etech quiz 2 - wood

1/113

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

114 Terms

wood

hard, fibrous substance beneath the bark of trees

timber

wooden product that has not been shaped or processed

lumber

wooden product that has been sawn into construction members

softwood

comes from need-leaved conifers, which are evergreen (ex: pine, fir, and spruce)

hardwood

come from broad-leaved deciduous trees, which shed their leaves annually (ex: cherry)

what is the difference between softwoods and hardwoods?

they each have a different cellular structure in the botanical sense. not all hardwoods are harder than softwoods.

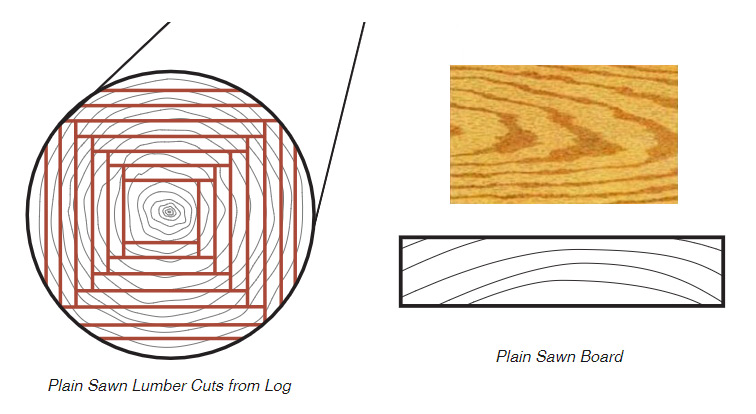

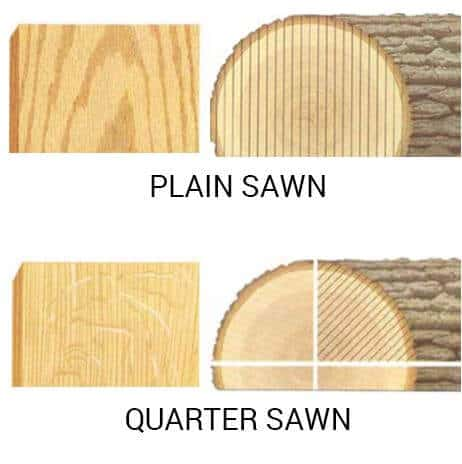

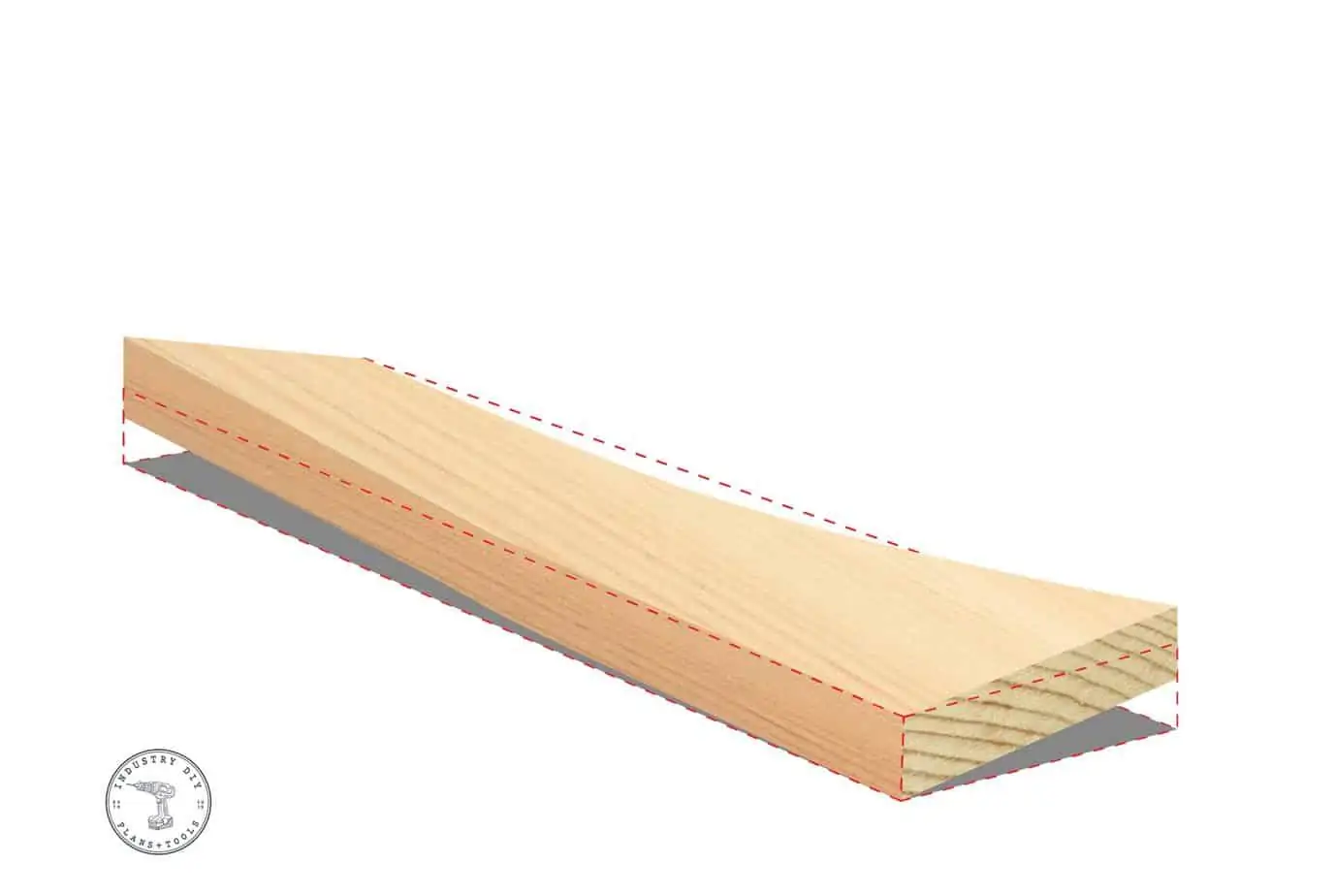

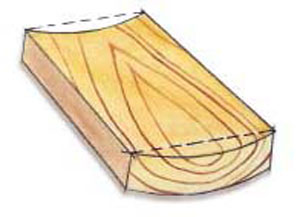

plain-sawn lumber

lumber cut tangent to the outermost annual rings; grain is 0-45 degrees to the wide face.

quarter-sawn lumber

lumber cut radially to the annual rings (perpendicular to the rings), grain is about 45-90 degrees to the wide face

characteristics of plain-sawn lumber

distinct grain pattern

tends to have raised grain

mat twist, cup, or unevenly

shrinks and swells more in width, less in thickness

less waste in cutting and less expensive

characteristics of quarter-sawn lumber

relatively even grain pattern

wears evenly with less warpage

shrinks and swells more in thickness, less in width

more waste in cutting and therefore more costly

shrinkage, distortion, and warpage depends…

partially on the way lumber is cut from a tree. wood shrinks most in the direction of the annual growth rings (tangentially, 8%), less across the rings (radially, 4%), very little parallel to grain (longitudinally, 0.01%)

