BMBL Biosafety cabinets

BSC 1 face velocity

75

Can you use a BSC 1 for nonvolatile chemicals and radionucleatides?

yes

Can you use a BSC 1 for volatile chemicals and radionucleatides?

yes, when exausted outside. Require a risk assessment

Which BSC has HEPA filter exaust air ONLY?

BSC 1

When should BSC’s be certified?

annually

Which BSC provides personnel and environmental protection but no product protection?

BSC 1

Which BSC has unfiltered room air drawn in through the work opening and across the work surface. Air movement to a chemical fume hood but has a HEPA filter in the exhaust system to protect the environment?

BSC I

Which BSC is direct-connected to the building exhaust system and the building exhaust fan provides the negative pressure necessary to draw room air into the cabinet. Having laminar flow?

BSC 1

What is a canopy connection mean regarding BSC II ventilation which is the proper method of connecting a Type A1, A2, or C1 cabinet to the building exhaust system?

A small opening or air gap (usually one inch) around the cabinet exhaust filter housing.

Are Class II Type A1 or A2 every direct connected to the exaust system?

Class II, Type A1 or A2 cabinets should never be direct-connected to the building exhaust system. BSC 1 is!

What are some fail-safe mechanisms when using type II BSC systems?

A pressure-independent monitor and alarm must be installed to provide a warning and shut off the BSC supply fan, should a failure in exhaust airflow occur. To maintain critical operations, laboratories using Type B BSCs should connect the exhaust blower to the emergency power supply.

What do HEPA filters capture regarding infectious diseases and volatile chemicals?

HEPA filters are effective at trapping particulates, and thus infectious agents, but do not capture volatile chemicals or gases.

What BSC systems should be used if using volatile chemical agents?

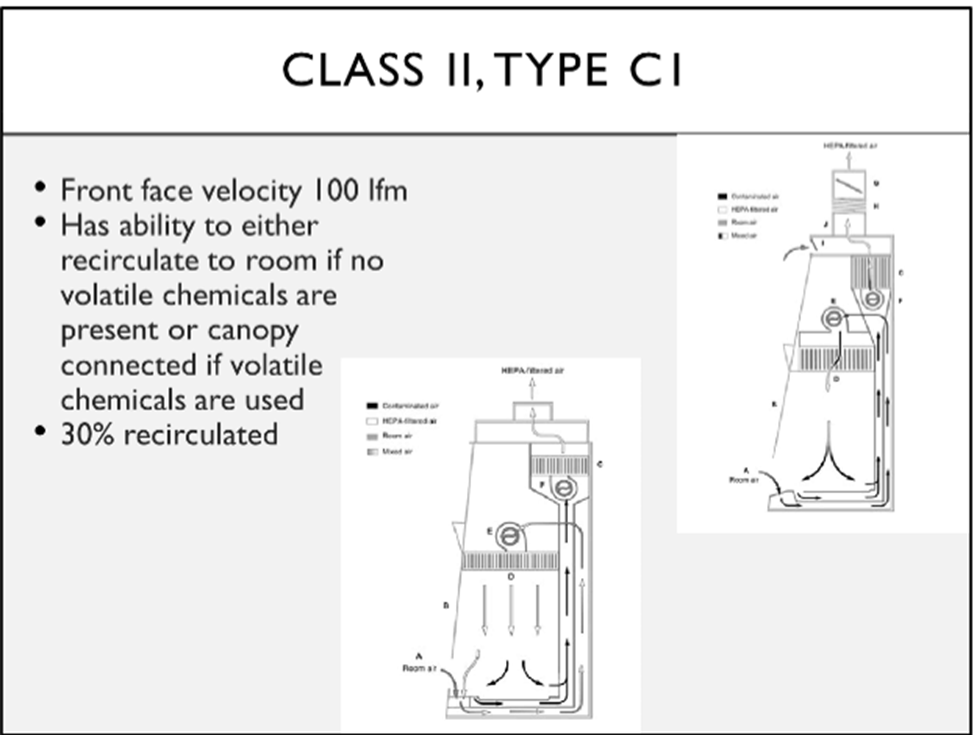

Only canopy-connected Type A1, A2, and C1 or Types B1 and B2 BSCs should be used when working with volatile, toxic chemicals, but amounts must be limited

What does the NSF/ANSI 49 Standard describe?

