HISTEC LAB MICROTOMY AND PARAFFIN SECTIONS

1/102

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

103 Terms

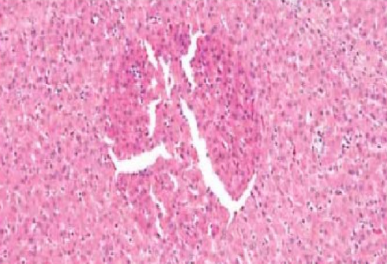

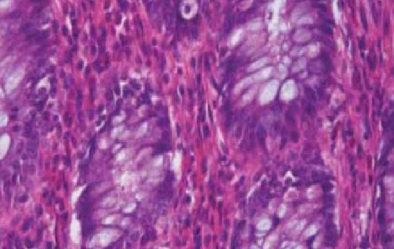

Microtomy

Process by which a processed tissue, most commonly a paraffin embedded tissue, is trimmed and cut into uniformly thin slices or “sections” to facilitate studies under the microscope.

40 deg Celsius

Heat of water bath

5 microns

Size of tissue sections cut

37 degrees Celsius

Temp for drying

Rotary wheel

Blade guard

Controller for microtome

Blade holder/Platform

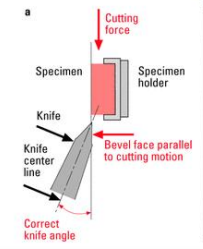

Bevel face parallel to cutting motion

Correct knife angle

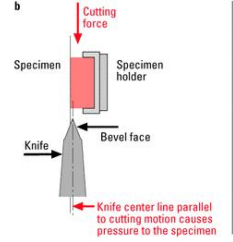

Pressure

Knife center line parallel to cutting motion causes ________ to the specimen

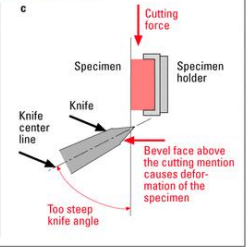

Deterioration

Bevel face above the cutting mention causes __________ of the specimen

Block holder

Knife carrier and knife

Pawl, ratchet feed wheel and adjustment screws

3 essential parts of a microtome (BKP)

Block holder

ESSENTIAL PARTS OF A MICROTOME

Where the tissue is held in position

Knife carrier and knife

ESSENTIAL PARTS OF A MICROTOME

For actual cutting of tissue sections

Pawl, ratchet feed wheel and adjustment screws

ESSENTIAL PARTS OF A MICROTOME

To line up the tissue block in proper position with the knife, adjusting the proper thickness of the tissue for successive sections

Rocking Microtome (Cambridge)

TYPES OF MICROTOME

Simplest and oldest among the different types of microtomes.

Only used to cut small and large blocks of paraffin tissues.

Paldwell Trefall in 1981

Invented Rocking Microtome and what year

Serial section

With the rocking microtome, what type of section is not possible since tissues are cut in slightly curved planes?

Rotary Microtome (Minot)

TYPES OF MICROTOME

Cut paraffin – embedded tissues

Most common type used for both routine and research laboratories

Has adjusting screws to make the tissue block parallel to the knife.

Minot in 1885-1886

Invented Rotary Microtome and what year

Sliding Microtome

Developed by Adams in 1789

2 types

Base-Sledge Microtome

Standard Sliding Microtome

2 types of Sliding microtomes

Base-Sledge Microtome

TYPE OF MICROTOME

Consists of 2 movable pillars holding the adjustable knife clamps, allowing the knife to be set at an angle for cutting celloidin sections

For hard tissue or large blocks that are usually sectioned

Standard Sliding Microtome

TYPE OF MICROTOME

Developed for cutting celloidin – embedded tissue blocks

Recommended for cutting extremely hard and rough tissue blocks

Most dangerous type of microtome due to the movable exposed knife

Freezing Microtome

TYPES OF MICROTOME

Used to cut undehydrated tissues in a frozen state, especially when rapid diagnosis is required