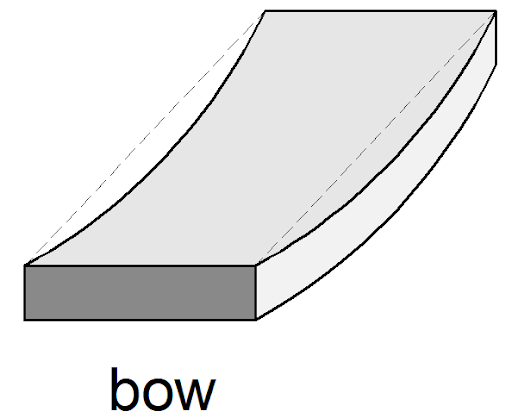

bow

a warp along the length of the face of the wood

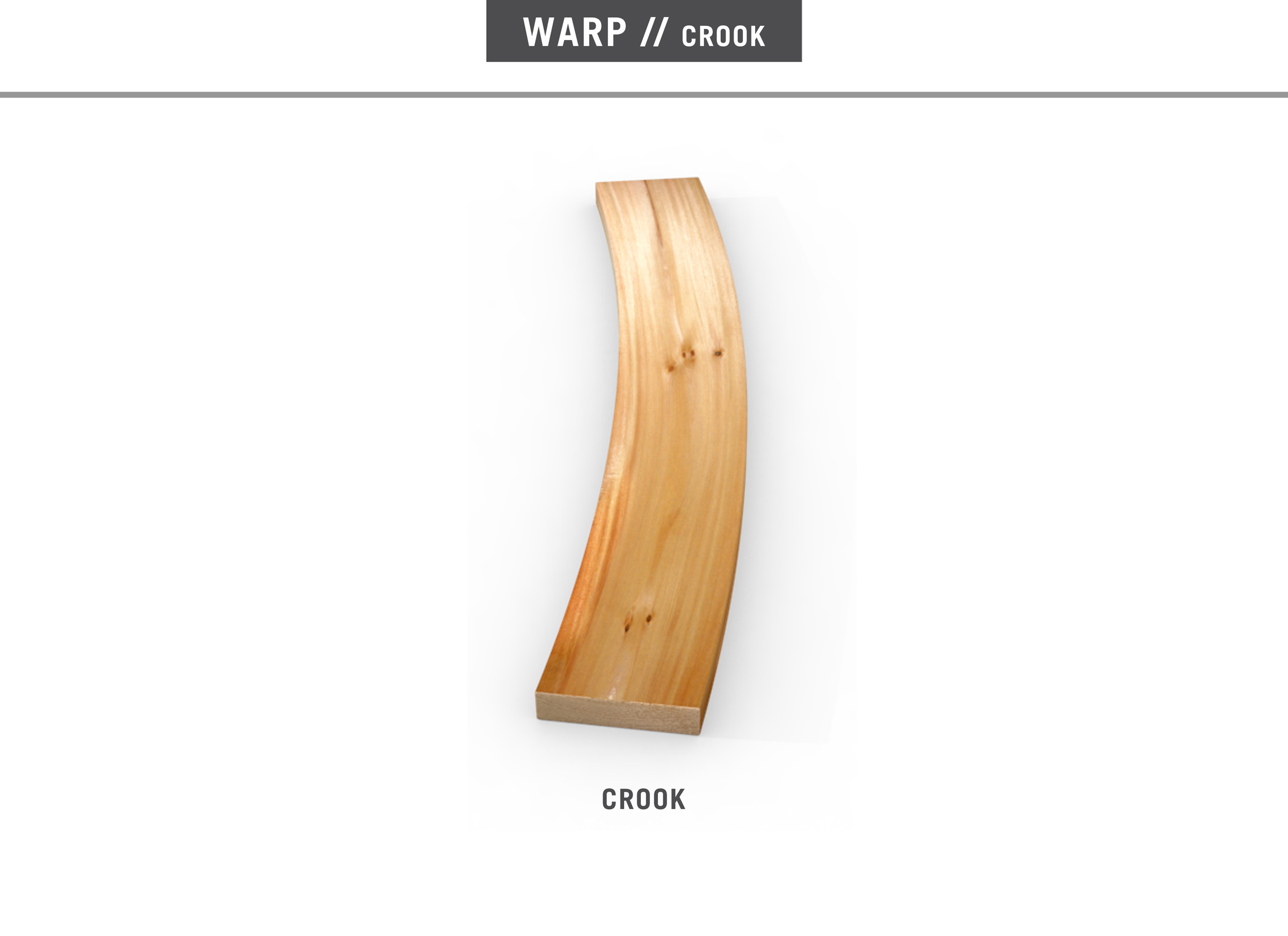

crook

a warp along the length of the edge of the wood

twist

a distortion in which the two ends do not lie on the same plane

cup

a warp across the width of the face, in which the edges are higher or lower than the center of the wood

moisture content

weight of water compared to the weight of dry wood (weight of water as % of the weight of dry wood

acceptable moisture content of framing lumber

19%

shrinkage

wood members change shape (shrink) if the change in moisture content is not done in controlled conditions. partially due to the cut, but also the drying process. greatest when measured tangent to the growth rings.

green wood

wood that contains a large amount of water (ex: wood in a tree), shrinks as it dries out.

ways to minimize shrinkage

season dry the wood by air drying or kiln drying. 90% of lumber is kiln dried.

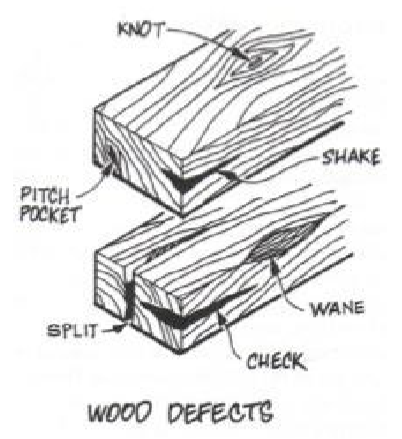

natural defects

damaged by insects, decayed by fungus, destroyed by fire

manufactured defects

defects that happen during the manufacturing process (ex: bow, cup, crook, etc.)

