[D.1] FLOOR COVERINGS

1/183

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

184 Terms

Carpet

Used as floor covering. It provides floors with both visual and textural softness, resilience, and warmth in a wide range of colors and patterns. It absorbs sounds, reduces impact noise, and provides a comfortable and safe surface to walk on and is fairly easy to maintain.

Carpita

The term carpet comes from this Old Italian term, meaning to pluck

Wool

Types of Natural Fibers

Used for centuries in the manufacturing of carpet. It is still the standard against which other carpet fibers are judged. It is generally the most expensive carpet fiber and is commonly used in woven carpets.

Wool

Types of Natural Fibers

Its outer layer is scaly, which diffuses light, thus hiding soil. When exposed to flame, wool chars, rather than melting like most synthetic fibers, making it naturally flame resistant.

New Zealand Wool

Characteristics of Wool from Different Countries

wool absorbs dye easily, colors with great clarity and uniformity, staple are lustrous and tough, and color is almost white

Argentinean Wool

Characteristics of Wool from Different Countries

noted for its gloss and sheen with natural resistance to soiling; not as white as New Zealand Wool

Indian Wool

Characteristics of Wool from Different Countries

crush resistant wool

Iraqi Wool

Characteristics of Wool from Different Countries

among the most luxurious and costly of wool; high abrasion resistance and durability

Scottish Wool

Characteristics of Wool from Different Countries

Scottish black face sheep bear finest of all carpet wool with stapes as long as 15 inches

Sisal

Types of Natural Fibers

Light cream or oatmeal in color; It is a strong, woody fiber produced from the leaves of the agave plant. Used mostly in twine, rugs, floor mats, ad rope.

Sisal

Types of Natural Fibers

It has a rough texture, is stiff, and inflexible. It tends to stain and crush easily, but is still stronger and more durable than any natural fiber.

Scratch Rush

This is another term for Sisal

Maize

Types of Natural Fibers

made from corn husks

Coir

Types of Natural Fibers

Strong and flexible hair like fiber from coconut shells. It is tough, does not pill, can withstand a great deal of abrasion, is highly rot resistant, and is proven to be unfriendly to insects.

Coconut Plush

What is another term for Coir?

Cotton

Types of Natural Fibers

Softer than wool but less durable; does not resist stains and also absorbs moisture

Jute

Types of Natural Fibers

Softest of all natural fibers; May fade or darken in color when exposed to sunlight, and its fiber disintegrates with prolonged exposure to moisture

Nylon

Types of Synthetics or Man-made Fibers

Most popular carpet fiber used today; It is versatile, and easy to maintain and clean, and withstands heavy foot traffic. It is the most widely used man-made fiber and is often combine with wool for durability

Acrylic

Types of Synthetics or Man-made Fibers

One of the first synthetic fibers to be used successfully in the production of carpet. It is always used as a staple fiber and has many of the characteristics of wool and has the lowest static build-up factor. It is highly resistant to sunlight, stains, and mildew. Used in bath mats and rugs.

Modacrylic

Types of Synthetics or Man-made Fibers

Has better heat retention and is flame resistant compared to acrylic

Polyester

Types of Synthetics or Man-made Fibers

Soft and luxurious; It is strong, durable with high abrasion resistance. Dyes well, and has low static build-up factor. Used for residential carpet applications as shags and random sheared carpet

Polypropylene Olefin

Types of Synthetics or Man-made Fibers

Newest and most economical. Comparable to nylon in durability, strength, and wear resistance. It is the lightest commercial carpet almost completely free of static build-up.

