ARCH 3007 Exam 3 - Brick / Masonry

1/29

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

30 Terms

Masonry

Constructed of materials used by masons: brickwork, concrete block work, and stone work

Mason

A skilled worker who builds by laying units of substantial material such as stone or brick

Brick masonry

Excavated clay, shaped, dried, stacked, fire resistant, small in scale

Likely to crack during drying

Easy to install and stack

Dimensioned to fit human hand

Clay

Extruded and cut or pressed in molds; then fired in kilns

Brick laying

Laid in position for visual and structural reasons

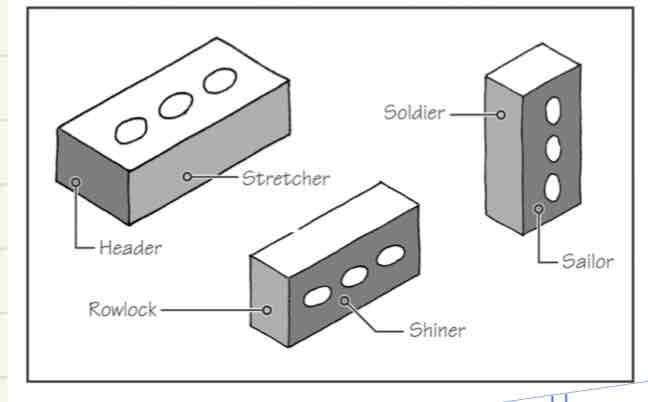

Parts of brick

Brick laying

Laid in position for visual and structural reasons pattern is called a bond

Mortar

Cushions the units giving them full bearing

Seals units to keep out water/wind

Bonds units into monolithic structure

Affects the finish or overall appearance

Occupies about 20% area

Portland cement, sand, water, lime

Mortar ingredients

Brick

Mortar in joints

Tile

Mortar behind, ground in joint

Repointing / tuckpointing

Scrape out and replace external layer of mortar

Brick joints

Average thickness is about 3/8”

Beaded joint

CMU

Larger than brick, made from concrete

Manufacturing

Vibration of stiff concrete mix into metal molds cured at an accelerated rate with steam