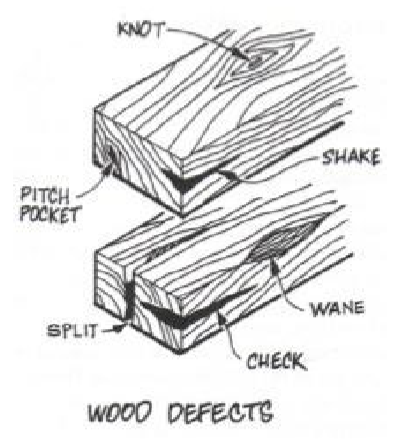

knot (natural defect)

branch embedded in a tree and cut through manufacturing

shake (natural defect)

pitted area sometimes found in cedar and cypress

pitch pocket

opening between growth rings and containing resin

check (manufactured)

lengthwise grain separation of wood extending from one face to another

split (manufactured defects)

lengthwise separation of wood extending from one face to another.

wane (manufactured defect)

lack of wood on the edge or corner

warp (manufacted defect

shrinkage distortion of a plane surface - bow, crook, cup, and twist

dimensional lumber

general name for framing lumber. most lumber is smaller than its name to give it a more finished look.

nominal size 1 × 2

actual size: 3/4” x 1 1/2”

nominal size 1 × 3

actual size: 3/4” x 2 1/2”

nominal size 1 × 4

actual size: 3/4” x 3 1/2”

nominal size 1 × 5

actual size: 3/4” x 4 1/2”

nominal size 1 × 6

actual size: 3/4” x 5 1/2”

nominal size 2 × 4

actual size: 1 1/2” x 3 1/2”

nominal size 2 × 6

actual size: 1 1/2” x 5 1/2”

nominal size 2 × 8

actual size: 1 1/2” x 7 1/4”

nominal size 2 × 10

actual size: 1 1/2” x 9 1/4”

nominal size 2 × 12

actual size: 1 1/2” x 11 1/4”

