OHS 422: L02: Substitution of Materials and Control Banding

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

71 Terms

What is green chemistry?

the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances

is the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances

green chemistry

Green chemistry applies across the

life cycle of a chemical product, including its design, manufacture, use, and ultimate disposal.

What are the general rules associated with substitution?

1. Prefer non-hazardous chemicals

2. Accept less-hazardous chemicals

3. Mission objective should be met

4. Consider physical, chemical, toxicological, and physiological characteristics

5. Consider sustainable outcomes

6. Consider green chemistry principles

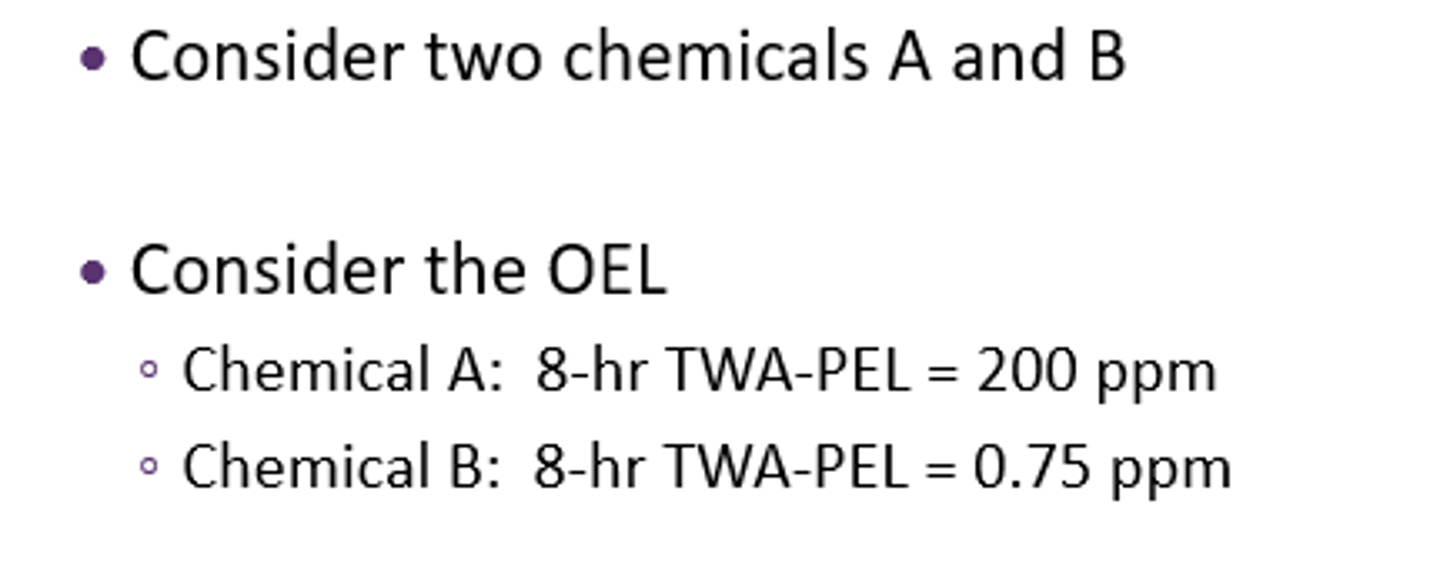

If we are just comparying OELs to determine what chemical to select then we should select the one with the

greatest limit

What are the limitations of just using the OEL to determine if it should be selected?

