APA3131 - 1.2 - Ergonomics as a Process

1/66

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

67 Terms

Ergonomics

Scientific discipline optimizing human-system interactions.

Systems Thinking

Understanding interactions among system elements.

ISO 26800-2011

Standard defining ergonomics and its applications.

Human-machine-environment model

Framework analyzing interactions in work systems.

Human-Centred Design

Designing systems to fit human characteristics.

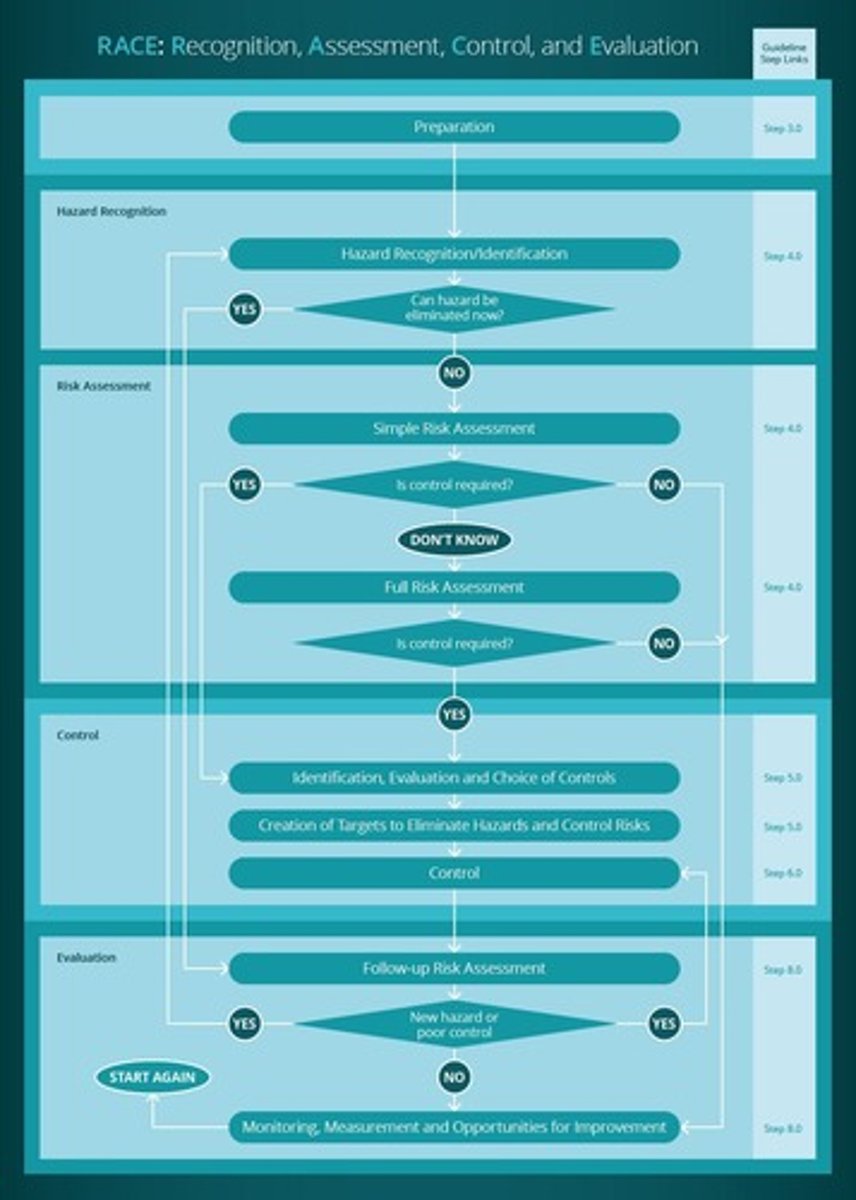

RACE Model

Workflow for organizing MSD prevention process.

Recognition

Identifying hazards in the workplace.

Assessment

Evaluating the severity of identified hazards.