Glass block

Clear, heat absorbing, reflective

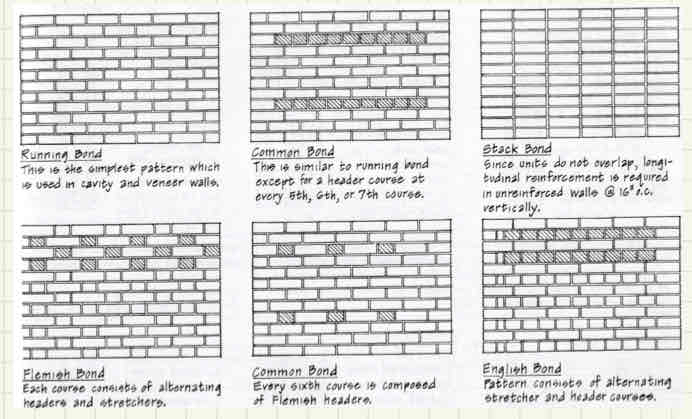

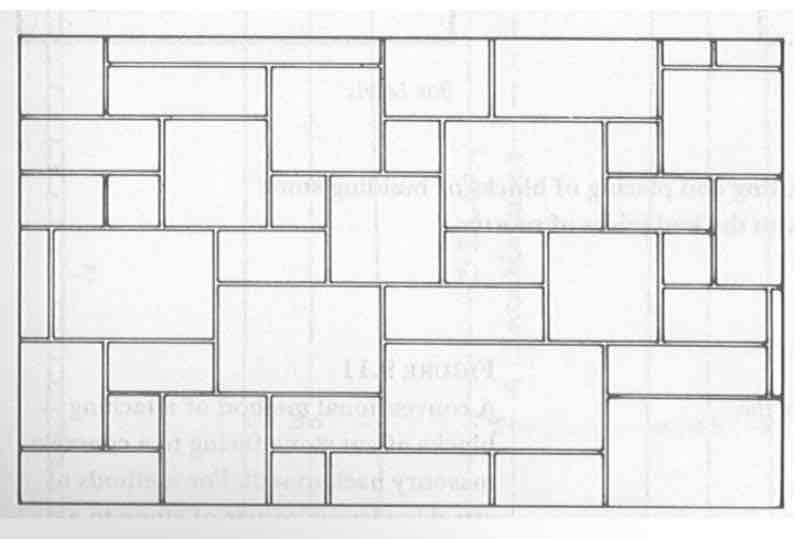

Types of bonds

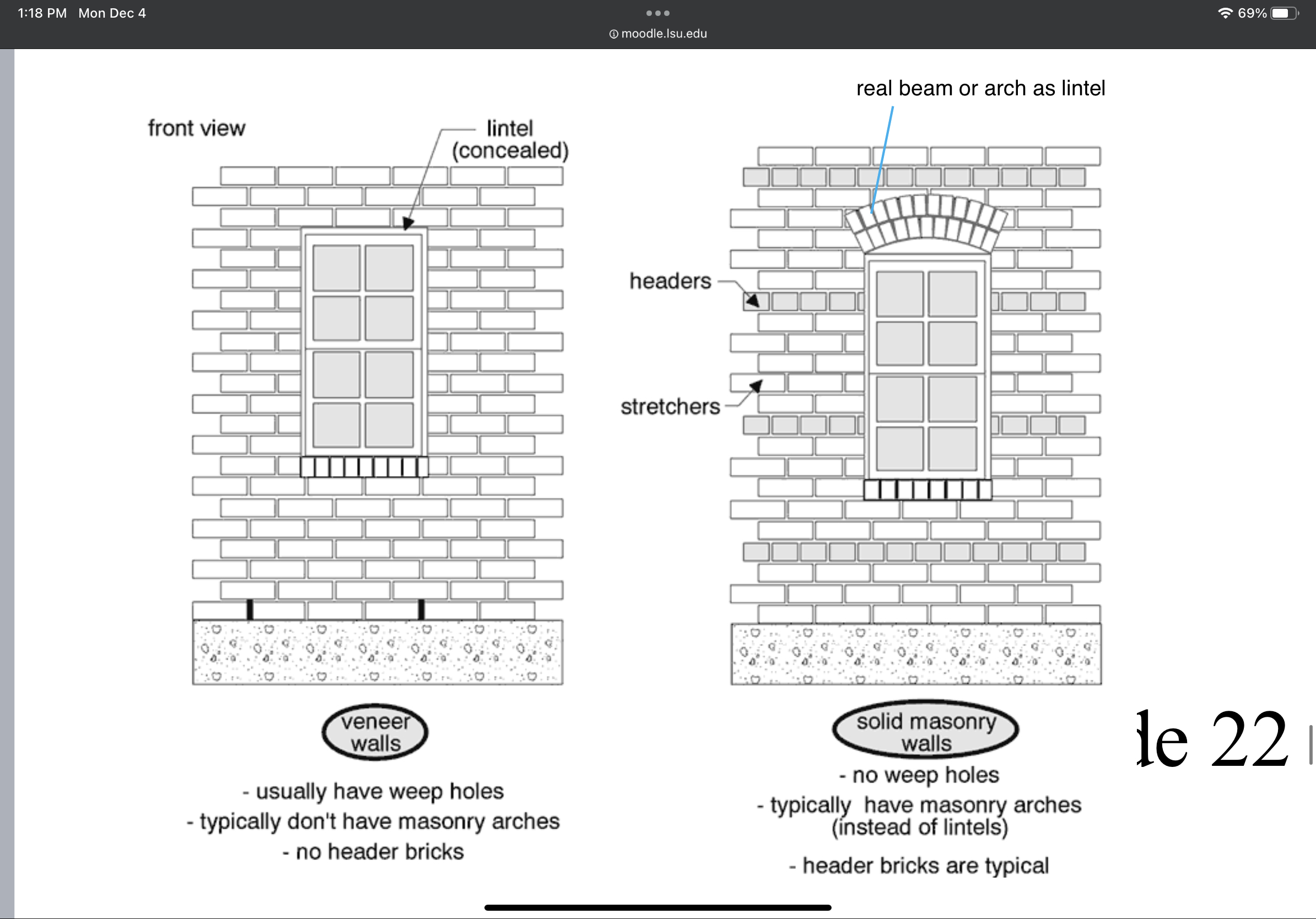

Veneer vs. solids masonry

Nominal dimensions of brick

Dimensions / 8” = X or X.5

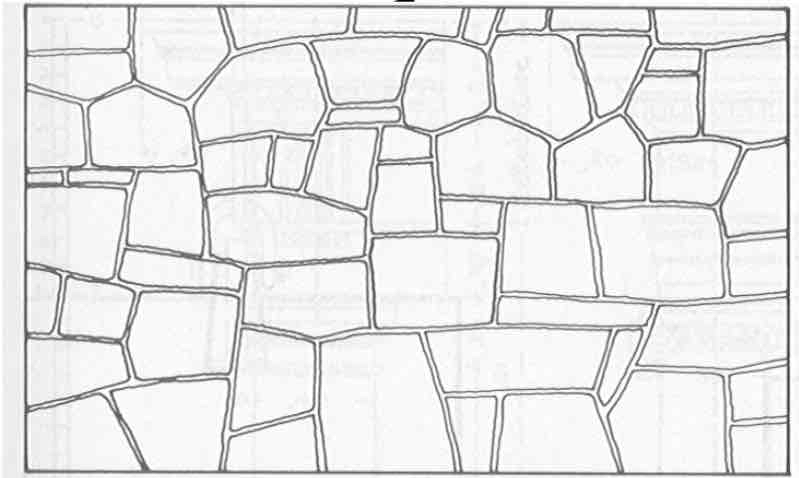

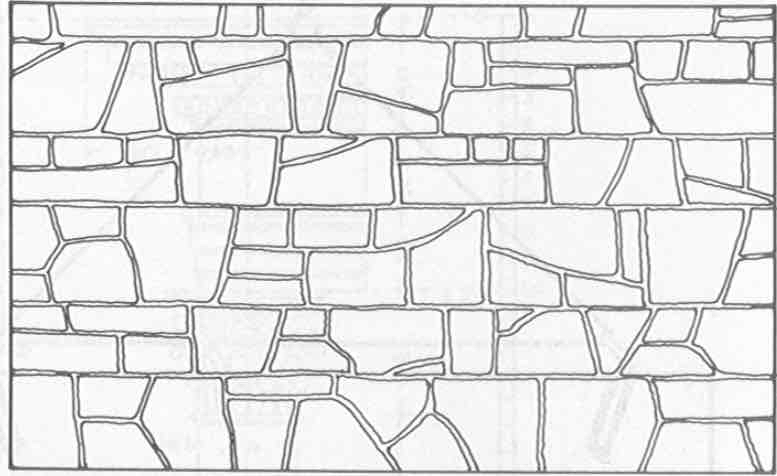

Random rubble