The Concurrent Balance Values (CBV) is published in this standard. The standard describes the requirements for the construction and function of a Class II BSC. When a BSC is certified to NSF/ANSI 49-2018, the standard method is to set the inflow velocities using a direct inflow measurement (DIM) hood.

Sets:

Design/construction;

Performance;

Installation recommendations; and

Recommended microbiological decontamination procedures.

What types of risk groups are BSC II’s all designed for?

Risk groups 1 - 4

What types of work are typically done in BSC IIs?

Class II BSCs provide the microbe-free work environment necessary for cell culture propagation and also may be used for the formulation of nonvolatile antineoplastic or chemotherapeutic drugs

Can BSC IIs be used for BSL 4 labs?

Class II BSCs may be used with organisms requiring BSL-4 containment in a BSL-4 suit laboratory by a worker wearing a positive-pressure protective suit. Maximum containment potential is achieved only through strict adherence to proper practices and procedures.

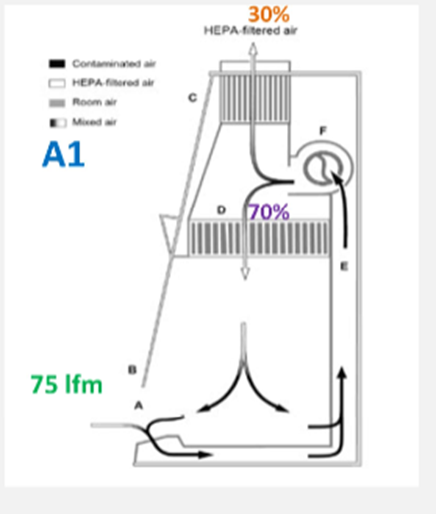

BSC II Type A1 inflow velocity?

75

BSC II type A2, B1, B2, and C inflow velocities?

100 LFM

In BSC type A2s, All _____________-pressure contaminated plenums within the cabinet are surrounded by a ________ air pressure plenum thus ensuring that any leakage from a contaminated plenum will be drawn into the cabinet and not released to the environment.

All positive-pressure contaminated plenums within the cabinet are surrounded by a negative air pressure plenum thus ensuring that any leakage from a contaminated plenum will be drawn into the cabinet and not released to the environment.

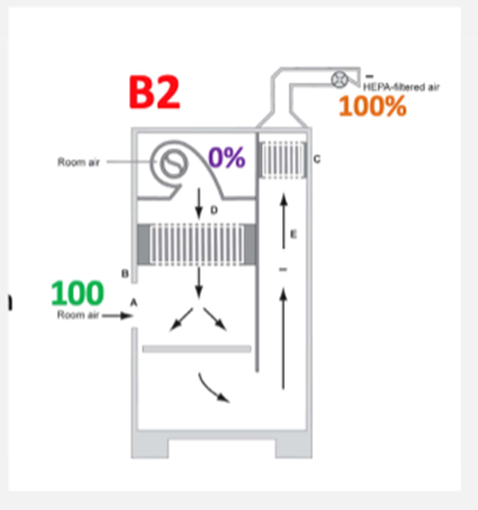

This BSC is a total-exhaust cabinet; no air is recirculated within it.

BSC II type B2

What is a fail stop mechanism unique to BSC type B2 systems regarding insufficient exaust flow?

Cabinets built since the early 1980s have an interlock system, installed by the manufacturer, to prevent the supply blower from operating whenever the exhaust flow is insufficient

Which BSC is specifically intended for work with toxic volatile chemicals?

BSC II type C1

Which BSC has an internal exhaust blower that allows the BSC to be either room recirculated if no volatile toxic chemicals or vapors are present or canopy-connected with an exhaust alarm?

