M4 - PROCESS VALIDATION

0.0(0)

Card Sorting

1/117

Earn XP

Description and Tags

Last updated 2:34 PM on 10/9/22

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

118 Terms

1

New cards

Process Validation

A documented process that provides a high degree of assurance that a facility, laboratory, computer, process or system will consistently produce product, meeting the predetermined specifications & quality attributes

2

New cards

- selection of quality components and materials,

- adequate product and process design,

- statistical control of the process through in-process

and end-product testing

- adequate product and process design,

- statistical control of the process through in-process

and end-product testing

Factors to consider in Process Validation

3

New cards

Process Validation

Action of proving, in accordance with the principles

of GMP, that any procedure, process, equipment,

material, activity or system actually leads to the

expected results

EU / PIC/S

of GMP, that any procedure, process, equipment,

material, activity or system actually leads to the

expected results

EU / PIC/S

4

New cards

Process Validation

• The collection and evaluation of data, beginning at

the process development stage and continuing

through the production phase, which ensures that

the manufacturing processes -including equipment,

buildings, personnel and materials -are capable of

achieving the intended results on a consistent and

continuous basis.

the process development stage and continuing

through the production phase, which ensures that

the manufacturing processes -including equipment,

buildings, personnel and materials -are capable of

achieving the intended results on a consistent and

continuous basis.

5

New cards

Process Validation

Validation is the establishment of documented

evidence that a system does what it is supposed to

do

evidence that a system does what it is supposed to

do

6

New cards

•Processes

•Manufacturing Steps

•Analytical Test methods

•Manufacturing Steps

•Analytical Test methods

General Rule in Process Validation: (3)

anything that can affect patient safety or product quality should be validated

anything that can affect patient safety or product quality should be validated

7

New cards

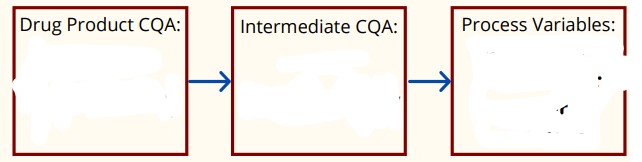

•Processes -

General Rule in Process Validation:

such as manufacturing processes that produce a

product

such as manufacturing processes that produce a

product

8

New cards

Manufacturing Steps

General Rule in Process Validation:

each step may be validated separately for

long processes

each step may be validated separately for

long processes

9

New cards

Analytical Test methods

General Rule in Process Validation:

applicable for raw materials, intermediates,

active pharmaceutical ingredients, finished pharmaceutical products,

method used for stability studies and those methods used in quality

control

applicable for raw materials, intermediates,

active pharmaceutical ingredients, finished pharmaceutical products,

method used for stability studies and those methods used in quality

control

10

New cards

Systems and Programs

including those that support

Good Manufacturing Processes (GMP) such as facility

(building specifications), utilities, programs like pest

control, software, hardware (enterprise Resource Platform)

and laboratory information management systems and

water for injection.

Good Manufacturing Processes (GMP) such as facility

(building specifications), utilities, programs like pest

control, software, hardware (enterprise Resource Platform)

and laboratory information management systems and

water for injection.

11

New cards

Facilities

including rooms and equipment used for

processing products that are sterile must adhere to strict

criteria and be validated before use.

processing products that are sterile must adhere to strict

criteria and be validated before use.

12

New cards

Cleaning processes

- including sterilize in place and clean in

place

place

13

New cards

Validation

is intended to apply to final verification at the

production scale

production scale

14

New cards

Validation

the action of checking the accuracy of something.

15

New cards

Concurrent Validation

is carried out during production. It is

more appropriate to validate process during routine production

due to well understanding of the process.

more appropriate to validate process during routine production

due to well understanding of the process.

16

New cards

Concurrent Validation

Extensive testing &

monitoring ensure the desired quality characteristics of product

with high degree of confidence.

monitoring ensure the desired quality characteristics of product

with high degree of confidence.

