Damage Control Coloring Book

1/121

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

122 Terms

6.1 Duties and Responsibilities of Divisional Damage Control Petty Officer (DCPO)

Maintains DC duties as primary responsibilities

Conducts all PMS on portable DC equipment in divisional spaces

Supervises daily setting of specified material conditions within divisional spaces

6.1 Duties and Responsibilities of Division Officers (DIVO)

Assigns personnel to DC organizations on the Watch, Quarter, and Station Bill

Ensures divisional personnel are assigned requisite DC PQS (Personnel Qualification Standard)

Recommends a DCPO to the Department Head

Ensures Compartment Check-Off Lists (CCOLs) are current, accurate, and posted

Conducts spot checks of DC PMS (Preventative Maintenance System)

6.1 Duties and Responsibilities of Damage Control Assistant (DCA)

Submits all-hands DC training schedule to the Planning Board for Training (PB4T)

Informs the Damage Control Officer

(DCO) of changes to DC equipment

status

Oversees training and qualifications

of repair lockers and Damage Control

Central (DCC) personnel

Supervises training of all DCPOs

6.1 Duties and Responsibilities of Damage Control Officer (DCO)

Maintains hull, machinery, and electrical systems in battle readiness

Supervises firefighting and ensures Fire Bill adequacy

Organizes and trains Repair 5 in accordance with the Battle Bill

Acts as authorizing officer for use of installed ventilation for desmoking spaces after a fire is extinguished

6.1 Duties and Responsibilities of Department Heads

Ensures optimum readiness within the department

Ensures cooperative DC training with the DCA

Provides required personnel for repair lockers and inport fire parties

Ensures that personnel are qualified and assigned as Damage Control Petty Officers (DCPOs)

6.1 Duties and Responsibilities of Executive Officer (XO)

Keeps the CO advised as to the status of the ship’s readiness

Commands the Damage Control Training Team (DCTT)

DCTT is the shipboard train team responsible for training and self-assessing the crew’s response to damage control casualties.

Gives final approval for DCPOs

Heads PB4T

6.1 Duties and Responsibilities of Commanding Officer (CO)

Responsible for the safety of the ship and the lives of the crew

Ensures the command is adequately trained and continually exercised

Maintains a full awareness of the adequacy and operability of all DC equipment

Gives the order for Abandon Ship if necessary

6.2 Damage Control Repair Stations are located:

Repair 3 (AFT)

Repair 5 (ENG)

Repair 2 (FWD)

6.2 Rapid Response Team (RRT)

Proceeds directly to the scene of the casualty without full Fire Fighting Ensemble (FFE) or Self Contained Breathing Apparatus (SCBA) to provide initial limited attack casualty response

Designated U/W and I/P

RRT Includes:

Fire Marshal

Repair Electrician

Two advanced DC qualified personnel

6.2 Flying Squad/At-Sea Fire Party

Backs up the Rapid Response Team

First team to man a Repair Locker in full dress out

Combats a casualty U/W that requires minimal DC effort

Usually advanced DC qualified personnel who stand watch or stand roving watches

6.2 Repair Party Leader

In charge of the repair locker

Responsible for DC efforts in a designated area of the ship

Locker Officer is often assigned but is not required IAW the NTTP 3-20.31

6.2 Investigators

Roves in pairs, autonomously, in areas adjacent to affected compartments

Continuously reports new findings and update statuses to locker via hand held radio

Searching for panting or sweating bulkheads, structural damage, and any secondary/cascading damage caused by the casualty

Will use a 30 min SCBA; “on-air” at their own discretion

Ensures casualty boundaries remain set

6.2 On-Scene Leader (OSL)

Directs the DC team at the location of the casualty

Reports to the Repair Locker Leader

Determines the method of attacking the casualty

6.2 Attack Team Leader (ATL)

Reports to the OSL

Leads the attack team

Directs attack team efforts at the scene of the casualty

6.2 Attack Team

Nozzleman

Hoseman

Plugman

6.2 Duties and Responsibilities of (In-Port DC Organization) Command Duty Officer (CDO)

Reports directly to the CO

Responsible for the safety of the entire ship and its personnel

Typically second-tour division officer or senior

Assumes the duties of the CO when the CO is off the ship

6.2 Duties and Responsibilities of (In-Port DC Organization) Engineering Duty Officer (EDO)

In charge of the engineering plant

Coordinates DC efforts from Damage Control Center (DCC)