Course rubble

Random Ashlar

Coursed ashlar

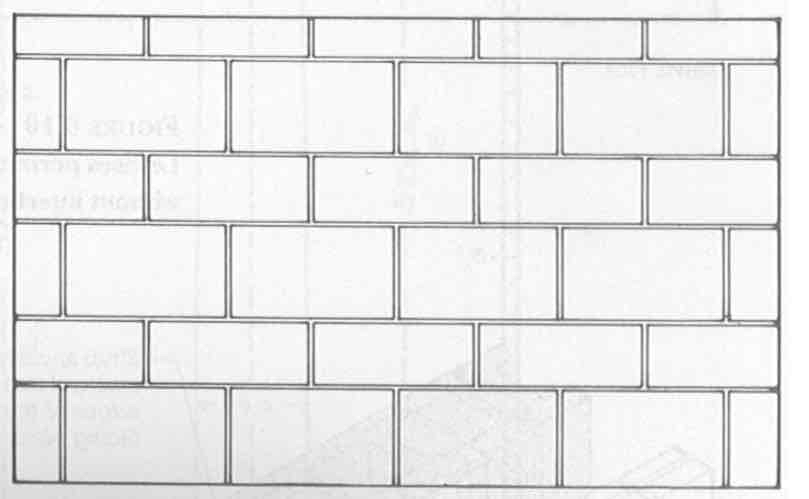

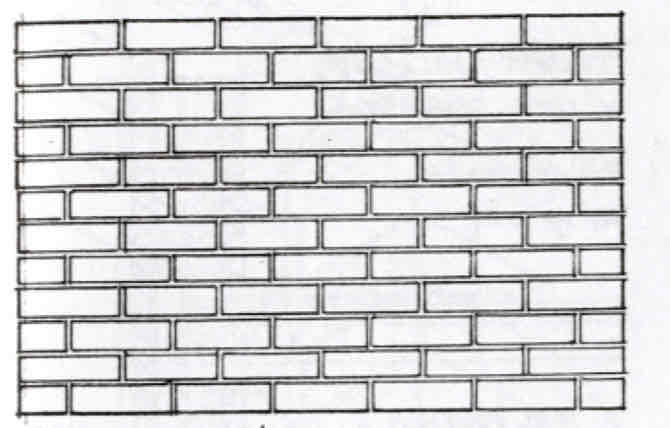

Running Bond - the simplest pattern

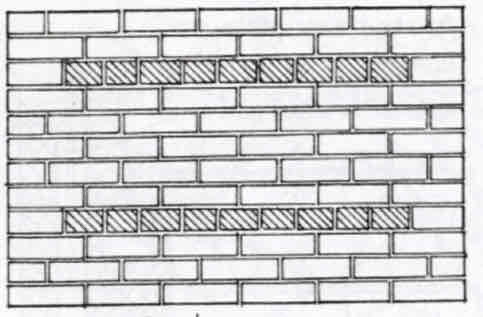

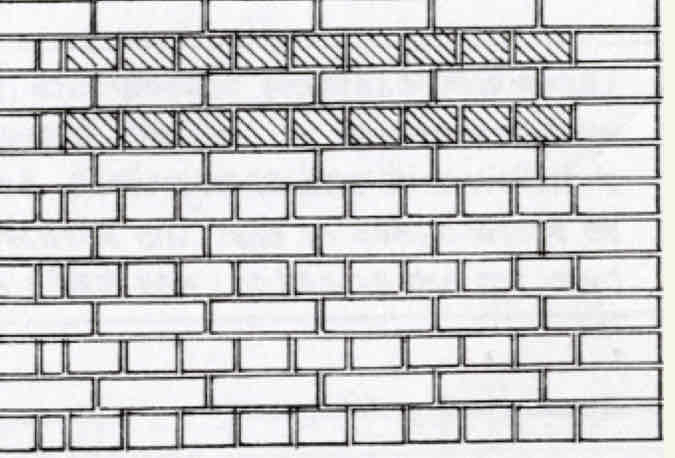

Common Bond - similar to running bond but a head course at every 5th, 6th, or 7th course

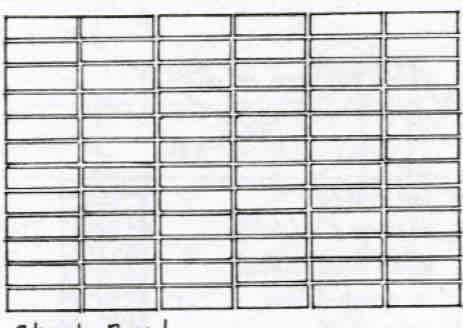