17

New cards

Concurrent Validation

In this type, verification of

process still goes on after three initial commercial batches are

taken and process is handled over to manufacturing personnel

process still goes on after three initial commercial batches are

taken and process is handled over to manufacturing personnel

18

New cards

Concurrent Validation

batch after batch, the process parameter is evaluated for

manufacturing facilities and studied if there is any change or

deviation is observed

manufacturing facilities and studied if there is any change or

deviation is observed

19

New cards

Prospective Validation

Concurrent Validation

Retrospective Validation

Revalidation

Concurrent Validation

Retrospective Validation

Revalidation

Types of Validation

20

New cards

Prospective Validation

-means validation is done during the development

stage.

stage.

21

New cards

Prospective Validation

During this step the input resources are selected and clearly specified

22

New cards

Prospective Validation

. During this step the input resources are selected and clearly specified.

Each step in the development of new manufacturing process is required to

be established to give a desired result.

Each step in the development of new manufacturing process is required to

be established to give a desired result.

23

New cards

Prospective Validation

The approach in this validation often

leads to transfer of the manufacturing process from the development function

to production.

leads to transfer of the manufacturing process from the development function

to production.

24

New cards

clearly defined material specification

defined

equipment and process parameter;

specified operating condition, if there is any;

and defined level of training of people

defined

equipment and process parameter;

specified operating condition, if there is any;

and defined level of training of people

Prospective Validation example:

25

New cards

Retrospective Validation -

is used for facilities, processes and

process control parameters used in operation that have not

undergone in documented validation process but it is possible

using historical data (QA/QC records) to provide the necessary

documented evidence that the process is doing what is believed

to do

process control parameters used in operation that have not

undergone in documented validation process but it is possible

using historical data (QA/QC records) to provide the necessary

documented evidence that the process is doing what is believed

to do

26

New cards

Retrospective Validation -

this type of validation is only acceptable for well

established processes.

established processes.

27

New cards

Revalidation -

is a repetition of the validation process and it is

required under the following circumstances: major changes in

critical process parameters of formula, equipment, procedures, or

quality of raw material or even in physical variation of raw

material like particle size, changes in facilities and installation

which influence process

required under the following circumstances: major changes in

critical process parameters of formula, equipment, procedures, or

quality of raw material or even in physical variation of raw

material like particle size, changes in facilities and installation

which influence process

28

New cards

• Process Design

• Process Qualification

• Continues Process Verification

• Process Qualification

• Continues Process Verification

Process Validation During the Product Life

29

New cards

Quality by Design (QbD)

A systematic approach to ) development that begins with predefined objectives and

emphasizes product and process understanding and process control, based on sound

science and quality risk management. (ICH Q8 R2

emphasizes product and process understanding and process control, based on sound

science and quality risk management. (ICH Q8 R2

30

New cards

Predefined objectives

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Define Quality Target Product Profile (QTPP)

Quality by Design (QbD)

Systematic Approach

Define Quality Target Product Profile (QTPP)

31

New cards

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Identify Critical Quality Attributes (CQA)

Quality by Design (QbD)

Systematic Approach

Identify Critical Quality Attributes (CQA)

32

New cards

Product and process

understanding

understanding

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Identify critical material attributes (CMA) and critical process

parameters (CPP)

Quality by Design (QbD)

Systematic Approach

Identify critical material attributes (CMA) and critical process

parameters (CPP)

33

New cards

Product and process

understanding

understanding

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Establish the functional relationships that link CMA/CPP to CQA

Quality by Design (QbD)

Systematic Approach

Establish the functional relationships that link CMA/CPP to CQA

34

New cards

Sound science

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Develop appropriate Control Strategy, including justifications

Quality by Design (QbD)

Systematic Approach

Develop appropriate Control Strategy, including justifications

35

New cards

Process control

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

• Science-driven development (scientific literature, prior

knowledge, DOEs etc.)

Quality by Design (QbD)

Systematic Approach

• Science-driven development (scientific literature, prior

knowledge, DOEs etc.)

