IGCSE DT Plastics & Shaping Plastics

1/27

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

28 Terms

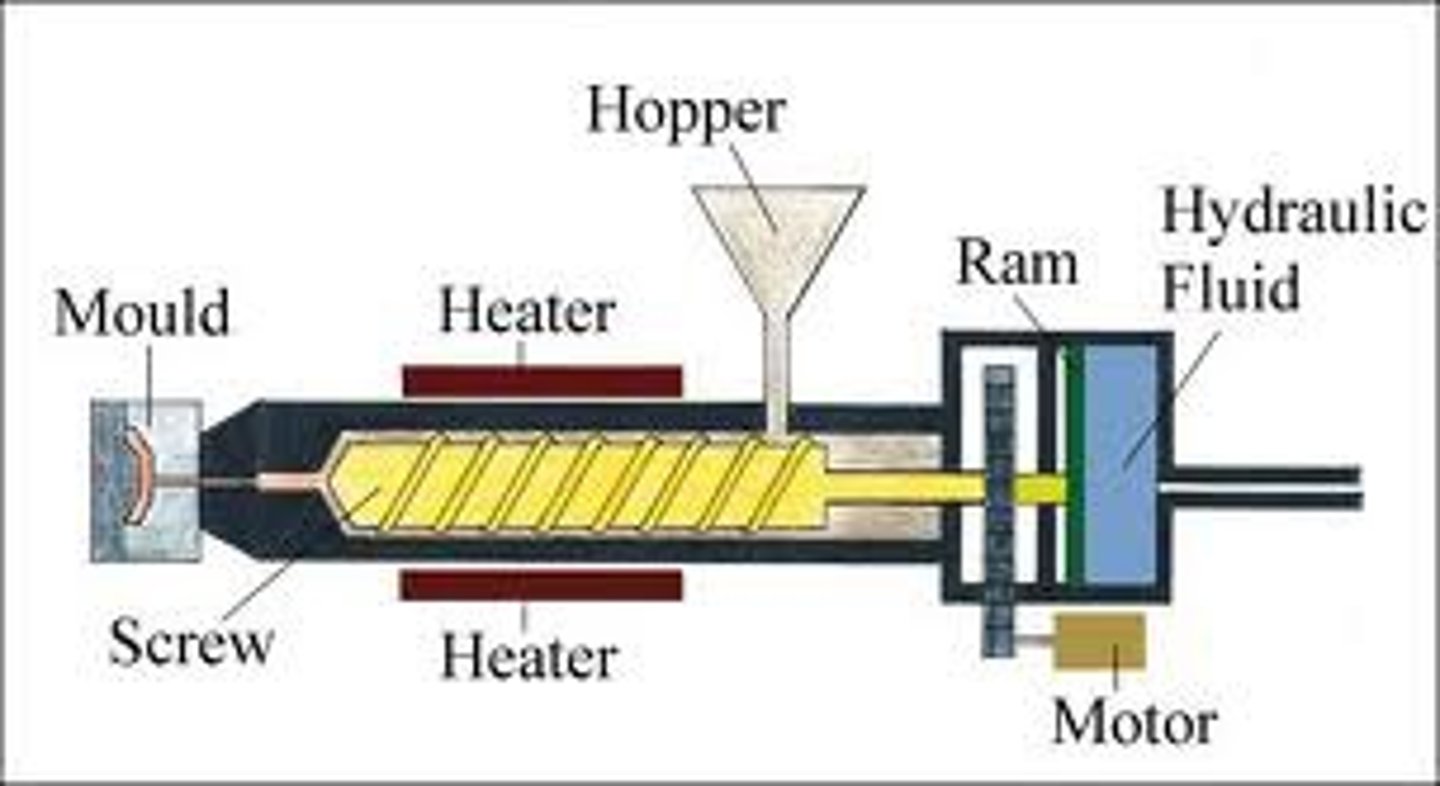

Injection Moulding

Molten plastic is forced into the mould by pressure from a screw thread.

