extended and delayed release oral formulations

1/51

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

52 Terms

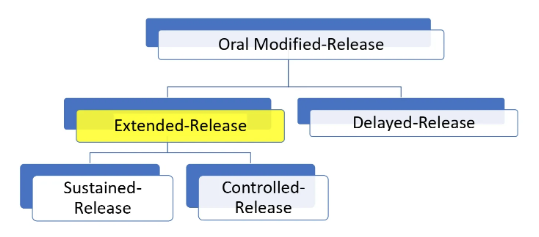

what formulation types are classified as extended release? (2)

sustained release

controlled release

advantages of extended release medications? (4)

less fluctuation in blood drug level

reduced SEs

reduction in dosing → enhanced convenience + compliance

maintaining therapeutic activity for extended time

disadvantages of extended-release dosage forms (2)

loss of flexibility in adjusting the drug dose + dosage regimen

risk of dose dumping (sudden and total drug release) due to technology failure

what should be considered before developing an extended release dosage form? (2)

suitability of the drug to be formulated into XR

solubility + permeability

suitability of an XR formulation in treating a medical condition

some conditions only need prn dosing - XR would not be ideal

class I XR formulation

most suitable

are high sol + high perm. drugs

drug release from dosage forms can be the rate-limiting step, altered by the dosage form design

class II XR formulation

low sol. high perm. drugs

rate limiting step is on drug dissolution itself, so already has inherent sustained release behaviour

dissolves v slowly, and as long as the resident time of the tab in the intestine is long enough, you will pretty much get all of the drug to be released

may or may not benefit from XR formulation

class III XR formulation

high sol, low perm. drugs

not suitable as absorption is already rate-limited

as the drug cannot permeate well, no matter how much drug is released and the rate at which the drug is released (fast/slow) will not change the fact that it will not absorb well

class IV XR formulation

low sol. and low perm.

most challenging to formulate

due to its low sol and perm, it is already challenging enough to give this drug as an oral formulation

unless it is being used to treat a local GI tract condition → i.e. don’t want the drug to absorb, but to act locally on the surface of the GI

to be a successful XR product… (4)

drug released at a predetermined rate

dissolved in GI fluids

maintain sufficient GI residence time

absorbed at a rate that replaces the amt of drug metabolised + excreted

characteristics of drug candidates for XR products (5)

used for chronic Tx, rather than acute

acute req. more dose adjustments

absorbed uniformly across GI tract

i.e. BCS class I drugs

high potency of drug (admin in small doses)

allows for practical compression of a single daily dose into a manageable tab size

relatively short half life (4-6hrs) with no active metabolites

good TI

in event of dose dumping, ensures it will not lead to significant SEs or emergency intervention

oral XR control technology (5)

chemical rxn/ix between medication + site-specific biologic fluids

barrier coatings → modify drug dissolution and access of biological fluids to the drug

controlling drug diffusion rates from dosage form

erosion control

drug transport control (e.g. osmotic pump)

what do matrix formulations contain?

certain types of insoluble/hydrophilic polymers, which are incorporated throughout the dosage form matrix

polymer will form an internal structural network, with spots of drug captured/embedded in within

as the matrix is insoluble → will be an intact unit throughout the process of transit thru the GI

what are the 4 processes that facilitate the rate and extent of drug release in matrix formulations?

liquid surrounding the dosage form penetrates the release unit

results in hydration of the tablet (swelling/dissolution) from the outside in

diffusion of water into the device

dissolution of the drug to form a solution

diffusion of the dissolved drug out of the device

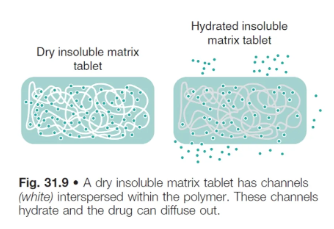

what type of polymer is used in an insoluble polymer matrix?

an inert, water-insoluble polymer, such as:

polyvinyl chloride

polyethylene

polyvinyl acetate

polymethacrylate

what is the rate of drug release from insoluble polymer matrices controlled by? (3)

pore size

no. of pores

tortuosity (twisting path) of the matrix

pore forming agents can be added to increase tortuosity and facilitate drug release

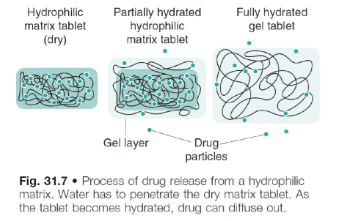

hydrophilic matrix systems can also be referred as…

swellable soluble matrices

what kind of extended release is hydrophilic matrix systems used for?