36

New cards

Quality risk management

STAGES OF PROCESS VALIDATION

Quality by Design (QbD)

Systematic Approach

Risk-based development (ICH Q9)

Quality by Design (QbD)

Systematic Approach

Risk-based development (ICH Q9)

37

New cards

STAGE 1 - Process DESIGN

The commercial

manufacturing process is

defined during this stage

based on knowledge gained

through development &

scale-up studies

manufacturing process is

defined during this stage

based on knowledge gained

through development &

scale-up studies

38

New cards

STAGE 1 - Process DESIGN

STAGE ???

Define commercial-scale process

Define commercial-scale process

39

New cards

STAGE 1 - Process DESIGN

STAGE ???

• Define unit operations and process

parameters

• Define unit operations and process

parameters

40

New cards

STAGE 1 - Process DESIGN

STAGE ???

Identify and understand sources of

variations

Identify and understand sources of

variations

41

New cards

STAGE 1 - Process DESIGN

STAGE ???

Identify critical process parameters

Identify critical process parameters

42

New cards

ICH Q8(R2)

Definition: A prospective

summary of the quality characteristics of a

drug product that ideally will be achieved to

ensure the desired quality, taking into account

safety and efficacy.

summary of the quality characteristics of a

drug product that ideally will be achieved to

ensure the desired quality, taking into account

safety and efficacy.

43

New cards

Critical Quality Attributes (CQA)

A physical, chemical, biological, or

microbiological property or

characteristic that should be within

an appropriate limit, range, or

distribution to ensure the desired

product quality (ICH Q8)

microbiological property or

characteristic that should be within

an appropriate limit, range, or

distribution to ensure the desired

product quality (ICH Q8)

44

New cards

Approach to Identify CQAs

Consider all DP quality attributes; physical

attributes, identification, assay, content

uniformity, dissolution and drug release,

degradation products, residual solvents,

moisture, microbial limits, etc.

attributes, identification, assay, content

uniformity, dissolution and drug release,

degradation products, residual solvents,

moisture, microbial limits, etc.

45

New cards

physical attributes,

identification,

assay,

content uniformity,

dissolution and

drug release,

degradation products,

residual solvents,

moisture,

microbial limits,

identification,

assay,

content uniformity,

dissolution and

drug release,

degradation products,

residual solvents,

moisture,

microbial limits,

Approach to Identify CQAs

Consider all DP quality attributes; _______ etc.

Consider all DP quality attributes; _______ etc.

46

New cards

severity of harm

Identify a CQA based on the ____ to

a patient (safety and efficacy) resulting from

failure to meet that quality attribute

a patient (safety and efficacy) resulting from

failure to meet that quality attribute

47

New cards

Approach to Identify CQAs

Identified before taking into account risk control

– Does not change as a result of risk management

– Does not change as a result of risk management

48

New cards

NO

is Physical apperance (apperance, odor, size, score, friability) is a Critical Quality Attributes (CQA)?

49

New cards

YES

is identification is a Critical Quality Attributes (CQA)?

50

New cards

YES

is assay is a Critical Quality Attributes (CQA)?

51

New cards

YES

is content uniformity is a Critical Quality Attributes (CQA)?

52

New cards

YES

is dissolution is a Critical Quality Attributes (CQA)?

53

New cards

Pre roller Compaction Blending and Lubrication

Roller Compaction

Milling

Final Blending and Lubrication

Compression (tableting)

Roller Compaction

Milling

Final Blending and Lubrication

Compression (tableting)

STAGE 1 - Process DESIGN

Process Map

Process Map

54

New cards

STAGE 2 - Process QUALIFICATION

The process design is

evaluated to determine if

the process is capable of

reproducible

commercial

manufacturing

evaluated to determine if

the process is capable of

reproducible

commercial

manufacturing

55

New cards

STAGE 2 - Process QUALIFICATION

STAGE ???

Confirmation at commercial-scale

of process design information

Confirmation at commercial-scale

of process design information

56

New cards

STAGE 2 - Process QUALIFICATION

STAGE ???

