

delivery

– Safety stock = small back up supply

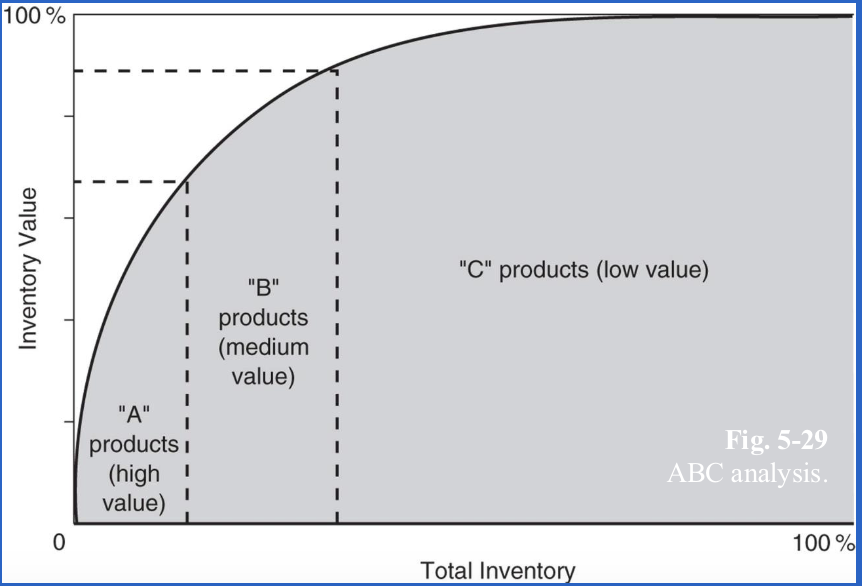

ABC method of inventory control

method of classifying items according to value

A Class only about 15-20% of inventory items account for 75-80% of the value of inventory