Histological demonstration of fat is needed

Neurological structures are to be studied

Sensitive tissue constituents are easily destroyed or damaged by heat

Queckett in 1848

Invented Freezing Microtome and what year

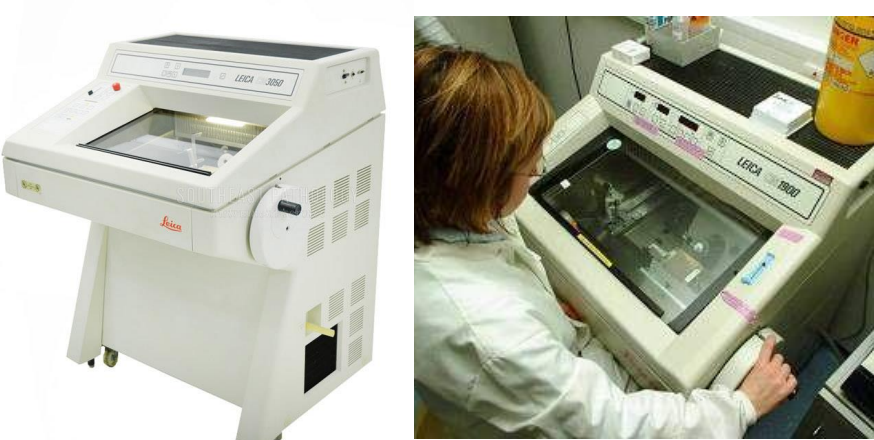

Cryostat

TYPES OF MICROTOME

A refrigerated apparatus used in fresh tissue microtomy for freezing the tissue into the block holder to the correct degree of hardness to facilitate easier and faster sectioning

Rotary microtome + Cold chamber

Fluorescent antibody staining techniques or histochemical enzyme studies

-5 to -30 degrees Celsius (average -20 degrees Celsius)

Cryostat temperature

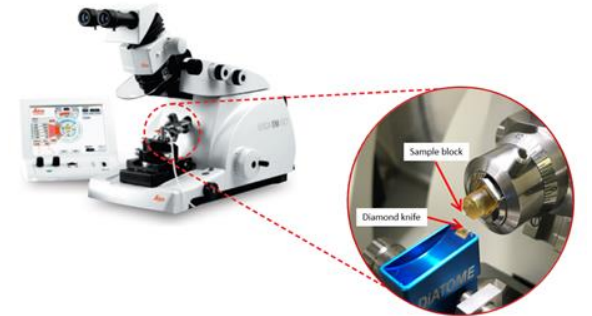

Ultrathin Microtome

TYPES OF MICROTOME

Used for cutting sections at 0.5 micra

Electron microscopy

Type of microscopy used in Ultrathin Microtome

Osmium tetroxide

Fixative of spx in ultrathin microtome

Plastic

Embedding medium of spx in ultrathin microtome

Plane-Concave knife

MICROTOME KNIVES

One side of the knife is flat while the other is concave.

Less concave sides are recommended for cutting celloidin – embedded tissue blocks on a sliding microtome.

More concave sides are used to cut paraffin sections on base – sledge, rotary or rocking microtome

Biconcave

MICROTOME KNIVES

With both sides concave

Recommended for cutting paraffin embedded sections on a rotary microtome

Plane-Wedge Knife

MICROTOME KNIVES

Have both sides straight

Recommended for frozen sections or for cutting extremely hard and tough specimens embedded in paraffin blocks, using a base – sledge type or sliding microtome

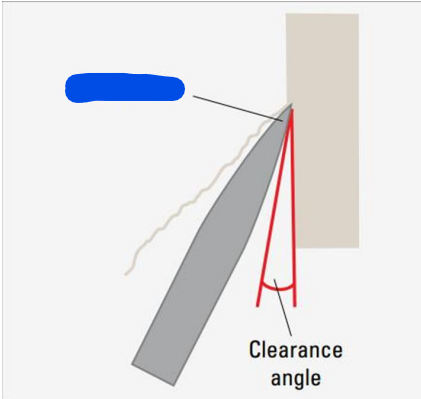

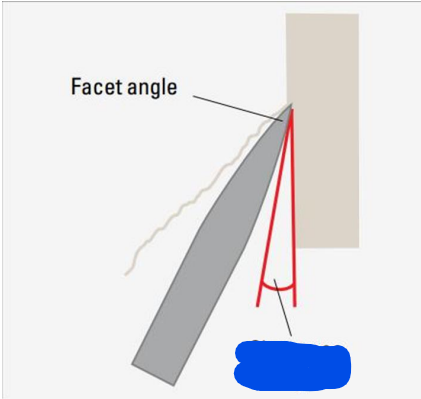

Facet angle

Clearance angle

Bevel Angle

Angle formed between the cutting edges

27-32 degrees

Normal bevel angle (range)

