1C. Manufacturing Plant Lay-out

1/89

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

90 Terms

Manufacturing plant lay-out

The efficiency of production depends on how well the various machines, production facilities, and employee amenities are located in a plant.

Manufacturing plant lay-out

Only the properly laid out plant can ensure the smooth and rapid movement of material from the raw to the end product stage.

Manufacturing plant lay-out

The plant layout encompasses a new layout, and improvements to the existing layout are needed. It is a very critical part of running an efficient and cost-effective business.

plant layout

technique of locating machines, processes, and plant services within the factory to achieve the right quantity and quality of output at the lowest possible cost of manufacturing

J. L. Zundi

According to __ “Plant layout ideally involves the allocation of space and arrangement of equipment in such a manner that overall operating costs are minimized”.

Riggs

According to __, “the overall objective of plant layout is to design a physical arrangement that most economically meets the required output – quantity and quality.”

plant layout

A systematic arrangement of physical facilities essential for producing goods, delivering services, grouping equipment, and operations in a factory for the greatest degree of efficiency.

machinery

equipment

furniture

features of a layout

Arrangement of physical facilities such as:

furniture

within the factory building in such a manner to have the quickest and most direct workflow of material at the lowest cost & with the least amount of handling in processing the product from the receipt of material to the shipment of the finished product.

facilitating communication and improving staff safety

also includes the features of a layout that may not be immediately quantifiable, such as __

plant layout

all work areas, production lines, material storage facilities, etc., should be designed to perform at the highest rate and the corresponding shortest cycle time.

plant layout

When designing, it is necessary to take into account all the functions within the business

plant layout

the design must include not only the needs of the present business levels but should also have provisions for future expansion. This is included to avoid frequent and costly changes to the design as demand increases..

plant layout

indicated on a floor plan, showing the distances between different plant features.

plant layout

Optimizing this can improve product productivity, safety, and quality

1. Distances through which the material has to move

2. Distances equipment has to move

3. Distance operators have to move

4. Types of handling equipment needed

5. Energy required to move items against resistance (i.e. gravity).

Unnecessary materials handling efforts can be avoided when the plant layout is optimized. This is valid for;

1. it can provide better or even the best functionality for the industry

2. streamline production and ensure a smooth flow of work, material, and information

3. save and prevent unwanted costs or expenses due to operational problems

Importance/Objectives of manufacturing plant layout

place necessary departments, such as the operating and recovery rooms, close together and keep apart those departments that should not be together.

TIP: For better functionality

Time really is money!

save and prevent unwanted costs or expenses due to operational problems According to an old adage or saying that....

1. provide the optimum relationship among output, floor area & manufacturing process to eliminate downtime

2. ensure flexible and efficient labor & operation

3. provide easy production flow

4. promotes the effective utilization of manpower

5. employee’s convenience

6. provide proficient communication between workers and supervisors

7. maximum exposure to natural light & ventilation 8. make economical use of the building

9. ensuring [material/ product] movement is not static

10. considers flexibility for future workflow changes

IDEAL PLANT LAYOUT should:

A. Manufacturing unit

B. Trading unit

C. Services Centers and Establishment

D. Administrative unit

BASIC & GENERAL DIVISIONS/AREAS

1. Product or line layout

2. Process or functional layout

3. Fixed position or location layout

4. Combined or group layout

TYPES OF PLANT LAY-OUT DESIGN in a MANUFACTURING unit:

Product or Line Layout

All the machine tools or other items of equipment must be placed at the point or in one line demanded by the sequence of operations required of the products

Product or Line Layout

The materials move from one workstation to another sequentially without any backtracking or deviation

Product or Line Layout

In this arrangement, each following machine or section is arranged to perform the next operation performed by its preceding machine or section…. EX. Raw material starts from one end of production lines and moves from one machine to the next with storage and material handling and minimum work in process in a sequential path

a. There should be no points where one line crosses another line.

b. Materials may be fed where required for assembly but not at one point.

c. Materials may be fed where required for assembly but not necessarily at one point.

d. All the operations, including assembly and testing packing, must be included in the line

Product or Line Layout: the grouping of machines should be done keeping in mind the following general PRINCIPLES.

