Other sterilization methods

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

What is convection?

Transfer of heat through a fluid (liquid or gas) caused by molecular motion (think a pot over a fire)

What is conduction?

The transfer of heat or electric current from one substance to another by direct contact.

Why would you use dry heat?

If an instrument is moisture sensitive, other is spotting is undesirable.

Common dry heat temperatures and times

160 C for 2 hours or 162 C for 1.5 hours

Is dry heat harmful to rubber, certain fabrics?

Yes

Is dry heat acceptable for powders?

No

2 types of dry heat sterilizers

Gravity oven: Hot air circulates due to gravity, not very reliable

Mechanical oven: a fan forces air around the chamber, more reliable

dry heat sterilization relies on heat to be conducted to the _____ of the item

Core

Dry heat packaging materials

Heat resistant glass

aluminum foil

stainless steel trays

Muslin can be used, but it deteriorates quickly

Metal canisters

Irradiation (gamma sterilization)

What is it?

Uses electromagnetic waves similar to radio, infrared heat, light and x rays to disrupt cell processes

Sponges, syringes, sutures and other SUD are sterilized using what method?

Gamma sterilization

What is installation commissioning done for?

To demonstrate that the sterilizer and related accessories have been supplied and installed according to manufacturer’s instructions

Who performs installation commissioning?

Manufacturer Technician

What is operational qualification?

Is done to verify that the sterilizer manufacturer’s operational specifications are being achieved

Requalification is done when?

is done following any event or change that could affect the performance of the sterilizer, such as a major repair

How many loads and how many biological indicators for requalification?

3 loads, 1 biological indicator in each

Dynamic air removal-type (Bowie-Dick test) for pre-vacuum sterilizers will be further tested with

three consecutive air detection tests

What are the three types of indicators that monitor the sterilization process more directly?

Physical monitors

Chemical indicators

Biological indicators

Monitors include….

Time, temperature, pressure recorders, digital printout and guages

How often does a leak test need to be done?

Every week on an empty machine

The leak rate on the printout should be less than

1.0mmHg/min

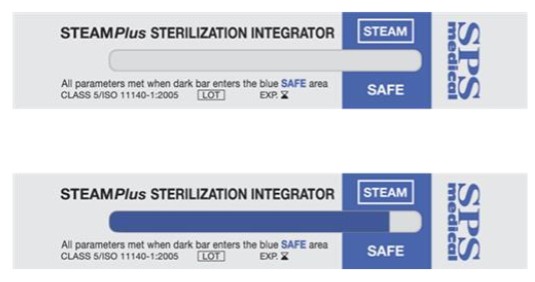

What is this?

Chemical indicator

Packages in loads that are monitored with a biological indicator now require each package to have a type _ or _ chemical indicator or integrator

5 or 6

which three parameters do type 5 and 6 BOTH measure?

Time, temperature and saturated steam

You MAY still use type 4 CI, however you must use a _____ in each load as well

Biological indicator