1. Volatility not considered

2. Limits may change with time

3. Limits do not represent a clear line between safe and unsafe conditions

4. Mainly inhalation is considered

5. Many chemicals do not have OEL

ACGIH TLV Disclaimer says you should

not use them as a relative indicator of toxicity

ACGIH TLV Disclaimer says you should not use them as a relative indicator of toxicity

TLVs are designed to

protect against a specific "critical effect"

Which chemical should we select?

chemical A

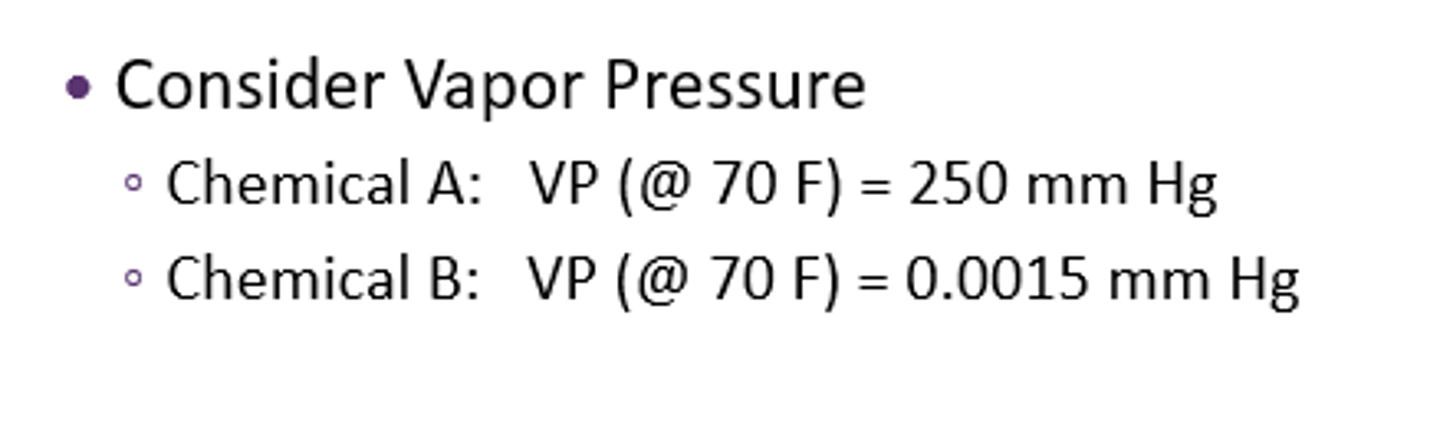

Which chemical should we select?

chemical B

the pressure exerted by a vapor/gas in equilibrium with its liquid phase at a given temperature, in a closed system

vapor pressure

Define vapor pressure.

the pressure exerted by a vapor/gas in equilibrium with its liquid phase at a given temperature, in a closed system

the tendency of particles to escape from the liquid

vapor pressure

the higher the VP of a substance at a given temperature, the

higher the volatility and the higher the concentration of the substance in the air

If we are just comparying vapor pressures to determine what chemical to select then we should select the one with the

lowest vapor pressure

Lower vapor pressures mean that it is

less volatile

What are three methods we can use to select chemicals that are the least dangerous ?

1. vaphor hazard ratio

2. dilution factor

3. toxicological data

What is the vapor hazard ratio?

A unitless number that takes into account (1) the toxicity of the chemical that is based on the OEL and the volatilty of the chemical

A unitless number that takes into account (1) the toxicity of the chemical that is based on the OEL and the volatilty of the chemical

vapor hazard ratio

When using the VHR, Ceq is the

equilibrium concentration in ppm

When calculating Ceq, the VP is in

mmHg

When using VHR, which chemical should we select?

the one with the lowest VHR

What are the problems associated with using the VHR?

1. Limitations of the OELs

2. Estimates of equilibrium concentration (Ceq) are different depending if the process allows molecular or eddy diffusion

3. Issues with mixtures of liquids

What is eddy diffusion?

you are promoting the evaporation process (i.e. you are forcing the chemical to evaporate)

The VHR is a

worst-case scenario because it is calculated right above the surface with no dilution

What are some of the limitations with the OEL?

there may not be one

which OEL do we use?

the OEL is not a safe line

What is molecular diffusion?

diffusion from high to low concentrations with no competing forces

When using the dilution factor, you should select the chemical with the

lowest DF

We should select the chemical agent with lowest DF. Why?

it means less air is needed to dilute it to a concentration under the OEL

What is the dilution factor?

the number of m3 of fresh air needed to dilute 1 liter of vapor of the contaminant below the TLV

the number of m3 of fresh air needed to dilute 1 liter of vapor of the contaminant below the TLV

dilution factor

What are the limits with use toxicological data?

we need to be comparing similar effects in similar animals

What are the two ways to find VHR when dealing with a mixture?

ideal or nonideal behavior

What is an ideal gas?

hypothetic gas whose molecules themselves take up no volume and do not interact with each other.... Thus they obey the gas laws exactly.

