3.2. Axial flight

1/60

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

61 Terms

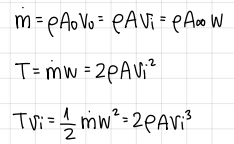

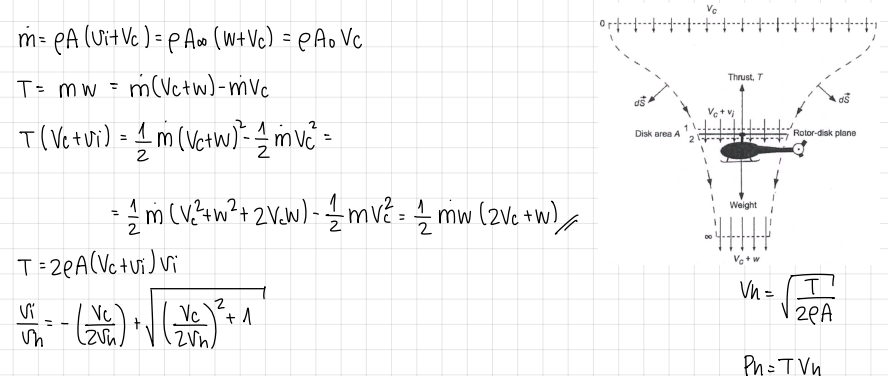

conservation laws formulas (axial flight)

formulas

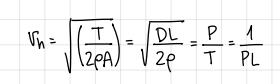

formula for the induced velocity at the rotor disk in hover

formula

we need to put 10kg in hover. which rotor do you choose?

the biggest one

how can one relate useful data across different scales? e.g. data from a scale model test in a wind tunnel to a full scale component?

Buckingham-Pi theorem

based on dimensional homogeneity

# of dimensional terms = # of independent variables - # of fundamental dimensions

choice of repeating variables is not unique → suggested choice for fluid dynamic analyses

length, scale, kinematic variable and dynamic variable

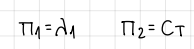

considering rotor flow:

five variables: v_i, v_tip=Omega*R, rho, T, A=pi*R²

three fundamental dimensions: mass, length and time

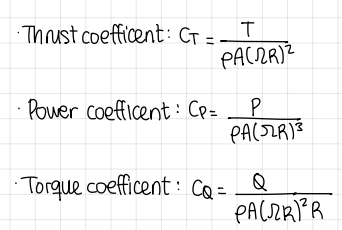

rotor coefficents: names and formulas

thrust coef

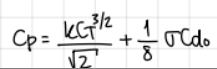

power coef

torque coef

non-dimensional coefficents formulas (rotor coefficents)

formulas

inflow ratio formula

formula

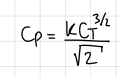

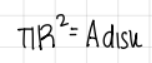

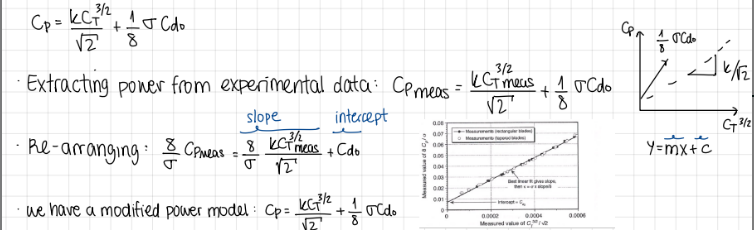

development and formula to relate power coefficent to thrust coefficent

formula

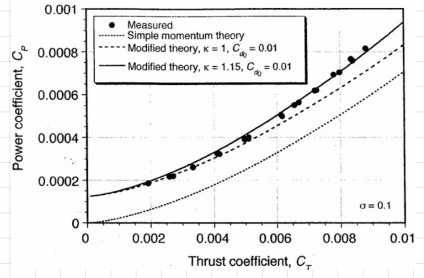

experimental observations:

experimental data is positively offset from momentum theory prediction

higher “slope” observed in experimental data at high thrust coefficents

regarding the higher “slope” observed in experimental data at high thrust coefficents, how do you correct it?

with the induced power factor

estimating the profile power

induced power factor:

symbol

characteristics

formula

k

characteristics

non-uniform flow

tip losses

wake swirl

finite number of blades

formula

how to estimate/model k?

extract from experimental data

advanced rotor aero models (BEMT, etc.)