Polypropylene Olefin

Types of Synthetics or Man-made Fibers

Used in outdoor carpeting. Most resistant synthetic fiber because it repels water and impervious to stains, and is less expensive than other fibers

Acetate

Types of Synthetics or Man-made Fibers

Made from cellulose obtained from wood pulp or cotton linters. These fibers are often used in carpets because they can mimic the look and feel of natural fibers like silk, wool, or cotton at a lower cost

Acetate

Types of Synthetics or Man-made Fibers

Brand names such as Avisco, Celaire, Cromspun, Estron

Azlon

Types of Synthetics or Man-made Fibers

Created from protein-based polymers, often derived from natural sources such as soybean protein or milk casein. These fibers are sometimes used in textiles, including carpets, as an alternative to traditional synthetic fibers like nylon or polyester

Azlon

Types of Synthetics or Man-made Fibers

Brands like Vicara

Rayon

Types of Synthetics or Man-made Fibers

A semi-synthetic fiber made from natural cellulose, usually derived from wood pulp; offers a soft and luxurious feel, similar to natural fibers like silk, making it an attractive choice for certain carpet styles but may not be as durable as other synthetic fibers

Rayon

Types of Synthetics or Man-made Fibers

Brands like Avicolor, Avicron, Avsio, Corval, Fibro, Kolorbon, Skybloom, Skyloft, Soluran, Spunvis, Staylux, Tufton

Saran

Types of Synthetics or Man-made Fibers

Brands like Rovana and Saran

Saran

Types of Synthetics or Man-made Fibers

Developed by the Dow Chemical Company in the mid-20th century; It is a polymer made from vinyl chloride, a type of plastic known for their resistance to moisture, chemicals, and sunlight, making them suitable for a variety of applications

Triacetate

Types of Synthetics or Man-made Fibers

Brands like Arnel

Triacetate

Types of Synthetics or Man-made Fibers

Derived from cellulose, typically obtained from wood pulp or cotton linters; Formed through a chemical process in which cellulose is treated with acetic acid and acetic anhydride

Blend

Types of Synthetics or Man-made Fibers

Combinations of two or more fibers into a single carpet yarn, with each yarn lending to the other its dominant characteristic