The mould is made in two parts to allow the moulding to be removed.

Initial tooling costs are high and to recoup costs, there is high volume production.

telephones and electrical casing

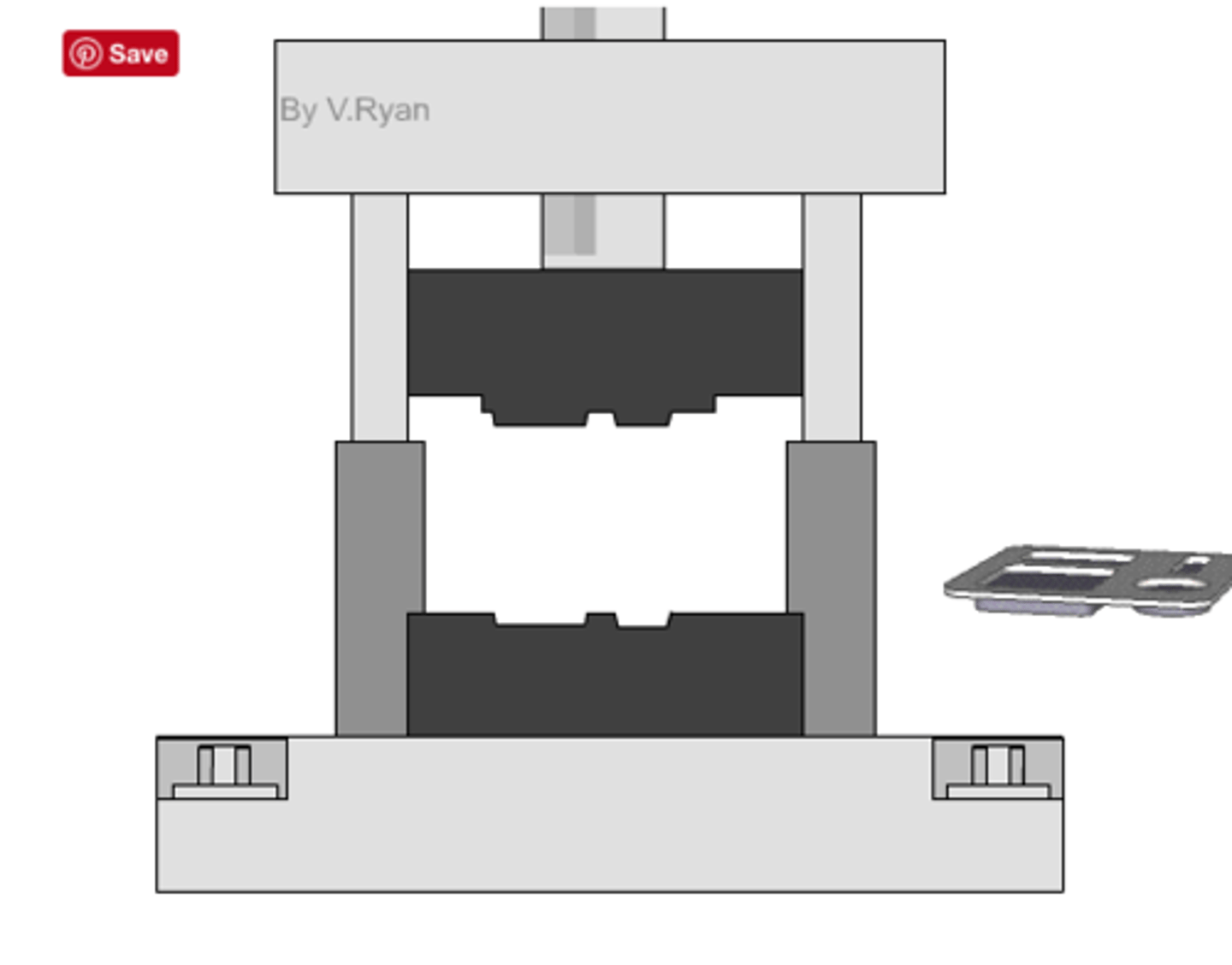

Press or Compression moulding

Sheet plastic (thermosetting) is placed between a mould made in two halves.