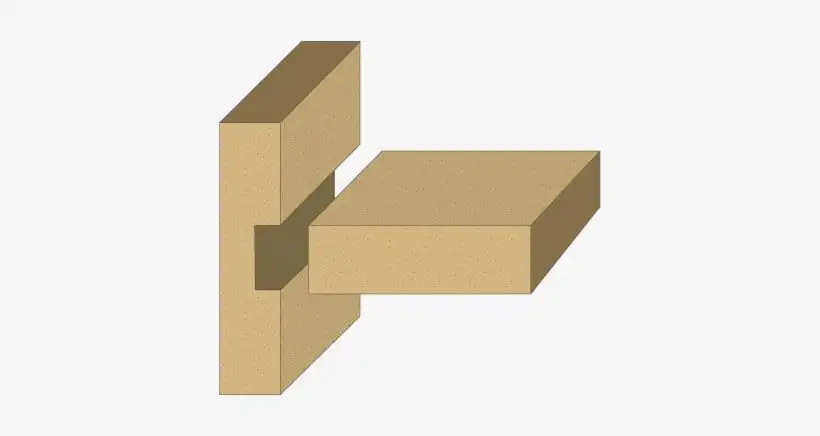

half lap joint

see picture

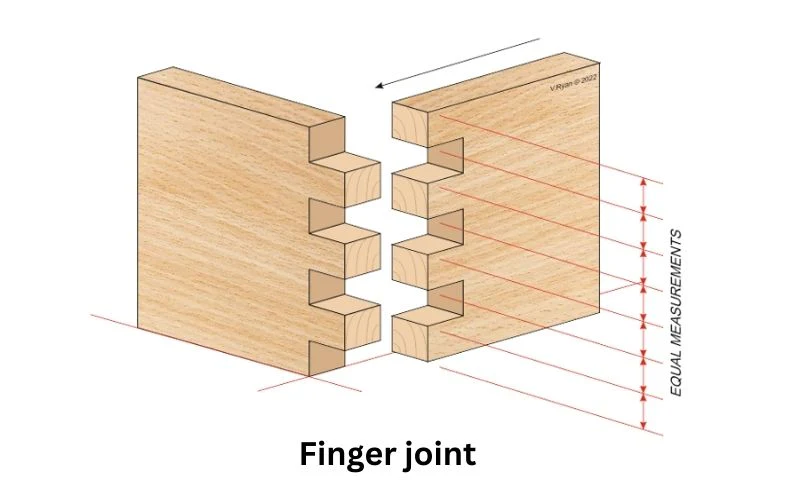

finger joint

see picture

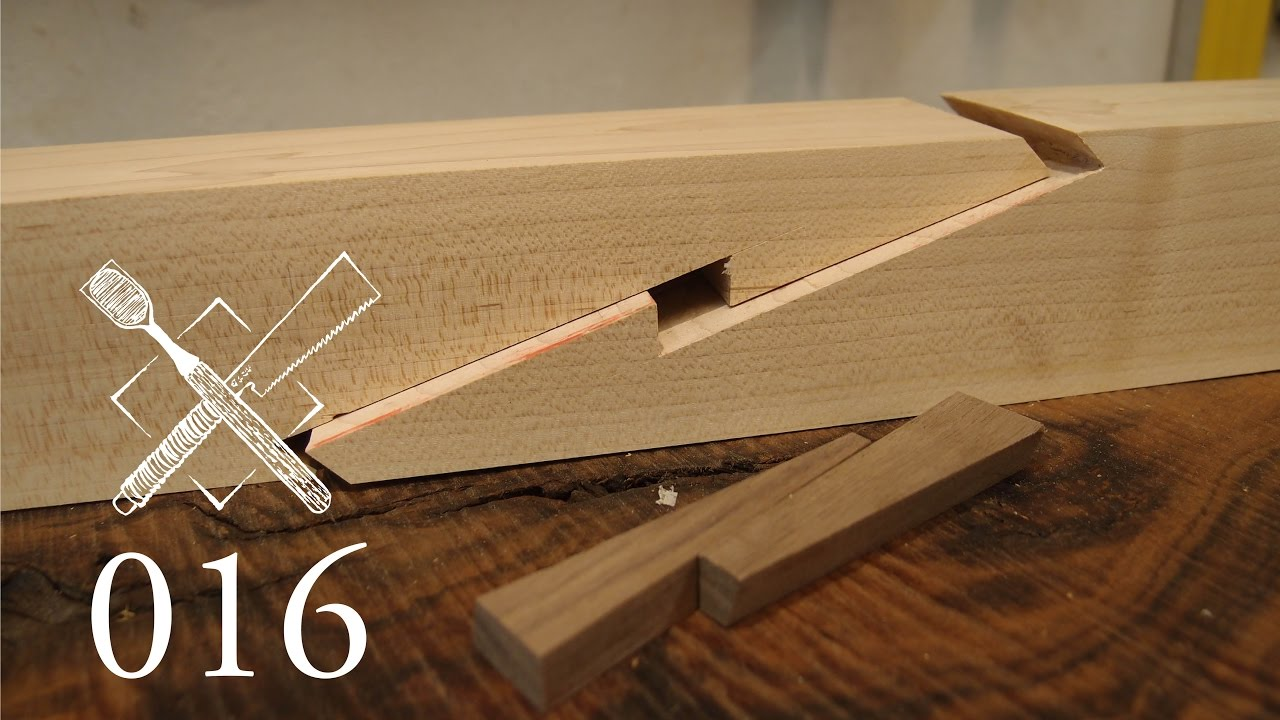

scarf joint

see picture