Face

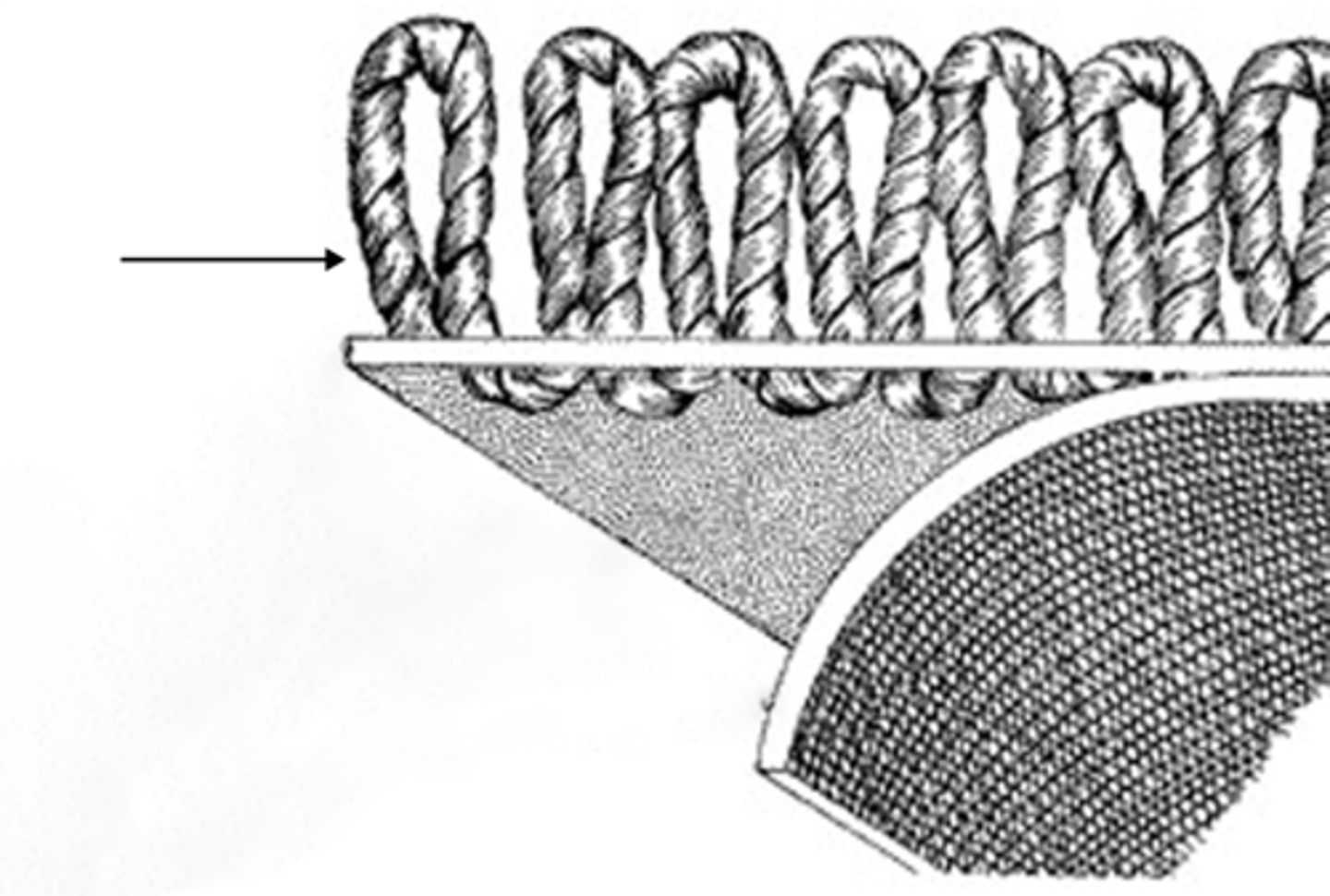

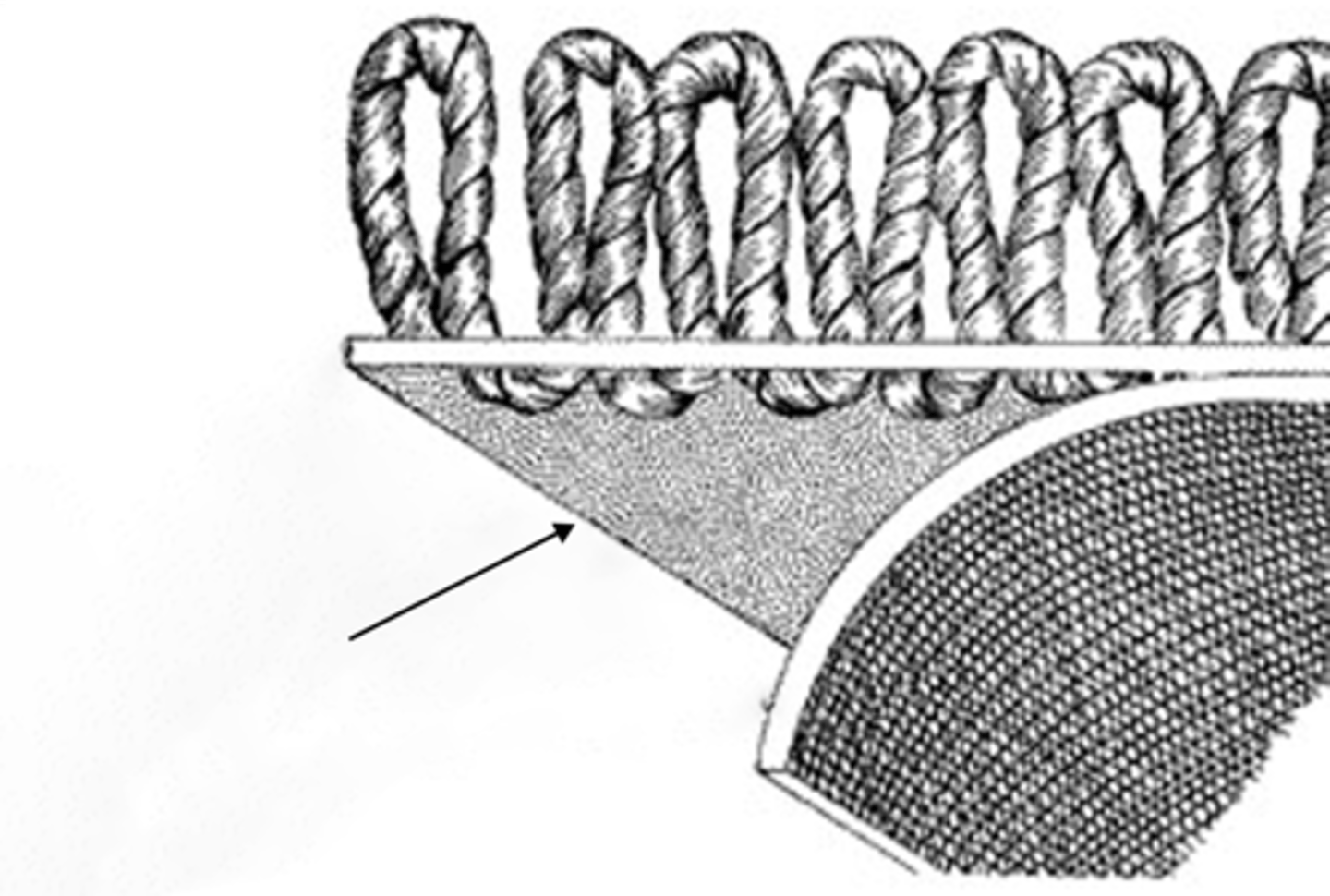

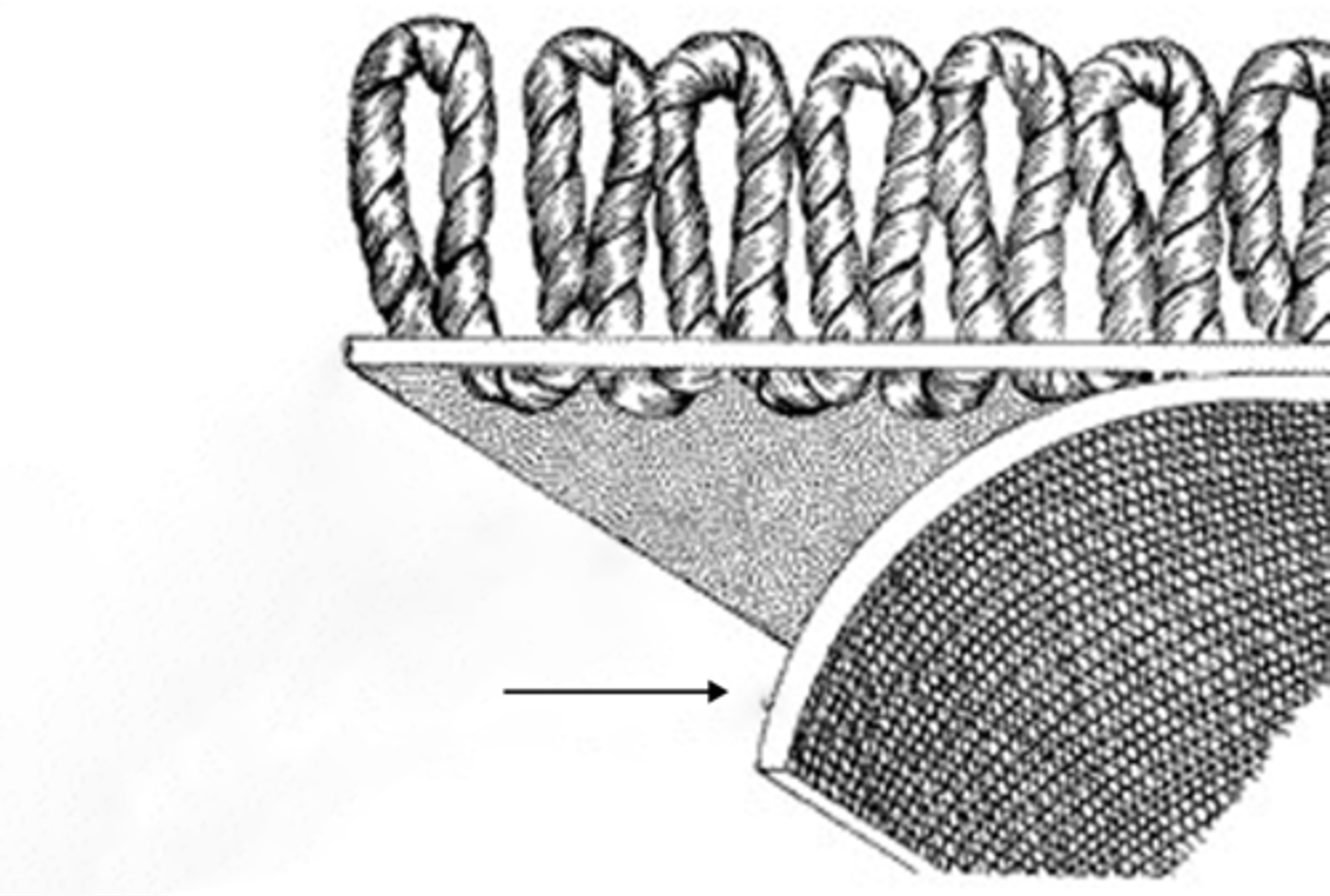

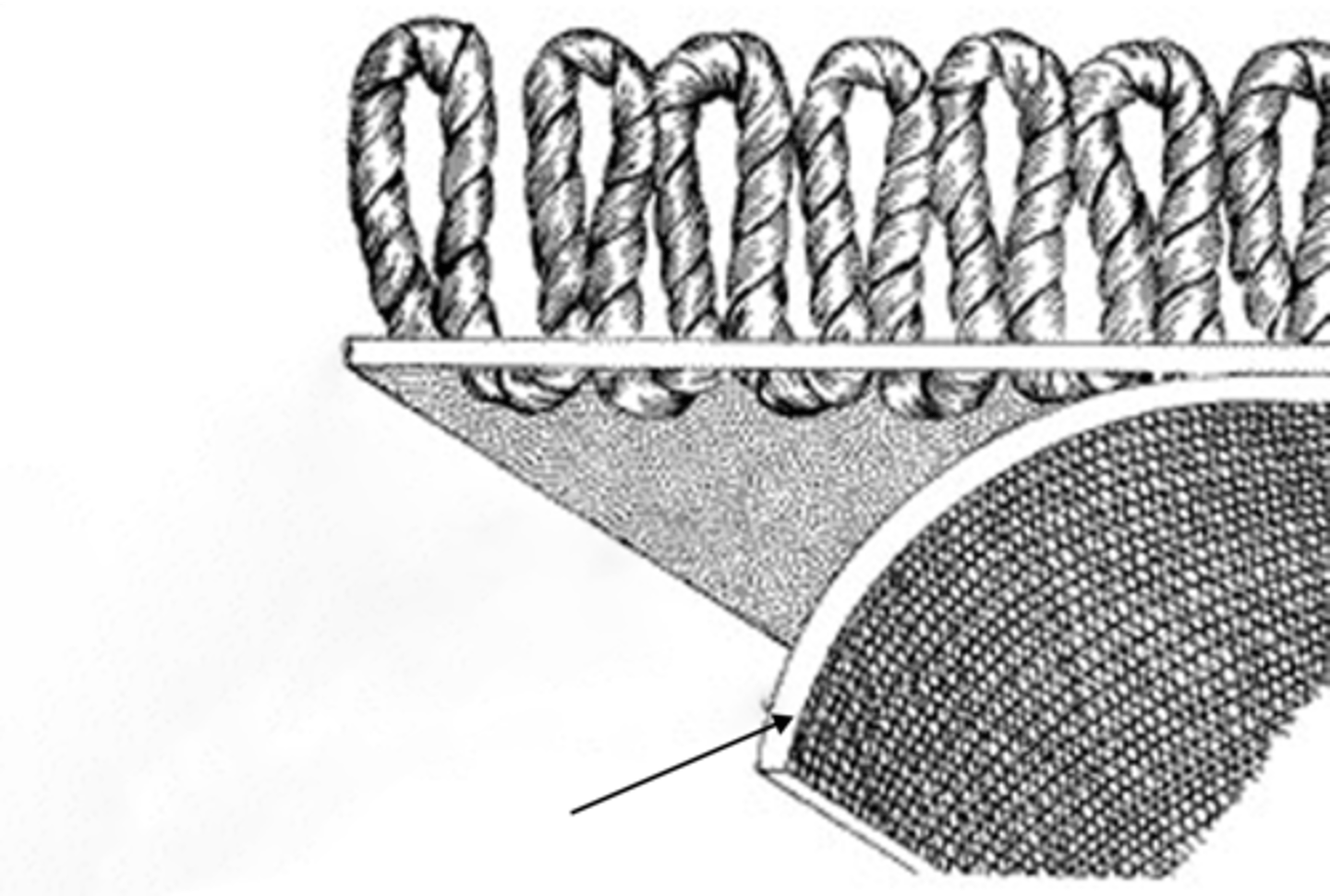

Parts of a Carpet

Composed of the pile. The upright ends of yarn whether cut or looped; Forms the wearing surface of carpet or rugs

Primary backing

Parts of a Carpet

a ground on which to hook the yarns. The foundation is the canvas on which the yarns are woven

Latex

Parts of a Carpet

To glue on the roots of the yarns onto the cotton canvas backing on which they are woven; Provides superior tuft lock and resilience in stretching, especially for wall-to-wall installations

Secondary backing

Parts of a Carpet

Carpet pads; Bonded to the primary backing in the latexing stage. Either Jute (stable and heat resistant but tends to shrink when wet and can stain the carpet face) or Polypropylene (moisture resistant)