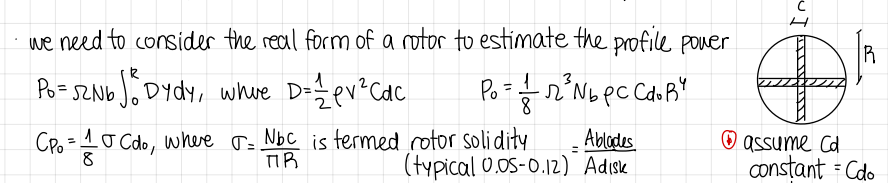

what do we need to do to estimate the profile power? formulas

consider the real form of a rotor

how to estimate/model Cd0?

extract from experimental data

CDF

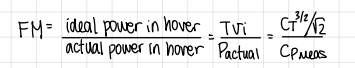

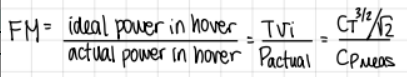

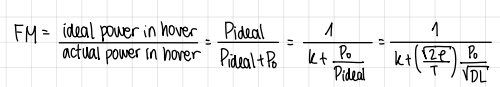

what if the required power is normalized by the ideal predicted power?

figure of merit:

formula

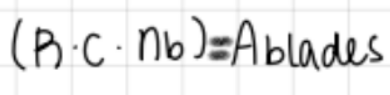

formula for area of blades

formula

formula for area of disk

formula

how do you estimate k and Cd0 from experiments?

with linearization

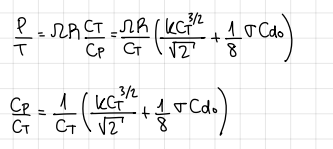

estimating k and Cd0 from experiments: linearization → development

development

modified power model formula

formula

is power loading dimensional?

yes

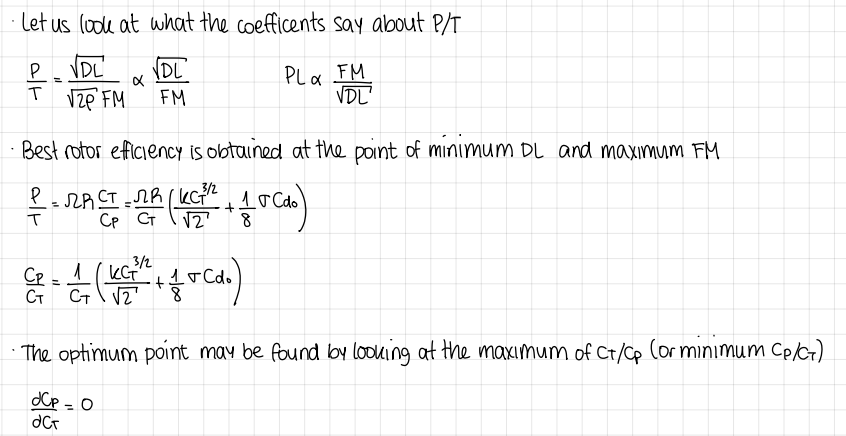

what is the mathematical objective regarding rotor efficiency?

to express efficiencies as non-dimensional coefficents

figure of merit formula

formula

what is figure of merit?

a non-dimensional measure of efficiency in hover

maximum value of FM? (and k)

0.86 (1.15)

two procedures regarding efficiency:

procedures

what is the FM value for most rotors?

between 0.7 and 0.8

what implies if FM is lower than 0.7

that the rotor has been optimized for non-hover conditions

what happens at low c_T?

profile power dominates

what happens at high c_T?

induced power dominates

an asymptote is expected at 1/l

profile losses begin to dominate again (stall)

FM formula depending on profile and induced power

formula

can we compare the rotors of these two rotorcrafts using FM?

No. Figure of Merit compares hover aerodynamic efficiency, not mission roles or operational purpose

FM is a valid measure to compare rotors only at the same (or very similar) DL!

alternative formulation of FM

formula

what happens if FM (Figure of Merit) is a function of DL (Disk Loading)?

it’s possible to “manipulate” FM values by only increasing DL

this will increase the induced power consumption compared to the profile power

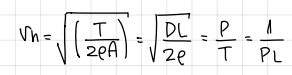

it is sought to ___ the ___ to produce a certain thrust, i.e. the ratio P/T

v_h formula

minimize DL, and consequently, ___ → this means…

minimize, power

v_i, a low rotor tip speed

how do we decide on a rotor tip speed?

set by the lowest speed that still satisfies noise, Mach and structural limits

can we optimize rotor size once a tip speed is selected?

