MP2-10/27

1/60

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

61 Terms

What is a memorable product made from bent plywood?

Paimio Chair

What is an advantage of bent plywood?

Allows for strong, lightweight wood components

How does bent plywood compare to hand carving wood?

Much less time consuming than hand carving wood

How can the rigidity of bent plywood be altered?

Rigidity can be changed with different amounts of glue

What is a disadvantage of bent plywood?

Involves many steps (35 from tree to chair)

What is a limitation of bent plywood in terms of structural support?

Can really only support the weight for furniture (unusable for supports in buildings)

What is a comparison point between bent plywood and steam bending?

Unable to bend 3 Dimensionally

Which can support more weight, bent plywood or steam bending?

Steam bending can support more weight

How does the natural grain of bent plywood affect its tolerance?

A set tolerance is indefinable but is far worse than any form of plastic molding

What is explosive forming?

A manufacturing process that uses explosives to shape metal.

Which rocket was partially built utilizing explosive forming?

The Saturn 5 Rocket.

What is an advantage of explosive forming?

Easily creates complex curves and large components in one piece.

What is another advantage of explosive forming?

High degree of accuracy with virtually no limit on size to producible parts.

What is a disadvantage of explosive forming?

It is incredibly energy intensive and requires explosives.

What is a limitation of explosive forming?

It doesn't allow for all types of metals.

What is an alternative to explosive forming for smaller pieces?

Press forming.

What is the tolerance range for smaller parts produced by explosive forming?

+/- 0.025mm.

What is the tolerance range for larger parts produced by explosive forming?

+/- 0.050mm.

For what type of metal parts is explosive forming better suited?

Much larger pieces of metal that need curves.

What is a benefit of blow molding compared to injection molding?

Cost effective

What is a key feature of blow molding?

Seamless construction for hollow parts

What is a disadvantage of blow molding?

Limited wall-thickness control compared to roto-molding

How does blow molding's precision compare to other molding methods?

Can have lower precision

What is rotomolding?

A manufacturing process that involves a heated, hollow mold filled with material, then rotated to disperse the material.

Give an example of a product made using rotomolding.

Kayaks

What are the process tolerances for Injection Blow Molding (IBM)?

±0.1% to ±0.5% (or ±0.002-0.010 in)

What are the process tolerances for Extrusion Blow Molding (EBM)?

±0.5% to ±1.5% of dimension (or ±0.010-0.030 in typical)

What is a notable product made using blow molding?

Plastic water bottle

What is Roto Molding?

A manufacturing process used to create large, complex geometries.

What is a memorable product made using Roto Molding?

Kayaks

What is an advantage of Roto Molding compared to blow and injection molding?

Easier to produce large complex geometries.

What is another advantage of Roto Molding?

Uniform wall thickness.

What is a disadvantage of Roto Molding?

Limited material choices, requires workable powdered thermoplastics.

What is a second disadvantage of Roto Molding?

Very long cycle times compared to blow and injection molding.

How does Blow Molding differ from Roto Molding?

Blow Molding has faster cycle times, higher production volumes, and longer mold lives.

What type of pieces does Blow Molding produce compared to Roto Molding?

Thinner, smaller, less complex pieces.

What are the process tolerances for Roto Molding?

+/- 0.02" to +/- 0.01"

What is a key advantage of CNC machining compared to laser cutting?

Incredible accuracy

What is a benefit of CNC machining regarding part replication?

Uniform part replication with no human error

What is a disadvantage of CNC machining related to costs?

High initial cost and potential maintenance costs

What is a limitation of CNC machining?

Limited bed sizes

What is the tolerance range for CNC machining?

+/-±0.005" to ±0.0001"

What is a notable product that uses CNC machining?

Motorcycle engines

What is a benefit of water jet cutting compared to plasma cutting?

No heat-affected zone (burning/melting)

What is another benefit of water jet cutting compared to plasma cutting?

Superior edge quality and precision

What is a disadvantage of water jet cutting?

High capital and cost

What is another disadvantage of water jet cutting?

Slower speed than plasma cutting, especially on thick materials

What is the typical tolerance range for water jet cutting?

±0.002 to ±0.004 inches

What is a notable product made using water jet cutting?

Gears

What is a benefit of Wire Electrical Discharge Machining (EDM)?

Can cut hard intricate metals

What is another benefit of Wire Electrical Discharge Machining (EDM)?

Smooth finish with no other work needed

What is a disadvantage of Wire Electrical Discharge Machining (EDM)?

Long process that takes time to cut

What type of materials does Wire Electrical Discharge Machining (EDM) work on?

Only works on conductive materials

What is the closest process to Sinker EDM?

Wire Electrical Discharge Machining (EDM)

What is the tolerance range for Wire Electrical Discharge Machining (EDM)?