sustained release

how are hydrophilic matrix systems formulated?

the drug is mixed with a water-swellable, hydrophilic polymer and compressed into a tablet

polymer is in powder/granule form and tablet is manufactured as per normal using the dry granulation process

the final tablet has drug material interspersed between polymer particles

process of drug release from hydrophilic matrix systems

polymer material in tablet swells on fluid contact, producing a gel matrix

gel allows drug release via either:

gel dissolving with the drug trapped within in

gel eroding, which releases/dissolves drug particles trapped within in

what affects the drug release rate from a hydrophilic matrix system?

the rate at which water can diffuse through the tablet, and later through the hydrated gel

the rate of hydration is affected by the gel’s structure

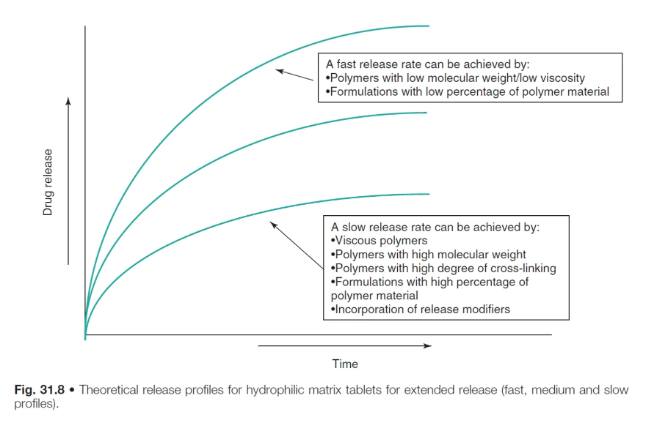

how does polymer type and concentration affect drug release in hydrophilic matrix systems?

the spaces between the matrix forms a tortuous pathway through which water and drug may diffuse

the tortuosity of this pathway is therefore impt for drug release

polymers with low MW/viscosity → fast release rate

polymers with high MW/viscostiy, high degree of cross-linking and high % of polymer material → slow release rate

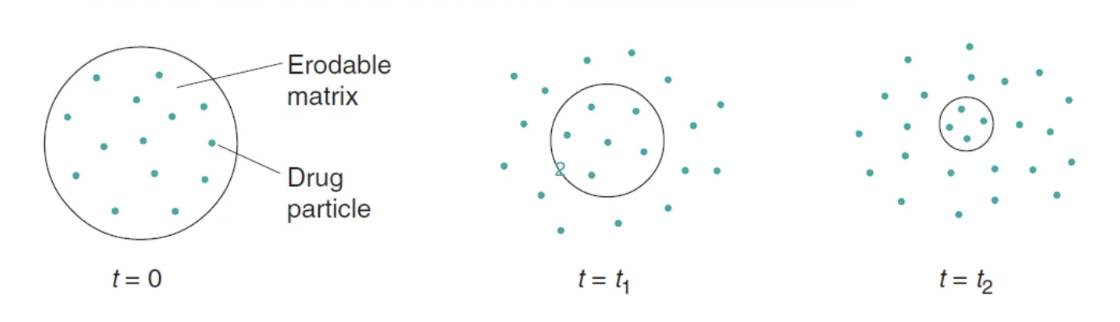

what is the drug release rate controlled by in erosion controlled release systems?

the erosion of the matrix in which the drug is dispersed

i.e. a surface erosion → continuous reduction in tablet weight during the course of the release process

process of drug release from erosion controlled release systems

polymer becomes hydrated after ingestion

drug is then exposed to GI fluids and mixed with (if drug is dissolved in matrix), or dissolved in (if drug is suspended in matrix) the fluid

a gel layer forms around the tablet’s surface and the gel layer thickness increases as water permeates further into the tab

outer gel layer erodes from the tablet core once is fully hydrated → thus rate of drug release is controlled by diffusion and tab erosion

what order is the release rate of a drug from erosion controlled release systems?

zero-order for a significant part of the total release time

what substances is the eroding matrix formed from?

lipids/waxes

drug is dispersed within

hydrophilic cellulose polymers

which gel on contact with water

drug can be either dissolved or dispersed within

hydroxypropyl methylcellulose (HPMC)

what does the polymer need to do for a successful hydrophilic matrix system?

the polymer must form a gelatinous layer rapidly enough to protect the inner core of the tablet from disintegrating too rapidly after ingestion