Control

Implementing measures to mitigate identified risks.

Evaluation

Reviewing effectiveness of control measures.

Physical Ergonomics

Focus on physical interactions in work environments.

Cognitive Ergonomics

Study of mental processes in system interactions.

Social Ergonomics

Impact of social factors on work systems.

Organizational Ergonomics

Designing systems considering organizational structures.

Integrated Framework

Holistic approach addressing multiple ergonomic issues.

Workspace Environment

Physical layout affecting worker performance.

Cultural Environment

Influence of societal norms on workplace behavior.

Organizational Environment

Work schedules and management affecting ergonomics.

Physical Environment

Temperature and spatial factors in work settings.

Hazard Elimination

Immediate removal of identified workplace hazards.

Engagement Team

Diverse group for ergonomic analysis preparation.

MSD Prevention Process

Strategies to reduce musculoskeletal disorders.

MSD Hazards

Sources of potential harm causing musculoskeletal disorders.

Reactive Measures

Actions taken after an incident to address hazards.

Proactive Measures

Preventative actions to avoid MSDs before they occur.

Hazard Assessment Tools

Tools like NIOSH Lifting Index for simple assessments.

Risk Assessment

Detailed evaluation of potential hazards and exposures.

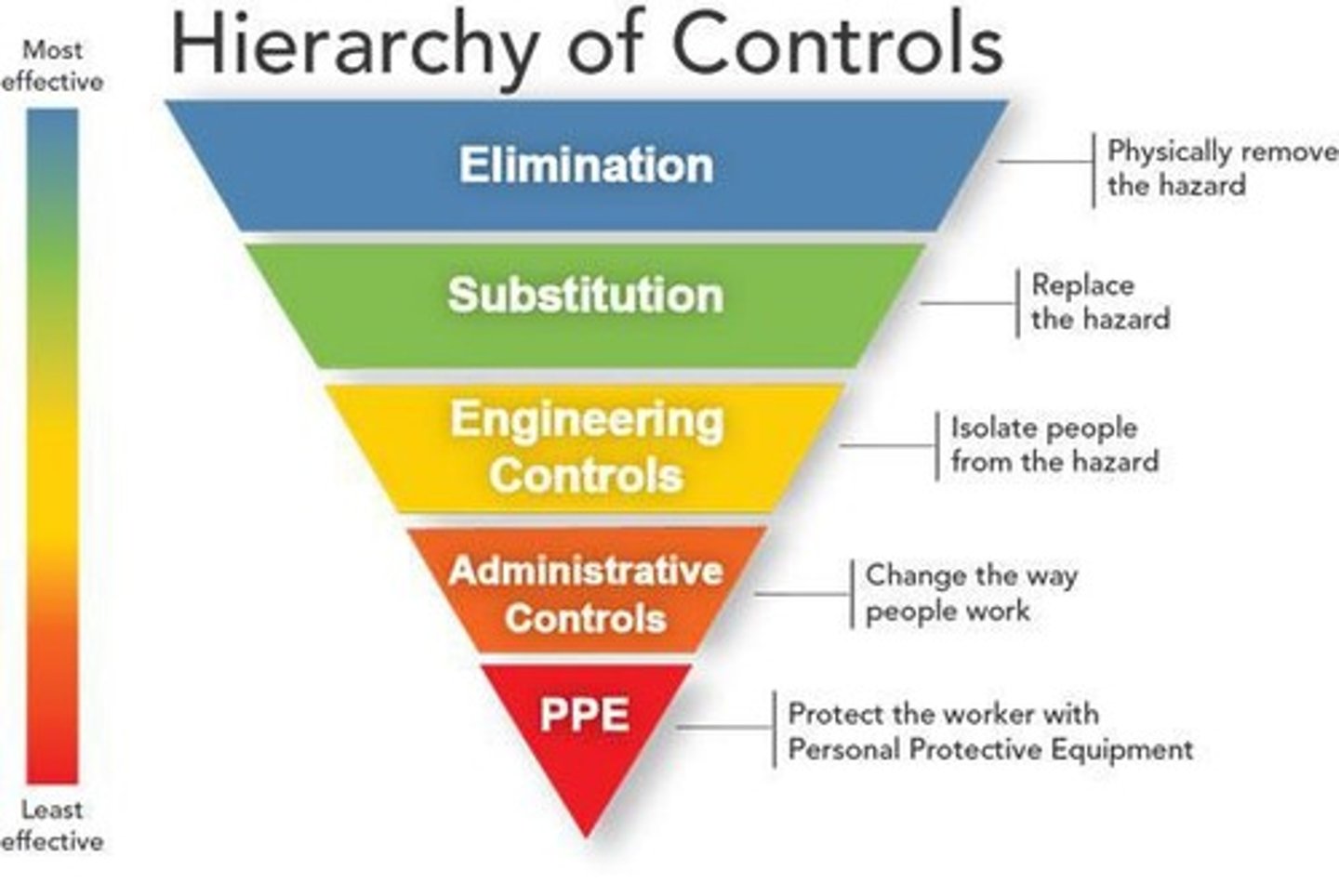

Hierarchy of Controls

Systematic approach to eliminate or mitigate hazards.

Injury Surveillance Data

Data collected reactively to monitor workplace injuries.