2-3 microns

A good cutting edge should be made of good quality steel and be able to cut good sections from a paraffin wax block about________ microns thick, without any serrations noted on examination

15 degrees

The perfect and optimum cutting angle is obtained when the sides of the wedge knife are inclined at an angle of about ______ causing maximum penetration of the tissues and minimizing distortion.

Jagged edges

Produce tears or striae in tissue sections

Mineral and Clove oil

Xylene

Liquid paraffin

Soapy water

Before honing, surface of the hone must be wiped clean.

Then cover the surface with a thin film of any of the following for lubrication (4) (MXLS)

Honing

Involves the removal of gross nicks on the knife edge

Coarse honing

HONING

to remove blemishes and then grinding the cutting edge of the knife on a stone

Honing proper

HONING

to acquire an even edge

Honing

removal of fine nicks

Heel to toe

Honing motion

Stropping

sharpen knife which is free of nicks

on leather strop

Toe to heel

Stropping motion

Carborundum

Hard grinding surface used in honing

Belgium Yellow

HONING GRINDING SURFACES

For manual sharpening when cutting edge has been rendered blunt or nicked. This type usually gives the best result.

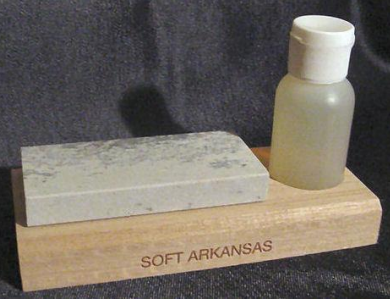

Arkansas

HONING GRINDING SURFACES

Gives more polishing effect than the Belgium Yellow

Fine Carborundum

HONING GRINDING SURFACES

Much courser than the first two types and is used only for badly nicked knives followed by either one of the first two knife sharpeners

Plate Glass Honing

HONING GRINDING SURFACES

A flat circular glass plate with finely powdered aluminum oxide made into paste with water (used as an abrasive)

Diamantine

Used as final polishing for plate glass honing

Automatic hone

Fast becoming indispensable in histopath laboratories

Time saving and fairly easy to manipulate

Consists of glass disc or wheel driver by an electric motor

The knife is pressed together against the flat side of the rotating glass wheel

8 × 3 inches

PRECAUTIONS DURING HONING

The hone should be long enough to allow the whole length of the knife edge to be sharpened. What size?

Warm soapy water or fine oil

PRECAUTIONS DURING HONING

The hone should be lubricated with __________ or __________ before using

20-30 times

PRECAUTIONS DURING HONING

The amount of strokes should be how many times in each direction?

Before, during, and after use

PRECAUTIONS DURING HONING

The hone should be cleaned __________, __________and _________use

Nailbrush

PRECAUTIONS DURING HONING

A black film that develops in the hone usually is imparted by the knife that is being sharpened and should be brushed out with a good _________ in running water.