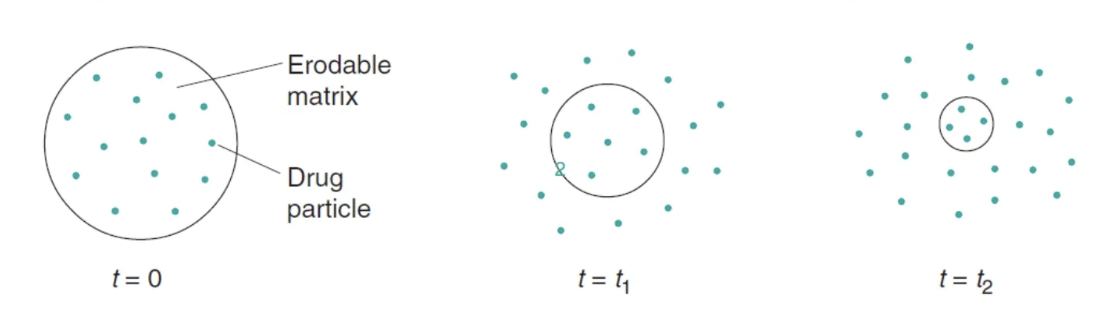

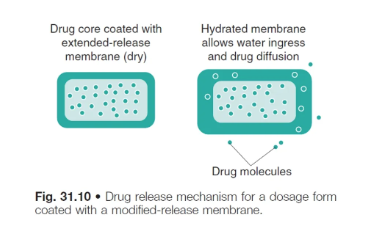

what is the drug release rate controlled by in membrane controlled systems?

it is controlled by the thickness and porosity of the membrane through which the drug must diffuse (rather diffusing through the whole matrix) and the solubility of the drug in the GI fluids

process of drug release from membrane-controlled systems

the tablet is formulated with 2 distinct layers → polymer membrane + drug core compartment

on exposure to fluids, water diffuses into the system to form a continuous phase through which drug diffusion and release can occur

as long as a constant drug conc. gradient is maintained, the release rate will be constant (i.e. zero order)

high MW poylmer membrane

film is normally formed from a high MW polymer → approx 5-20 nanometres thick

what can the membrane porosity and pore tortuosity can be affected by?

adding water sol. components to the membr

in the presence of water, the water sol polymers will dissolve, forming tunnels/channels, which then allows water to enter the core and diffuse drug out

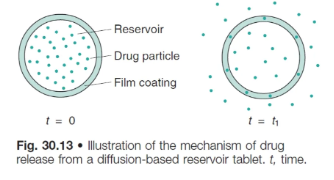

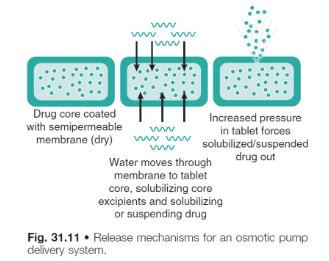

what is the difference between an osmotic pump system and the ‘classic’ membrane controlled system?

only 1 diffusion process is required

in this case, water is able to only able to diffuse in, via a semi-permeable membrane mechanism

process of drug release from osmotic pump systems

osmotic transport of liquid into the unit

the tablet core is coated with a semi-permeable membrane that allows only water to pass into the core

drug dissolves once water diffuses into the core

dissolution of drug increases the internal hydrostatic force

drug solution/suspension is then forced out of the tablet via a laser drilled orifice due to increasing hydrostatic pressure inside the tablet

drug does NOT diffuse out of the semi-permeable membr as it is NOT permeable to the drug

what do osmotic pump systems require exposure to in order to build up internal osmotic pressure?

exposure to sufficient fluid → which depends on the fluid levels in the GI

what is the drug release rate controlled by in osmotic drug systems?

the rate at which water can pass thru the membr. and how quickly the drug soln/suspension can pass out of the hole

the rate of water flow in is driven by a difference in osmotic pressure between the inside and the outside of the tab

changing the viscosity of the soln/susp formed inside the system also alters the rate at which the drug is forced out

orifice size in osmotic drug systems

needs to be small enough to prevent diffusion, but large enough to minimise hydrostatic pressure

600 micrometer to 1mm diameter

what are gastro-retention drugs used for?