keep a minimum amount

B Class lesser value items 10-15% of items but value of 20-25%

C Class $ value 5-10% but make up 60-65% of inventory item

Minimum-Maximum method of inventory control

Goal is to have 0 of an item when shipment is received

Maximum is the correct # to order

Need to establish a safety factor

Need to have adequate LEAD TIME interval between ordering & receiving

Reorder point - lowest stock level that is safe

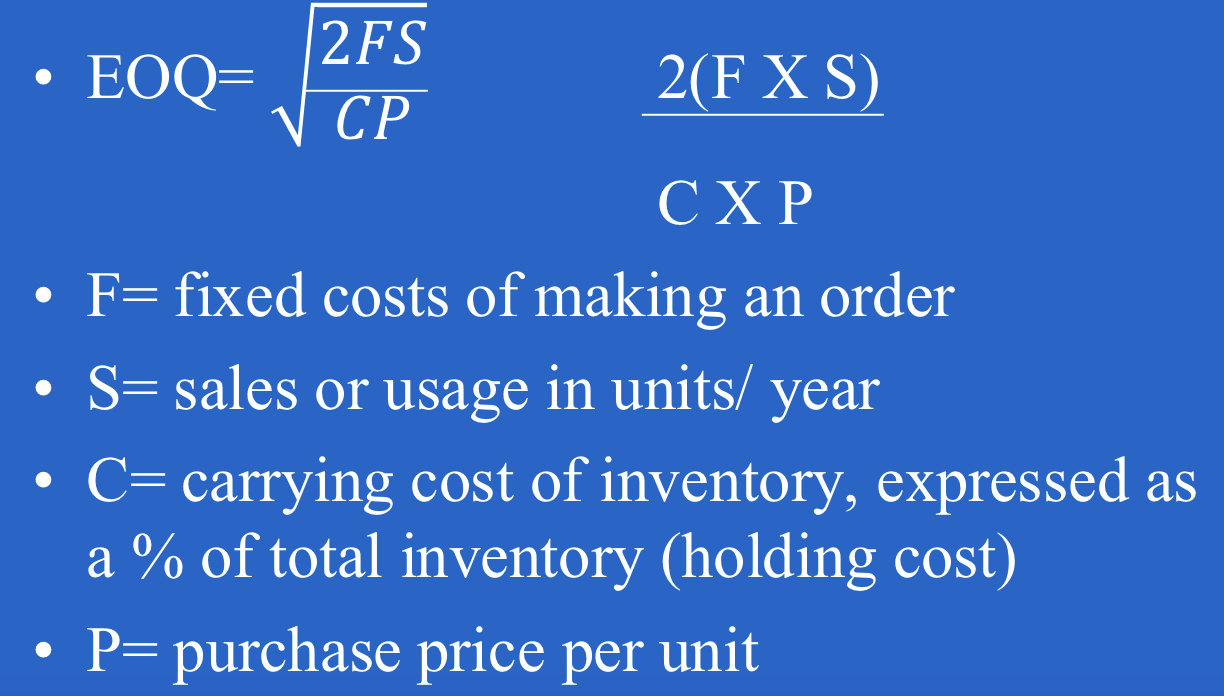

EOQ inventory control method

Attempts to find the quantity that minimizes both purchasing and inventory costs

Order size that is most economical

Inventory valuation: Actual Purchase Price

– specific identification

– price at actual cost of item

– detailed record keeping

– unrealistic

Inventory valuation: Weighted Average

– average cost method

– items marked at purchase price

Inventory Valuation: FIFO

– Use the most recent price paid for an item

– reflects flow of goods value of inv highest

– cost of goods sold lowest

– Used most frequently in food service

Inventory valuation: LIFO

– Use the oldest price paid for an item

– feel that this keeps up with current production inv is lowest

– cost of goods sold highest (used to reduce profit)

liquidity current ratios

current assets / current liabilities

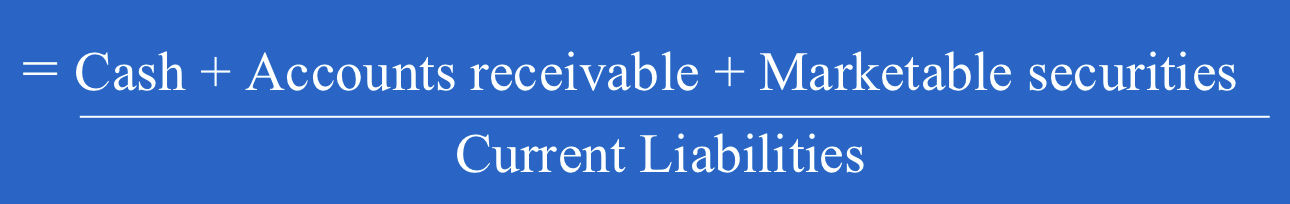

acid test ratios

looking at actual ability to pay

inventory turnover ratio

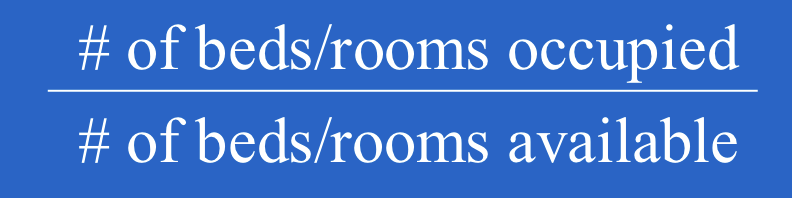

percent occupancy

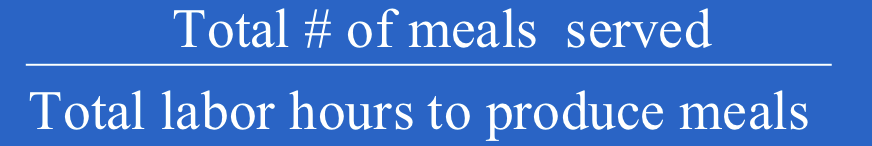

meals per labor hour

revenue

total amount of money an entity brings in from its activities during a specific period

cost of sales

cost of the raw food and beverage sold (and labor?)