BSC II C1

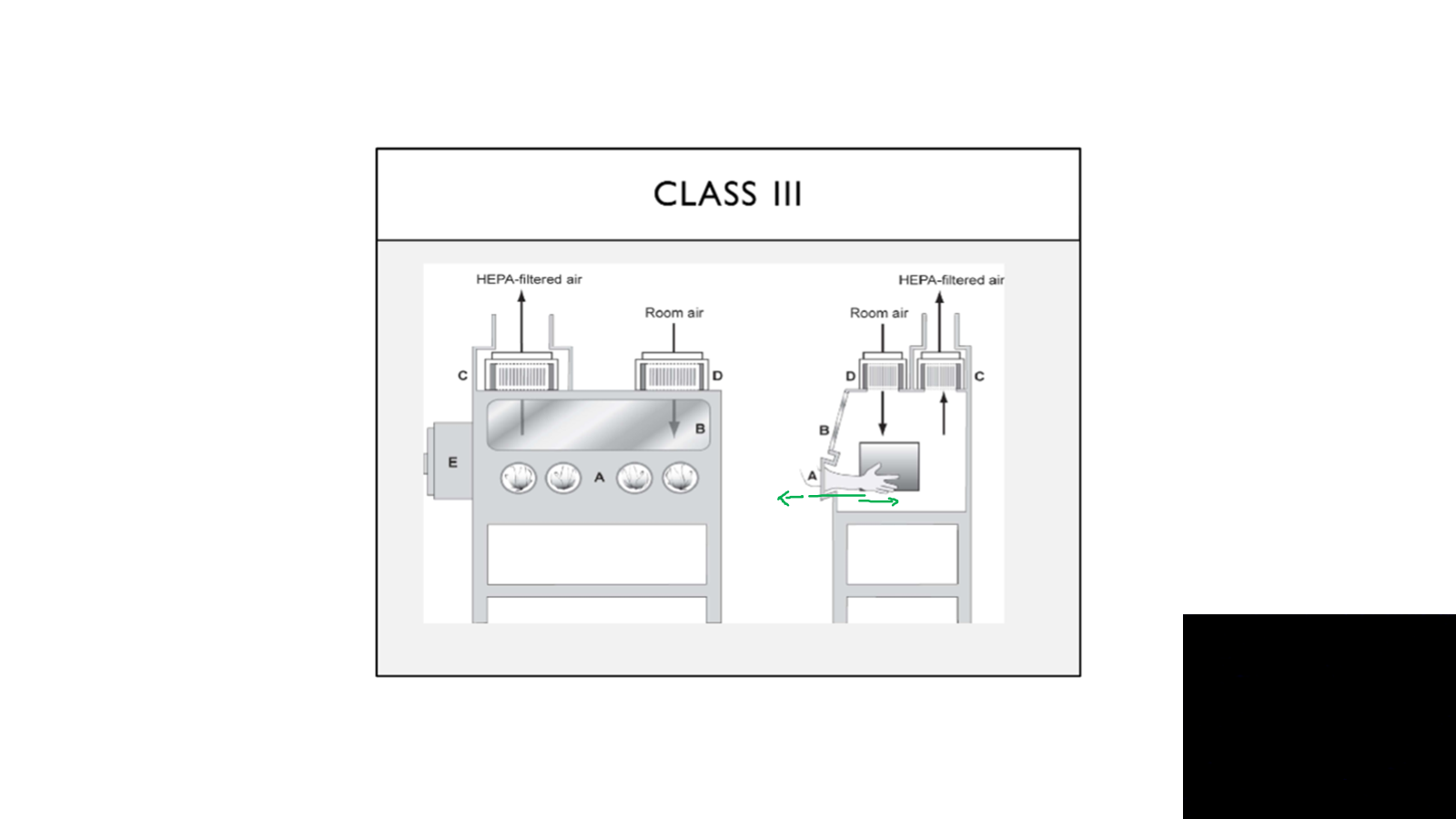

which bsc is designed for gnotobiotic chambers?

Class III

Which BSC is designed for work with highly infectious microbiological agents and the conduct of hazardous operations and provides gas tight, maximum protection for the environment and the worker?