Equipment 1 Milling

Equipment 2 Wetting

Equipment 3 Granulation

Equipment 4 Lubrication

Equipment 5 Compression

A line layout for two products is given below.

Product A Paracetamol tablet 500mg

Equipment 1 Milling

Equipment 2 Wetting

Equipment 3 Granulation

Equipment 4 Lubrication

Equipment 5 Compression

Equipment 6 Sugar-coating

A line layout for two products is given below.

Product B Paracetamol chewable tablet 150mg

▪ Low cost of material handling due to straight and short routes and absence of backtracking

▪ Continuous flow of work – no backtracking

▪ Lesser investment in inventory and work-inprogress

▪ Optimum use of floor space

▪ Shorter processing time or quicker output

▪ Lower cost of manufacturing per unit

Manufacturing plant lay-out advantages

▪ High initial capital investment in specialpurpose machine

▪ Heavy overhead charges

▪ Breakdown of one machine, the whole production process is stopped

▪ If the output rate of one machine is slower than the other machine, the overall production rate decreases

Manufacturing plant layout disadvantages:

1) Mass production of standardized products

2) Simple and repetitive manufacturing process

3) Operation time for different processes is more or less equal

4) Reasonably stable and steady demand for the product

5) Continuous supply of materials and production materials

Product layout is useful under the following conditions:

continuous manufacturing process

Therefore, the manufacturing units involving ___ ,producing few standardized products continuously on the firm’s own specifications and in anticipation of sales would prefer product layout

➢ examples: chemicals, sugar, paper, rubber, refineries, cement, automobiles, food processing, electronics, etc.

process layout

aka “Functional layout”

process layout

In this type of layout, machines of a similar type are arranged together in one place.

process or functional layout

is followed from the historical period. It evolved from the handicraft method of production.

process layout

The work has to be allocated to each department in such a way that no machines are chosen to do as many different jobs as possible or no such thing as a “General-Purpose” machine

process layout

For all the different types of functions, separate machines are available…

➢ Example: All the raw materials mixing machines are grouped together to carry out the mixing process, and all the granulation machines are arranged together to carry out the granulating process.

a. The distance between departments should be as short as possible to avoid long-distance movement of materials.

b. All the similar machines are positioned together so that all the similar operations are performed at the same place.

c. Machines are arranged according to the nature or type of the operations or their functions.

d. The departments should be in a sequence of operations.

e. The arrangement should be convenient for inspection and supervision.

Process layout: The grouping of machines according to the process has to be done keeping in mind the following PRINCIPLES:

a. Products are not standardized

b. Quantity produced is small or low-volume production.

c. There are frequent changes in the design and style of the product

d. Job shop type of work is done. e. Machines are very expensive.

Process layout is adopted when;

process layout or functional layout

is suitable for job order production involving batch production and non-repetitive processes, customer specifications, and non-standardized products, e.g., tailoring, light and heavy engineering products, made-to-order furniture industries, and jewelry.

▪ Lower initial capital investment in machines and equipment

▪ Breakdown of one machine does not result in a complete work stoppage

▪ Supervision can be more effective and specialized ▪ There is greater flexibility in the scope of expansion

Process Layout Advantages

▪ Material handling costs are high due to backtracking

▪ More skilled labor is required, resulting in higher costs

▪ Work-in-progress inventory is high

▪ Needing greater storage space ▪ More frequent inspection is needed, which results in costly supervision

▪ Production time is longer

▪ Bottlenecks occur due to more work in a queue and waiting for further operation