It's used to make electrical fittings

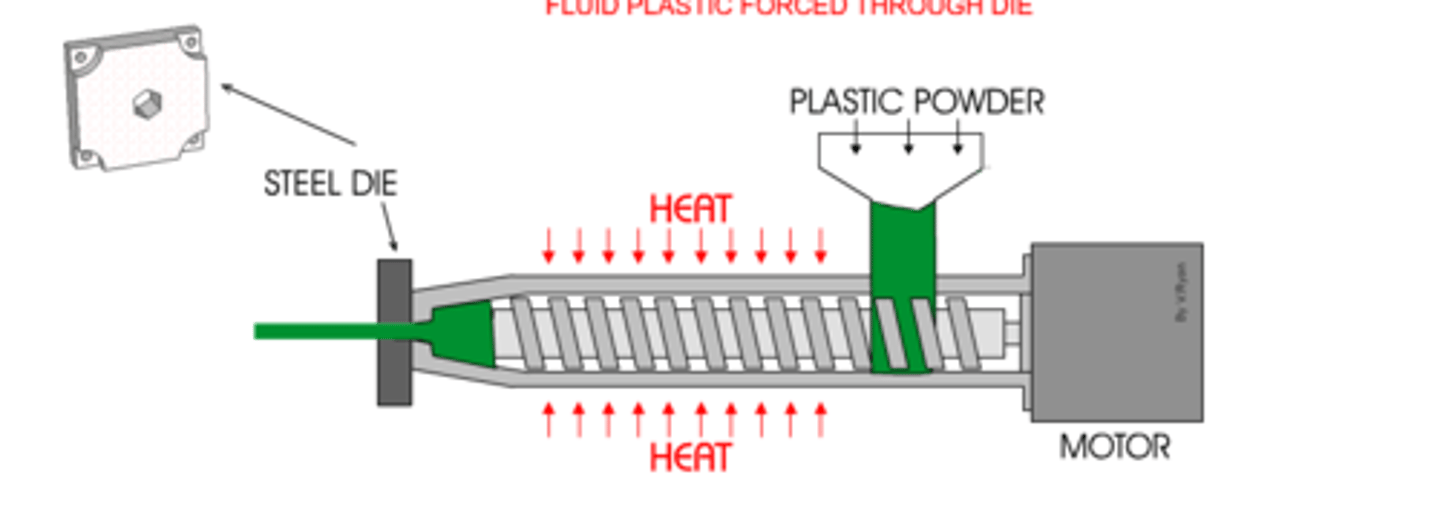

Extrusion

Used to produce long, thin products such as pipes or curtain racks. Molten plastics are forced through a die, forming a long tube like shape.