BSC III

Which BSC has passage of materials into the cabinet through a dunk tank that is accessible through the cabinet floor or a double-door pass-through box (e.g antechamber, autoclave) that can be decontaminated between uses?

Class III

Which BSC has both supply AND exhaust air is HEPA-filtered?

Class III

Which BSC has exhaust air that must pass through two HEPA filters, or a HEPA filter and an air incinerator, before discharge directly to the outdoor?

Class III

Which BSC has airflow maintained by an exhaust system exterior to the cabinet, which keeps the cabinet under negative pressure (minimum of 0.5 in water gauge)?

Class III

Important considerations as a user of BSC II cabinets?

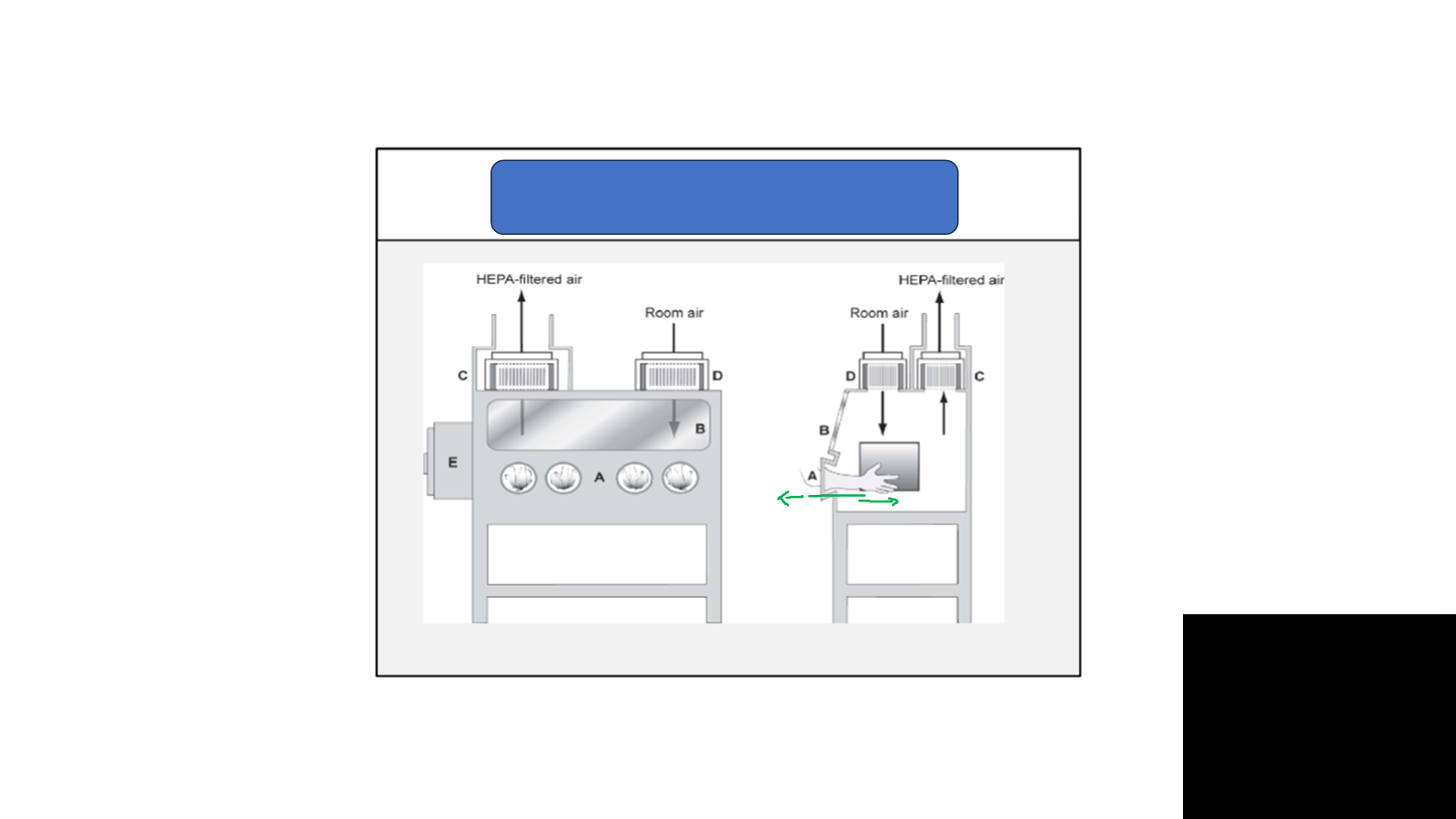

Moving arms in and out slowly, perpendicular to the face opening of the cabinet will reduce the risk of disrupting the air curtain and compromising the partial containment barrier.

Manipulation of materials should be delayed for approximately one minute after placing the hands/army inside the cabinet to allow the cabinet to stabilize.

The front grill must not be blocked. Users who rest the arms flat across the front grill risk occluding the opening and allowing room air laden with particles to enter the work area. Keeping arms raised with an ergonomic elbow rest can alleviate this concern.

If the cabinet has been shut down, the blowers should be operated at least ______ minutes before beginning work to allow the cabinet to purge.

If the cabinet has been shut down, the blowers should be operated at least five minutes before beginning work to allow the cabinet to purge.

Aerosol-generating equipment (e.g. vortex mixers, tabletop centrifuges) should be placed toward the ______ of the cabinet to take advantage of the air split. The correct sash position should be indicated on the ______ of the cabinet. An audible alarm will sound if the sash is in the_______position while the fan is operating. Biological material and other hazardous agents should be placed in the BSC ______.