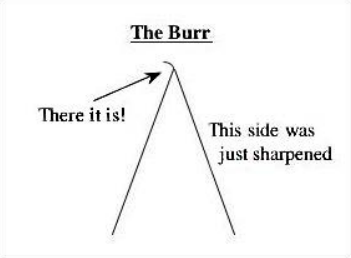

Stropping

The process whereby the “burr” formed during the honing is removed and the cutting edge of the knife is polished

Delicate work

STROPPING

For ___________, knife should be stropped before every object is sectioned

Sagging

STROPPING

A paddle strop made up of the best quality horse leather, firmly attached to a solid back, in order to prevent __________ is preferred

Xylene

PRECAUTIONS OBSERVED IN STROPPING

The knife should be flushed with ________

Disposable blades

Sharp cutting edge that can cut 2-4µ thick sections with ease

Glass Knives

Knife generally used for trimming and semi – thin sectioning of tissue blocks for Electron Microscopy

Diamond Knives

Used to cut any type of resin block for EM

Brittle and expensive, but very durable and the cutting edge must be kept clean to make it cut longer and to avoid damage during sectioning

Sectioning

is a process whereby tissues are cut into uniformly thin slices or “sections” with the aid of a machine, to facilitate the studies under the microscope.

Course and fine trimming

2 types of trimming

15mm

Fine trimming is set at what thickness?

4-6 microns

Routine section thickness

Discard

What to do with incomplete sections?

Camel hair brush

Pair of forceps

Fingers

Complete sections are picked up using? (3) (CPF)

Exhaling

Tissue that tend to crumble or do not form a smooth flat surface can be sectioned with ease, by ___________ gently into the block surface while the section is being cut slowly to reduce the effects of static electricity

45-50 degrees Celsius, 6-10 decrees Celsius lower than melting point of wax

Temperature of water bath after sectioning

30 seconds

Maximum time for sections to be left on water to avoid undue expansion and distortion of tissue

Floating out bath

The circular, thermostatically controlled bath, 10 to 12 inches in diameter and 3-4 inches in depth is widely used

The inside surface is black and this enables the sections to be easily seen in the bath

Bath should be filled with water to within ½-1 cm from the top

Emptied and thoroughly wiped clean after use

False, must not be floated out simultaneously to avoid cross-contamination

Sections from 2 different blocks can be floated out simultaneously. (T/F)

Protein

Adhesive mixtures are all _______ solutions

Adhesive mixture

Reduce the surface tension thereby producing closer capillary adhesion of the sections to the slides

Thymol

Adding this in adhesive mixtures prevents bacterial contamination

Mayer’s egg albumin glycerol

Adhesive mixture for coating slides

Most popular adhesive mixture

Composed of 50mL of white fresh egg and 50mL of glycerol which are mixed and then filtered through several layers of gauze

Thymol is added as the preservative

Aminopropyltriethoxysilane (APES)

Adhesive mixture for coating slides

BEST SECTION ADHESIVE!!

Clean slides are dipped in 2% APES in acetone and drained two times and finally dipped in distilled water

2-5 degrees Celsius above melting point of paraffin used

The mounted section is then placed in a paraffin oven to dry.

Maintained at a temperature of?

Hot plates

___________ are NOT recommended because they can cause overheating and there is a risk of dust falling onto the section during the drying period

25

Amount of slide divisions of a metal rack

5 minutes

How long to dry mounted sections in heated oven

Collagen

Overheating should be avoided because it will distort the tissue and melt some of the structures like?

Celloidin sections

Sections are usually cut by a sliding microtome

Both the sections and the block are being kept moist with 70% alcohol during alcohol (wet method) to avoid dehydration and shrinkage

Sections do not come off in ribbons and have to be collected into 70% alcohol immediately

Stored in the same solutions in jars with tightly fitting lids and finally mounted on to slides after they have been stained

Section too thick

First section in ribbon chosen

Sectioning at too great a speed

Poor processing

Microtome needs recalibration

Holes from rough trimming

Block trimmed too quickly

Block surface not polished by cutting some thin sections after roughing

Inappropriate section thickness used when trimming

Block brittle or too cold when trimmed

Knife lines

Damaged knife or blade used

Poor processing

Hard material such as calcium in block

Debris in unfiltered in wax

Buffer salts precipitated in specimens

Disruption

Rough handling of specimen during grossing

Fine cracks or micro-chatter

Tissue over-processed

Block too cold

Cutting too fast

Coarse chatter

Clamping mechanism not securely locked

Very large or hard specimen

Worn microtome

Folds

Poor flotation technique

Excessive compression

Poor processing (insufficient support)

Bubbles under the section

Bubbles adhering to base and sides of flotation bath