gross profit

Profit shown after subtracting raw food and beverages (cost of sales) from sales/ revenue

net profit

Profit shown after ALL expenses have been deducted from sales

calculate number of FTEs

employee turnover

Total number of separations from previous year

Average number of employees company has- not FTEs actual numbers; # at beginning and end ofyear then average

calculate total number of employees needed

Multiply the number of full time employees by 1.55

trend analysis

Comparison of results several periods of time

usually as an absolute number or a %

oftentimes as a graph to show trends

sales, food, labor, operating expenses

common size statements

Financial statements expressed as percentages

Might have assets as 100% and then look at categories as a percent of the whole

operating budget

Sales/ revenue portion of the budget

- look at both internal & external influences

- review past performance & budgets

- changes in prices/rates

- seasonal variations

expenditures

- food what are anticipated changes?

- labor what is happening with ee salaries, cost of living, changes in taxes?

- Operating expenses

incremental budget

uses an existing budget as a base & projects changes for the ensuing year

zero based budgeting

start from scratch

fixed budget

prepared at one level of sales or revenues

flexible budget

adjusted to various levels of operation or sales

expense budget

• Personnel costs

• Fringe benefits

• Overhead

– Heating, light, telephone

• Depreciation

– Converting an asset to an expense

• Cost of goods

• Rent expense

• Insurance

• Taxes

cash budget

• cash inflow and outflow

• seasonal changes

• large cash outlays

capital expenditure budget

• Improvements, expansions, & replacements

• Buildings, equipment, & land

• Over a certain amount of money, oftentimes

$5,000

• Often project for 5 - 10 years

net present value

– Preferred method of evaluating expenditure

– Value of a $ today not = to a $ - 2 yrs from now

– Initial investment

– Expected income or cash savings

– Cost of capital

– Table of discounted cash flow factors

profit margin

net profit / sales

return on equity

net profit / equity

return on assets

net profit / total assets

average customer check

total sales / total # of customer checks

meals per FTE

number of meals / number of FTEs required to produce

labor minutes per meal

total labor minutes to produce meals / number of meals served

layout based on menu

• Type of delivery system

– Conventional

– Commissary

– Ready Prepared

– Assembly Serve

• What equipment you need and where it will be placed

• Good flow of materials and labor

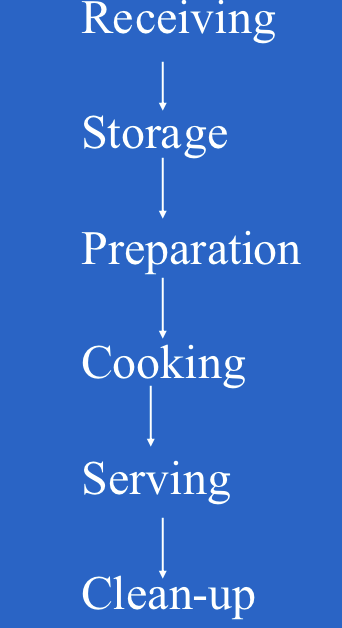

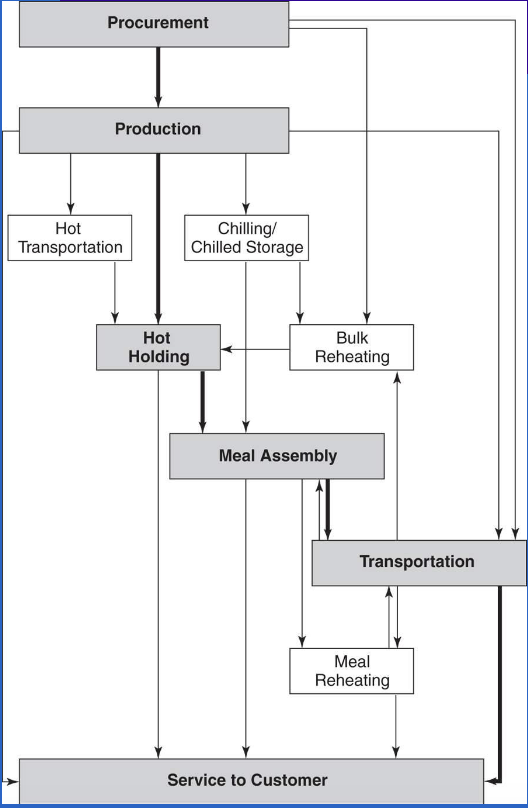

flow of food service

conventional food service

– Foods are purchased in various stages of preparation for an individual operation, and production, distribution, and service are completed on the same premises