Functions as the DCA when the DCA is off the ship and casualties occur

6.2 Duties and Responsibilities of (In-Port DC Organization) Duty Fire Marshal

Assists the DCA with daily fire prevention, material conditions, and duty section training

Leads the ship’s Rapid Response Team

6.2 Duties and Responsibilities of (In-Port DC Organization) In-Port Emergency Team (IET)

The IET is a limited force which responds to a designated locker in case of a casualty in-port; normally called upon outside of normal working hours

The IET includes the RRT

6.2 Duties and Responsibilities of (Battle organization underway) Bridge Personnel

Officer of the Deck (OOD) is the CO’s primary assistant and their direct representative on the Bridge

Possess extensive knowledge of the ship’s systems and DC emergency procedures

Maneuver the ship to minimize the effects of wind, fire, and smoke

6.2 Duties and Responsibilities of (Battle organization underway) Damage Control Central (DCC)

General Quarters (GQ) station for the DCA

Receives and evaluates information from all repair parties

Keeps the Bridge informed

of DC progress

Initiates orders to repair

partiesMaintains all DC plots

Controls routes through

the ship to minimize

breaking of watertight

integrity

6.2 Duties and Responsibilities of (Battle organization underway) Main Control (MC)

GQ station for the Engineering Officer of the Watch (EOOW)

Controls and monitors Engineering Operational Casualty Control (EOCC) procedures

Responsible for starting and stopping installed systems

Responsible for propulsion

6.2 Duties and Responsibilities of (Battle organization underway) Central Control Station (CCS)

GQ station for the DCA and EOOW

One space that serves as MC and DCC on certain ship classes

6.2 Duties and Responsibilities of (Battle organization underway) Combat Information Center (CIC)

Led by the Tactical Action Officer (TAO), who maintains knowledge of engineering electrical plant status for warfare priority

Communicates with the DC organization as repairs are made and systems are brought back online

6.2 Duties and Responsibilities of (Battle organization underway) Combat Systems

Maintenance Center (CSMC)

The Combat Systems Officer of the Watch (CSOOW) coordinates all Combat Systems-related DC casualties from CSMC

Ensures that all damaged electronic equipment is repaired and brought back online

Serves the function of Repair 8 on ships with a robust combat suite

6.2 Duties and Responsibilities of (Battle organization underway) Helo Control Officer (HCO)

Communicates with pilot, coordinates landing with the Bridge, and oversees casualty control efforts

- On ship’s with an Air Operations

Department (LHA/LHD/LPD):

HCO is usually stood by a

departmental officer or CPO

- On ships just equipped for

helicopter operations

(LSD/CG/DDG/LCS): HCO is

usually stood by SUPPO

(Supply Officer) or ASUPPO

(Assistant Supply Officer)

6.2 Duties and Responsibilities of (Battle organization underway) Crash and Salvage Team

A.K.A. Crash and Smash Team

Trained in pilot rescue and to respond to flight deck emergencies

- Teams are comprised of Air Operations

Department personnel

- On ship’s without an Air Operations Department, all departments will provide personnel to ensure a fully manned Crash and Salvage Team

6.2 Duties and Responsibilities of (Battle organization underway) Medical

GQ station for the Senior Medical Officer (SMO) on big decks

GQ station for the Independent Duty Corpsman (IDC) on small decks

6.2 Duties and Responsibilities of (Battle organization underway) FWD & AFT Battle

Dressing Stations (BDS)

Administers first aid to personnel casualties in battle situations

Manned by medical department personnel and qualified stretcher bearers

Distributed throughout the ship to afford easy access (most ships have at least two)