Tufting

Methods of Manufacturing Carpets

Far less expensive and faster to produce than woven carpet. It enabled to mass production of an affordably priced textile floor covering

Tufting

Methods of Manufacturing Carpets

Constructed by punching tufts of yarns into a backing. Yarns are threaded through hundreds of individual needles on a device that extends the entire width of the finished carpet

Tufting

Methods of Manufacturing Carpets

he needles are forced through a loosely woven or non-woven primary backing material, which forms the loops or tufts. Adhesive is added to hold the loops in place and then a secondary backing

Weaving

Methods of Manufacturing Carpets

Traditional way of making carpet on a loom. Produced by intertwining the surface pile and the backing simultaneously into an integrated whole.

Weaving

Methods of Manufacturing Carpets

This produces heavy, dimensionally stable, and strong carpets and does not require a secondary backing. It is a slower, more labor-intensive process than tufting and is more expensive

Velvet

Three Basic Types of Weaving

Least complex weaving method and the most inexpensive. Produces solid color carpets and is made on looms similar to Wilton looms, but without the Jacquard mechanism. All yarn in this type appears on the back of the carpet.

Wilton

Three Basic Types of Weaving

Named after a town in England. Constructed on a modified Jacquard loom. Used to produce carpet of more than one color with as many as 5 colors possible. It is thick and heavy because yarn of every color used is carried beneath the pile surface

Axminster

Three Basic Types of Weaving

Inspired by European and Oriental patterns. Combinations of patterns and colors are virtually limitless, because the colored yarns are inserted individually. It is intricate, multi-colored patterns and a backing heavily ribbed, and can only be rolled lengthwise. Tends to stretch quite a bit in length and very little in width.

Velvet, Wilton, Axmister

What are the three basic types of weaving processes?

Knitting

Methods of Manufacturing Carpets

Similar to woven carpet because pile and backing are made in a single operation. Uses 3 sets of needles to loop the pile backing yarn and the stitching yarns together. Latex is given to the back for additional strength and body.

Knitting

Methods of Manufacturing Carpets

Known for their plush piles because there is more yarn in the wear surface than tufted carpets. Has a tendency to stretch, especially on the diagonal, and is difficult to seam during installation.

