CONVERSIONS & CONSTANTZ

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

71 Terms

HP to ft-tb/min

33,000 ft-lb/min

HP to kW

.746 kW

HP to BTU/hr

2545 BTU/hr

Kelvin to Rankine

1K = 1.8R

kW to BTU/hr

(1HP/.746kW) x (2545BTU/hr/HP)

or 3412 BTU/hr

BTU to ft-lb

778 ft-lb

BTU to cal

252 cal

BTU to J

1055 J

BoHP to kJ/hr

9.81kW → 9.81kJ/s ÷ 3600

Or 35,322 kJ/hr

BoHP to kW

9.81 kW

BoHP to HP

13.15 HP

ft³ to gal

7.481 gal

m³ to L

1000 L

gal to L

CALCU

3.785 L

bbl to gal

42 gal

English Ton

2000 lbf

atm to kPa

101.325 kPa

atm to psi

14.7 psi

atm to mmHg

760 mmHg

atm to inHg

Calcu 760mm to in

psi to Pa

6895 Pa

inHg to psi

calcu in to mm = mmHg

760mmHg = 1atm = 14.7psi

fathom

6ft

bar

100kPa

speed of sound

343 m/s

speed of light

300 ×10⁶ m/s

N

kg-m/s²

kgf

9.81 N

lbf to N

4.4482 N

slug to lbm

32.174 lbm

slug = lbf/ft/s²

ɣ water

9810 N/m³ = 62.4 lbf/ft³

water density

1000 kg/m³

1 kg/L

ft H2O to psi

0.433 psi

Water Power

ɣQh

Efficiency

Output/Input

Motor Efficiency

Brake Power/Power Consumed

Pump Efficiency

Water Power/Brake Power

Heat Rate

3412/η = BTU/kWh

3600/η = kJ/kWh

kcal to BTU

3.97 BTU

TOR

12,000 BTU/hr

Tons of Refrigeration

Cp air

1.0 kJ/kg-K

0.24 BTU/lb-R

Cv air

0.7186 kJ/kg-K

0.171 BTU/lb-R

R air

0.287 kJ/kg-K

53 ft-lb/lb-R

0.0821 atm-L/mol-K

air density @ NTP

1.2 kg/m³

0.075 lbm/ft³

Cp water

4.187 kJ/kg-K

1 BTU/lb-R

Triple Point Temp of Water

0°C

water hfg @100°C

2257 kJ/kg

970 BTU/lb

Cp Ice

½ of Cp water

Cp vapor

2.0 kJ/kg-K

0.49 BTU/lb-R

Latent Heat of Fusion

Melting/Solidifying

334 kJ/kg

BTU/lbm

Latent Heat of Vaporization

Vaporizing/Condensing

2257 kJ/kg-K

970 BTU/lbm

g

9.81 m/s²

32.2 ft/s²

Molecular Weights

Ammonia (NH3) = 17 g/mol

Oxygen (O2) = 32 g/mol

Nitrogen (N2) = 28 g/mol

Air = 28.97 g/mol

CO2 = 44 g/mol

Helium = 4 g/mol

Helium k = 1.667

Bolts “C” values

Alloy Steel - 15,000 psi

Carbon Steel - 5,000 psi

Bronze - 1,000 psi

Metal Densities (ρ)

Steel - 0.284 lb/in³

Cast Iron - 0.255 lb/in³

Factor of Safety (FS)

Yield Stress/Working Stress

Ampere

Coulombs per second

Current = charge/time

Heat Transfer (Conduction & Convection)

q = ∆T / Total Resistance

Conduction Resistances

Wall - x / kA

Pipe - ln(r2/r1) / 2πkL

Spherical - (1/r1 - 1/r2) / 4πkL

Convection Resistances

1/hA

Radiation

Q = σFₑA(∆T⁴)

σ = 5.67 ×10^-8

Fₑ = 1 for black body

Correction Factor (CF)

1-𝛼∆T

𝛼 = 0.0007/°C

𝛼 = 0.0004/°F

Cycle Efficiencies

Before solving cycles..