Aerosol-generating equipment (e.g. vortex mixers, tabletop centrifuges) should be placed toward the rear of the cabinet to take advantage of the air split. The correct sash position should be indicated on the front of the cabinet. An audible alarm will sound if the sash is in the wrong position while the fan is operating. Biological material and other hazardous agents should be placed in the BSC last.

Class II cabinets are designed so that horizontally or vertically nebulized spores introduced into the cabinet will be captured by the downward flowing cabinet air within ____inches of travel. Therefore, keeping clean materials at least foot away from aerosol-generating activities will minimize the potential for cross-contamination.

Class II cabinets are designed so that horizontally nebulized spores introduced into the cabinet will be captured by the downward flowing cabinet air within 14 in of travel. Therefore, keeping clean materials at least one foot away from aerosol-generating activities will minimize the potential for cross-contamination.

Workflow in BSCs should be clean to dirty? true or false?

True

The most common decontamination methods use for BSCs?

The most common decontamination methods use formaldehyde gas, hydrogen peroxide vapor, or chlorine dioxide gas

Which are primary vs. secondary containment barriers regarding BSCs and the rooms themselves?

BSC: Primary

the room: secondary

Can UV lamps be the sole use of disinfection?

No

When should you replace UV lamps (at what fluence rate)?

Replace the bulb when the fluence rate is below 40 uW/cm2.

Should you close or open the sash when operating the UV lamp to be most effective?

close

Where in a room should a BSC be located and why?

In a low trafficked area because movement of people can cause air flow to change within the system

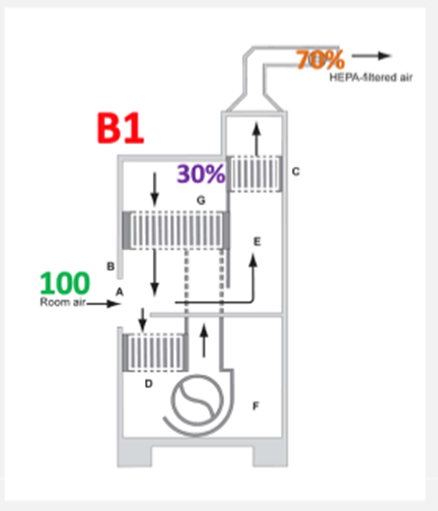

Type II A1 BSC exausted vs. recirculated air %?