▪ More floor area is required

Process Layout Disadvantages

Milling

Mixing

Granulation

Tableting

Lubrication

Sugar coating

Process layout of product A

Granulation

Milling

Mixing

Tableting

Lubrication

Sugar coating

Process layout of product A

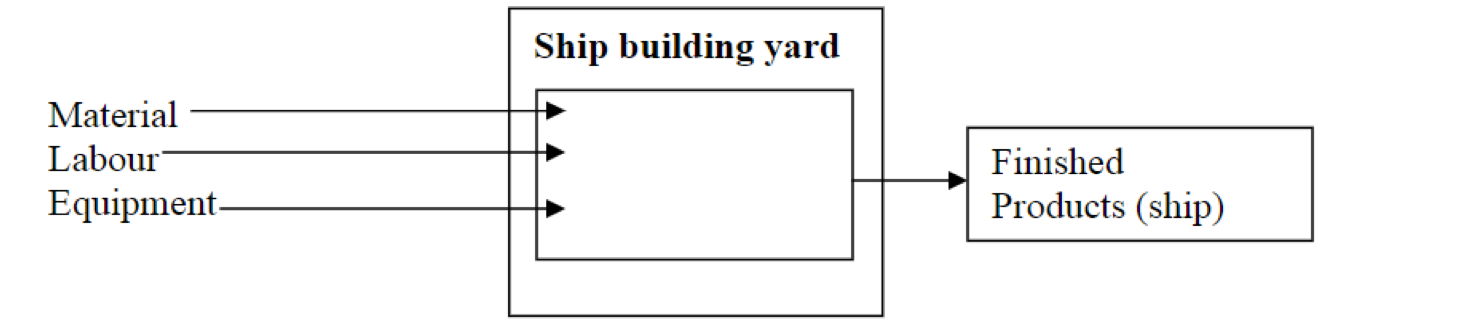

Fixed Position or Location Layout

the major part of the material remains at a fixed position or at one location, and all accessories, materials, required tools, machinery, and other supporting equipment are brought to this location

Fixed Position or Location Layout

also known as “project layout”.

a. Equipment labor and components are moved to that location.

b. All facilities are brought and arranged around one work center.

principles of fixed position or location layout

Fixed Position or Location Layout

This layout is good for extremely large items manufactured in very small quantities and is highly preferable when the cost of moving a major piece of material is high.

Fixed Position or Location Layout

This layout is used in the boiler manufacturing factory, hydraulic and steam turbines, etc

Fixed Position or Location Layout

1. Manufacture bulky and heavy products such as locomotives, ships, boilers, generators, wagon building, aircraft manufacturing, etc.

2. Construction of buildings, flyovers, and dams.

3. Hospital, the medicines, doctors, and nurses are taken to the patient (product)

The following conditions follow the fixed position layout;

▪ Less capital - saves time and cost

▪ Less material and worker movement

▪ Less production cost

▪ Flexible layout as changes in job design and operation sequence can be easily incorporated

▪ Adjustments can be made to meet the shortage of materials or absence of workers by changing the sequence of operations

▪ Ensures Continuity

Fixed Position or Location Layout Advantages:

▪ Production period being very long

▪ Capital investment is very heavy

▪ Very large space is required to store materials and equipment near the product

▪ As several operations are often carried out simultaneously, there is possibly confusion and conflicts among different workgroups

▪ Complicated fixtures

▪ Required highly skilled manpower

▪ Movement of machines is time-consuming

▪ Machines are not fully utilized

▪ Limited to large items only

Fixed Position or Location Layout Disadvantages:

▪ In most industries, only a product, process, or fixed location layout does not exist.

▪ Connect all the good features of all the types of layouts to obtain a compromise solution that will be more economical and flexible

▪ Combination Layout is also known as group layout.

▪ Generally, a combination of the product and process layout or other combinations are found in practice or have adopted this layout

▪ Every layout has advantages and disadvantages; therefore, industries prefer to use a combination of layouts.

principles of combined layout

product, process, or fixed location

In most industries, only a __ layout does not exist.

combined layout

Connect all the good features of all the types of layouts to obtain a compromise solution that will be more economical and flexible

group layout

Combination Layout is also known as __

combined layout

Generally, a combination of the product and process layout or other combinations are found in practice or have adopted this layout

combined layout

Every layout has advantages and disadvantages; therefore, industries prefer to use a combination of layouts.