Worker Feedback Measures

Employee input on discomfort and hazard recognition.

Awkward Postures

Body positions that increase risk of injury.

High Force Exposures

Heavy loads leading to increased injury risk.

Repetition

Frequent movements contributing to cumulative trauma.

Vibration Exposure

Exposure to vibrations increasing risk of disorders.

Local Contact Stress

Pressure on specific body parts causing injury.

Cold Environment Risks

Working in cold increases musculoskeletal disorders.

Control Measures

Actions taken to eliminate or reduce hazards.

Engineering Controls

Physical modifications to reduce hazard exposure.

Personal Protective Equipment (PPE)

Gear worn to protect against workplace hazards.

Management Commitment

Leadership support for health and safety initiatives.

Worker Participation

Involvement of employees in safety processes.

Targets and Goals

Specific objectives for hazard elimination and risk control.

Biomechanical Modelling

Analysis of forces acting on a worker's body.

Evaluate Effectiveness

Assess if control measures worked and identify new hazards.

Ergonomics Process

Systematic application of ergonomics in work systems.

Proactive Ergonomics

Implementing ergonomics early enhances safety and performance.

User-Centred Approach

Design considers diverse worker characteristics and needs.

Worker Participation

Involvement of workers improves work system design.

OHSMS Integration

Ergonomics must align with Occupational Health and Safety Management.

RACE Process

Recognition, Assessment, Control, Evaluation in ergonomics.