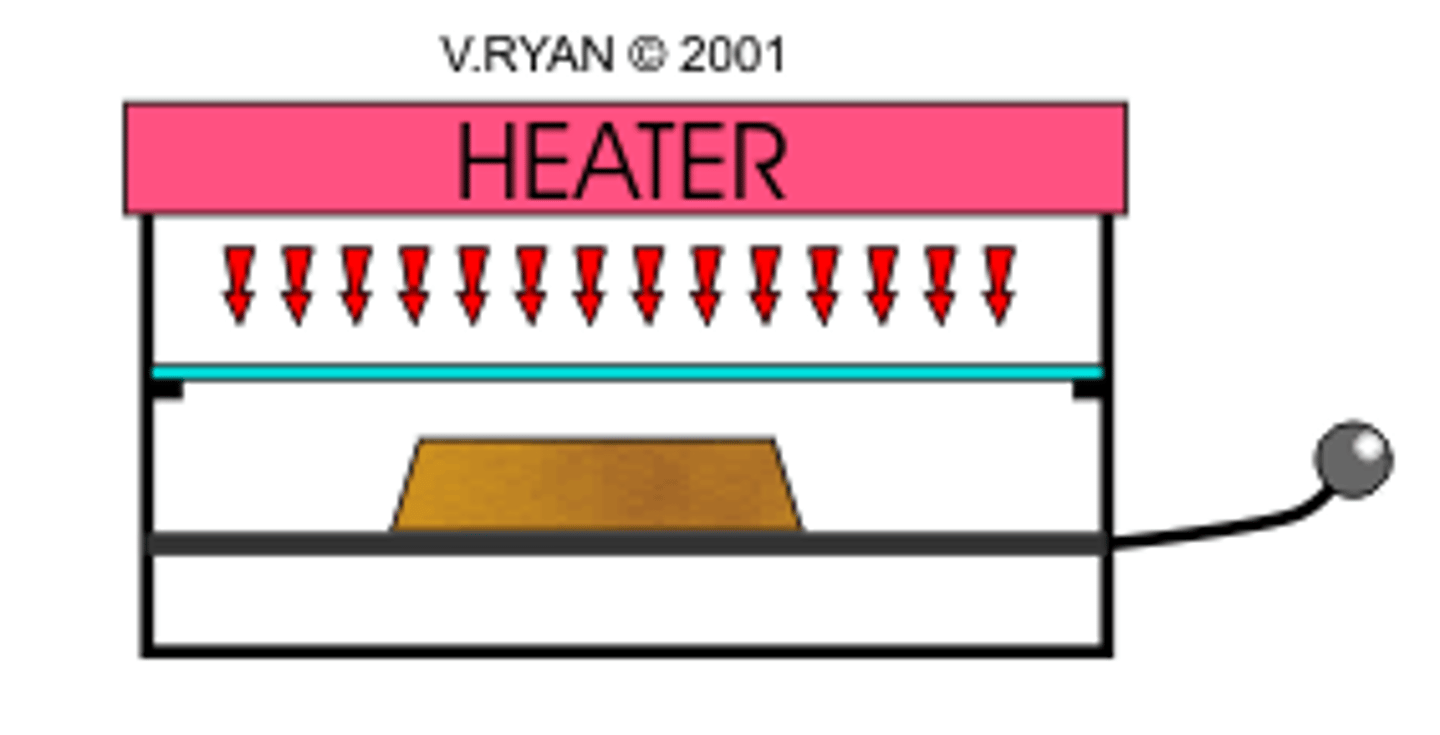

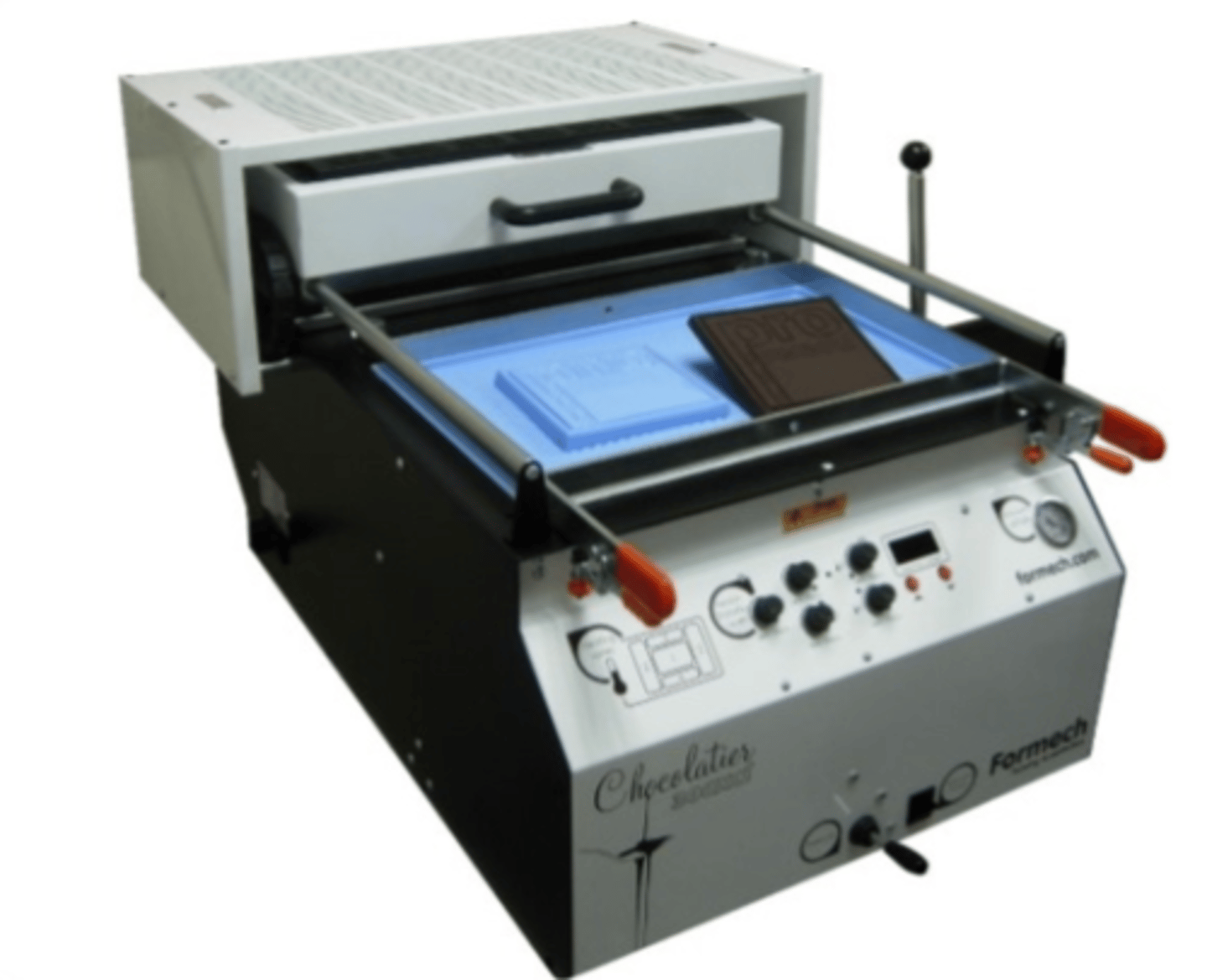

Vacuum forming

Used to heat and mould plastic sheet (High Impact Polystyrene or thin Acrylic) into a variety of hollow forms (e.g. inserts for toy packaging, biscuit or chocolate box trays)