Stack Bond - no overlapping units, longitudinal reinforcement

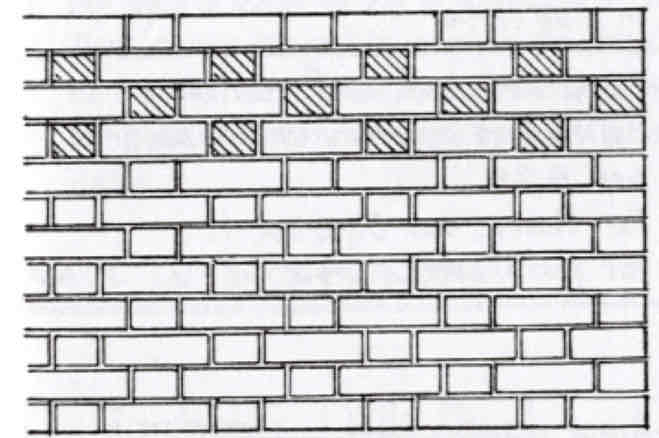

Flemish Bond - each course consists of alternating headers and stretchers

Common Bond - every 6th course is composed of Flemish headers

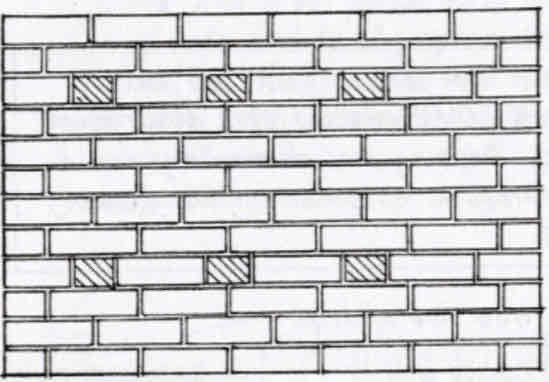

English Bond - Pattern consists of alternating stretcher and header courses