Qualification of equipment,

utilities, facilities

Qualification of equipment,

utilities, facilities

57

New cards

STAGE 2 - Process QUALIFICATION

STAGE ???

Identify and understand sources of

variations

Identify and understand sources of

variations

58

New cards

STAGE 2 - Process QUALIFICATION

STAGE ???

Identify critical process

parameters

Identify critical process

parameters

59

New cards

Critical Process Parameter (CPP)

A process parameter whose variability has an impact on a

CQA and therefore should be monitored or controlled to

ensure the process produces the desired quality. (ICH Q8)

CQA and therefore should be monitored or controlled to

ensure the process produces the desired quality. (ICH Q8)

60

New cards

Identify drug product

STAGE 2 - Process QUALIFICATION

Step 1

Step 1

61

New cards

For each procces step, identify intermediate CQAs that impact drug product

STAGE 2 - Process QUALIFICATION

Step 2

Step 2

62

New cards

Identify materaill attributes and process parameters that may impact the intermediate CQAs of the process step

STAGE 2 - Process QUALIFICATION

Step 3

Step 3

63

New cards

Control Strategy

“a planned set of controls, derived from current product and

process understanding, that assures process performance and

product quality

process understanding, that assures process performance and

product quality

64

New cards

STAGE 3 - Continued Process Verification

Ongoing assurance is

gained during routine

production that the

process remains in a

state of control

gained during routine

production that the

process remains in a

state of control

65

New cards

STAGE 3 - Continued Process Verification

STAGE ???

• Timely monitoring of critical

operating and performance

parameters

• Timely monitoring of critical

operating and performance

parameters

66

New cards

STAGE 3 - Continued Process Verification

STAGE ???

monitor product characteristics,

materials, facilities, equipment

and SOP changes

monitor product characteristics,

materials, facilities, equipment

and SOP changes

67

New cards

STAGE 3 - Continued Process Verification

STAGE ???

activities to assure process

remains in validated state

activities to assure process

remains in validated state

68

New cards

• Need to be determined

• Need to be monitored during validation

• May affect the quality of the product

• Need to be monitored during validation

• May affect the quality of the product

Critical factors or parameters

69

New cards

Regulators

Satisfaction

Consistent

Quality Product

Shareholder

Value

Shareholder

Value

Satisfaction

Consistent

Quality Product

Shareholder

Value

Shareholder

Value

Benefits of Validation

Appropriate level of

qualification for each

process/facility

Established process

control

Reduction/elimination

of uncertainty,

variability, deviations

Reliable, understood

and compliant

processes

Appropriate level of

qualification for each

process/facility

Established process

control

Reduction/elimination

of uncertainty,

variability, deviations

Reliable, understood

and compliant

processes

70

New cards

Benefits of Validation

Appropriate level of

qualification for each

process/facility

qualification for each

process/facility

71

New cards

Benefits of Validation

Established process

control

control

72

New cards

Benefits of Validation

Reduction/elimination

of uncertainty,

variability, deviations

of uncertainty,

variability, deviations

73

New cards

Benefits of Validation

Reliable, understood

and compliant

processes

and compliant

processes

74

New cards

Drug Product CQA:

Content

Uniformity

Intermediate CQA:

Blend

Uniformity

Process Variables:

Particle size

distribution;

Number of

revolutions

Content

Uniformity

Intermediate CQA:

Blend

Uniformity

Process Variables:

Particle size

distribution;

Number of

revolutions

75

New cards

Cleaning Processes

Facilities

Processess

Systems and Programs

Manufacturing Step

Analytical Test Methods

Facilities

Processess

Systems and Programs

Manufacturing Step

Analytical Test Methods

PRODUCT VALIDATION [6]

76

New cards

validation

The term `____’ is intended to apply to final verification at the production scale.

77

New cards

3

The term `validation’ is intended to apply to final verification at the production scale. Typically a minimum of ____ consecutive production batches should be successfully validated prior to the marketing of the product.

