Mix Design and Concrete handling

1/66

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

67 Terms

why should aggregates be saturated?

to avoid absorption of needed hydration water

what two things sum up to the absolute volume of a material?

volume of solid + volume of its pores (permeable and impermeable)

difference between mix design and mix proportioning

mix design = selecting materials and desired properties.

mix proportioning = determining how much of each material is needed to produce 1 cubic yard of fresh concrete

What is not included in the absolute volume of a material

voids between particles

w/c ratio is determined by:

durability and strength

for the w/c ratio, which one of the two values for the w/c ratio is considered?

the lowest one

Purpose of air content in the cement paste

improve workability and increase resistance

typical air content

5-8% (commonly 6% +- 1%)

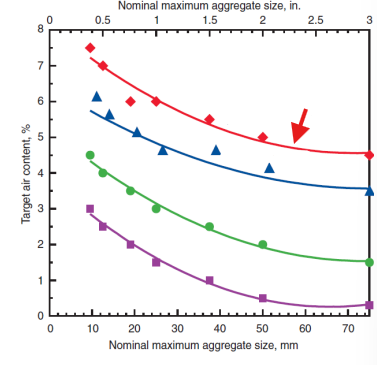

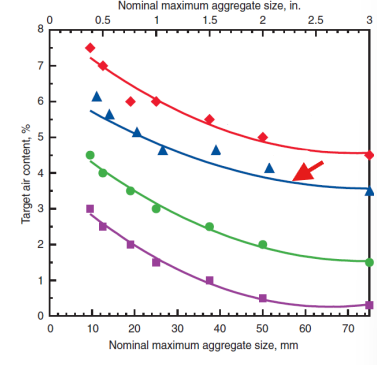

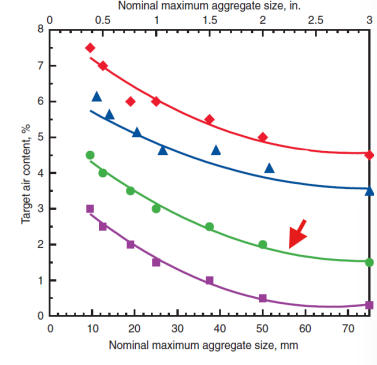

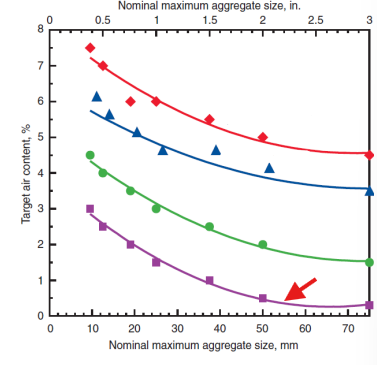

If the paste amount decreases as the aggregate maximum size (Dmax) increases, the air content increases or decreases?

increases

What is affected by the air content in mix calculations?

volume balance

Maximum aggregate size must be:

≤ 1/3 slab thickness

≤ 3/4 of spacing between bars

≤ 1/5 of minimum cover

True or False. Required compressive strength (f’cr) must be higher than specified f’c.

True

rounded vs angular shaped aggregates in a mix:

rounded = more workability, less water needed

angular = less workability, more water needed

The event where separation of the coarse aggregate from the fine part in the concrete mix occurs is known as:

Segregation

An example of a curing method that prevents the loss of moisture is:

Impermeable membranes

The common practice is to test the hardened concrete at the age of:

7 and 28 days

The method of measuring the air content in the concrete mix that is not affected by the elevation is:

Pressure and Gravimetric

In a PC concrete mix calculation, the formulas resulted in w/c ratios of 0.42 and 0.44 when there is statistical data. Also, the w/c must be not higher than 0.45 to satisfy exposure conditions. Which w/c ratios must be used in this mix?

0.42

If the concrete is maintained under an adequate moisture conditions for the hydration process to occur, it may continue developing its strength for how long?

1 year or more

severe exposure

moderate exposure

mild exposure

non-air entrained concrete

Mixing:

homogeneous mix with all ingredients evenly distributed

Consistency:

Measured by slump test (ease of flow).

Workability:

Ease of placing, consolidating, and finishing without segregation

Segregation

Coarse aggregates separate from the mix

Bleeding:

Type of segregation where water rises to the surface

general values for slump

between 1 in and 6in

slump for flowing concrete

>7 1/2 in

slump when segregation occurs

>10in

rpm for Central-mixed concrete (all mixing at plant)

2-6 rpm

rpm for Truck-mixed concrete (all mixing on the truck)

4-16 rpm

rpm for Shrink-mixed concrete (partial plant, partial truck)

4-6 rpm

How should concrete be placed on site

In horizontal layers and consolidated before adding another

Method used for consolidating concrete

vibration

what should vibration never be used for

moving concrete horizontally

Why is vibration used to consolidate concrete

removes air pockets and stone voids

what does over-vibration cause

segregation

when does slab finishing (floating) starts?

after bleeding stops

Purposes for Slab Finishing (Floating)

embed coarse aggregates, smooth surface, compact top mortar

Frequency of ASTM C172 and ACI 318-19

once a day, once every 150 yd3 of concrete, once for every 5,000 ft2 of surface for slabs or walls

From where is the concrete sample taken when sampling fresh concrete

from middle portion of truck batch

size of concrete when sampling fresh concrete

1ft3 (28L), taken within 15 min

When should slump, temperature, and air content be measured

within 5 min

measures of standard cone in slump test

4in top, 8in bottom, 12in high

3 volume layers mold should be filled in slump test:

70mm, 160mm and top

What is measured/tested in fresh concrete

slump, sampling, temperature, unit weight and yield, air content

Steps of sample molding:

Cylinders: 6×12 in. or 4×8 in. (based on agg. size)

Compact in 3 layers, 25 strokes each, plus tapping

Cure at 76.5 ± 3.5°F

Remove molds after 24 ± 8 hrs

Purpose of curing process

prevent moisture loss and maintain temperature

Curing Methods:

saturated water coverings

plastic sheets

steam/electric heat for fast curing

Primary cause of cracking

drying shrinkage

True or False. f’c increases over time

True

Normal concrete compressive strength

3000-6000 psi

High concrete compressive strength

>6000 (up to 20,000)

tensile strength of concrete

8-12% of f’c

conventional methods for evaluating hardened concrete

compression, tension, flexural tests

non-conventional methods for evaluating hardened concrete

rebound hammer, penetration probe, ultrasonic pulse, maturity test

What causes an Alkali-silica reaction

reactive silica + high pH + moisture

Control methods for Alkali-silica reactions

use supplementary cementitious materials, low-alkali cement, lithium compounds

density of lightweight concrete

85-115 pcf

density of heavyweight concrete

400 pcf

strength of High-strength concrete (HPC)

10,000psi

What type of concrete flows and consolidates under its own weight

self-consolidating concrete SCC

what type of concrete has a dry mix, no slump is needed and is compacted like pavement

roller compacted concrete RCC

Which type of concrete is applied by being sprayed on

Shotcrete

What type of concrete is added for impact/crack resistance

Fiber-reinforced concrete