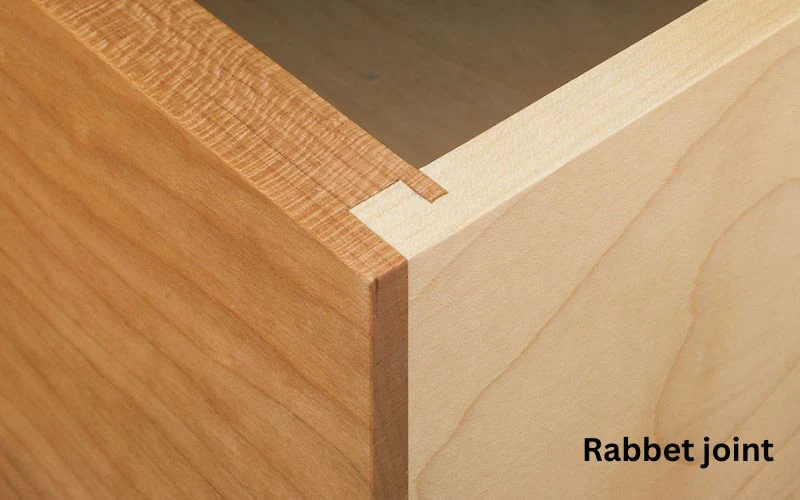

rabbet joint

see picture

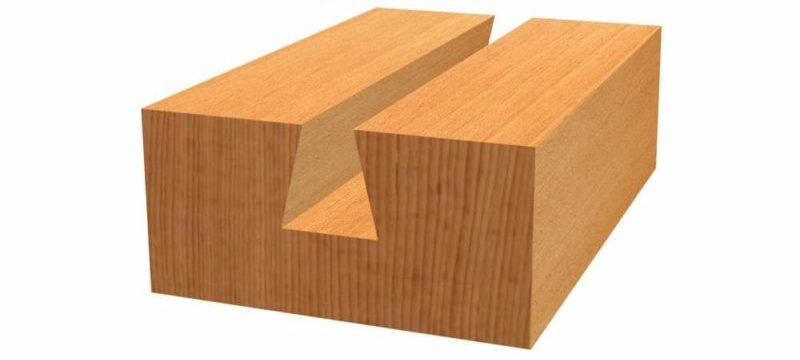

dado joint

see picture

dovetail dado joint

see picture

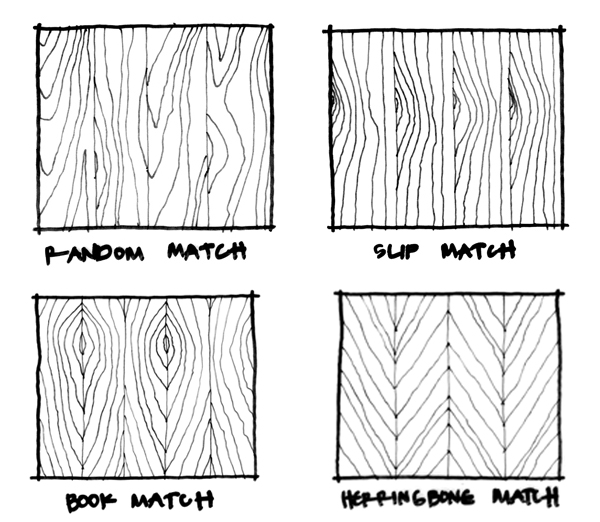

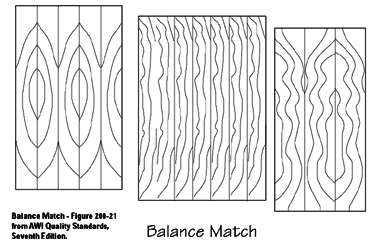