Needlepunched Carpet

Methods of Manufacturing Carpets

Fibers, usually acrylic or polypropylene are punched into a web of synthetic fiber to form a homogenized layer of fiber. Put under heavy compression to form the characteristic of fabric

Flocked Carpet

Methods of Manufacturing Carpets

Uses an electrostatic method. Fibers are electro-statically treated and sprayed onto an electrically charged backing sheet which has been treated with adhesive

Pile Density

Factors to Consider in Carpet Construction

Weight of pile yarn in a given volume of carpet face

Gauge

Widthwise Density Measurement

distance between the needles in tufted carpets

Pitch

Widthwise Density Measurement

number of ends in a woven carpet

Stitch Rate

Lengthwise Density Measurement

Defines the number of times per inch a stitch occurs in tufted carpets. The number of times an individual needle inserts a tuft into the primary backing as the primary backing moves one inch through tufting machines; Also called Stitches per Inch

Rows/Wires

Number of ends per inch lengthwise

Pile Height

Lengthwise Density Measurement

length of the tuft from the primary backing to the tip

Face Weight

Factors to Consider in Carpet Construction

Weight of the pile yarn stated in ounces per square yard of carpet. Describes the amount of yarn in the wear surface of the carpet

Total Weight

Factors to Consider in Carpet Construction

Includes the face weight and the weight of backing materials, finishes, and coatings

Yarn Weight

Factors to Consider in Carpet Construction

indicates the fineness or coarseness of the finished yarn

Woolen Count

Factors to Consider in Carpet Construction

number of running yards in one ounce on finished yarn

Denier

Factors to Consider in Carpet Construction

measurement of weight in grams of a standard 900m length of yarn

Ply

Factors to Consider in Carpet Construction

affects color, surface texture, and feel underfoot. The number of strands of a single yarn twisted together to form one pile yarn

Twist Level

Factors to Consider in Carpet Construction

products with higher twist levels have the tendency to hold their original appearance longer than lower twist products

Cut Pile, Loop Pile, Loop and Cut Pile

What are the three major categories of carpet textures?

Cut Pile

Textures of Carpets

cutting each loop of pile and produces wide range of textures

Cut Pile Plush

Types of Cut Pile

Smooth cut pile; The cut ends of the yarn blend with each other for a consistent surface appearance. Has a luxurious look and feel but is subject to shading and shows foot marks

Saxony Plush

Types of Cut Pile

texture between cut pile plush and cut pile shag. Makes use of thicket yarns and has a twisted yarn, which gives definition to each tuft. Made with heat-set yarn usually in a dense, low-pile construction

Twist/Frieze

Types of Cut Pile

made from yarns that have been tightly twisted and the twist set by a special heating treatment that imparts a grainy appearance. Has a heavier, rougher texture than cut pile plush. Made in solid color or multi-tone effects and it hides dirt well

Shag

Types of Cut Pile

multi-directional, high pile twist, giving an attractive, informal look. Has a heavily textured surface created by the long twisting yarns

Loop Pile

Textures of Carpets

weaving, tufting, or knitting the pile yarn into loops. Left uncut and is called Round Wire. Tougher and more easily maintained than cut pile, but is less versatile in color and pattern

Level Loop Pile

Types of Loop Pile

made of uniform uncut loops which are of the same height. Very sturdy and offers little textural variation. Has a pebbled surface texture that conceals soilage and hides footprints and other indentations. Used for heavy traffic areas and commercial installations

Multilevel Loop

Types of Loop Pile

made of different pile heights, all uncut loops. Gives a dimensional character to the carpet. Capable of producing sculptured patterns

Loop and Cut Pile

Textures of Carpets

adds a degree of warmth to an all-loop pile. Can be produced in tufted and woven constructions

Level Type Shear

Types of Loop and Cut Pile

some of the loops are cut and some remain uncut. Adds interest to colors and gives a desirable pattern effect

Random Shear loops

Types of Loop and Cut Pile

are sheared to different heights, forming a pattern that can be definite or irregular. Produces tonal contrast between the cut and uncut loops of varying heights