78

New cards

Process validation

involves a series of activities taking place over the lifecycle of the product and process.

79

New cards

Stage 1 – Process Design

The commercial manufacturing process is defined during this stage based on knowledge gained through development and scale-up activities

80

New cards

Stage 2 – Process Qualification

During this stage, the process design is evaluated to determine if the process is capable of reproducible commercial manufacturing.

81

New cards

Stage 3 – Continued Process Verification

Ongoing assurance is gained during routine production that the process remains in a state of control.

82

New cards

STAGE 1 - PROCESS DESIGN

is the activity of defining the commercial manufacturing process that will be reflected in planned master production and control records.

83

New cards

STAGE 1 - PROCESS DESIGN

The goal of this stage is to design a process suitable for routine commercial manufacturing that can consistently deliver a product that meets its quality attributes.

84

New cards

STAGE 1 - PROCESS DESIGN

Although early process design experiments do not need to be performed according to cGMP, they should be conducted under guidelines of sound scientific principles.

85

New cards

STAGE 1 - PROCESS DESIGN

Good documentation practices should be followed. In particular, studies that result in improvement of process understanding are expected to be documented.

86

New cards

STAGE 1 - PROCESS DESIGN

Continuous testing and re-testing at this stage until the process fails is not normally expected by the FDA.

87

New cards

STAGE 1 - PROCESS DESIGN

The establishment of process controls serve to ensure product quality, and by the same token address variability in product. The FDA expects that process controls include examination of material as well as equipment monitoring.

In particular, process control and monitoring is critical when:

the product attribute is either not detectable or otherwise measurable (eg. microbial contamination).

Or when intermediates/products are not well-characterized

In particular, process control and monitoring is critical when:

the product attribute is either not detectable or otherwise measurable (eg. microbial contamination).

Or when intermediates/products are not well-characterized

88

New cards

STAGE 2 - PROCESS QUALIFICATION

During the process qualification (PQ) stage of process validation, the process design is evaluated to determine if it is capable of reproducible commercial manufacture.

89

New cards

1) design of the facility and qualification of the equipment and utilities

(2) process performance qualification (PPQ).

(2) process performance qualification (PPQ).

STAGE 2 - PROCESS QUALIFICATION ELEMENTS

90

New cards

2

During Stage __, CGMP-compliant procedures must be followed.

91

New cards

2

Successful completion of Stage ___ is necessary before commercial distribution.

92

New cards

STAGE 2 - PROCESS QUALIFICATION

Products manufactured during this stage, if acceptable, can be released for distribution.

93

New cards

STAGE 2 - PROCESS QUALIFICATION

Appropriate design of the manufacturing facility is required under cGMP mandates.

94

New cards

STAGE 2 - PROCESS QUALIFICATIONQ

Proper selection of utility systems and equipment that are built according to required design specifications.

95

New cards

STAGE 2 - PROCESS QUALIFICATION

Verifying that systems and equipment operate within required specifications.

96

New cards

STAGE 2 - PROCESS QUALIFICATION

The process performance qualification (PPQ) combined facility, utility, and equipment with properly trained personnel. The FDA highly recommends that objective measures such as statistical metrics be employed whenever possible.

97

New cards

STAGE 2 - PROCESS QUALIFICATION

Written protocols and expected outcomes are very important to this stage of process validation. It's recommended that protocol descriptions include manufacturing conditions, data collection, tests that need to be performed, and sampling plan.

98

New cards

THIRD

The goal of the ____validation stage is continual assurance that the process remains in a state of control (the validated state) during commercial manufacture.

99

New cards

STAGE 3 - CONTINUED PROCESS VERIFICATION

A system or systems for detecting unplanned departures from the process as designed is essential to accomplish this goal.

100

New cards

STAGE 3 - CONTINUED PROCESS VERIFICATION

Adherence to the CGMP requirements, specifically, the collection and evaluation of information and data about the performance of the process, will allow detection of undesired process variability.