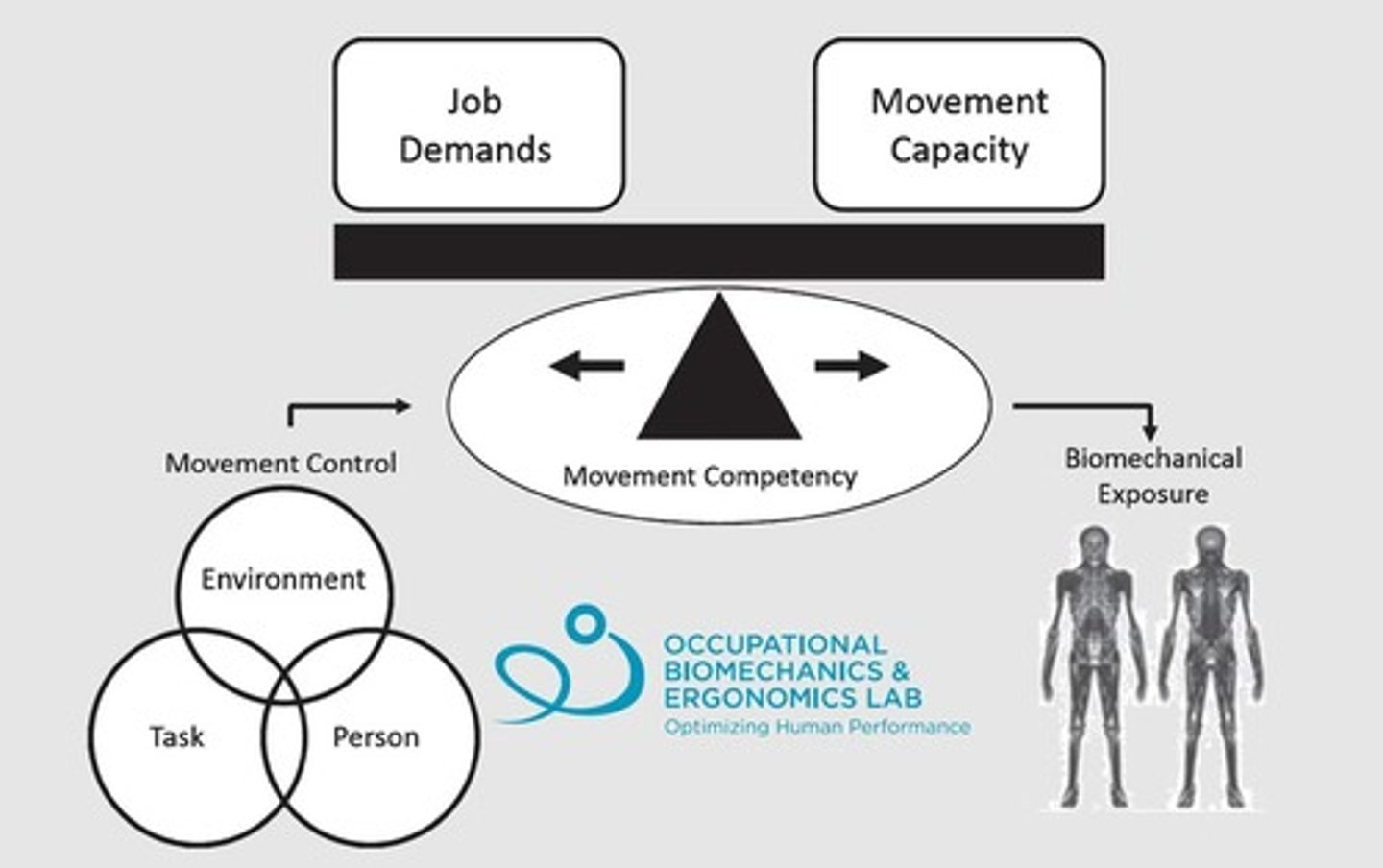

Demand-Capacity Model

Injury risk increases when demand exceeds capacity.

Injury Risk Formula

Injury risk ∝ demand/capacity ratio.

Risk Continuum

Evaluates job safety between high and low risk.

Decision Criteria

Establish boundaries for acceptable and unacceptable tasks.

Threshold Limit Value (TLV)

Safe exposure level for hazardous substances.

75% Capability Rule

75% of women can perform the task safely.

Acute Injury

Injury from low repetition tasks.

Repetitive Strain Injury

Injury from high repetition tasks.

Repetition and Fatigue Index

Measures risk based on task repetition.

Lessons Learned Documentation

Recording feedback to improve safety processes.

Control Hazards

Implement changes to mitigate identified risks.

Education and Training

Providing knowledge to enhance workplace safety.

Evaluate Controls

Assess effectiveness of implemented safety measures.

Review Processes

Analyze achievements and identify improvement areas.

System Performance

Overall effectiveness of ergonomics in work systems.

Job Demands

Physical and mental requirements of a job.

Movement Capacity

Physical ability to perform job tasks.