Stocked and fully equipped to handle battle casualties

6.2 Duties and Responsibilities of (Battle organization underway) Rescue & Assistance Team (R&A)

Can be manned up In-port or U/W

Provides aid in the form of equipment and personnel for a different ship experiencing a casualty

Team will stage a specific list of DC equipment on or near the boat deck

6.3 Symbols (optional)

Fire: A, B, C, D

Smoke: S

Fire Protection System: FPS

Fire Fighting Water: FFW

Flooding: FL

Progressive Flooding: PFL

Structural Damage: STR

Hole: H (OVD, BHD, Deck)

Rupture: R (system)

Personnel Failure (injury): P, list name of person

Mechanical Failure: M, list equipment or system

Mechanical Damage: MD, list equipment or system

Weapons Hazard: WPN, list weapon type

Jammed Access: J, list hatch/scuttle number

Electrical Power Loss: E, list space

Toxic Gas: TOX

Chemical: CHM

Biological: BIO

Radiological: NUC

Fire Boundary: FB

Smoke Boundary: SB

Casualty Boundary: CB

6.3 Electronic Phone Circuits

J-Dial: Ship’s Service Telephone Circuit

Just like your home phone (keypad)

Shouldn’t be relied upon in emergency situations (fragile)

Requires power source (no redundancy)

IVCS: Integrated Voice Communication System

Operates on Ship’s Power

Can be used as for multi-station net or space to space comms

Up to 1 hour battery back-up

6.3 Sound Powered Phone Circuits

2JZ Damage Control and Stability: receiving reports and issuing orders to Repair Stations from DC Central

3JZ Main Deck Repair Circuit: coordinating DC efforts main deck and above

4JZ Forward Repair Circuit: DC Central to Repair 2

5JZ After Repair Circuit: DC Central to Repair 3

6JZ Amidships/Forward Repair Circuit: DC Central to Repair 4

7JZ After Propulsion Engineer Repair Circuit; DC Central/Main Control to Repair 5

8JZ Crash and Salvage Team: DCA to Flight Deck

6.3 General Announcing System

1MC General Announcing System:

Transmits general orders, information, and alarm signals to all areas in the ship

Includes Collision alarm, General alarm, Chemical Attack alarm, and Flight Crash alarm

Interior communication: Fast and direct means of comms between stations

4MC – Damage Control

21MC – CO’s Command

26MC – Machinery Control

6.4 Fire Triangle

Fuel

Heat

Oxygen

Triangle must be intact to create and sustain a fire

6.4 Fire Tetrahedron

Fuel

Heat

Oxygen

Chain Reaction

Product of the fire triangle’s uninhibited chemical chain reaction

Extinguishing agents disrupt the fire tetrahedron by eliminating one or more of the elements

6.4 Classes of Fire and their

Extinguishing Agents

Alpha: Water

Bravo: AFFF, PKP, HALON

Charlie: CO2

Delta: Jettison

Sierra: Water, AFFF, Jettison

6.4 Space Isolation

Mechanical and electrical isolation are performed at the discretion of the OSL

Electrical isolation is performed to de-energize equipment in casualty area prior to fire fighting efforts

Mechanical isolation is performed by operating valves and or fittings prior to space entry; reference: Main Space Fire Doctrine

6.4 Post Fire Actions

De-smoking is used to force an air change in the effected space

Ram Fan 2000 or Electric Box Fan may be used

Satisfactory post-atmospheric testing required before re-entry without an SCBA

Overhaul is performed by the attack team to ensure that the risk of smoldering materials don’t reflash