If it's an ideal mixture, we know from chemistry the mixture will

obey Raoult's Law

What is Raoult's law?

The partial vapor pressure of a component in a mixture is equal to the vapor pressure of the pure component at that temperature multiplied by its mole fraction in the mixture (i.e. molar fraction in the liquid phase).

The partial vapor pressure of a component in a mixture is equal to the vapor pressure of the pure component at that temperature multiplied by its mole fraction in the mixture (i.e. molar fraction in the liquid phase).

Raoult's Law

What is the formula for Raoult's Law?

Partial VP = (mole fraction) x VP

the molar fraction used in the VHR calculation of ideal mixtures is

the molar fraction in the liquid phase

How do you calculate molar fraction is the % by volume is known?

1. Assume 100 mL of liquid

2. Obtain the mL of each component

3. Convert mL into grams (use liquid density)

4. Convert grams to moles (use MW)

5. Calculate the molar fraction of each component

when finding VHR for a non-ideal mixture you must consider the

coefficient of activity for each chemical in the mixture

What type of mixture will we always assume in industrial hygiene?

ideal

When does Control Banding (CB) become a viable strategy to control occupational exposures?

CB becomes a viable strategy for controlling occupational exposures when there are no established occupational exposure limits (OELs). Without established OELs, employers and workers often lack the needed guidance on the extent to which occupational exposures should be controlled; control banding can serve as the solution for this.

What is the conceptual basis for CB?

The conceptual basis for CB is the grouping of chemical exposures according to similar physical and chemical characteristics, intended processes/handling, and anticipated exposure scenarios (amount of chemical used and how workers would be exposed).

One of the least complex models of CB includes a four-level hierarchy of risk management options. Which are these options?

1. Good occupational hygiene practices, which may be supplemented by use of appropriate personal protective equipment (PPE)

2. Engineering controls, including local exhaust ventilation (LEV)

3. Containment

4. Seeking specialist advice

Should CB be a considered an equivalent substitute to the Occupational Exposure Limits (OELs)?

CB is not meant to be a substitute for OELs, and the use of CB does not erase the need for environmental monitoring and industrial hygiene expertise. Labeling of chemicals in CB is a useful practice, but it is not intended to replace OELs, exposure assessment, or classic IH protocol.

Why is the reliance upon sampling and then comparing the sampling results with published OELs becoming more difficult?

Strict reliance upon sampling, analyzing airborne contaminants, and then comparing the results with OELs has become increasingly difficult in recent decades because of the growing number of hazardous chemicals. This increasing number far outweighs the ability and resources of agencies external to chemical manufacturers to develop OELs. If we do not have an established OEL, we cannot compare our sampling results with an OEL for that chemical making it hard to rely on OELs alone to determine safe levels.

What is expected that the regulation known as REACH accomplish in the European Union?

The European Commission promulgated regulations known as the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) to shift the burden of proof of chemical safety to manufacturers. This would apply to most chemicals in commerce.

What is the objective of COSHH? Where was this system developed?

Control of Substances Hazardous to Health (COSHH) is a simplified strategy to assess health risks in the workplace. It was developed in the United Kingdon (England) in the late 1980s to control workplace exposures to hazardous chemicals and is enforced by the United Kingdom Health and Safety Executive (HSE).

What control option is most commonly selected in England, even after the passage of COSHH?

Most respondents took measures to protect workers, mainly by making personal protective equipment available, followed by process controls.

What were the conclusions reached by Topping et al. concerning the OEL system?

