materials definitions

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

metals

inorganic dense materials that conduct electricity and heat and are typically solids that are malleable and ductile with a lustrous appearance

ceramics

inorganic, non-metallic compound. Constituent atoms typically comprise metal and non-metal (oxygen, boron, carbon) which are wither covalently or ionically bonded to each other

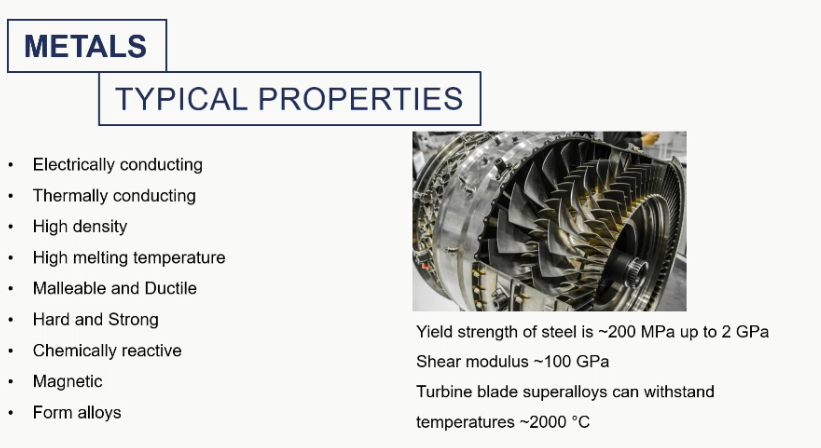

metal properties

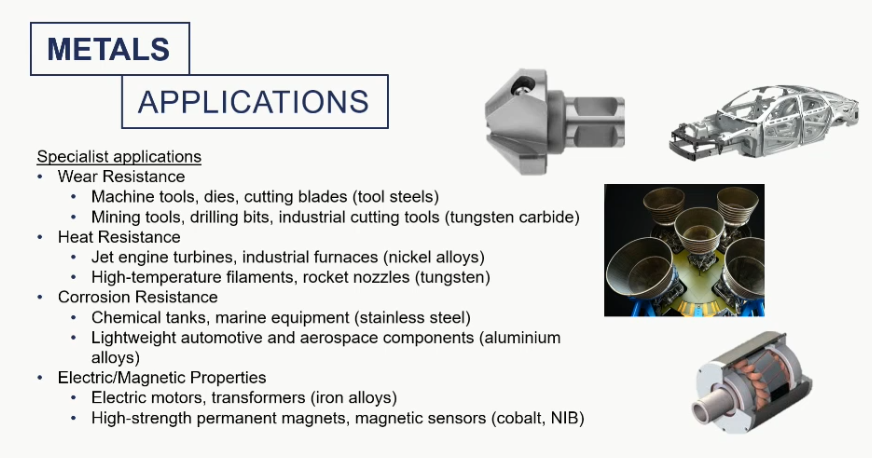

metal applications

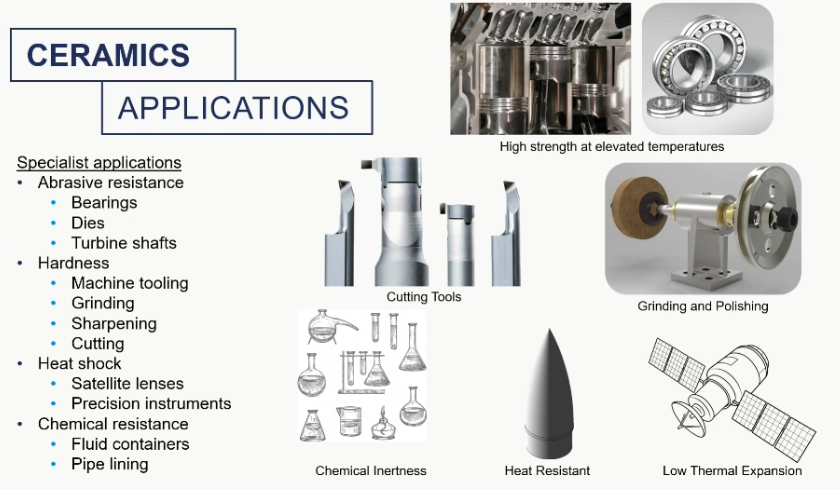

ceramic properties

ceramic applications

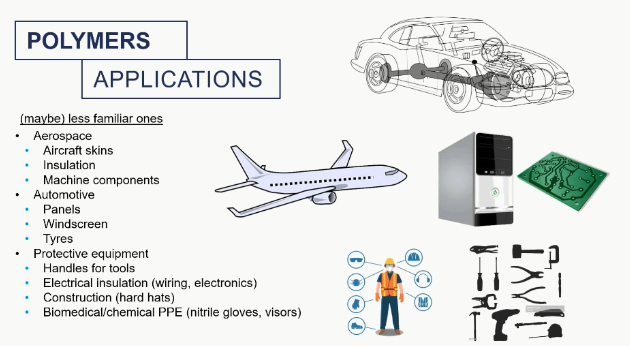

polymers

long chain (macromolecules) made up of repeat units, typically linked by covalent bonds between atoms

linear

branched

ring

stars

brush/comb

polymer properties

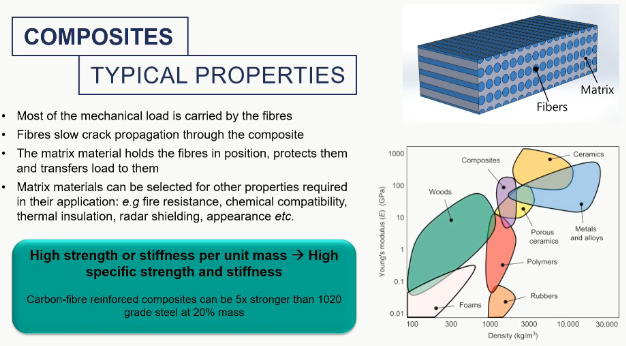

composites

composite material is composed of at least 2 materials, which combine to give modified, and superior properties to those of the individual constituents

composite properties

composite applications

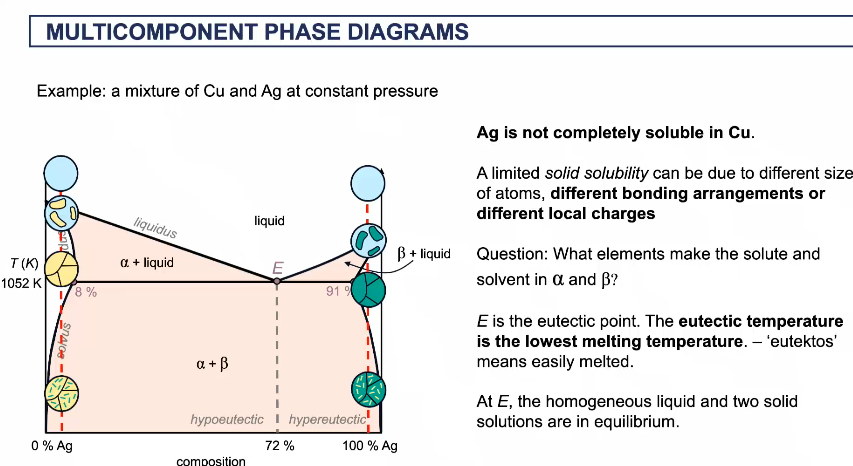

phase diagrams

indicate the conditions at which different phases are found at thermodynamic equilibrium

phase

material with distinct chemical compositions and physical state

entropy S

measure of disorder. The number of ways to arrange the atoms in the material at a given temperature (T)

system internal energy (U)

total energy associated with all the bonds in the material

triple point

all 3 phases are in equilibrium (are are equally likely to be observed)

degrees of freedom

describes the number of independent variables that can be changed without affecting the equilibrium

Eutectic point E

eutectic temperature is the lowest melting temperature (easily melted at that point)

seen in the phase diagrams

at E, the homogeneous liquid and 2 solid solutions are in equilibrium

precipitates

crystals of different phases can also form within crystalline solid solutions

crystals

in cooled liquids, the changes in free energy give rise to crystals

nucleation

emergence of a new phase and is rate determining

growth

the speed of which has a strong influence on microsturcture

continuous casting

is an efficient high through put process for producing large amount of metal products, by continuously pouring and solidifying molten metal into desired shapes

superior to ingot casting, as it has fewer defects and can be fed directly into the rolling mill

heat capacity

the amount of heat energy required to raise the temperature of a material by 1 degree

quantifies how much energy can is absorbed/ released by the bonds in material

specific hear capacity

is the mass dependent heat capacity

enthalpy of fusion ( Hf)

provides the amount of heat energy required to change the state of a material from liquid to solid or solid to liquid

also known as latent heat/ heat of fusion

is negative when freezing (liquid to solid)

is positive when melting (soldi to liquid)