Collaborative Robots and Safety

1/12

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

13 Terms

Collaborative Robots

A robot that can be used in a collaborative operation

Defined by the operation that they are doing not by the type of robot itself

Collaborative Operation

A state in which a robot works in direct cooperation with a human within a defined collaborative workspace

Collaborative Workspace

A workspace within the safeguarded space where the robot and human can perform tasks simultaneously during production operation

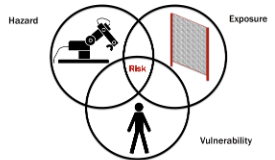

The Robot Risk Model

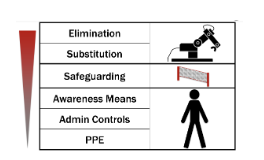

Robot Risk Reduction

ISO 10218 Part 1

Outlines the six steps to be considered as part of a risk assessment

The intended operations of the robot, including teaching, maintenance, setting and cleaning

Unexpected startup

Access by personal from all directions

Reasonably foreseeable misuse of the robot

The effect of failure in the control system

Where necessary, the hazards associated with the specific robot application

ISO 10218 Part 2

Requires a risk assessment for collaborative applications to evaluate task/hazard combinations and set appropriate limits

Means of anticipating tasks and hazards with the goal of applying suitable risk reduction measures

Uses iterative process to determine the desired effect is achieved

Avoids “one size fits all”

ISO TS 15066

Technical Specification about collaborative operations, which may include one or more of the following methods:

Safety rated monitored stop

Hand guiding

Speed and separation monitoring

Power and force limiting

Safety Rated Monitored Stop

What the collaborative robot does in the presence of an operator or obstruction

Stop motion condition ensured

Drive power remains on

Motion resumes after obstruction clears

Robot motion resumes without additional action

Protective stop delivered if stop condition is violated

Hand Guiding

Where an operator leads robot movement through direct interface

Robot stops when operateor arrives

Operator grasps enabling device, activating motion

Robot motion responds to operator commands

Non-collaborative operation resumes when operator leaves collaborative workspace

Speed and Separation Monitoring

Where the robot speed reduces when an obstruction is detected

Separation distances are monitored

Robot speed directly correlates to sparation distance

Stop given if direct contact proximity is attained

Power and Force Limiting

Where incidental contact initiated by robot are limited in energy to not cause the operator harm

Forces robot can exert are limited

Robot system design eliminates pinch points, sharp edges, to prevent the robot trapping operators

Robot complies and reacts when contact is made

Reduce robot velocity or inertia

Modify robot posture, to increase possible exposure surface area (reduce pressure)

Avoid sensitive body areas

ISO TS 15066 Onset of Pain Study

Guidance for power and force limits based on study examining these conditions and the onset of pain in 29 body regions.