– Cook serve

ready prepared food service

• Menu items are produced and held chilled or frozen until heated for service later.

– Food items are stored & recorded in storage & withdrawn when needed for production.

– After production, items are stored in refrigerators or freezers, and entered in thedistribution inventory.

commissary food service

• centralized procurement & production facilities

• distribution of prepared items to several remote areas for final preparation & service

• central commissaries, commissariats, or food factories

• Satellite service centers

assemble/serve

• Assembly/serve foodservice occurred primarily because of the market availability of foods that are ready to serve or require minimum cooking.

– convenience-food foodservices, or minimal cooking concept

– Another factor has been chronic shortage of skilled personnel in food production & increasing labor cost

• limited processing needs to occur

point of first use

Keep products close to where they will be used

economy of motion

– Store based on usage; heavy use within normal reach

– Heavier products lower

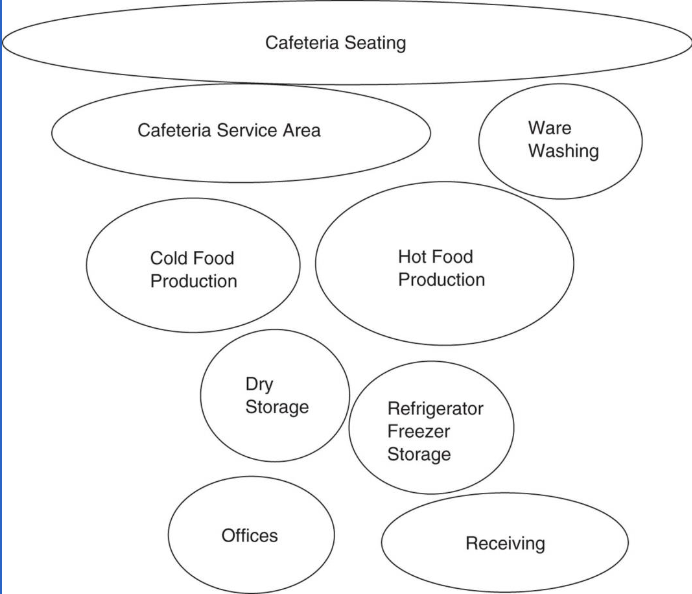

charente

collaborative planning session for design project

bubble diagram

factors to consider when planning a design

• Quantity of food and supplies

• Amount and kind of production (to determine equipment)

• Type of delivery system

• How food served to the customers

• to renovate or build

• Operating cost of the facility

• Any food safety issues of concern

• # of employees

• Any future plans

blueprints

– Specifics

– Mechanicals, electrical, plumbing

– Drawn to scale- usually ¼ inch = 1 foot

– Accompanied by a specifications book

LEED certification

sustainability certification

sustainability in food service

green energy efficient equipment

water conservation

waste management

dry storage factors to consider

– must be off floor 10” to 12” for air flow

– use vertical space

– opaque windows

– one door

– Secured

– 50-70 degrees F

conduction

transfer of heat by direct contact

convection

hot air circulating

radiation

energy transferred by waves of heat or light

induction

cooking vessel made of specific magnetic material

faster and energy efficient

types of heating equipment

• Heat lamps

• food warmers

• pass through refrigeration & warmers

• drawers

• lowerators

• steam tables

clean up equipment

garbage disposals

pulpers - dehydrates the product

recycling

direct lighting

light aimed at specific location