Naval Firefighter’s Thermal Imager (NFTI) and rakes are used to locate hot spots

6.5 Purple-K-Powder (PKP)

Class BRAVO fires

Extinguishes the fire by breaking up the combustion chain reaction

No cooling capability

Sizes: 18 / 27 pounds

Ranges: 19 / 21 feet

Discharge Times: 10 / 11 seconds

Compound will foul electronic components

6.5 Carbon Dioxide (CO2)

Class CHARLIE fires

Extinguishes the fire by displacing oxygen

Size: 15 pounds

Range: 4 to 6 feet

Discharge Time: ~35 seconds

Located within 30 ft of equipment with high potentials for a class “C” Fire

Keep grounded to deck to avoid shock from static electricity

6.5 Aqueous Film-Forming Foam (AFFF)

Class BRAVO fires

Extinguishes the fire by creating a vapor barrier and cooling

Size: 28 lbs (2.5 gal of premixed AFFF producing 16 gal of foam)

Range: 10 ft and decreasing

Discharge Time: 45 to 65 sec

6.5 Naval Firefighter’s

Thermal Imager (NFTI)

Used to locate the seat of a fire in smoke filled and dark spaces

Operated by the Attack Team Leader

2 modes of operation: PAN-while moving, CHOP-while fighting the fire

Can “wash out” in an environment that is too hot for too long

6.5 P-100 Portable Emergency Pump

Diesel engine driven centrifugal pump

Provides 100 gpm at 83 psi

20 ft suction lift; max 39 ft when used with a portable educator

Be mindful of exhaust if operating inside the ship

6.5 Electric Submersible Pump (ESP)

Centrifugal pump driven by a water-jacketed constant speed A/C electric motor

140 gpm at 70 ft, 180 gpm at 50 ft static head pressure

Cooled by pumped fluid and always used with a strainer

MUST wear proper electrical PPE in accordance with the NSTM 300: 450 VAC!

6.5 Perijet Eductor

Jet-type pump, no moving parts

Often used with an ESP or P-100 pump

Can be used with fluids with small particulate matter or that are more viscous

6.5 S-Type Eductor

Jet-type pump, no moving parts

Often used with an ESP or P-100 pump

Has a Foot Valve with a strainer to prevent flooding and clogging

6.5 Soft Patch

Used for systems of 150 psi or less

Gasket material must extend 2 in past damage

Not recommended for fuel or steam lines

6.5 Jubilee Patch

Used for systems with 100 psi or less

Gasket material must be large enough to overlap 2 in on all sides

6.5 Emergency Water-Activated

Repair Patch (EWARP)

Used for systems with 150 psi or less and does not exceed 300 degrees

Cannot be used on fuel or potable water systems (can contaminate the system)

2 Sizes: 3 in x 9 ft, 4 in x 15 ft

Fully hardened in 30 minutes

6.5 Various Patches

Box Patch: effective for holes with jagged edges

Hinged Plate Patch: designed for use over relatively small holes

Folding T-Patch: used for unevenly shaped holes

Hook Bolts: used to anchor a patch

6.6 Loop Configuration

Designed as a system of independent loops

Battle damage will not impact the entire firemain

Two types:

Horizontal

Vertical offset

6.6 Horizontal Loop Configuration

Two cross-connected mains on the damage control (DC) deck

Separated athwartships

6.6 Vertical Offset Loop Configuration

Components of the vertical offset loop

A starboard loop that is located on the first deck

A port loop that is located on the third deck, with cross-connects

Supplied by six fire pumps

6.6 Composite System Loop Configuration

Consists of more than one type of firemain system

6.6 Installed Eductor Activation

D: Open overboard DISCHARGE valve

F: Open FIREMAIN actuating valve

(Throttle valve to get eductor’s rated operating pressure)V: Ensure VACUUM is created by checking associated gage

DO NOT CONTINUE IF VACUUM IS NOT PRESENT

S: Open Drainage Main Cutout & Suction Valves

(Post a watch to monitor water level)

6.6 Dangers

Flooding the space

Ensure eductor is not misaligned

Make sure suction check valve is not degraded

Asphyxiation

Scuttle open

Ensure ventilation is operational

Secure eductor operation when water level is below suction line

6.6 (Installed Drainage Systems) Main

Provides emergency dewatering in engineering spaces

Reliable and has no moving parts

Uses galvanized pipe or copper-nickel tubing

Segregated by bulkhead stop valves

6.6 (Installed Drainage Systems) Secondary

Serves spaces at or below the waterline for spaces forward and aft of the main spaces