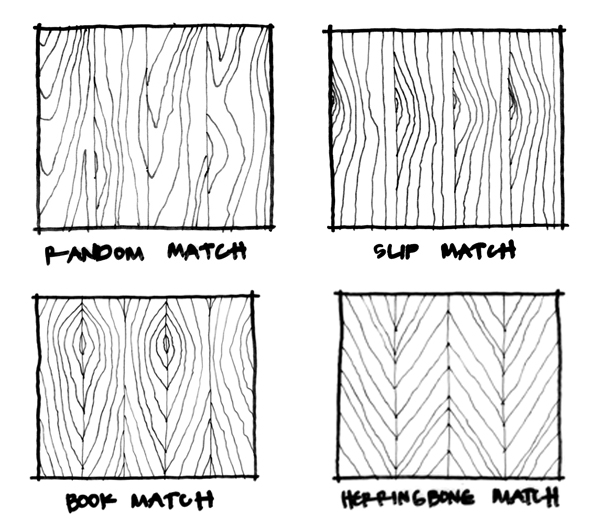

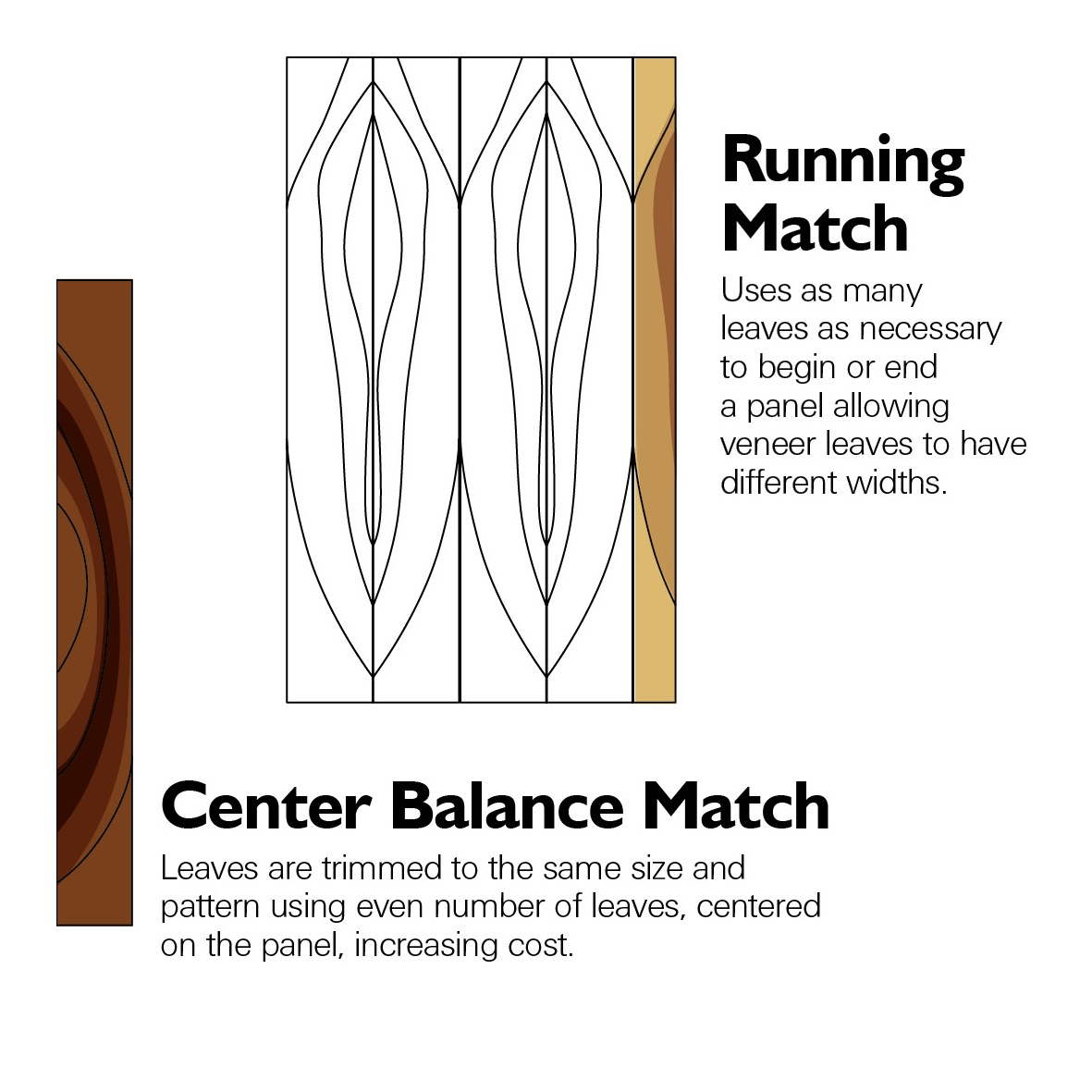

plywood veneer cutting

rotary forms random pattern, plain slicing forms repeating pattern, quarter slicing forms parallel pattern