retains dosage form for longer in the stomach to maximise drug absorption in the upper GIT:

drugs for local action in the stomach (e.g. H. pylori infection)

drugs w narrow absorption window in small intestine

drugs degraded in the colon

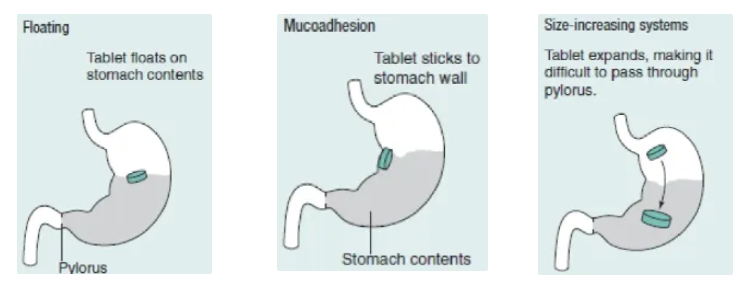

what are the 3 gastro-retention drug delivery systems?

floating

tab floats on stomach contents due to being less dense, thus avoiding gastric emptying

mucoadhesion

tab sticks to the stomach wall to be retained in the stomach

size increasing

tab expands in the stomach, making it harder to pass through the pyloric sphincter so it is retained in the stomach

what are the advantages of delayed release formulations? (4)

protecting the active substance against degradation due to low pH

targeting the active substance to a specific segment of the GI tract for local tx or better absorption

improve bioavail of protein/peptide drugs

targeting active substance release at specific time points

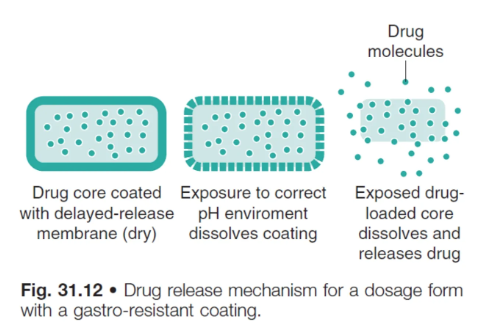

what is coated formulation?

when a modified-release coating is applied to a dosage form

drug is contained in the core and is released/dissolved through the modified release coat

what are the 2 different types of film coating?

immediate release film coatings

modified release film coatings

delayed release (enteric coated)

extended release coatings

enteric coating/gastro resistant formulations are only soluble in pH…

pH >5-6, depending on the polymer

advantages of gastro-resistant coatings (2)

protect stomach from the drug (gastric irritants)

protect acid-sensitive drugs from being degraded in stomach environment

what is the drug release rate of gastro-resistant coatings controlled by?

its exposure to the correct pH

colonic drug delivery formulation

can be achieved by using pH-responsive polymers (dissolve around pH 7) to target the colon

or the use of gut bacteria as a trigger for drug release

what is the highest pH in the GIT?

generally at the ileocaecal junction, just before the colon

the pH is around 7

why is targeting the colon difficult?

the dosage form may be in the region of the highest pH (at the ileocaecal junction) for only a short time, and the target pH (often 7) may not be reached

hence this can lead to dosage form failure → does not disintegrate and is passed intact in stools, thus no drug is released

how is gut bacteria colonic drug delivery formulated?

a coating is prepared from material that is insoluble to GI fluids

but will also contain a component that can only be digested by colonic bacteria, and not by pancreatic enzymes

what component is used in the coating for gut bacteria colonic drug delivery?

a polysaccharide known as ‘resistant starch’ which can only be broken down by bacterial enzymes in the colon

the starch component is digested and dissolved in the colon, leaving pores through which the drug can be released

single unit delayed release dosage form

aka monolithic dosage forms

conventionally manufactured → via compaction + film coating

as they do not disintegrate in the stomach, the tablet could become trapped in the stomach for a long time, esp in the presence of food

this can prevent drugs targeted to the small/large intestine from reaching their site of action

multiple-unit delayed release dosage form

e.g. pellets/granules filled into a hard capsule shell

advantages of multiple-unit delayed release dosage form

more reproducible gastric emptying → because of its small size, can pass thru the sphincter and into the SI more readily

reduced risk of dose dumping

if a tab coating fails, then the whole dose can be dumped

however with a pellet formulation, the disruption of one pellet coating may release only a small fraction of the drug dose

benefits of coating of multi-particulates

capitalising on small size (0.5-2mm)

particles <2mm can pass thru the constricted pyloric sphincter even during the digestion phase

can distribute themselves more readily throughout the GIT

minimising irritant effects

small size reduces likelihood of being lodged in the GIT which can cause localised release of the drug and therefore mucosal damage (if the drug has irritant properties)

drug conc. is also spread out over a larger no. of discrete particles

reducing consequences of imperfect coatings

dose dumping due to imperfections in the coating such as pores can compromise performance of MR dosage forms

but with multi-particulates → risk is reduced as an imperfect coating on a few particles is unlikely to cause harm or lack benefit to the pt