DRAW DIAGRAMS

Dulong’s Formula

Qh = 33,820(C) + 144,212(H-O/8) + 9,304(S)

kJ/kg

Qh Liquid

41,130 + 139.6(°API)

°API

(141.5/SG@15.6) - 131.5

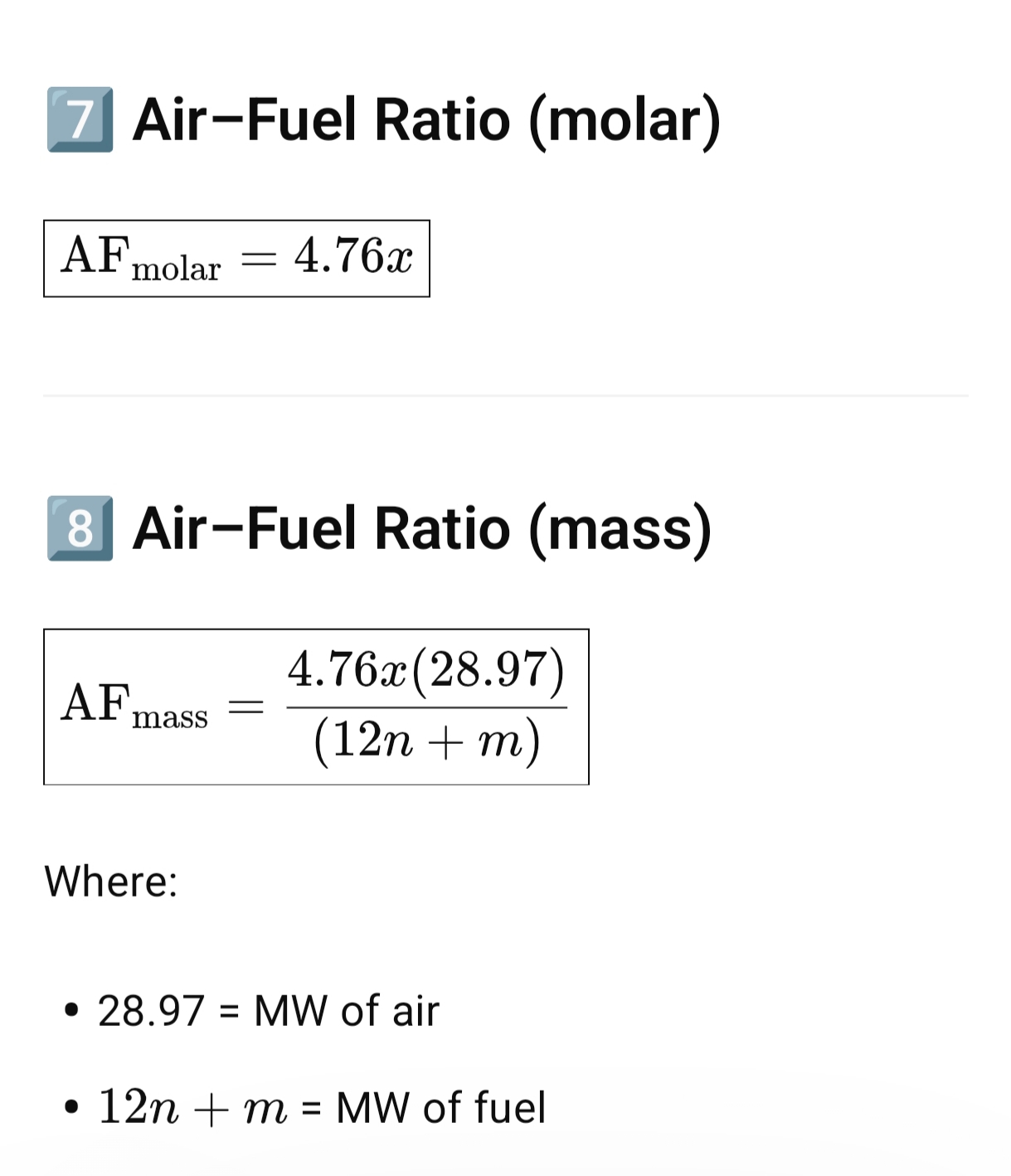

Air Fuel Ratio

11.5(C) + 34.5(H-O/8) + 4.3(S)

Products of Combustion

CnHm + xO2 + x(3.76N2) = yCO2 + zH20 + x(3.76N2)

x= n + m/4

y= n

z= m/2

concrete density

2406 kg/m³

Candela to Lumens

4π Lumens