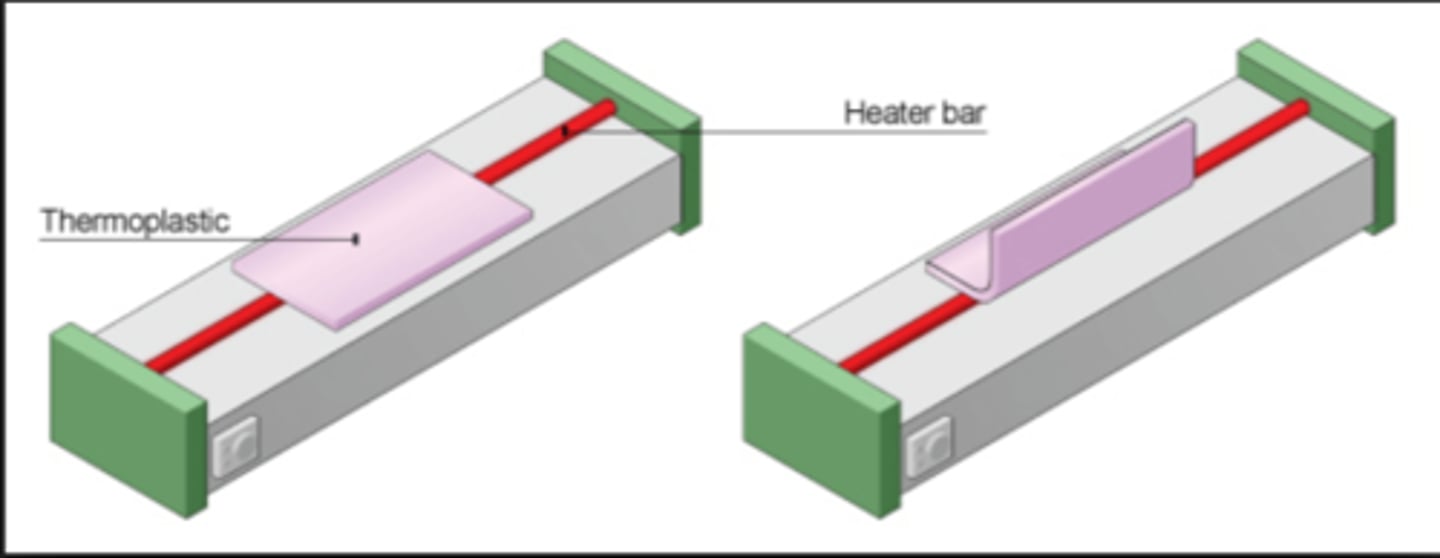

Bending plastics on Strip heater (Line-bending)

Thin plastic sheet (e.g. acrylic) is heated so it can be easily bent along a line

Blow moulding

A tube of softened plastics is extruded into a mould. Air is forced into the mould which forces the plastic to the sides, giving the shape of a bottle.

Bending plastics in oven

Thin acrylic sheets can be heated and bent around moulds to create bends.

Acrylic (PMMA)

A thermoplastic. Come is sheet form and in a range of colours. It can be translucent (e.g. smoked), transparent or opaque. It is resistant to most acids and weather conditions. Used for bathroom furniture/products. It's self finishing.

High Density Polyethylene (HDPE)

thermoplastic

most common plastic in everyday life.

'plastic' bottles, grocery bags, shampoo bottles and children's toys.

Polyethylene Terephthalate (PET)

thermoplastic

soft drink bottles

lightweight, usually transparent, available in a range of colours.

Low Density Polythene (LDPE)

thermoplastic

extrusion or blow moulding process.

It is durable and will last along time.

Often products such as soap dispensers are refilled which makes this plastic an excellent choice.

Polyvinyl Chloride (PVC)

thermoplastic

chemical resistance

water pipes, coating on electrical wires.

Acrylonitrile-butadiene-styrene (ABS)

thermoplastic

strong resistance to corrosive chemicals and physical impacts

low melting temperature

injection moulding manufacturing processes or 3D printing.

Used for keys on a computer keyboard, LEGO toys.

Polystyrene (PS)

thermoplastic

prototyping and food packaging.

It lasts a long time in the natural environment which poses a litter hazard as the material is typically thrown away after an extremely short lifespan.

Polypropylene (PP)

thermoplastic

packaging and labelling, stationery, reusable containers of various types, laboratory equipment