Topping et al. concluded that, given the widespread lack of understanding about OELs, the creation of additional lists of OELs would not be cost effective and that OELs should be limited to widely used substances of concern. They also recognized that OELs and other information about the chemical (e.g., physical properties, use) could be used to recommend appropriate control measures. These authors suggested reappraisal of the traditional OEL system, which resulted in the birth of control banding.

Development and implementation of CB requires five actions. Which are these actions?

Development and implementation of a CB strategy requires five actions: creation of the strategy, its application, the installation and operation/maintenance of controls, postcontrol monitoring, and failure analyses at each step of the CB process.

Users of CB must have a complete understanding of R-phrases. What are R-phrases?

R-phrases are risk phrases. R-phrases describe the specific risks associated with a hazardous substance. The hazard posed by exposure to a chemical via a given route was ranked according to the chemical's European Union risk phrases, and potential for exposure was estimated by the quantity in use and the volatility of liquids or, for solids, potential for airborne particulates.

What are the parameters related to exposure assessment that the user of CB must provide?

1. Acquire complete understanding of the strategy, including R-phrases, quantity of substance in use, and dustiness/volatility of substance.

2. Construct strategy to combine quantity in use, dustiness/volatility, and other determinants, to predict exposure band.

3. Use hazard information with task activities to determine the control guidance level.

4. Select Control Guidance Sheet (CGS)

The COSHH Essentials model is limited to substances under Chemical Hazard Information and Packaging (CHIP) regulations. What substances are excluded from the COSHH model?

Because COSHH Essentials is limited to substances classified under CHIP regulations, the model is not applicable to pesticides, pharmaceuticals, and process-generated hazards such as wood particulate and welding fumes. (Silica dust is also excluded but has been addressed with the HSE development of the silica hazard and task-specific guidance sheets.)

What are the four control approaches (bands) used in the COSHH Essentials model?

Control Approach 1 - General Ventilation (Good standard of general ventilation and good working practices).

Control Approach 2 - Engineering control (Ranging from LEV to ventilated partial enclosure).

Control Approach 3 - Containment (Containment or enclosure, allowing for limited, small scale breaches of containments).

Control Approach 4 - Special (Seek expert advice).

What is control banding?

Approach to controlling exposures when norelevant OELs are available

Control banding focuses resources on

exposure controls

greater potential for harm = greater degree of control

When using control banding, you classify chemical exposures according to

1. Expected toxic outcomes

2. Chemical and physical characteristics

3. Intended process handling

4. Anticipated exposure scenarios

Control banding uses the expected toxic outcomes, chemical and physical characteristics, intended process handling, and anticipated exposure scenarios to

put the chemical agent into a risk class or band which has a control option attached to it

What is the justification for using control banding?

1. Majority of chemical substances do not have published Occupational Exposure Limits (OELs)

2. Employers do not have guidance when selecting controlsfor these chemicals

3. Control options for chemicals with similar toxicity and use conditions tend to be the same

Describe the models used for control banding.

There are several models adopted for control banding-

1. These models have different number of control bandsor levels (minimum four)

2. One of the first models used is the Control of Substances Hazardous to Health (COSHH) Essential developed in England

3. See also models adopted by the pharmaceuticalindustry and nanotechnology posted on Canvas

What does COSHH stand for?

Control of substances hazardous to health

what model for control banding did we use in lab?

COSHH

The COSHH Essentials was developed for

small and medium-sized companies

What are the input variables for the COSHH Essentials model?

1. Toxicity of chemical agent

2. Likelihood of Exposure

• Quantity used

• Ability to become airborne

What is the output for the COSHH Essentials model?

1. Exposure Prediction (paper copy only)• Estimates exposure concentration range (e.g. 5-50ppm)-

2. Control Selection• Engineering controls necessary

Describe the general conceptual model for the COSHH Essential Model

health hazard + exposure potential --> generic risk assessment --> control approach

CB is a valuable tool for

risk management of chemical agents without OELs

Is CB meant to be a substitute for OELs?

no

Does CB eliminate environmental monitoring or IH expertise?

no