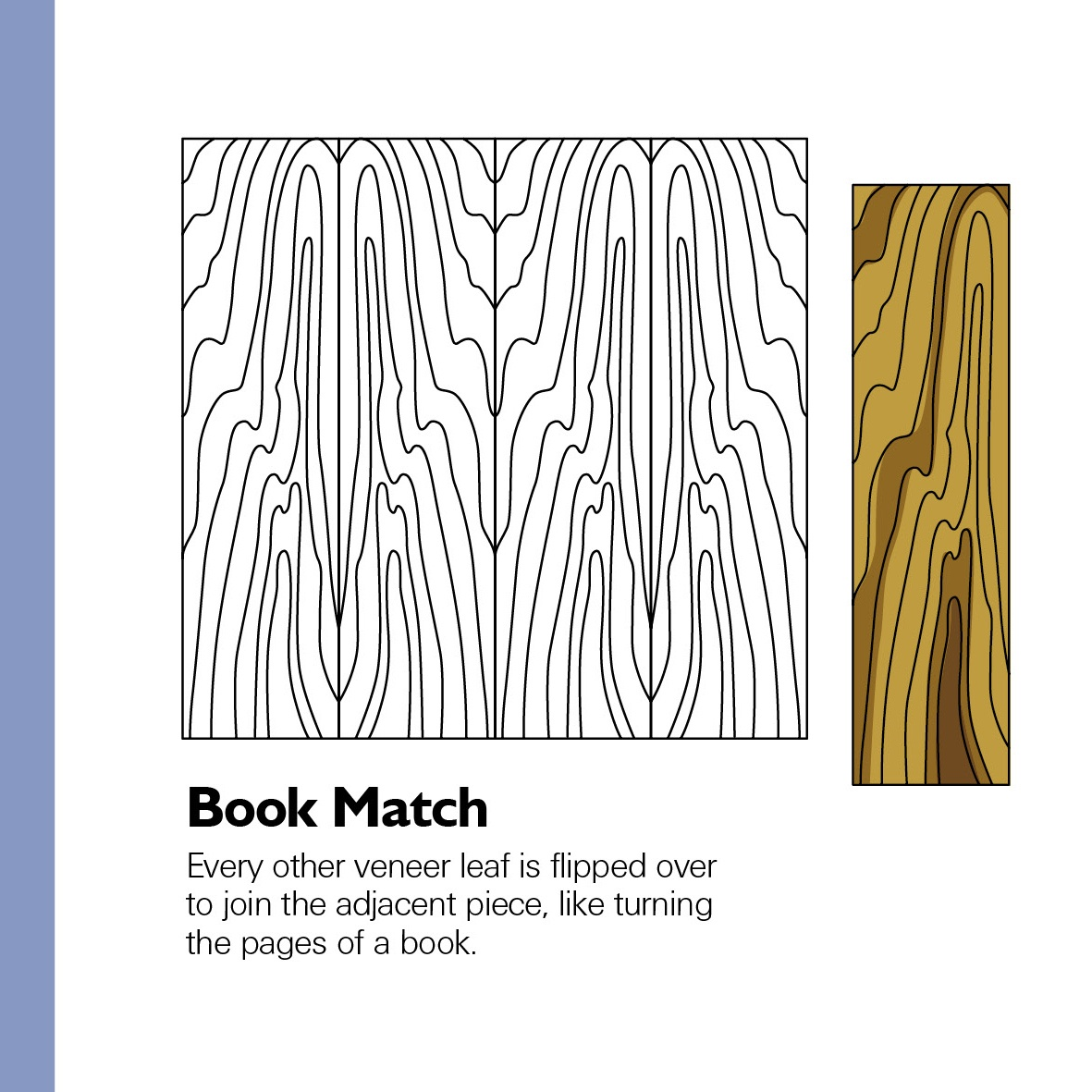

every other veneer turned over, creates symmetrical pattern. most common, used with plain slicing most.

book matching

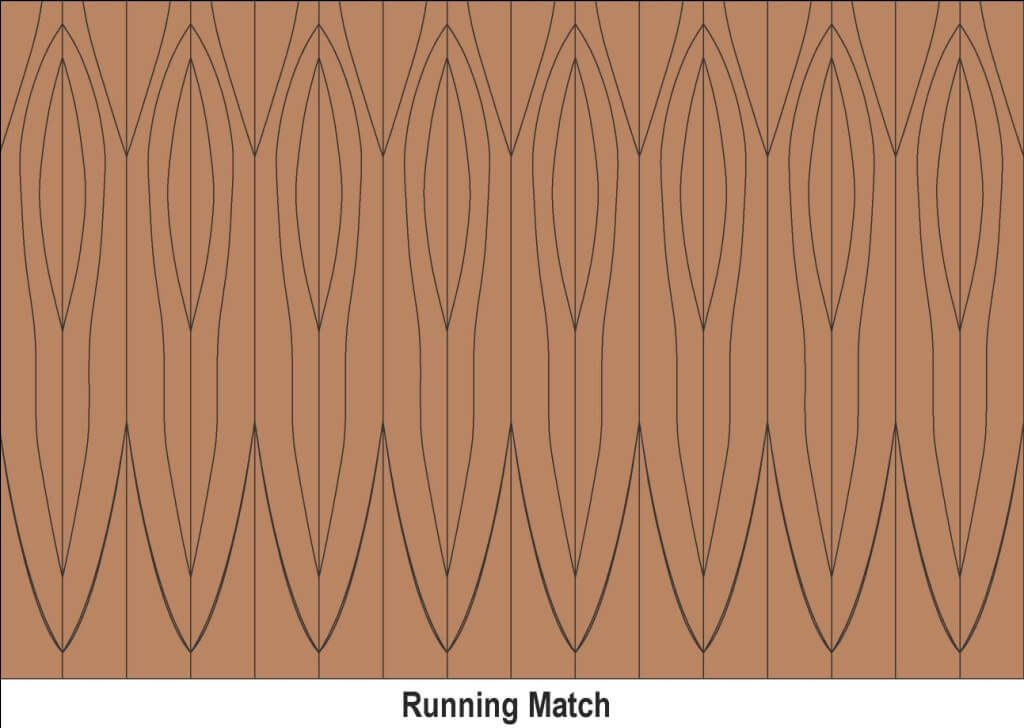

running match

veneers are joined in sequence without turning. joints are not obvious, and often used with quarter cut veneers

slip matching

balance match

veneer book broken, leaf sequence destroyed on purpose and most difficult

random matching

center match

wood is stronger in…

compression than tension

wood is stronger when the load is applied…

parallel to the grain rather than perpendicular to the grain

for shear, wood is very strong…

perpendicular to the grain and relatively weak parallel to the grain

particle board

manufactured from wood particles, such as wood chips, sawmill shavings, or even saw dust. made with larger pieces of wood than used to make MDF

oriented strand board (OSB)

formed by adding adhesives and the compressing layers of wood strands in specific orientations. OSB features long wood “strands”

laminated strand lumber (LSL)

lumber made up of strands instead of veneersl

laminated veneer lumber (LVL)

made by gluing sheets of veneer together. unlike plywood, here all veneer layers are going in the same direction. wide panels are manufactured to the thickness of the desired lumber.