2 Microns 0.001 to 0.0005

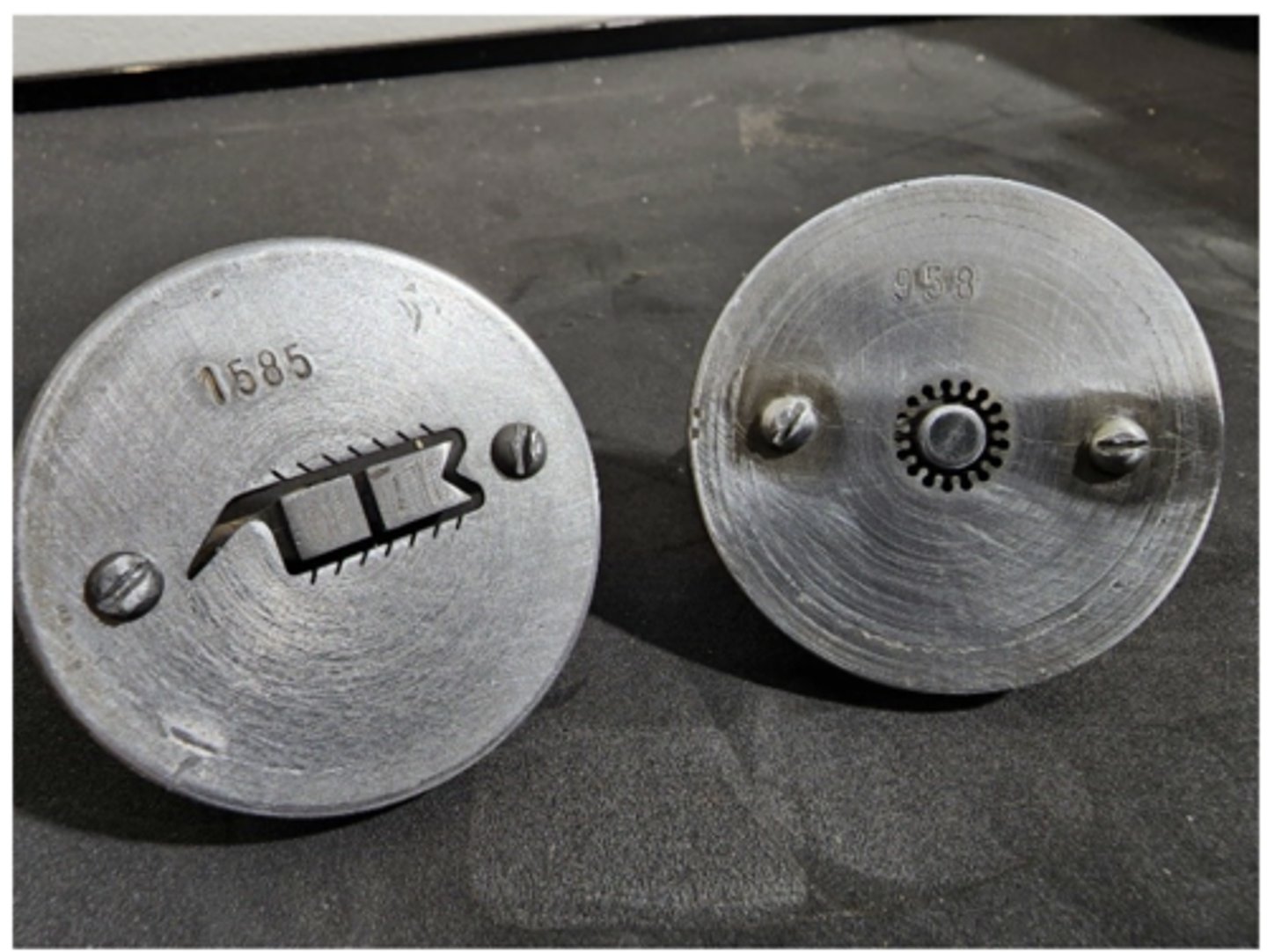

What is a notable product made using Wire Electrical Discharge Machining (EDM)?

Die cuts

What is the tolerance level that Electron Beam Machining (EBM) can achieve?

±0.0001

How does Electron Beam Machining (EBM) avoid oxidation during the machining process?

EBM operates in a vacuum chamber.

What is a limitation of Electron Beam Machining (EBM) regarding workpiece size?

EBM requires a vacuum chamber, which limits the size of the workpiece.

How does the energy consumption of Electron Beam Machining (EBM) compare to Plasma arc cutting?

EBM uses 0.4 to 50 kW, while Plasma arc cutting uses 7.2 kW to 19.2 kW.

What is a notable product made using Electron Beam Machining (EBM)?

Orthopedic Implant