yes. choose rotor radius to minimize disk loading while meeting thrust and design constraints

development for minimization formulation

development

where is the best rotor efficiency obtained? (and formula)

at the point of minimum DL and maximum FM

how can the optimum point be found? (and formula)

by looking at the maximum of c_T/c_P (or minimum c_P/c_T)

formulas when minimizing c_P/c_T

formulas

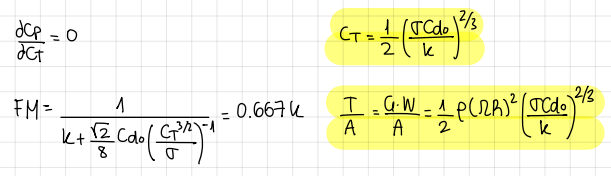

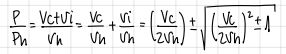

formulas for axial climb

formulas

(axial climb) as climb velocity increases, the induced velocity…

decreases

formulas for axial descent

formulas

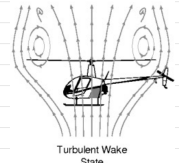

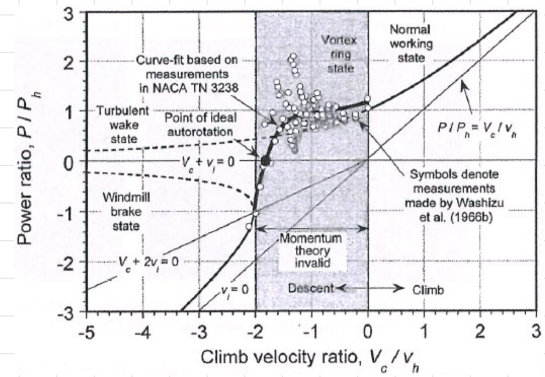

axial descent: rotor flow states

normal → hover, climb, V_D « V_h → 0<V_c

vortex ring state → intermediate state: -2V_h<V_c<0

turbulent wake → intermediate state: -2V_h<V_c<0

windmill → V_c< -2V_h

intermediate states characteristics

a very complicated flow is observed

momentum theory is no longer valid

vortex ring state characteristics (setting for power)

the rotor pushes tip vortices down

oncoming air at the bottom pushes them up

vortices get trapped in a donut-shaped ring

the ring periodically grows and bursts

flow is highly unsteady

can only be empirically analized

turbulent state wake characteristics

rotor looks and behaves like a bluff body (or disk)

the vortices look like wakes behind the bluff body

the flow is unsteady, cannot be analyzed using momentum theory

need of empirical data

windmill brake state

flow is well behaved

no trapped vortices, no wake

momentum theory can be used

formula of axial flight induced velocity (MT)

formula

formula of axial flight power requirements (MT)

formula

we observe a “zero power” point in the power curve. how is that possible? what is happening?

Zero power occurs at autorotation:

airflow through the rotor drives part of the blade, while drag on other parts absorbs the same amount.

The torques cancel, so net power is zero, even though the rotor still produces lift.

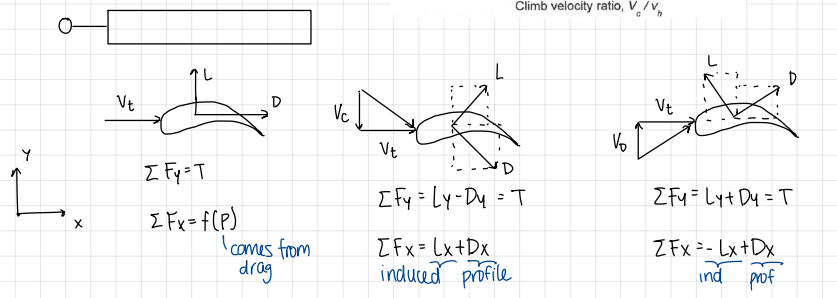

different diagrams and formulas depending on forward flight normal, upwards, downwards

formulas

autorotation mechanics:

the NET power consumption is zero

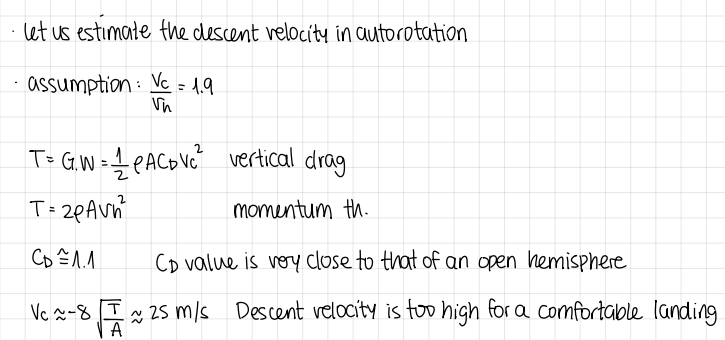

estimation of the descent velocity in autorotation: development

development

what do all helicopters must demonstrate for certification?

autorotation

what are all helicopters equipped with?

freewheeling hubs, to disconnect the rotor from the powertrain during autorotation

how is the vertical velocity in autorotation reduced?

by adding a horizontal velocity component, i.e. forward flight

what is MT good for?

to estimate rotor performance

what can’t be MT used for?

for rotor design

what doesn’t MT take into account?

number of blades

airfoil characteristics (lift, drag, angle, zero lift)

blade planform (taper, sweep, root-cut-out)

blade twist distribution

compressibility effects