Paper and Boards

1/11

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

12 Terms

Papers

|

|

Layout paper | Thin translucent paper used for sketching and technical drawing |

Cartridge paper | Off white, slightly textured paper used for sketching, rendering and can be used for printing |

Tracing paper | Translucent paper slightly thicker than layout. Used for copying images |

Bleed - proof paper | Similar to cartridge but has bleed proof layer so colours do not run when rendering with markers |

Treated paper | Plan paper with clear or dye layer to hold/ brighten image. Different sheens available. Used for photographs |

Watercolour paper | Available in absorbent, smooth, hot or cold pressed, heavily textured. Used for watercolour painting |

Boards

|

|

Corrugated card | Fluted middle layer. Gives protection. Used for outer packaging, food packaging eg take away boxes and modelling |

Bleached card | Chemically treated to brightened surface for high quality printing such as greetings cards |

Mount board | Compressed cotton fibres. Used for modelling, and picture mounting |

Duplex card | 2 layers one coated to give glossy feel used in food packaging, disposable cups and plates |

Foil backed and laminated card | Film or foil applied on one or both sides. Makes it water resistant or heat insulating. Layer must be removed before recycling- milk cartons/ takeaway lids |

Metal effect card | Thin metal effect layer for enhanced aesthetics for items such as gift boxes and packaging |

Moulded paper pulp | Recycled paper moulded into a shape for items such as eco friendly packaging |

Applications

Packaging: Corrugated cardboard, food packaging, and cosmetic cartons.

Printing and Writing: Cartridge paper, bleed-proof paper, tracing paper, and watercolor paper.

Model Making: Foam-core board.

Hardback Books: Solid white board.

Greeting Cards and High-Quality Packaging: Bleached card.

Stock Forms and Sizes

Die Cutting

Cut out nets for folding and assembly or shapes

Steel dies are shaped and pushed into a board to cut out the stock material

Where parts need to be folded creasing rules score the paper as they are blunt

Ejection rubber can be added to stop stock material stocking to the press

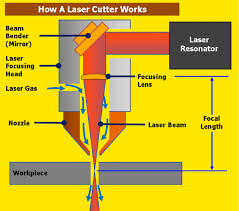

Laser Cutting

Prototype/ small scale production construction

Can cut, engrave, perforate and carve

Intricate cuts

Common due to high speed, accuracy and high level of detail

Can often leave burnt/ brown edge where laser has been

Creasing

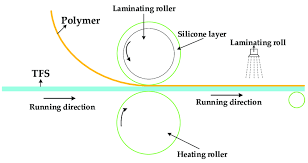

Laminating

Via Encapsulation

Desk top laminator

Paper is encapsulated by polymer sheet (PET AND EVA)

Paper fed through laminator and heat sealed

Via surface coating

Liquid – rolled or spray. Used on signs to prevent colour fading and moisture and dirt

Film- Hot or cold, made of pp with adhesive and red from a roller onto paper where pressure is applied. Used on menus

Embossing

Creates a raised design

Decorative technique for greeting cards and packaging

Uses 2 dies (male and female) made from stainless steel or brass

A sheet is placed between the 2 dies and held under pressure

Can have ink or foil applied

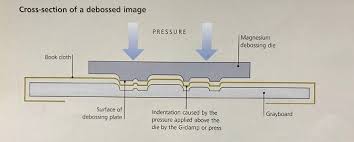

Debossing

Opposite of embossing

Created imprinted depression

Create same way as embossing

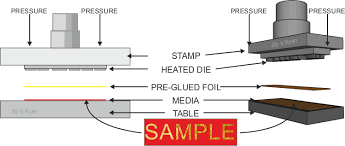

Foil Blocking

Applying heat and pressure to a metallic foil

Creates areas of depth and texture

Foils – metallic, gloss, matt, clear

Used on business cards, logos and letterheads

A heated die is stamped onto the material through the foil

Needs accuracy and consistency

If the die is too hot or held on for too long it will bubble or peel or if not hot enough it may not stick to the paper

Off-Set Lithography

Substrate is sheet or web rolled fed into the machine

Printing plates are produced on a computer and laser etched onto the plate. Rollers are attached to the machine and dampened

Ink is applied to the plate. The roller rotates onto a blanket roller which becomes coated and the substrate is fed through