Carving

Sculptured Textures

incising a design into a carpet or rug which has already been woven

Hairline Carving

Types of Carving Sculptured Textures

used between colors in a multicolor design rug in order to accentuate and give a design some dimension

Recessing

Sculptured Textures

weaving a design into a low level rather than shearing down or carving it into the carpet

Embossing

Sculptured Textures

weaving a design in a higher level

Beveling

Sculptured Textures

rounding off the parts of a carpet that have already been carved, recessed, or embossed

Stock Dyeing

Methods of Coloring

dye is applied to the synthetic fibers before they are extruded or spun into yarn. This means that the color is integrated throughout the entire fiber, providing uniform coloration

Carpet Coloring

Accomplished by predyeing the carpet fibers before the carpet is manufactures or postdyeing the finished piece of carpet

Skein Dyeing

Methods of Coloring

also known as Yarn Dyeing; involves dyeing the yarn after it has been spun from the fiber but before it is woven or tufted into carpet. The yarn is typically wound onto skeins or cones and then immersed in a dye bath to apply the color

Solution Dyeing

Methods of Coloring

the color pigment is added to the polymer solution before it is extruded into fibers. This means that the color is an inherent part of the fiber itself, providing excellent colorfastness and resistance to fading, even in harsh environments

Piece Dyeing

Methods of Coloring

method in which the entire carpet, typically in the form of a large roll or "piece," is dyed after it has been tufted or woven. In this process, the carpet is passed through a dye bath or sprayed with dye to apply the color evenly across the entire surface

Jig Dyeing

Types of Piece Dyeing

carpet or fabric is wound onto a perforated roller known as a jig. The jig then moves through a dye bath, where the dye is forced through the fabric using pressure or vacuum

Winch, Real, or Back Dyeing

Types of Piece Dyeing

involves immersing the carpet or fabric in a dye bath contained within a large cylindrical vessel known as a winch, reel, or beck. The carpet or fabric is wound onto a reel or placed on a winch, which is then submerged and agitated in the dye bath

Open Beck Dyeing

Types of Jig Dyeing

produces 1000 yards of dyed carpet. Carpet ends are attached to form a large loop, which is submerged in a dye vat

Jet Beck Dyeing

Types of Jig Dyeing

has a very consistent level of color. Carpet is sewn together end to end, forming a continuous loop places in a large circular tubes called jet becks

Pad Dyeing

Types of Piece Dyeing

continuous dyeing process where the dye is applied to the carpet or fabric using a padded roller or applicator. The carpet or fabric passes through a dye bath, and the dye is transferred onto the surface using pressure

Differential

Methods of Coloring

Also known as Cross-Dyeing; dyeing technique used in textiles, including carpets, to achieve multicolor effects. In this process, different fibers or yarns within the same fabric or carpet are dyed with different types of dyes or different colors, resulting in a fabric with distinct color variations

Space Dyeing

Methods of Coloring

different colors are printed along the length of the yarn before it is manufactured into carpet, with different color baths for each of the yarns

Resist Dyeing

Methods of Coloring

yarn is treated to resist additional dyes. It produces no discernible pattern and used for shading only

Continuous Dyeing

Methods of Coloring

dyeing carpet in a continuous production line, rather than piece-dyeing separate lots

Package Dyeing

Methods of Coloring

spun yarns are wound on large perforated forms. Under heat or pressure, dyes are forced through the perforation and onto the yarn

Random Multicolor Dyeing

Methods of Coloring

achieved with a random dye application or a TAK random pattern machine which disperses regulated amounts of dye on carpet that is already dyes a single ground color or even on undyed goods

Printing

Patterns are applied to carpet after it is manufactured. Simulates the intricate patterns of woven carpet at a much lower cost

Screen Printing

Types of Printing

flat templates, or screens, through which dyes are forced to form finished pattern on the carpet pile

Deep dye Printing

Types of Printing

electrostatic charge forces the pre-metallized dyes used in this process deep into the pile. Puts down all the colors in the design at the same time