30% exaust, 70% recirc

BSC II A2 exaust vs recirc %

exaust: 30%

recirc: 70%

BSC II A2

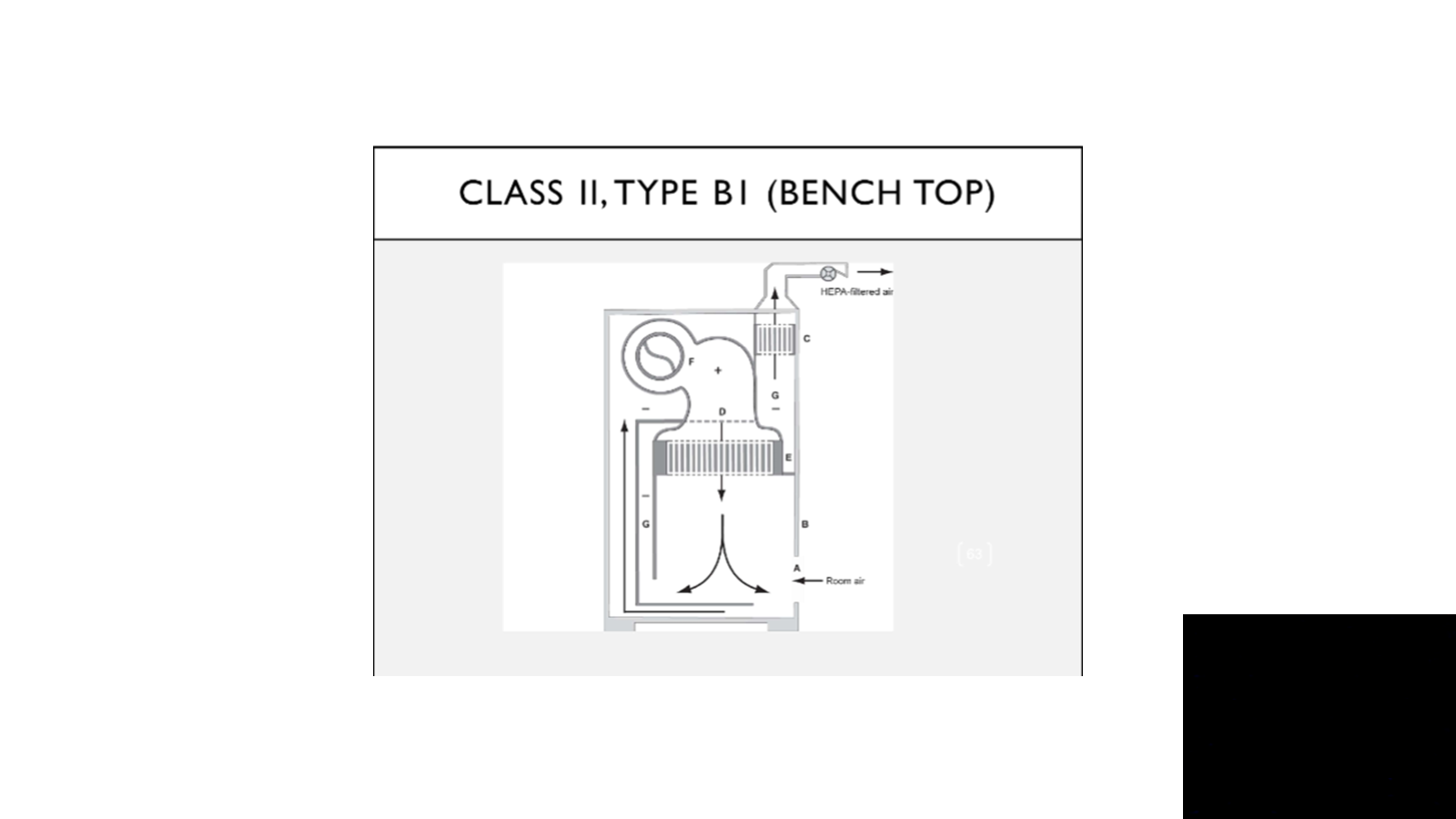

BSC II B1 exaust vs recirc %

Exaust: 70%

recirc: 30%

Which BSC must be hard ducted?

BSC II B1 / B2