Independent of main drainage with its own eductors and sea connections

Piping is smaller in size than main drainage piping but can be cross connected

Example spaces served:

Steering gear rooms

Emergency diesel

generator roomsA/C machinery rooms

Chain lockers

List & trim control tanks

6.6 (Installed Drainage Systems) Special

Service spaces (heads, galleys, sickbays)

Magazines w/ sprinklers

Above waterline, near weather deck: drain through bulkhead check valve

Above waterline, NOT near weather decks: overboard discharge with deck drains

Below waterline: installed secondary eductors

6.6 (Installed Drainage Systems) Gravity

Consists of plumbing and deck drains

Installed most extensively in compartments above the waterline

Spaces above waterline are directed overboard

Spaces below waterline directed to tank or space where installed drainage can remove water

NOT designed to remove flooding water from ship as a result of damage

6.7 Buoyancy

An object floating or submerged in a fluid experiences an upward force equal to the weight of the fluid displaced by the object

6.7 Displacement

Weight of the volume of water that the ship displaces when floating freely

(in tons)

6.7 Draft

Depth of water a ship draws especially when loaded

Calculative: distance from the keel to the waterline (numbers on the bow and stern, 6" increments)

Mean: average of forward and aft drafts

Navigational: distance from the waterline to the lowest projections from the ship (i.e. sonar dome and screws)

6.7 Trim

Difference between the forward and aft drafts

6.7 Pitch

Up and down motion of the ship’s bow and stern as it moves through the sea

6.7 List

A definite attitude of transverse inclination of a semi-permanent nature

Inclination of a vessel to one side is normally due to weight distribution

6.7 Heel

A temporary inclination, generally involving motion. A ship normally

heels due to a sharp turn or a steady wind from the beam.

6.7 Sagging

Often due to seas or loading.

compression at the weather deck and tension at the keel, often due to seas or loading

6.7 Hogging

Often due to seas or loading.

Compression at the keel and tension at the weather deck, often due to seas or loading

6.7 Define Center of Buoyancy (COB) and how it moves

The center of the underwater hull volume when viewed in transverse direction

It’s the point at which all buoyant forces can be considered to be acting in a vertical direction

COB stays in the center of underwater hull volume

When the ship rolls starboard, the center of buoyancy (B) moves starboard

COB follows the waterline

As displacement increases from a weight addition, the ship sinks down, waterline goes up, and COB goes up

More underwater hull volume

6.7 Define Center of Gravity (COG) and how it moves

The point at which all weights could be concentrated

COG moves towards a weight addition

COG moves away from a weight removal

Gravity (G) follows the weight shift

If weight is shifted up, Buoyancy (B) and Meatcenter (M) do not change

6.7 Gravity Metacenter (GM)

Distance (GM) between the center of gravity (COG) and the metacenter is a prime determiner for stability:

Large GM: fast roll period

Small GM: Slow roll period

6.7 Stability always reduced when

Gravity is high

Gravity is off centerline

6.7 Free Surface Effect

Occurs when a compartment or tank is only partially flooded / filled.

As the ship rocks, water tends to maintain a level condition causing sloshing of water

As water shifts in direction of heel, center of gravity shifts decreasing the righting arm and reducing the stability

This effect is reduced by pocketing, swash plates, and baffles

Breadth is the biggest factor in the free surface effect, not the depth

6.7 Free Communication Effect

Three conditions for Free Communication Effect:

Compartment must be open to the sea

Compartment must be partially flooded

Compartment must be off centerline

The continuous addition and removal of water causes a horizontal shift of COG

Equates to a virtual rise of COG

6.7 Benefit of Compartmentalization

Isolates the Casualty

Reduce Free Surface & Free Communication Effect

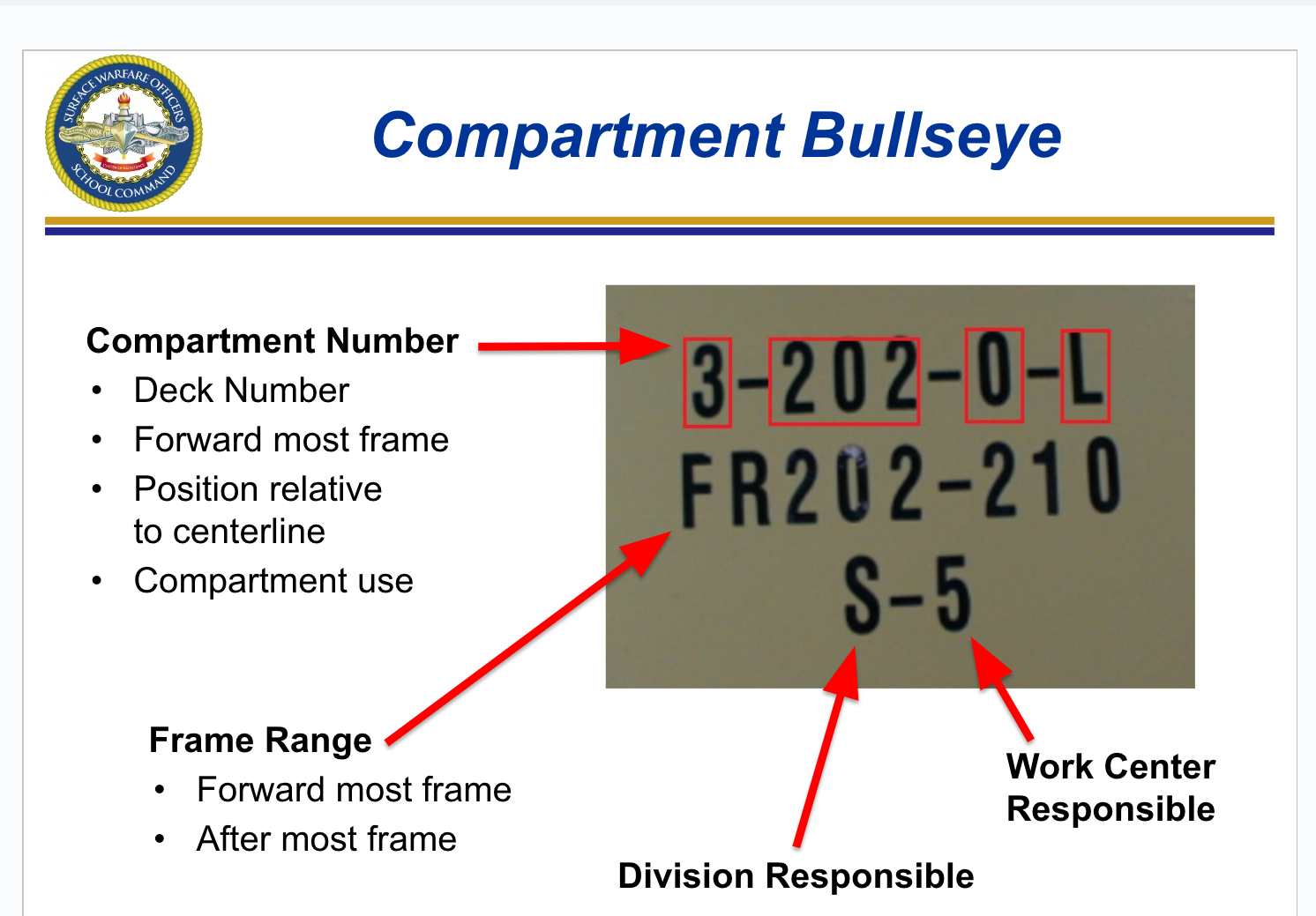

6.7 Compartment Bullseye

6.7 Classification of Fittings

X-RAY / YOKE / ZEBRA: Special permission required, must be logged in the DC Closure Log if opened during the corresponding Condition of Readiness

CIRCLE X-RAY / CIRCLE YOKE / CIRCLE ZEBRA: May be opened with out special permission to transit, inspect, and access vital spaces