plywood

made from thin sheets of wood veneer, called plies or veneers, layered in opposite directions

masonite

formed using the mason method, using wooden chips and blasting them into long fibers with steam and forming them into boards. boards are pressed and heated to finish. no glue is added.

glue laminated lumber

gluing many boards together to form a structural member bigger than the trees from which the board were sawn. the middle is the only part that must resist shear. high quality lumber is used on the top and bottom, while middle grade lumber is used in the middle.

I-beams and i-joists

veneer lumber is used for the flanges, and plywood or OSB is used for the web to resist shear

recycled plastic lumber (RPL), Trex

lumber-like products with a plastic content of 50% or more. higher expansion and contraction with temperature changes. less structural strength

cross laminated timber

solid premanufactured wood panel product made up of layers of laminations in 90 degree intervals.

light frame construction

uses small. closely spaced members, such as 2×4 or 2×6 studs for walls and partitions and nominal 2 in thick members for floor and roof joists.p

platform framing

uses separate studs for each floor of the building, with the top plates, floor joists, and floor framing of the second level being constructed before the second floor walls are erected.

benefits to platform framing

each floor can be completed and used for constructing the next floor

shorter studs cost less

structural problems may occur after completion

balloon framing

uses continuous wall studs from foundation to second-floor ceiling

benefits to balloon framing

fewer problems are expected post-construction

increased durability

faster construction

longer studs cost more

step 1 of 18

soil testing + footing placement

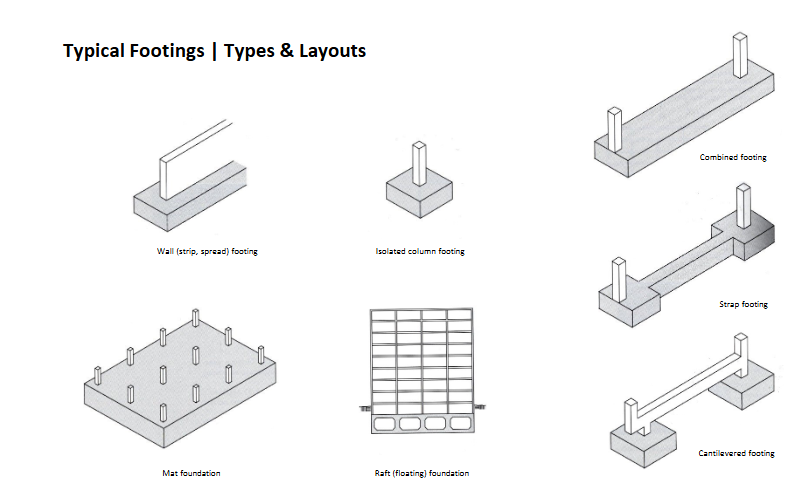

typical footings

wall, isolated column, mat foundation, raft foundation, combined footing, strap footing, cantilevered footing

topsoil excavation

involves the removal of the top level of soil including vegetation and its root zone. this method is used to remove anything that would be unsuitable to bear structural loads.

earth excavation

involves the removal or the layer of soil directly beneath the topsoil. spoil is often stockpiled for later use or restoration

muck excavation

undercutting. consists of the removal and disposable of unsuitable materials (soil with 20-80% organic matter)

unclassified excavation

removal of material within cut sections to the subgrade elevation.

step 2 of 18

placing the foundation walls and waterproofing

waterproofing

usually asphalt-based, that is either sprayed or hand applied to the outside of the wall.

step 3 of 18

placement of the perimeter drain

step 4 of 18

backfill the surrounding

step 5 of 18

adding the sill plate

sill plate

a type of plate that separates the foundations from the structural members to give it an extra base

pressure treated lumber used for…

framing members that rest on concrete exterior foundation walls that are less than 8 inches from exposed ground

the best way to air seal the sill plate is…

place a sill sealer/gasket on the concrete before laying down the sill plate.

step 6 of 18

place the bottom plate

bottom plate

used to connect the wall to the floor

step 7 of 18

place the floor joists

cross bracing or bridging

typically are set at the mid-span of joists

purpose of cross bracing

evenly distribute loads

prevents joist rotation

add stability and stiffness

some engineered wood joists

wood truss joists, wood II joists

step 8 of 18

placement of wall sheathing

sheathing

boards or panels that line the walls, floor and roof

purpose of sheathing

create a surface on which other materials can be placed to increase the stability while providing increased insulation.

wall sheathing is…

primarily a structural material. non-structural sheathing is applied to the outside and is called “insulated sheathing”

common exterior wall sheathing types

OSB and Plywood

foam board/rigid foam

foam applied to the exterior to increase the insulation. applied directly over the OSB or plywood and fastened.

step 9 orf 18

header placement

step 10 of 18

stud placement

hanger

material that helps beams hold together at intersections