Last bit of casting info

1/7

Earn XP

Description and Tags

slides 123 - 146

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

8 Terms

General Casting Defects

Misrun: solidified before filling whole cavity

Shrinkage Cavity: depression in surface cause by solidification shrinkage

Foundry Inspection Methods

Visual inspection, dimensional measurements, and metallurgical or chemical

Castability

ease with which a cast part can be produced

based on…

Part Design

Casting Metal

Proper selection of casting process

Casting metals

Processes done after casting has solidified

Trimming: remove sprues, runners, risers, parting lines, etc.

Remove Core: manually, mechanically, or chemically

Surface Cleaning: remove sand from surface by tumbling, air blasting or wire brushing

Inspection: detect quality defects

Repair: if required and/or possible

Heat Treatment: enhance processes or subsequent machining

Classification of Casting Quality Defects

General Defects: common to all casting processes

Defects related to sand casting process

Sand Casting Defects

Infiltration: when fluidity of liquid metal is high it may infiltrate the sand mold or core

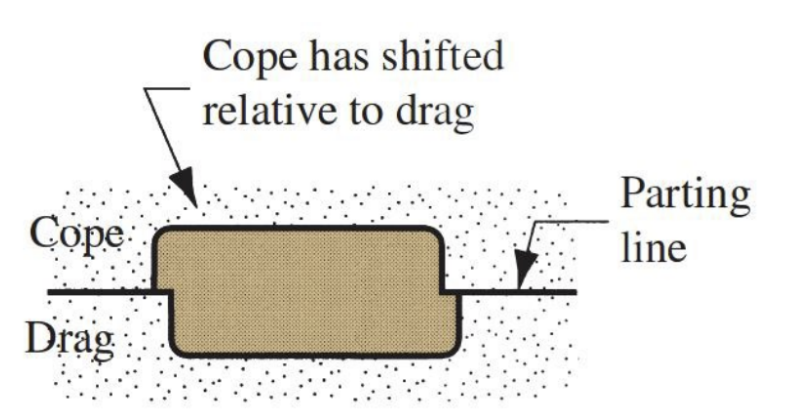

Mold Shift: step in the casting at the parting line caused by displacement of cope and drag