▪ Reduction in cost of material handling and machine set-up time

▪ Elimination of excess work-in-process inventory

▪ Simple production planning functions

▪ Smooth flow of work

combined layout advantages

▪ Change of the existing layout is costly and time consuming

▪ Including new components requires thorough analysis

▪ Complex to use

combined layout diadvantages

trading unit

area or division that is responsible for the marketing and advertising of the product/s or merchandise/s of the manufacturing plant

trading unit

When several manufacturing plants carry almost the same merchandise, it is challenging for traders to attract possible customers ( distributors, wholesalers); thus, they must keep a good layout.

▪ Good lighting

▪ Attractive colors

▪ Good ventilation

▪ Air conditioning

▪ Modern design

trading unit layout should have:

customer convenience, customer appeal, and greater business volume

trading unit layout things mean

▪ Self-service or modified self-service layout

▪ Full-service layout

▪ Special service layouts

There are three kinds of layouts in retail operations today.

Services Centers And Establishment

must give due attention to customer convenience, quality of service, and efficiency in delivering services

Services Centers And Establishment

Provide ease of utilization, convenience, and satisfaction for the personnel of the manufacturing plant

Services Centers And Establishment

includes public restrooms, canteen, visitor's or employees lounge, parking area, gym, etc

administrative unit

area for the CEO, Directors and Department managers/heads

Factory building structure

Nature of product

Nature of material

Production volume

Machinery

Factory Location

FACTORS TO CONSIDER IN DESIGNING A PLANT LAYOUT

frozen

Once a Plant layout is __it’s almost impossible or very costintensive to change the layout especially after the civil works are completed and it is a critical investment for any manufacturing company

Do you know how much time your employees waste in moving for material, inventory and in searching for tools?

How often does your machine break down and are workers satisfied with the current workflow?

Factory building structure

The size and nature of the building determine available floor space and cubic area, and according to the availability of area, we can decide on a particular type of Layout.

nature of product

that will be manufactured has a significant role in deciding the Plant Layout type of any factory

process or functional layout

For small and light products that can move from one machine to another with minimum effort and time, select

fixed layout

for large products

line layout

if the production is in sequence.

nature of material

Nature and state of the material, durability, heat and cold resistance, etc., are many factors to keep in mind when selecting the type of plant layout because Dimensional tolerances can be inconsistent; cracking is possible, and some material’s environment so processing can be challengin

production volume

is also a big factor in choosing the type of Plant Layout.

production volume

If a factory manufactures products on a large scale, then a line layout can be the best option, and for different products, then we can go with a process layout.

line layout

If a factory manufactures products on a large scale, then a ___can be the best option

process layout

for different products, then we can go with a

machinery

The requirements of each __are quite different in terms of their space, speed, maintenance, and repair, and material handling process, so these factors should be given proper consideration while choosing a particular type of layout.

machinery

If we arrange machines according to our needs, then we can get adequate space between machines and movement of inventory, people become easy.

factory location

also affects our Plant Layout decision. Climate, sunlight, noise, ventilation, etc are factors to be considered for adequate safety arrangements.

factory location

The efficiency of any production depends on how well the various machinery, tools, equipment, and other supportive production facilities and employee amenities are located in a plant.

pilot plant

It is part of the pharmaceutical industry where a lab-scale formula is transformed into a viable product by developing the practical procedure of manufacture.

Phil. CGMP Basic Guidelines for Premises

SECTION 2: PREMISES

The premises for manufacturing shall be of suitable size, design, construction, and location to facilitate proper operation, cleaning, and maintenance.

SECTION 2: PREMISES

The individual working areas shall be adequate to avoid any risk of confusion, cross-contamination, and other mistakes that will adversely affect the quality of drugs and devices.

2.1.1 Premises shall be so located and protected against contamination from the environment.

2.1.2 Premises shall be constructed and maintained to protect against weather, flood, ground seepage, and the access and harboring of vermin, rodents, birds, insects or other animals.

2.1.3 In determining the design and layout of premises, consideration should be paid to:

❖ For more details on the Location, Construction, Design & Layout , please refer to your copies of A.O. No. 43 s. 1999 , Part 2 sec. 2..

2.1 Location, Construction, Design & Layout