Dog ZEBRA: Set for Darken ship

WILLIAM: Vital sea suctions,

ventilation, and maintenance

fittings for mobility

CIRCLE WILLIAM: Access and

ventilation fittings

6.7 Material Conditions of Readiness

Provides increasing degrees of protection

against the spread of damage

X-RAY: In homeport, in fair weather, normal working hours

YOKE: At sea / inport during peacetime, outside of normal working hours

MODIFIED YOKE: fittings below the waterline are closed, above the waterline may be left open to improve accessibility and habitability

ZEBRA: Set during General Quarters, entering and leaving during wartime, when in danger

MODIFIED ZEBRA: CO may wish to set a modified material condition ZEBRA to provide higher survivability stance than condition YOKE but less restrictive than ZEBRA

CIRCLE WILLIAM: Set to prevent contamination in a CBR environment

6.7 Compartment Check-Off

Lists (CCOL)

Located at every entry to a compartment

Required for every compartment or weather deck where DC facilities are located

Provide an itemized list and location of all DC fittings and the personnel responsible for the setting of material conditions of readiness

Master/Duplicate/Partial CCOLs maintained

6.8 Installed CO2 system

Used on Class A, B, and C fires, found in auxiliary spaces and lockers.

CO2 Fixed-Flooding systems: installed in spaces that require protection of flammables

Paint lockers

Paint mix and issue rooms

Flammable liquid storerooms

Flammable compressed-gas cylinder storerooms

GTM / GTG Modules (DDG/CG’s)

Identified by red bottles with no stripes

System Actuation:

Activated either manually or pneumatically

Break glass on pull-box cover

Grasp handle and pull

Pull cable out three to five inches

System Operation:

Activated at the local pull station or pull box

Activation of the system causes release of all CO2 into a discharge manifold

The entire protected space is flooded with CO2 gas

CO2 hose reel system: is used in electrical and machinery spaces where the potential for a class C fire is high

Two 50 lb CO2 cylinders

50 ft of hose on a reel

Valve assembly

Horn assembly

6.8 Halon 1301 System

Used against “B” fires in:

Main machinery and engine rooms

Auxiliary machinery and boiler rooms

Ship service or emergency generator rooms

Main propulsion or generator engine modules

Recovery, Assist, Secure, and Traverse (RAST) machinery rooms

Tactical Towed Array Sonar (TACTAS) handling rooms

Flammable liquids storage and issue rooms

CO2 actuators are installed inside and outside the space

Actuates local and remote audible and visual alarms

Ventilation automatically shuts down

Time delays:

60 sec (manned)

30 sec (unmanned)

Completely discharges in 10 sec

6.8 HALON 1301 System Safety Precautions

Personnel are not allowed in a space where Halon has been discharged without an SCBA (Self- Contained Breathing Apparatus)

Gas Free engineering procedures must be conducted for reentering spaces after being flooded with Halon 1301

Lethal byproducts of Halon:

Hydrogen Cyanide

Hydrogen Fluoride

Hydrogen Bromide

6.8 AFFF Stations

Designed to protect compartments or areas where flammable/combustible liquid fires are likely to occur:

Machinery spaces, fueled vehicle stowage spaces, helicopter hangars

Stations provide a solution of 6% AFFF concentrate and 94% seawater at a flow rate of 60 to 1,000 GPM to installed AFFF Systems

6.8 AFFF Piping System

Supplies AFFF bilge sprinklers, hose reels, and hangers

Can be cross connected so the forward station can provide to the aft station and visa versa

6.8 Installed AFFF Systems

Locations where overhead AFFF sprinkler systems are installed

Hangers

Tank decks

Well decks

Vehicle cargo holds

Weapon elevator pits

Fuel pump rooms

Safety concerns

Hydrogen Sulfide (H2S) exposure

Hearing protection at AFFF station

6.8 AFFF Bilge Sprinkler System

Installed throughout the machinery spaces

Used to create a vapor barrier if flammable liquid spills in the bilges

6.9 Battle Dress

Battle dress requirements:

Flame resistant variant (FRV) coveralls

All buttons buttoned

Pant cuffs tucked into boots or socks

Life preserver worn on the waist (or kept at General Quarters station)

Flash hood and gloves

Remove metal from uniform

Empty pockets

6.9 Fire Fighter’s Ensemble (FFE)

Provides optimal protection from exposure to heat, cold, steam, water, and sharp objects

Consists of an outer shell, a vapor barrier, and an inner fire-retardant thermal liner

Helmet

Protects the head, neck, and face from short-duration flame exposure, heat, and falling objects

Made of heat-resistant fiberglass

Gloves

Protect against abrasions, flash exposure, and heat

Flash Hood

Provides protection to the head, neck, and face, except for the eyes

Made of a Kevlar and rayon knit with an elastic face closure

Available in a single size that fits all

Boots

Have steel safety toes and puncture-proof

steel insolesAuthorized for repair party electricians to wear

when performing their duties

6.9 Self-Contained Breathing Apparatus (SCBA)

Delivers air through a second stage regulator and face shield

Can be refilled in a smoke-filled environment

Available in two different sizes of bottles (30 or 45 minutes) with an external pressure indicator: both bottles charged to 4,500 PSI

Exertion and physical limitations of user impact available time of bottle

6.9 Emergency Escape

Breathing Device (EEBD)

10 Minutes of O2, smoke protection only

Never used to combat a fire! Wearing the hood is optional, bottom bag is pressure relief

Activated when pulled out of the box. Single use, disposable unit

Can create unbreathable air, contaminated with Lithium Hydroxide if damaged

Check pressure gage, ensure needle points to GREEN, not RED

The total shipboard quantity for EEBDs as found in NSTM 077

Ship’s Complement 150%

Embarked Personnel 100%

Berthing Spaces 100%

(one EEBD per rack)Engineering Spaces 200%

6.10 Electric Box Fan

115V A/C Electric fan

Moves 3200 cubic feet of air /min

Used with smoke curtains to create smoke control zones using installed ventilation or CPS

6.10 RAM Fan 2,000

Water turbine actuated by Fireman or P-100 Pump which operates Fan Blades

Moves 2000 cubic feet of air/min

Must be grounded to prevent static electricity build up

Used with “elephant trunks” to direct contaminated air

6.11 Toxic

A space where poisonous substances are present, exposure cannot exceed OSHA (Occupational Safety and Health Administration) standards

6.11 Permissible Exposure Limit (PEL)

The maximum permissible concentration of a toxic or harmful physical agent to which personnel may be exposed

6.11 Lower Explosive Limit (LEL)

The minimum percent by volume of a gas that, when mixed with air, will form a flammable mixture

6.11 Upper Explosive Limit (UEL)

Upper end of the explosive range. Concentrations above this limit are too rich to explode or burn. Concentrations below the UEL are within the explosive range.

6.11 Immediately Dangerous to Life and Health (IDLH)

Any atmosphere that meets any of the following conditions:

- flammable vapors 10% or greater of the LEL;

- an oxygen content of less than 19.5% or greater than 22%;

- the presence of toxicants above a level that would not allow personnel to escape within 30 minutes without impairment or irreversible health effects.

Oxygen surplus: oxygen level above 22%

Increased danger of explosion

Oxygen deficiency: oxygen level below 19.5%

19.5%: normal

17%: deep, fast breathing

15%: dizziness and buzzing in the ears

9%: unconsciousness

7%: can cause death

6.11 Fire Watch Requirements

All affected sides must be watched

Communication devices must be available

Portable fire extinguisher or hose must be within reach

PPE (Personal protective equipment) must be worn

Goggles or safety glasses (as required)

Helmet (as required)

Hearing protection (as required)

NAVOSH (Navy Occupational Safety and Health) approved respirator (as required)

“30, 40, 50” Rule

Watch must stay until 30 minutes after work or until cool to touch

No hot work can be performed within 40 feet of painting or chemical cleaning

Flammables must be moved 50 feet from work area