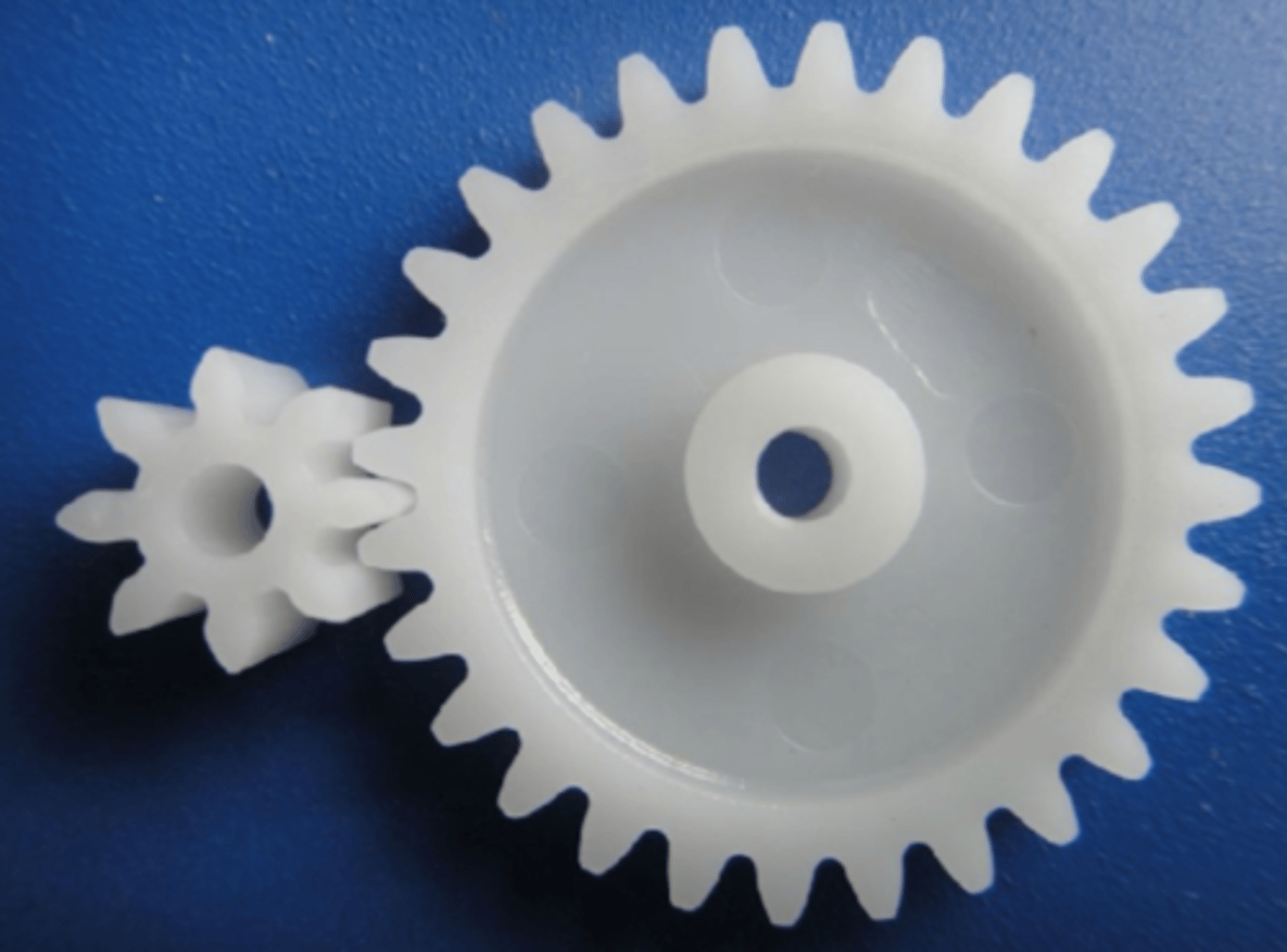

Nylon

A thermoplastic that is used in engineering to make gears and bearings. It's oily nature means that friction is reduced between moving parts.

Polyester Resin

thermosetting plastic

can be combined with a material such as fibre glass to create a tough material that can resist impact

Urea Formaldehyde

thermosetting

electrical fittings

scratch resistant and a good electrical insulator

Epoxy Resin

thermosetting plastic

high adhesive strength

Melamine Formaldehyde

Thermosetting

plastic laminates, sockets and switches

Phenol Formaldehyde

thermosetting plastic

stiff, hard and resists some chemicals and stains.

pool balls adhesives.

PET bottles are made by:

Blow Moulding

Trays for chocolates are made by:

Vacuum forming

Plastic pipes and rails are made using which process?

Extrusion

High volume products like buckets are manufactured by:

Injection moulding

Urea formaldehyde

Sockets and plugs

Gears are commonly made from

Nylon

A former

Shape commonly made of wood which plastic is formed